Debut issue:

We interview Roni Szigeti, founder of FieldFlō

Demolition runs on FieldFlō

FieldFlō is the management platform purpose-built for demolition subcontractors. From real-time safety tracking to instant compliance documentation, FieldFlō keeps your projects moving, your crews safe, and your margins protected.

Centralize Operations

Time, materials, equipment, waste tracking and compliance in one dashboard

Strengthen Safety

Customizable and trackable forms, certification tracking and bilingual training videos

Job Profitability

Know your budgets vs. actuals in real-time. Save $80K+ Annually Proven ROI per office.

SCAN ME

Welcome to the very first issue of Demolition North America – or, as we’ve affectionately nicknamed it, DNA—the latest addition to our publishing family and the natural sister title to the UK’s Demolition Hub magazine. For several years we’ve been proudly #ChampioningDemolition across Britain and Europe, and it feels only right that we now cross the Atlantic to celebrate, support and spotlight the people and projects shaping the North American demolition landscape.

Our mission is simple: to do for the North American markets what Demolition Hub has done for the UK—provide an unapologetically positive, engaging and connected platform for demolition contractors, suppliers and consultants. DNA will bring you the latest industry news, case studies, innovations, and interviews from across the continent, focusing on the remarkable people and businesses driving this industry forward every single day.

In this pilot issue, our Supplier Talk interview features Roni Szigeti, founder of FieldFlō, whose drive to bring digital innovation to specialty subcontractors has produced a platform that is revolutionising how contractors plan, track and deliver their work. From scheduling and certification tracking to waste management and safety training, FieldFlō is redefining efficiency in the field—and we’re delighted to share Roni’s story.

We’ve also packed this debut with a mix of North American and international case studies. You’ll find insights from explosivedemolition legends Controlled Demolition Inc., perspectives from DB3 Group, and lessons from across the pond courtesy of Clifford Devlin, fresh from their wins at the British Demolition Awards 2025. Add to that features from the National Demolition Association, a closer look at the Demolition Group of America, and a preview of CONEXPO-CON/AGG 2026, and you’ve got an issue that perfectly sets the tone for what’s to come.

This launch marks an exciting new chapter for us and, we hope, a valuable new voice for you. DNA is here to inform, connect and celebrate the North American demolition community—its people, its passion and its progress.

So, welcome aboard. Whether you’re blowing down bridges, reclaiming city blocks or leading your crew from the cab or the boardroom, this magazine is for you. Let’s build it together, from the roof down.

Ben Chambers

PUBLISHER

Ben Chambers

ben@chambers.media +44 1903 952 648

EDITOR

Toby Wilsdon toby@chambers.media +44 1903 952 645

ADVERTISING SALES

Ben Chambers

ben@chambers.media +44 1903 952 648

Wayne Bristow wayne@chambers.media +44 1903 952 649

DESIGN

Joe Chambers joe@chambers.media

PRODUCED & PUBLISHED BY

Demolition Hub Ltd

Suites 5-6 Chapel House, 1-6 Chapel Road, Worthing, West Sussex BN11 1EX. United Kingdom demolition@demolitionhub.com +44 1903 952 640

Demolition Hub is a proud member of the National Demolition Association

Demolition Hub is a media partner for the Demolition Group of America

Demolition Hub is published six times a year. The subscription rate is $100 per year. Subscription records are maintained at Demolition Hub Ltd, Suites 5-6 Chapel House, 1-6 Chapel Road, Worthing, West Sussex BN11 1EX, United Kingdom

Articles and information contained in this publication are the copyright of Demolition Hub Ltd and may not be reproduced in any form without the written permission of the publishers. The publishers cannot accept responsibility for loss of, or damage to, uncommissioned photographs or manuscripts.

Caterpillar crowns Belgian champion in Global Operator Challenge

With Roni Szigeti, Founder and CEO at FieldFlō

Controlled Demolition Inc clears MV Dali from Francis Scott Key Bridge in explosives truss separation plan

DB3 Group leads demolition planning activities in demomissioning of 1970s oilfired power plant

We preview the construction event of the year

Digging Deep with the Orlando Utility Commission and Pece of Mind Environmental

Maximizing scrap value in demolition: what every contractor needs to know

Rising to the Challenge of Ashbridges Bay Treatment Plant, Toronto

National Demolition Association unveils comprehensive workforce development toolbox to strengthen industry

Demolition Group of America: Building relationships in demolition, by Kevin Wiley

Gunter Dewit rises to victory as Caterpillar crowns champion from Belgium in Global Operator Challenge

The best machine operators from across Europe, Africa and Middle East gathered in Malaga, Spain to forge their legacy and prove their mastery of both equipment and technology. The 20 competitors first had to win local Cat® dealer competitions to qualify for regionals. Only three emerged victorious and earned the right to advance to the final round in the Caterpillar Global Operator Challenge.

The overall champion of the Malaga based competition was Gunter Dewit from Belgium representing dealer Bergerat Monnoyeur Belgium. Dewit finished the four GOC events with the lowest points total of 983, which is a combination of time and penalties.

At the same time, both Nicolai Thomsen from Denmark, representing dealer Zeppelin Denmark, completed the challenges with 1,048 points, emerging as the first runner up and Sebastian Behr from Germany, representing dealer Zeppelin GmbH with 1,101 points emerged as the second runner up. Both of these operators will also progress to the finals.

EVENT HIGHLIGHTS

All competitors competed in the same four Challenges using Cat® equipment and technology.

“Our team worked tirelessly to make sure operators could show off their skills in every area,” said Serena Janssen, industry solutions lead for Caterpillar.

“We created challenges where every operator had the same shot at winning, competition was fierce and everyone gave it their best shot to be crowned the winner of this prestigious event.”

The Touchdown Challenge saw competitors using a Cat 320 hydraulic excavator fitted with 3D GPS to pick up two rugby balls consecutively and drop them in a nearby basket. Contestants then needed to touch two targets using the machines’ 3D GPS technology.

In celebration of a century of earthmoving excellence, the Centennial Push Challenge had operators put a Cat D4 dozer through a predetermined course within a specified timeframe. Operators were able to use optional aids via Steer

Left to right: Julian Roux (Caterpillar), Sebastian Behr (second runner up), Gunter Dewit (first place), Nicolai Have Thomsen (first runner up) and Jas Kundra (Caterpillar)

Assist and Slope Assist, which are built into the machine to help with precision maneuvers.

Featuring a Cat 938 small wheel loader, the Loader Labyrinth Challenge highlighted the agility and adaptability of the operators as they navigated a dual-phase course. Starting with a bucket, participants loaded and hauled material along a marked path before dumping it into a Cat off-highway truck. The challenge then shifted to precision handling, where operators had to swap their bucket for forks and transport a pipe across a designated route and place it accurately on the ground. After reversing the process and reconnecting the bucket safely, operators reversed through the course to the original starting position. It was a test of speed, control, and seamless equipment transitions.

The Articulator Challenge featured the recently announced next generation 730 articulated truck where competitors maneuvered the machine through a designated course. Operators had to avoid obstacles along the way before safely and precisely reversing to a pre-determined dumping area where they had to safely lower the truck body completely before returning to the travel position and coming parking correctly under a wheeled loader at the end position.

CHALLENGE WINNERS

Touchdown Challenge: Dino Toic representing Teknoxgroup, Croatia

Centennial Push Challenge: Silvian-Alexandru Milea representing Bergerat Monnoyeur, Romania

The Loader Labryrinth: Gunter Dewit representing Bergerat Monnoyeur, Belgium

The Articulator Challenge: Gunter Dewit representing Bergerat Monnoyeur, Belgium

Regional competitions across the globe determine the nine operators who will compete in the global finals. The winner receives either a $10,000 cash prize or an equal value trip for two where Caterpillar has a location worldwide.

www.cat.com/operatorchallenge www.caterpillar.com

SUPPLIER TALK

Roni Szigeti Founder and CEO at FieldFlō

Roni Szigeti has a background in specialty subcontracting and a relentless commitment to developing innovation solutions for specialty subcontractors. His journey began at Northstar Environmental Group (Formerly LVI), where he was a key player in the company’s mission to provide innovative environmental and demolition contracting solutions. Driven by a desire to bring innovation and efficiencies to specialty subcontractors, Roni founded FieldFlō, a technology company synonymous with innovation, providing tools that enhance efficiency, reduce waste, and contribute to a more sustainable future.

One of the things I love about the demo industry specifically is how connected all the contractors are “

What is your core message to our demolition contractor readership?

FieldFlō is the only software that was built specifically for the demolition/ environmental industry.

Give us some background on FieldFlō and how you started out in both the built environment and business administration software industries. I was recruited shortly after college into one of the biggest demolition companies in the country. So I started boots on the ground working in the industry.

I worked there for a while, then I bounced between roles; estimating, operations, project management-you name it. I learned the business from every angle.

Later on, I ran operations at both midsized and smaller contractors that handled everything from demolition and environmental work to self-perform carpentry and masonry—a mix of trades across the board.

What we started to realize was that the operational processes at many of these companies were completely broken. Time tracking, payroll, safety, scheduling, warehouse and inventory management, job costing, waste tracking—you name it. In some cases, these things weren’t even being done. And when they were, it was often painfully inefficient.

At one point, I stepped away to get my MBA thinking maybe I’d move on from construction entirely. But nope. Right after graduating, I was back at it, running operations again. Only this time, I was itching for change and I had a vision for how I could help the companies I partnered with to make things better—give demolition contractors a single platform to manage everything from the field to the office, helping leaders reduce risk, keep teams safe, and run operations more efficiently.

So I teamed up with two friends and started building a simple software tool—just digital timesheets and some simple forms to start. We convinced a few local contractors in Colorado to give it a shot. They liked it. They actually used it. And just like that, FieldFlō was born.

We’ve collaborated closely with our amazing clients to refine it, and now we’re live in all 50 states and operating in four countries. Every day, we’re working alongside contractors to solve the real problems and inefficiencies that specialty subcontractors deal with on the job.

Regarding software, are you a front end or a rear end person? Do you enjoy getting your hands dirty under the hood?

Ha, I never wanted to be the front or rear end person, but I’ve grown into learning about both. That said, I’m more the ideas guy and love being somewhat of a consultant to our clients. I hire and partner with people way smarter than me who know how to code and build the software. I do love getting my hands dirty and learning as much as I’m capable of, but my team prefers that I stay out of the actual coding!

Tell us about the services FieldFlō provides and how your relationship with clients works. We’re a full-stack platform solution which means that we incorporate various modules that handle nearly all needs from the office and the field, with the exception of invoicing and payroll (though we integrate with ERP and payroll companies). Our platform has modules for scheduling, time, CMR, inventory/warehouse tracking, change orders, certification tracking, close-out reports, waste tracking, safety training and more. Within every module are built-in safety components which

of course are critical for demolition subs.

We have amazing relationships with our clients, because we understand what they’re going through. Almost everyone from our customerfacing team has worked in the field or office at a contractor business before, which gives them the empathy, but also the conviction, that FieldFlo can help make their lives easier. We hold our clients’ hands through the implementation process and celebrate their successes along the way.

How do you gain business and spread the word about FieldFlō?

It’s funny, you probably don’t see our name anywhere because we don’t really do much advertising or marketing. Most of our growth comes from word of mouth and referrals. One of the things I love about the demo industry specifically is how connected all the contractors are. It’s one big family.

What makes FieldFlō different from the competition?

The biggest competition is paper and pen. So many contractors are uncomfortable with change, and so they’re still using outdated processes. For the few other softwares out there, I really do believe— and have heard from our clients—that we’re the only solution that is purpose-built for the selfperforming trades. You see this when you see how our demolition specific forms work, our waste and scrap tracking capabilities and the various aspects of how we’ve integrated a safety/compliance first mentality all throughout FieldFlō.

Tell us about your team and working culture. What’s it like to work for FieldFlō?

I consider us a family-business. Both my brother and my wife work with us, and while that might be a turn-off for some, I believe it enables us to have similar values as so many of our clients, many of whom are also family-run. Our first core value is “fun” and both our employees and our clients have said that it’s felt across most all of the interactions we have with

each other. We’re also very focused on a growth mindset and making ourselves as individuals, and as a team, as well as with our clients better every day. Our company is currently fully remote, so finding time to connect with each other and have fun is really important to us. Are there any standout product developments from FieldFlō’s history?

We have had so many fun dev projects over the years, but I’d say the day that our auto language translation feature hit the product was super exciting! We made it so that you can talk or type in any language into any form in FieldFlō (Daily Reports, JHA’s, Inspections etc) and FieldFlō will automatically convert it back to English if the user wishes.

Additionally you can convert FieldFlo into any language so it’s easier for the user to work in their own native language. This was so huge because of the incredible diversity that exists in our industry and making FieldFlō easier to use and less intimidating for users.

Are there any key events that told you that you were on the way to making it?

This might sound funny to some, but the first time I was able to write myself a paycheck was the moment that I truly felt we were on our way to making it. Anyone who has started a business knows the incredible sacrifices it takes to build something great. For me, one of those sacrifices was prioritizing the investment in the right team—even before paying myself—because I believed that, in time, it would all pay off.

Another milestone I’ve come to appreciate is attending events like the National Demolition Association’s annual conference. Watching our booth grow in attendance year after year is a powerful reminder of the progress we’re making and the impact we’re having.

How has the scope of FieldFlō’s business developed over time and will you be expanding or developing your range of services?

Absolutely, we’re adding new modules and capabilities every month. This year, we’re adding 4–5 major modules. The most recent developments were our OSHA Reporting Suite and our FieldFlo Safety Academy which is ~600 bilingual video trainings built into our Trainings module.

Is there a good pool of potential new recruits to the industry—are they armed with the right knowledge and skills?

One of the best parts of working in this industry is seeing how many sharp young people are interested in getting their hands dirty and learning the ropes. It kinda feels like a changing of the guard is happening in our industry and now younger leaders are emerging as the legends are retiring. This is also resulting in some incredible innovation at these companies.

Now, all that said, it still appears there is a serious shortage in the demo workforce (much like all of the trades) and we’re seeing a lot of our clients finding unique ways to recruit and train young talent. We’ve partnered with several contractors who are running great apprenticeship and trainee programs. The NDA also does an awesome job at providing apprenticeships and training through their educational committees.

How is AI impacting FieldFlō? Do you see it as a tool to expand your functionality or is it a potential competitor? Is it writing your code for you?

We see AI as a force multiplier, not a threat. I’m genuinely excited about what it can do, not just for us as a software company, but for the contractors we serve. The AI components we’re building in our software are so amazing and will revolutionize the way foreman, project managers and safety professionals are going to manage their projects! Is it writing our code for us? Sometimes! But it’s our team’s creativity and industry knowledge that turns that code into something meaningful. The real magic comes from understanding the nuances of demolition and abatement workflows, and that’s something AI still can’t replicate.

How do you keep your workforce’s skills up to date?

Most of our team comes from the industry so they are already super dangerous but we keep up with the industry through our bi-monthly Guru calls where we hop on with every client and get feedback from them on the industry and ways in which FieldFlo can help alleviate any pains or bottlenecks. We also stay sharp by attending industry events like the NDA annual and quarterly conferences, EIA events and regional industry association events.

What are the biggest technological developments you have seen in your industry and what do you envisage will be the future game changers?

AI has obviously been the biggest technological development and it’s unbelievable the ways in which it is being baked into other technologies and hardware to make everything more efficient. You’re setting me up here a little but FieldFlō will continue to be the game changer amongst AI enable machines.

How do you see the outlook for business administration, management and IT/AI tools in demolition?

I’m very optimistic. There’s definitely pressure on margins due to the great companies out there creating more competition and every day compliance is only getting tighter, but that’s exactly where good systems come in. We’re seeing more contractors embrace digital tools, not just to check boxes, but to actually run smoother, leaner operations.

I think innovation and business administration are going to be the quiet MVPs of the next few years. Those who get their back office dialed in and innovate will have a serious edge.

Tell us about any engagement FieldFlō has in the community, or social responsibilities?

We’re big believers in giving back. Our community is like a family so we try to help everyone that we hear is going through hard times in any way we can. We have donated to so many GoFundMe pages these past years and, while the stories are heart wrenching, it’s incredible to see our community come together to help out one of their own.

Besides that we have charities that are near and dear to our hearts, many of which we’ve found through our partners: MarFan Foundation, Navarro Farms, Rocky Mountain Children’s Hospital, Kempe Foundation and the Solace House

How do you envision FieldFlō in 5 to 10 years?

I’d love to see FieldFlō become the go-to platform for every demolition, environmental and specialty contractor across North America... and beyond. That means listening to our clients’ needs and expanding our feature set without losing the simplicity and flexibility that our partners love us for.

And how about you in a few years?

I’m in this for the long haul. I didn’t start this to flip it, I started it because I saw a real need and wanted to build something meaningful. I hope I’m still growing both personally and professionally at FieldFlō, maybe doing a bit more mentoring, speaking at events, or helping other startups. But most importantly, I want to still feel challenged and useful. I also hope to hold two trophies for winning my son’s football team and daughter’s soccer team that I coach.

PRODUCTS

Tell us about one of the key demolitionrelevant functionalities of FieldFlō.

You’re gonna make me pick one? There are so many. Everything was built for demolition contractors. If you’re holding me to the fire then I would say the waste/scrap tracking and reporting feature. It allows the foreman to capture the loads in the field, tracks against the budget and gives reporting capabilities to the office and PM’s for instant visibility. Nothing exists like it in the world.

Outline its key functions.

CRM (job walk, reach outs, proposal builder), time tracking and approval, project management, certification/license management, safety inspections, demolition daily reports, demolition JHA’s, scheduling, warehouse and inventory management, job costing, waste tracking, production tracking, training… you name it!

How is it critical for demolition contractors? Why should they buy it?

Contractors specializing in demolition present operational, compliance and safety challenges, often operating in high-risk environments with large, multilingual field crews. These companies need unified safety, operational management, field management and project management solutions as they expand across commercial markets.

FieldFlō is built for demo crews to give them that unified FLŌ—plain and simple. It’s not some overcomplicated software designed for highrise GCs. It’s made for our industry and for the people actually doing the work. It’s a business in

a box for demolition contractors of all sizes and lets them do almost everything from one platform. You can track your hours, loads, equipment, safety, opportunities and see where you are on a job without having to chase paperwork or call the office.

Why should you buy it?

Because it keeps you on top of your numbers. You’ll know if you’re ahead or behind on your scrap, your waste, or your labor—right there on your phone. It helps you stay profitable, avoid surprises, and run a tighter ship without adding more work to your plate. And honestly, once the crew gets the hang of it, they won’t want to go back.

Can you quantify any of these benefits?

We ran several case studies across 1,000 projects to understand cost and time savings across US-based subcontractors.

How have you found take-up among demolition contractors? How do you push it out to them?

We’ve seen amazing traction, especially through word of mouth. When one contractor sees another using FieldFlō on-site, they’re usually curious. Covid also created a huge demand for FieldFlō because of the need to be interconnected between the office and the field without physically being connected. We also spend a lot of time at industry events, meeting folks face- to-face. That personal connection goes a long way.

Have you had any feedback and how do you see its development?

AND FINALLY

Who/what would you be in an alternative life?

A musician. I love playing the guitar, piano and making music. My dream is to play at Red Rocks but unfortunately God didn’t bless me with natural ability.

Who is your favorite artist?

My son and daughter. No painting in the world can give me the joy that I feel when seeing a hand drawn picture from my kids.

Who do you most admire?

My wife Brittany. She’s such a badass and I admire her ability to succeed at everything she puts her mind to, no matter how challenging it is.

When and where are/were you happiest?

Right now! This is such a fun time in life between my family and work!

What’s the most expensive nonessential you’ve ever bought?

My mountain bike. I hope you interview me next year and I can tell you a boat.

What’s your bucket list activity?

Get my pilot’s license.

What’s your ideal weekend?

In the mountains with my family, hiking, getting out on the lake, riding my mountain bike, seeing some live music, and eating and sleeping well.

The feedback has been incredible and the industry is excited to have something that’s built specifically to solve their unique set of pain points. In fact it’s been so well received, and proven itself to be such a game changer, that we keep getting asked to build more and more features. I don’t want to give too much away, but we have many fun projects in works surrounding AI, production tracking, task planning and safety.

What would you do for a company excursion, money no object?

I would take the team to Kauai so that everyone could get some R&R in paradise.

fieldflo.com hello@fieldflo.com (888)

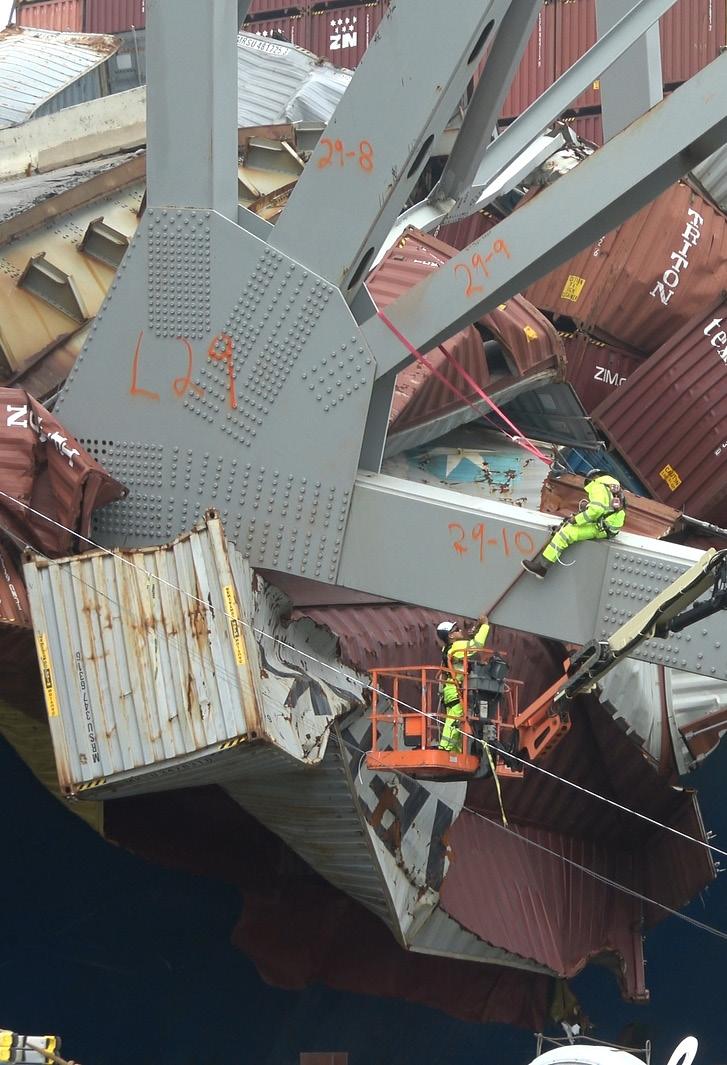

CASE STUDY

Project: Francis Scott Key Bridge explosives truss separation plan

Structure: Partially collapsed steel arch continuous through truss bridge

Site: Patapsco River

Contractor: Controlled Demolition Inc.

Client: Resolve Marine marine salvage corporation

Significant stakeholders: US Army Corp of Engineers, Skanska

Completion date: May 2024

Techniques: Explosive separation

When the MV Dali container ship lost power to its propulsion system and subsequently ploughed into the Francis Scott Key Bridge in Baltimore in the early hours of 26 March 2024, it made world headline news. DNA magazine spoke with explosive demolition pioneers Controlled Demolition Inc about its work to separate the bridge’s truss from the ship, which the section of bridge was weighing down.

The MV Dali had been pinned to the bottom of the Patapsco River since the total collapse of the Francis Scott Key Bridge in Baltimore, Maryland on 26 March 2024.

The US Army Corp of Engineers (USCOE) was responsible for clearing debris from the main channel; Skanska was responsible for clearing debris outside of the main channel; Resolve Marine was hired by the MV Dali Ownership and Operations company to remove the vessel and return it to port for offloading of undamaged cargo and removal of final bridge debris from the bow before being towed to a shipyard in Norfolk, Virginia for repairs.

Controlled Demolition Inc (CDI) was hired by Resolve Marine as an extension of its contract with the ship owner/operator and their insurers. CDI’s task

was to separate the truss from the MV Dali to permit Resolve Marine to refloat it for transport to the Seagirt Marine Terminal in Baltimore for offload of cargo.

CDI’s plan was to use explosives charges to isolate structural members in a 18-metre wide portion of the fallen bridge truss on the port side of the vessel, to remove the load imposed on the bow of the MV Dali vessel by the 180-metre-long section of fallen truss.

The presence of combustible materials in the damaged containers on the bow prevented CDI from placing explosives charges in that area to sever truss elements completely. This resulted in a plan that would leave some truss elements on the bow of the vessel and some of the truss elements draping over the port side of the bow for subsequent removal with cranes. Given the damaged and twisted condition of the

fallen truss, extensive investigation and engineering design was required before precutting for placement of explosives charges could be safely performed by CDI personnel. Once that precutting was completed, placement of explosives charges and some atsource protection was conducted as wind/weather conditions permitted safety of explosives loading.

Resolve Marine placed fire-retardant blankets and a fire suppression water mist over the bow of the ship during detonation of the separation charges as a precautionary measure, given the presence of flammable materials.

CDI detonated the explosives on schedule at 17:00 Eastern Time (22:00 BST) on Monday 13 May, just before low tide. CDI’s linear shaped charge separation system worked exactly as planned,

removing the weight of the truss from the bow of the MV Dali, creating the needed separation that permitted Resolve to refloat the vessel on 20 May.

CDI’s calculated peak air overpressure from the detonation of charges was consistent with that recorded on the vessel at the time of truss separation. There were no reported damages to either the vessel or its cargo as a result of CDI’s explosives separation.

While the CDI personnel detonating the charges remained on the fan tail at the stern of the vessel during the detonation, the crew of the MV Dali was isolated below decks in a soundproof room at the stern of the vessel during the explosives operation, without incident.

One hundred and fifty-one pieces of linear shaped charge explosives were placed at 52 cut points in the truss. The linear charges were connected with a nonelectric initiation system, which eliminated concern for the high powered marine radios on the salvage vessels working at the bridge collapse site or risks associated with thunderstorms if an electric system were used.

The total quantity of explosives detonated for the entire truss separation operation was approximately 142 kg. That quantity was detonated over 9.6 milliseconds to ensure initiation of all the linear shaped charges to sever the steel truss members, as needed, to accomplish total separation of the truss from the MV Dali.

CASE STUDY

Structure: 1970s oil-fired single unit, steam turbine with external boiler and all structural steel exposed to the elements.

Contractor: Confidential – a US based demolition contractor.

Scope of works (The DB3 Group): To lead demolition planning activities including budget development, development of the project manual and bid documents, bid assistance (pre-qualification, bid walk, addendum development, bid evaluation) and project management.

Scope of works (demolition contractor): Decommissioning and demolition of the boiler, chimneys, duct systems, and superstructure within a live plant; removal of asbestos and universal waste; scrap recovery and recycling.

Client: Confidential. The site is owned by an American energy company that generates power throughout North America with a portfolio that includes natural gas, coal, oil, nuclear, wind, and distributed solar generation.

Other significant stakeholders: Owners of multi-owned 500+ MW combined cycle unit adjacent to the demolition unit.

Start date: February 2025

Completion date: Estimated October 2025

Techniques: Asbestos and universal waste removal; strategic and controlled dropping of boiler components; dismantling of boiler superstructure using cranes; strategic and controlled felling, and mechanical demolition. Future use: Potential construction of new generating unit.

The DB3 Group is supporting the safe and complex decommissioning and demolition of a 700+ MW oil-fired steam turbine unit at a major operational power plant (almost 2,000 MW nameplate capacity) in North America. The work is being conducted for a confidential client that owns and operates a diverse portfolio of generating assets across the continent, including oil, gas, coal, nuclear, wind, and solar facilities.

Demolition is taking place in a constrained environment, surrounded by the client’s operational units and an adjacent multi-owned unit. The plant is bordered by a natural bayou, multiple operating units on two sides, and a large electrical substation that is part of the critical infrastructure to support ongoing growth in the area. It is also adjacent to an active construction project of a new generating unit.

Following the contract award, DB3 provided on-site project management to ensure contractor adherence to specifications, coordination of site activities between all team members, and to assist in scrap, contract and change order management.

DB3 reviewed and consulted on all major tasks, technical approaches and work submittals, and project progress while collaborating with contractors on project challenges. It conducted weekly progress calls with the owner, plant operation staff, and contractor to discuss continued coordination between all team members’ ongoing operations, project progress and project safety.

The demolition contractor had subcontracted an environmental abatement on the structures to be demolished and this

“A multi-sequenced approach was taken, with various methodologies for safe execution

was completed flawlessly. A multi-sequenced approach was taken, with various methodologies for safe execution, including the removal of:

• Asbestos and universal waste,

• Two steel chimneys,

• Two regenerative air heaters,

• Multiple deaerator tanks, multiple air duct systems,

• A supercritical boiler and its 225-feet tall superstructure.

Following the environmental removals, demolition of the air duct systems and Selective Catalytic Reduction (SCR) foundations was completed to provide a greater footprint. The steel chimneys were dismantled using a hydraulic crane lowering sections safely to ground level, as predetermined by the contractor’s structural engineer. Simultaneously, the team began the strategic dropping of the boiler within its footprint. The dropping was conducted working continuously from the bottom

to the roof level of the boiler. Dropping of its components was briefly halted to facilitate the strategic and controlled felling of the two regenerative air heaters. This activity was engineered by the contractor’s third-party structural engineer, who conducted their calculations, diagrams, cut pattern, and other safety measures that were evaluated prior to the event, reviewed daily on site, and during the work.

Once the boiler footprint was cleaned of all debris and the surrounding area was prepped, a 660-ton crane was mobilized for removal of the superstructure and associated 190,000+ pound girders, which were predetermined by the contractor’s structural engineer and laid out in advance.

As work on the superstructure was conducted, the team was conducting a full-length separation at multiple levels between the turbine deck

and boiler superstructure. This was partially conducted from the ground level up to promote the safe dropping of materials to ground level. Upper levels of the separation point containing the multiple deaerator tanks remained in place, to be safely dismantled and lowered by the crane.

All concrete and recyclable materials (ferrous and non-ferrous metals), which exceeded 7,000 tons, were appropriately segregated and recycled off site at approved facilities.

Operational challenges

The project required an absolute commitment to safety. Each day commenced with a briefing to communicate the planned work activities with all team members and contractors, discuss safety concerns for those work activities while also discussing ongoing trends in project safety based on findings from the safety observation program. The safety observation program was designed to capture trends on the project site and to be discussed with all team members to prepare and eliminate as an ongoing concern.

The two units solely owned by the client underwent a plant outage for service during the peak of the demolition work with vibration and dust being critical concerns. Dust was controlled using a DustBoss suppression system, multiple three-inch fire hoses from multiple angles during all scopes of work, and a thorough wash down of the boiler unit internals prior to each drop. Monitoring systems were established in specific areas to measure dust, noise and vibration for worker and plant staff safety, and effects to sensitive ongoing plant operations.

Due to the outage work at the plant and the commencement of construction of a new operating unit, a logistics plan was established to control truck traffic from the ongoing off-site shipments of debris and recyclable materials, mobilization and demobilization of the cranes, and for the safety of all plant personnel, outage workforce, and the demolition staff.

The team put together a plan and work procedures establishing hard barricades around the boiler footprint to prevent flying debris and limit access to the drop zone; implementing extensive training in fall protection and drop zone procedures; and putting in place a thorough communication plan using two-way radios between elevated workers, ground personnel, and operators.

The client’s concerns were well received

and efforts between DB3 and the demolition contractor prevented impact to its ongoing operations and to all stakeholders.

As the project approaches its final stages; DB3 remains committed to the safe execution of the remaining work in partnership with the demolition contractor, exceeding client expectations, and its own pursuit of excellence in the demolition industry.

About The DB3 Group

The DB3 Group’s methodology for decommissioning and demolition projects is based on assembling a team with the relevant demolition experience. This is driven by the group’s founder, Donald Barris, III, who comes from a third-generation demolition family and has demonstrable experience serving as a laborer, high-burner conducting the felling of structures and crane removals, lead demolition equipment operator, and every other managerial role in demolition. His experience in the industry allows The DB3 Group to build proper teams of contractors and for DB3 to successfully execute demolition projects.

www.db3grp.com (site under construction)

Donald.Barris@db3grp.com (419) 262-1451

CONEXPO-CON/AGG gears

up for 2026 with a century plus legacy of innovation and industry growth

As CONEXPO-CON/AGG 2026 nears, the construction industry’s premier event celebrates its rich lineage—117 years in the making and North America’s unmatched platform for construction innovation.

From humble beginnings in 1909, when the original Road Show in Columbus, Ohio hosted 40 equipment manufacturers in a 40,000-sq-ft space, to today’s 2.9 million-sq-ft, 2,000 exhibitor event, CONEXPO-CON/AGG’s evolution embodies the exponential growth of the construction industry.

Milestones in a storied past

• 1909—The inaugural Road Show, Columbus, Ohio, spotlighted machinery soon dubbed “hazardous equipment” over 40,000 sq ft,

• 1928—Detroit hosted the Combined Biennial Show, later known as the Concrete & Aggregates Show,

• 1963—The Columbus Road Show rebranded to the Construction Equipment Exposition & Road Show,

• 1969—“ConExpo” emerges as the new moniker for the event,

• 1996—ConExpo and Con/Agg formally unite under the CONEXPO-CON/AGG banner in Las Vegas, transitioning to a triennial frequency,

• 2005—AEM assumes sole responsibility for managing the show; in 2018, it secures operation rights through 2040.

Record-breaking scale and reach Exhibitors rose from 800 in 1996 to 2,056 in 2023; over the same time period exhibit space ballooned from 1 million to 2.83 million sq ft and attendees jumped from 84,000 to 139,110.

In 2023, CONEXPO attracted ~139,000 visitors, including 24,000 international attendees from 133 countries—with exhibitors representing 36 nations.

Forging the future—CONEXPO-CON/AGG 2026

Set for March 3–7, 2026, at the Las Vegas Convention Center and Las Vegas Festival Grounds, the next edition continues the tradition of excellence with:

• 2,000 exhibitor brands,

• 2.9 million square feet of indoor and outdoor displays,

• 150 educational sessions spanning technology, sustainability, and industry best practices,

• New Ground Breakers Stage,

• New Workshops: Small Business, EmpowerHER, Shop Talks and Walks.

Dana Wuesthoff, CONEXPO-CON/AGG Show Director said: “A century of progress is reflected in CONEXPO-CON/AGG’s scale, scope and spirit. This event continues to elevate the equipment manufacturing industry— amplifying innovation, insight and influence.”

About CONEXPO-CON/AGG Held every three years, CONEXPO-CON/AGG is the must-attend event for construction industry

professionals. The show features the latest equipment, products, services and technologies for the construction industry, as well as industryleading education. CONEXPO-CON/AGG is owned in partnership with NRMCA, NSSGA and AEM and managed by AEM. The next CONEXPO-CON/AGG will be held March 3-7, 2026, in Las Vegas, Nevada.

About the Association of Equipment Manufacturers (AEM)

AEM is the North America-based international trade group representing off-road equipment manufacturers and suppliers with more than 1,000 companies and more than 200 product lines in the agriculture and construction-related industry sectors worldwide. The equipment manufacturing industry in the United States supports 2.3 million jobs and contributes roughly $316 billion to the economy every year.

www.conexpoconagg.com www.aem.org

CONEXPO-CON/AGG

celebrates Careers in Construction Month with industry-wide call to build, train and inspire

North America’s largest construction trade show was proud to join the nationwide celebration of Careers in Construction Month in October, recognizing the professionals who shape our roads, infrastructure, and skylines, and calling attention to the rewarding career paths that power the built world.

CONEXPO-CON/AGG spotlighted the people behind the machines and promoting pathways to strengthen and sustain the construction workforce this October.

“The future of construction is bright, but it’s also being built right now in classrooms, in apprenticeships, and on job sites across the country,” said Dana Wuesthoff, CONEXPO-CON/ AGG Show Director. “This month, we’re celebrating not just the equipment and innovation that define CONEXPOCON/AGG, but the skilled individuals and employers who bring it all to life. We’re inviting the industry to invest in people as much as in machines.”

Building

the workforce starts with hiring the right people

As the demand for skilled workers remains high, effective hiring and retention strategies are more critical than ever. A recent survey by the Associated General Contractors of America found that 94% of construction firms reported open skilled labor positions, and 42% increased training investments to address the gap.

Dr Larry Kokkelenberg, a long-time expert on organizational development who spoke at CONEXPO-CON/AGG 2023, emphasized in his free e-book Hiring and Retaining Good Employees that successful companies start by identifying the traits of top performers and hiring with intentionality.

“When employees talk to their friends and family about good pay, strong leadership, and growth opportunities, they become your best recruiters,” Kokkelenberg noted. “It’s not just about filling roles; it’s about building commitment.”

His insights offer a roadmap for developing referral programs, leveraging internships, engaging veteran pipelines like the Department of Defense SkillBridge Program, and offering robust training programs that show employees they matter.

New highlights and workshops for CONEXPO CON/AGG 2026

• Ground Breakers Stage: Located in the West Hall, this all-new keynote platform will feature industry voices on the topics that matter most— technology, workforce development, mental health, sustainability, and the public policies shaping tomorrow’s jobsite.

• EmpowerHER Workshop: Celebrating Women in Construction Week, this new addition will bring women professionals together for panels, networking, and leadership insights to drive inclusion and advancement in the field.

• Small Business Workshop: Designed to equip small contractors and vendors with tools for growth, attendees will gain access to resources, business strategies, and connection-building opportunities tailored for lean teams and emerging players.

• Shop Talks & Walks: Get hands-on with real-world solutions to daily challenges. This workshop focuses on equipment maintenance, operational efficiency, and quick wins you can take back to the jobsite.

Why attend CONEXPO CON/AGG?

With more than 150 expert-led sessions, CONEXPO-CON/AGG 2026 offers a uniquely immersive opportunity to sharpen skills, explore solutions, and stay ahead of industry change. The education tracks are designed to meet the evolving needs of contractors, business owners, fleet managers, and tradespeople.

Attendees can participate in tailored learning experiences across core areas such as:

• Sustainability: Eco-conscious practices that reduce environmental impact,

• Equipment Management & Maintenance: Maximizing uptime and asset life,

• Technology Solutions: Increasing accuracy, efficiency, and productivity,

• Safety & Health: New protocols and training to protect crews and job sites,

• Business Best Practices: Financial, operational, and strategic insights,

• Workforce Development: Recruiting, retaining, and growing talent.

World

construction leaders to spotlight autonomy, sustainability and workforce at new Ground Breakers Stage

From robotics to resilient infrastructure,construction’s boldest ideas debut in Las Vegas

CONEXPO-CON/AGG will debut the Ground Breakers Stage, a new keynote platform showcasing autonomous tech, sustainable solutions and workforce innovations from global construction leaders.

Keynotes and presentations on the Ground Breakers Stage will be features of the show, complementing robust educational programming and more than 2,000 exhibitors across the 2.9 million sq. ft. of exhibit space. Speakers will range from the CEOs of Fortune 100 companies to successful entrepreneurs.

“Autonomous and sustainable technologies are redefining how we build, hire and innovate, and CONEXPO-CON/AGG is where the industry tests those technologies at scale,” said Dana Wuesthoff, Show Director at CONEXPO-CON/ AGG. “The Ground Breakers Stage gives attendees a front-row seat to the ideas and investments shaping construction’s global future.”

Every three years, nearly 140,000 construction leaders gather in Las Vegas to discuss innovation, technological advances, challenges and opportunities impacting the more than $2 trillion US construction industry.

The innovative leaders who will be featured on the Ground Breakers Stage will be announced in the months leading up to CONEXPO-CON/AGG 2026.

Push limits. Smash barriers. Break boundaries. And when you’ve conquered all those obstacles? You discover your full capacity for greatness. World of Concrete delivers all the real-world solutions that will crush your challenges and take your expertise to new heights. Growth opportunities are everywhere, whether you’re getting hands-on with game-changing tools and tech or shaking hands with your future partners. Ready for maximum success? Nothing’s standing in your way.

ACHIEVE PEAK PERFORMANCE

VIEW GLOBAL EVENTS

EXHIBITS: JANUARY 20-22, 2026

EDUCATION: JANUARY 19-22, 2026

LAS VEGAS CONVENTION CENTER

Step into the spotlight: Nominate groundbreaking innovations for the 2026 Next Level Awards

New for 2026, the Next Level Awards program is expanding into two new categories: Equipment and Technology. The Next Level Awards program celebrates companies pushing the boundaries and delivering innovative products, services, and technologies that move the construction industry forward. It premiered during CONEXPOCON/AGG 2023, when Holcim’s ECOPact LowCarbon Concrete was selected as the Next Level Award’s Contractors’ Choice Award Winner

Nominations can be made through December 1, 2025. A panel of industry experts and leaders will select 10 finalists in each category ahead of CONEXPO-CON/AGG. During the show, attendees will be encouraged to visit all the finalists and vote for their favorite in each category. Winners will be announced on the “Ground Breakers” keynote stage the morning of Friday March 6.

“The Next Level Awards shine a spotlight on the extraordinary innovations shaping the future of construction,” said CONEXPO-CON/AGG

show director Dana Wuesthoff. “These awards not only honor the remarkable achievements of our industry, but also inspire companies to push boundaries, embrace new technology, and drive real progress. We can’t wait to see what new advancements will be on display and celebrate the visionaries moving our industry forward.”

The Next Level Awards provide an excellent opportunity for companies to gain extra exposure and recognition for their innovative contributions to the industry. Finalists will be recognized in CONEXPO-CON/AGG press releases, social media, and other applicable channels, encouraging attendees to visit their booths and learn more about their cutting-edge products.

If you have not registered yet for the show, use code NEWS30 to save 30% off admission. Offer valid thru December 5, 2025.

www.conexpoconagg.com/for-exhibitors/ awards-and-recognition?tab=next-level-awards

Digging deep

When the Orlando Utility Commission (OUC) needed to repurpose a historic site for a new electrical substation, the challenge of clearing decades-old debris required expertise, precision and problem solving. Pece of Mind Environmental, an NDA member based in Florida, rose to the occasion and delivered a project that met the high standards of safety, sustainability and efficiency.

OUC tasked Pece of Mind Environmental with clearing the remnants of a power plant demolished and buried on-site over 35 years ago. The project began in February 2021 and was completed in January 2022. While the plant’s remnants posed significant challenges, Pece of Mind Environmental’s team utilized ingenuity and cutting-edge equipment to navigate the complexities.

One of the unique aspects of this project was the absence of as-built plans to delineate the limits of the former power plant. Pece of Mind Environmental relied on old aerial photos, surveys and even newspaper archives to determine the extent of the buried debris field. Once the outer limits were identified, the team conducted test pits to confirm the depth and size of the basement structure — ultimately revealed to span 200 feet wide, 500 feet long and 15 feet deep.

The team then phased debris removal to manage the vast area efficiently, maintaining a staging area for screening debris and maximizing soil reuse for backfilling.

A range of heavy equipment was mobilized to tackle the project:

• Volvo 480 excavator

• 2 Cat 336 excavators

• Kobelco 210 excavator

• Cat D5 dozer

• Komatsu D51 GPS dozer

• Cat 730 end dump truck

• McCloskey R230 screen plant This fleet enabled efficient excavation, debris screening and site grading.

Execution steps

• Site clearance: The team began by removing all known infrastructure, including underground stormwater piping, electrical duct banks, and various concrete slabs and footers,

• Excavation and investigation: Careful excavation exposed the limits of the basement and debris field, followed by the installation of a dewatering system to ensure proper compaction during backfilling,

• Recycling and soil reuse: Pece of Mind Environmental screened the debris, achieving an impressive 99.99% recycle rate, including 45,000 cubic yards of concrete,

• Safety and structural integrity: Sheet piling was installed in areas with significant elevation changes to prevent undermining adjacent properties. Additionally, a 90-inch stormwater outfall pipe, abandoned for 40 years but still connected to a lake, was meticulously inspected using robotic technology and permanently capped.

Overcoming Challenges

Several hurdles tested the team’s expertise:

• Petroleum contamination: Localized contamination required a carefully designed dewatering system to avoid discharging effluent,

• Elevation variations: Significant elevation changes necessitated sheet piling to stabilize the site,

• Stormwater pipe risks: Ensuring the integrity of the outfall pipe was critical to avoid turning the site into a lake.

A Model of Success

Pece of Mind Environmental’s team of 10 crew members logged 10,000 manhours with zero injuries, completing the project on time and within budget. The company also imported 55,000 cubic yards of clean fill to return the site to its original elevation, ready for the new substation.

Maximizing scrap value in demolition: What every contractor needs to know

At Demolition New Orleans in March, one education panel tackled a deceptively complex topic that can make or break your project’s bottom line: maximizing the value of scrap in demolition. From vendor selection to market timing, the discussion made it clear that when it comes to scrap, strategy matters.

Panelists included Brad MacAulay, associate editor for metals at Argus Media; Andrew DeBaise, executive manager at Rocky Mountain Recycling Inc.; and Bryan Cherkasky, vice president

of ferrous metals at GLE Scrap Metal.

Why vetting your scrap vendor is critical

It might be tempting to go with the lowest bid when choosing a scrap vendor, but panelists warned that could cost you more in the long run. A thorough vetting process ensures you’re working with someone who understands the specific materials on your site—especially valuable or regulated ones like copper, lead or asbestos—and has the expertise

and equipment to process them properly.

A good scrap partner will offer transparent pricing, reliable service and full compliance with safety and environmental regulations. Cutting corners here can lead to undervalued materials, unexpected fees or worse: liability for mishandled hazardous waste. You might pay a little more for the right vendor, but the long-term return is well worth it.

Navigating a volatile scrap market

The scrap market isn’t what it used to be—and it’s constantly changing. The panel shared that geopolitical tensions, shifting trade policies and global supply chain disruptions are all causing significant fluctuations in material prices.

Here in the US, increased infrastructure spending has boosted demand for raw materials like steel and aluminum, pushing up the value of scrap. But that demand also raises competition, while rising energy and transport costs can eat into your profits.

Sustainability is also playing a larger role.

are increasing the complexity and cost of compliance.

Key considerations for demolition contractors

To get the most value out of your project’s scrap, contractors need to think ahead:

• Identify and segregate materials early. Know what’s on-site, from steel and aluminum to concrete and copper, and make a plan to sort and separate. This reduces contamination and increases return.

• Watch the market. Scrap prices can change quickly. If timelines allow, schedule demolition to align with favorable pricing.

• Prioritize compliance and safety. Your team should be trained to handle hazardous materials, and your vendors must be properly certified to avoid environmental violations.

• Plan for logistics. Scrap is heavy and expensive to transport. Partnering with a local processor or creating an efficient transportation strategy can save big.

Rising to the challenge

by Katie Grube

Location: Ashbridges Bay Treatment Plant, Toronto, Canada

Owner: City of Toronto

Design and construction management: Hatch Ltd. with Jacobs and Baird

Contractor: Southland Mole of Canada and Astaldi Canada Design & Construction Joint Venture

Dates: 2020-2025

Duration: 6 months

Materials removed: Georgian Bay shale

Project scope: Locating 50 preinstalled risers

Equipment: 2 Brokk 120DIIs, 1 Brokk 110, 2 Brokk Breaker 155s, 3 Gantry Platforms, Muck Box, work platforms and other support equipment

Two hundred sixty feet below the surface of Lake Ontario, crews worked day and night to expand Toronto’s wastewater treatment capacity. The Ashbridges Bay Treatment Plant Outfall project, part of the largest and most significant stormwater management program in the city’s history, sought to create a new fallout and watertight shaft to replace the existing 80-year-old system.

The project required extensive underground tunneling with an 11,500-foot tunnel and 50 connected risers. The contract for the tunneling and concrete work was awarded to Southland Mole of Canada and Astaldi Canada Design and Construction Joint Venture. Southland Mole of Canada, an excavation company specializing in trenchless technologies and difficult tunneling configurations, joined the project to create the tunnel and break through the lakebed to the risers above. For such a complex project, the company needed hard-hitting, durable machines that didn’t require operators to stand in the danger zone.

The Ashbridges Bay Treatment Plant outfall project

The City of Toronto embarked on the largest and most significant water quality improvement project in its history in 2020. The project was designed to address shortcomings in the Ashbridges Bay Treatment Plant, the largest wastewater treatment

facility in the city, as well as one of the oldest. Its outfall was where treated water from the city’s sewer system was released and dispersed into Lake Ontario. However, a shared pipe system carried both raw sewage and stormwater. The combined sewers occasionally released untreated wastewater into the waterways, increasing pollution. The outfall also had insufficient capacity and no longer met regulatory standards.

A new outfall was constructed as part of the fiveyear project to improve the city’s shorelines, beaches and Lake Ontario’s water quality. The Ashbridges Bay Treatment Plant Outfall Project’s budget was estimated at $300 million and required creating a new 52.5-foot onshore shaft that’s 278.9 feet deep and 11,500 feet long with an internal diameter of 13.1 feet. The project also involved excavating through the floor of the lake to locate 50 preinstalled risers, which convey treated and disinfected effluent from the city of Toronto’s Ashbridges Bay Treatment Plant into Lake Ontario. Once the new outfall is constructed, all effluent flows from the plant will be directed to the new outfall up to the wet weather design capacity of 264,120 gallons per day. With only 3.3 feet of hydraulic head available at peak design flows under the highest recorded lake water level conditions, the outfall components were designed to minimize head losses and allow the outfall to operate by gravity.

Southland Mole began work on the project in 2020, using a tunnel-boring machine to mine the shaft. At the same time, another team on a barge positioned the risers and inserted them into the lakebed of Lake Ontario.

“The point of the project is to convey the treated wastewater, which has been processed through the wastewater treatment plant, back into the lake,” said

Kevin Collins, equipment manager with Southland Mole. “Barges prepositioned the risers, so we just had to locate them by drilling up into the rock. Although the project is straightforward, it is not simple.”

Connecting the risers to the tunneling system became the most intricate aspect of the project. The Southland Mole crew had to excavate upward through the new tunnel into the lakebed above to link the risers to the tunneling system. This necessitated forward thinking and careful consideration of equipment.

The Brokk advantage

Collins and his crew needed to dig straight upward into the lakebed to locate the risers positioned between 5 and 10 feet above. The team on the barge used GPS to locate each riser, but the location wasn’t exact. This meant they needed to excavate more material than was strictly necessary to find the risers. As the team worked, debris and water would fall directly onto any machine being used as well as the operator inside the cab. Southland Mole’s team knew they needed a unique machine that could withstand the harsh working conditions. The solution required enough hitting power to break through the concrete shell of the tunnel and into the Georgian Bay shale beyond without succumbing to the pressure. They also required

more precision. The risers were full of water and featured 2-inch valves at the bottom of the pipe. Breaking the valve would result in a deluge of water falling into the tunnel. This not only endangered the machine, but also the operators. Fine control of the machine was crucial to guard against these dangers.

At the beginning of the project, they attempted to use a large piece of equipment. However, while the larger machine broke the concrete, they found that it lacked consistency and accuracy. It was also too large to perform trimming. Fine trimming required workers to use pneumatics, rivet busters or chippers to break down the edges of the material.

In the past, Southland Mole used Brokk remotecontrolled demolition robots for tunneling, so they knew the benefits of the compact yet powerful machines. They understood that given the type of work they would be undertaking in the outfall project, they would need a smaller, more compact piece of equipment. That’s why they decided on a Brokk 120DII armed with a Breaker 155 attachment. The Brokk 120DII comes in a compact size of 2.5 feet wide, 6.5 feet long and 4 feet high, weighing about 2,700 pounds. Powered by a compact and efficient diesel engine, the Brokk 120DII can run a full shift independent from any power source. The diesel engine features a Tier 4 emissions control

system, making it safe to operate underground.

Excavating up to the risers required extensive overhead work. The Brokk 120DII boasts a vertical reach of 14 feet with the breaker attachment. Collins and his crew commissioned three outfall riser gantry platforms for the project. The first platform was manufactured to raise and lower with the Brokk 120DII loaded onto it, while the second and third platforms were only rated to transport personnel and equipment. The platform stands at 5 feet and can be raised up to 7 feet, positioning the Brokk 120DII and crew members anywhere from 5-10 feet above the tunnel surface. The arm of the Brokk extended up to break through the concrete and into the lakebed above, was primarily composed of Georgian Bay shale.

However, the size of the shale wasn’t consistent. The way the shale layered, when it broke off, it would fall and break on top of the Brokk robot. So, the machine regularly battled falling rock and water while working up toward the risers. The crew ended up renting two Brokk 120DIIs. With the extreme conditions the machines were subjected to every day, the team had to stay on top of maintenance. As such, Collins and his crew worked closely with

Brokk’s team on equipment maintenance.

“We underestimated where Southland Mole’s team needed to position the machines,” said Mike Martin, Vice President of operations for Brokk Inc. “They were directly in the line of fire when it came to the debris field, both for the shale and for falling water; and the arm was fully extended upward. We knew the machines would take a beating for this application. But it got to the point where we needed to send another machine up there as a backup to ensure nonstop service.”

The Brokk team sent a Brokk 110 to the Ashbridges Bay Treatment Plant to ensure they could continue to work at full capacity. However, since only one machine needed to operate at a time, when a Brokk 120DII required downtime for maintenance, the other worked.

“No matter what conditions our equipment is working in, we do everything we can to get the job done,” Martin said. “We always work to provide our best people and our best equipment no matter the application. And that’s the attitude we took when working with Southland Mole. Whether it was spare parts, inventory, extra hammers or something else, we

gave everything we could to get this very difficult job completed. It’s really a testament to the Brokk itself, and how willing Southland Mole was to work with us to keep these machines working.”

Thankfully, the Brokk team got parts and equipment to the worksite in time to keep both Brokk 120DIIs up and running despite the demanding conditions.

“The Brokk robots were really the only equipment option to get this type of work done. To achieve the same power, we would have needed bigger machines that didn’t fit in the tunnel as well, and then we’d require handwork, which put our crew in the danger zone,” Collins said. “We would much rather have the machine itself be at risk than risk one of our crew members. While the machines took a beating from the shale and water, it was much safer and much more productive than any other option.”

The Southland Mole crew worked 24-hour days with 20 workers per 12-hour shift. The first platform that supported the Brokk carried three crew members with a second and third platform following behind. The second platform carried the crew that completed rock bolts and mesh, while the third platform applied shotcrete to the mesh and rock before sealing the surface.

To find all the risers and complete this portion of the project, the crew worked for a little over six months. The project is projected to be fully completed in 2025.

National Demolition Association unveils comprehensive workforce development toolbox to strengthen industry

The NDA has announced the launch of its new Demolition Workforce Development Toolbox, a comprehensive system designed to help member companies recruit, train and retain top talent. This professional development platform provides a structured framework for lifelong career growth, from entry-level positions to leadership roles.

The new toolbox addresses critical needs in the demolition industry by offering a suite of tools for recruitment, mentorship, selfdevelopment, education, and certification. It provides members with resources to build a more skilled, safer, and more professional workforce.

“Demolition is built on the expertise of our people,” said NDA President Ben Hayden of Hayden Wrecking, East Saint Louis, Illinois. “The Workforce Development Toolbox is a game-changer. It gives our members the resources to define clear career paths, invest in their employees and, ultimately, elevate the entire demolition profession.”

The Workforce Development Toolbox is a comprehensive resource with six main sections designed to help demolition professionals and companies. The Job Descriptions section provides a standardized framework for roles, outlining responsibilities, skills and career paths from laborers to leadership to help employers build effective teams and workers see opportunities for growth. In the Organization & Recruitment

section, companies can find tools like the Anatomy of a Demolition Crew and pre-screening questions to create a strong team foundation and ensure a consistent hiring process.

To encourage knowledge transfer, the Mentorship section guides companies in setting up pre-apprenticeship and peer-to-peer programs that help new hires get up to speed quickly while strengthening team cohesion. The Self-Development section empowers employees with resources for personal growth, including the NDA Safety App and the Starting Out Right Video Series. For those looking to advance their careers, the Education section offers courses like Demolition Methods, Planning and Design Course, Hands-On Equipment Maintenance Course, Superintendent Bootcamp and the Foundation of Demolition Management Training Series, covering topics such as estimating and project management.

Finally, the Certification section includes nationally recognized credentials, including the Certified Demolition Supervisor and Certified Demolition Technician. These certifications validate a professional’s expertise, experience and dedication to maintaining the highest industry standards.

The Workforce Development Toolbox is now available for download. NDA invites all demolition professionals to explore how these tools can transform their teams and contribute to a more skilled and successful industry.

SelfDevelopment

The NDA provides resources for skill-building and career advancement for demolition employees, including:

Safety App: Access to safety materials in English and Spanish

Starting Out Right Video Series: Introduces new workers to the industry and safety practices

NDA Resource Library: Offers technical documents and safety materials

Online Learning: Partnership with 360training com for OSHA 10 and 30 courses and more

These tools support ongoing learning and professional growth

Workforce Development Toolbox

The National Demolition Association (NDA) offers tools for recruitment, mentorship, selfdevelopment, education and certification to help member companies develop personnel Links provided in this document and available in the NDA members-only Resource Library, key resources include:

Job Descriptions

Self-Development

Mentorship

Education

Organization & Recruitment

Certification

Job Descriptions

These documents establish a standardized framework for demolition teams, detailing roles from laborers to leadership They outline responsibilities, skills and career advancement, aiding employers in structuring crews and helping workers envision career growth Key roles include:

National Demolition Association

Demolition Workforce Development Toolbox

General Laborer

Field Laborer

Skilled Laborer

Support Operator

Primary Operator

Foreman

Project Manager

Superintendent

A Professional Development System for Members

Demolition Group of America: Building relationships in demolition

by Kevin Wiley, owner and National Demolition Business Development Manager, DGA

The Demolition Group of America (DGA) provides a unique set of services for specialty contractors, marketing our members to customers that we have dealt with for more than a combined thirty years. By utilizing our long-term relationships, we are able to offer contractors access to these good customers while avoiding troublesome ones.

As Business Development Manager, my primary role in DGA is to lead and oversee our business development initiatives on a national scale. With my extensive industry knowledge, I am responsible for developing comprehensive strategic business plans that align with DGA’s overall vision and growth objectives. These involve identifying potential expansion opportunities in different regions, evaluating market trends, and setting clear business development goals.

Business development

The DGA offers members a proven business development group, saving members the expense of employing full-time staff to perform a similar function. As we discuss the areas of the market companies wish to focus on, our thorough understanding of the growth trajectories of the demolition industry enables us to support them in their expansion efforts and develop a plan to further penetrate that sector. This may involve offering consultation on market entry strategies, risk assessment, and due diligence to make informed decisions. And when we bring a potential deal to them, they can be confident that it has already been qualified by us.

DGA can assist in every aspect of a project and we are with our members throughout the lifetime

of the job. We not only offer marketing but can assist with estimating, project specific document preparation, issue resolution, staffing, vendors, subcontractors, and any other needs that arise during the project. With our resources, the DGA can also offer property owners numerous cost engineering options to maximize the value of all parts of the site, from the property itself to the salvage value of all aspects of the structure to be removed.

We make the best use of everyone’s most valuable asset—we will not waste our members’ time or our own. We don’t chase the endless stream of ITB’s that go nowhere. We are here to decrease the number of estimates and increase the number of successful bids.

Partnerships and shared knowledge

Leveraging our extensive industry network, DGA fosters strategic partnerships with demolition companies nationwide. Our deep understanding of the industry allows us to share valuable insights and best practices, creating opportunities for knowledge-sharing, resource pooling, and collaborative projects that benefit all parties involved.

Our in-depth market research and analysis is invaluable in identifying potential markets and assessing the competition; this information is critical in positioning the DGA strategically and understanding how to effectively support demolition companies seeking growth in various regions.

From technical expertise to safety protocols and sustainable demolition practices, DGA’s guidance elevates overall industry standards. The team has extensive knowledge of local, state, and federal regulations related to the demolition industry and provides guidance on navigating complex compliance requirements to ensure our operations and those of other companies remain in full compliance with relevant laws.

At DGA we recognize the importance of continuous learning and skill development, and we organize training programs and workshops for the DGA team and other demolition companies to enhance their capabilities, foster innovation, and promote safety and efficiency. We also actively participate in industry events, conferences, and forums to share insights, advocate for the demolition sector, shape industry discourse, and influence policy decisions.

Demolition across the United States

Demolition is critical to the construction industry, serving a range of sectors including residential, commercial, industrial, and infrastructure.

The market continues to grow due to urban development, real estate trends, economic growth, infrastructure upgrades, and sustainability initiatives, playing a vital role in reshaping communities and supporting new developments. The sector is projected to experience further growth, making it an attractive opportunity for existing and aspiring demolition businesses to capitalize on the evolving market trends. Membership of the DGA can help you access that growth.

The future of commercial demolition

As ever, thorough planning will continue to be crucial to success. By increasing their knowledge and skills base, conducting detailed site assessments and identifying potential challenges early on, demolition companies can develop precise execution plans that minimize unforeseen expenses.

In the coming years, there will be a significant emphasis on sustainable and eco-friendly demolition practices. Contractors and regulatory authorities are increasingly concerned about environmental impacts, leading to a higher demand for demolition companies that prioritize recycling, salvaging materials, and reducing waste.

Implementing robust waste management and recycling practices can reduce disposal costs and generate additional revenue through salvaging valuable materials. Investing in on-site processing capabilities can further enhance cost containment. Collaborating with recycling facilities, waste management companies, and other industry partners can lead to cost-sharing opportunities and economies of scale, reducing overall project expenses. Embracing green demolition practices not only benefits the environment but also enhances the company’s reputation and attracts eco-conscious members.

Rapid advancements in demolition technology, such as high-reach excavators, remote operation, robotic demolition systems, and innovative demolition

attachments, will revolutionize the industry. Embracing these technologies can lead to more precise and efficient demolition processes, reducing time and costs for members while enhancing safety on the worksite.

The integration of BIM (Building Information Modeling) technology into the demolition process is gaining prominence. BIM allows for detailed digital representations of structures, enabling precise planning and simulations before the actual demolition begins. This helps to identify potential challenges, streamline operations, and improve cost containment.

To stay competitive, commercial demolition firms will increasingly offer value-added services beyond traditional demolition work. These may include deconstruction, hazardous material removal, site remediation, and even repurposing or redevelopment consulting. By diversifying service offerings, companies can cater to a broader range of members and projects. Our thought leadership and participation in events helps members stay up to date with these opportunities.