This page intentionally left blank.

This page intentionally left blank.

Organisation: Connectus

Document Title: Air Quality Delivery Work Plan

Fulcrum Document Number: CRL-PAT-ENV-CON-PLN-000899

Document based on MMS No: n/a

Client: Auckland Transport

Project: CRL Enabling Works: Contract Two

Location: Auckland CBD

Project No: 2665

This document remains the property of Connectus. Its contents are confidential and shall not be reproduced, destroyed or given away without the express, written permission of Connects. The electronic version of this document in MMS Database on designated server(s) is the Master Copy and is a controlled document. Unless specifically noted thereon, other copies of this document are uncontrolled.

This page intentionally left blank

Term Definition

AC Auckland Council

ACZ Active Construction Zone

AQ DWP Air Quality Delivery Work Plan

CEMP Construction Environmental Management Plan

CFA Continuous Flight Auger

CLG Community Liaison Group

CRL City Rail Link

CSA Construction Support Area

DRI Dust Risk Index

DWP Delivery Work Plan

ESM Environmental and Sustainability Manager

IPRP Independent Peer Review Panel

ISCA Infrastructure Sustainability Council of Australia

TSP Total Suspended Particulate

This page intentionally left blank

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

The City Rail Link (CRL) project comprises the construction, operation and maintenance of a 3.4 km underground passenger railway, running between Britomart Station and the North Auckland Rail Line in the vicinity of Mt Eden station.

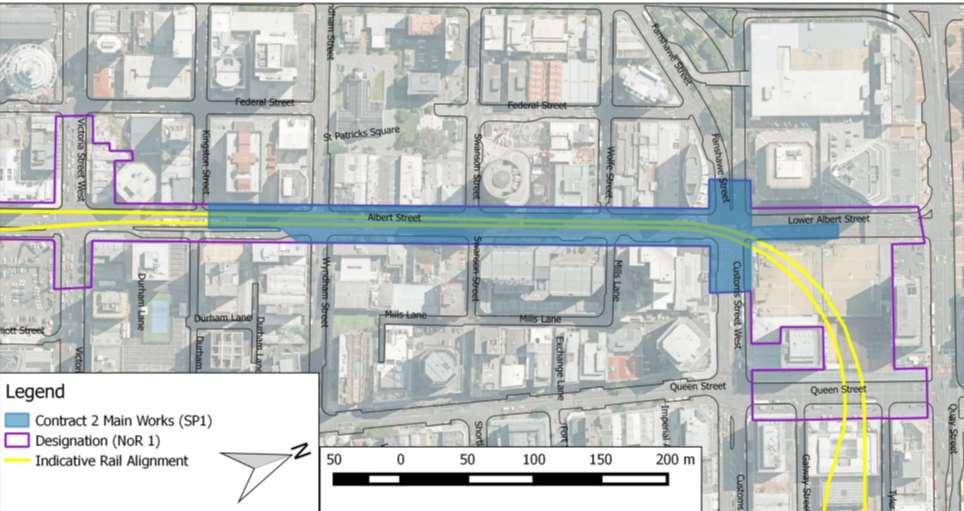

The works relating to this Air Quality Delivery Work Plan (AQ DWP) constitute part of the enabling works for the CRL The works (the Project) involve the construction of twin rail tunnels within the Albert Street road corridor from Customs Street West to Wyndham Street. The tunnels will be constructed using a staged cut and cover method and are expected to take 33 months to complete. Figure 1 outlines the extent of works for the Project.

Project #: 2665

No. CRL-PAT-ENV-CON-PLN-000899

Client: Auckland Transport Revision: 05, Date: 21 March 2016

Project #: 2665

Client: Auckland Transport

No. CRL-PAT-ENV-CON-PLN-000899

Revision: 05, Date: 21 March 2016

This AQ DWP has been prepared by AECOM New Zealand Limited (AECOM) and forms part of the Construction Environmental Management Plan (CEMP) for the Project. The AQ DWP specifically relates to CRL designation condition 59 and resource consent conditions 64-76 (discharge permit R/REG/2014/5437).The requirement to prepare an air quality management plan under both the designation and resource consent conditions is therefore addressed through this single AQ DWP. The AQ DWP is generally consistent with the Draft Air Quality Management Plan prepared by Golder Associates1 as part of the resource consent application for the Britomart to Wyndham section of the CRL project.

The purpose of this AQ DWP is to detail the best practicable options to avoid, remedy, or mitigate the adverse effects of discharges of dust, odour and hazardous air pollutants generated by construction activities for the Project.

Amongst other things, the AQ DWP includes procedures for ensuring that construction and earthworks activities do not result in the following effects beyond the boundary of the Project worksite:

Offensive or objectionable dust or odours; or

Hazardous air pollutants that cause, or are likely to cause, adverse effects on human health, environment or property.

This AQ DWP identifies the following:

Environmental Performance Standards;

Various sources of dust, odour and hazardous air pollutants that may be created during the construction works;

Specific sensitive locations;

Dust mitigation and prevention methods;

Odour mitigation and prevention methods;

Methods to minimise the discharge of hazardous air pollutants;

Monitoring methods; and

Methods for managing complaints regarding discharges into air and keeping compliance records.

The AQ DWP is a living document and will be updated throughout the course of the Project to reflect material changes associated with construction techniques or to the natural environment. A formal review process is described in Section 10 of this AQ DWP.

This AQ DWP has been prepared in consultation with a Community Liaison Group (CLG) and reviewed by Independent Peer Review (IPR) prior to submission to Auckland Council (as per designation conditions 7 and 11, and condition 19 of the resource consent conditions). A record of consultation outcomes (CLG and IPRP) is included in Appendix C.

This AQ DWP has been prepared by Andrew Curtis, an Air Quality Consultant in the air quality team for AECOM. Andrew is a Technical Director with almost 30 years’ experience and specialist knowledge in the field of Air Quality.

1 Golder Associates Auckland City Rail Link – Britomart to Wyndham Draft Air Quality Management Plan 1378206325-028 Rev0

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

Andrew has a combined background, in industry and consultancy roles. His consultancy experience has included project management, atmospheric dispersion modelling, environmental effects assessments (AEE), preparation of air quality management plans, workplace exposure assessments, expert evidence, odour monitoring and atmospheric dispersion modelling.

Table 1 outlines the designation and resource consent conditions relating to air quality and how these are addressed within the AQ DWP.

Table 1 Air Quality conditions from CRL designation and discharge permit R/REG/2014/5437

Designation Conditions

59.1

59.2

59.3

An Air Quality DWP shall be prepared to avoid, remedy or mitigate the adverse effects on air quality during the construction of the City Rail Link or any part of it.

The objective of the Air Quality DWP is to detail the best practicable option to avoid dust and odour nuisance being caused by construction works and to remedy any such effects should they occur.

To achieve the above objective the following shall be included in the Air Quality DWP and implemented as required:

(a) The procedures to be implemented for the continuous monitoring of Total Suspended Particulate (TSP) concentrations and meteorology including, but not limited to, the establishment of two monitoring sites (to the north and south of the site);

(b) Identification of the sensitive locations, and the specific methods for monitoring, including trigger limits to determine whether further action (such as implementation of the mitigation measures discussed below or other mitigation measures) is required;

(c) Procedures for responding to malfunctions with construction machinery or works causing accidental dust discharges including, but not limited to, the requirement to remedy any malfunction within 24 hours;

(d) Procedures for monitoring weather conditions and the requirement that water spray is used on soil stockpiles, any non-paved construction areas, and the wheels of trucks where dust may disperse beyond the site; 5 and 6 3

(e) Procedures for establishing when the covering of trucks will be required; 6.3

(f) Procedures for determining when hard surfaced areas in construction yards and active construction areas should be cleaned including, but not limited to, the requirement that such areas be cleaned whenever dust generation occurs due to traffic on these surfaces;

(g) Procedures for responding to discharges of odour (including in the event of excavation of contaminated sites) including, but not limited to, the requirement to address discharge of objectionable odour by immediately ceasing the activity causing the discharge; 6.4.2

(h) Procedures for equipment inspection (including timeframes for regular inspections), maintenance, monitoring and recording, including baghouses, pressure relief valves and high level alarms to mitigate dust emissions;

Project #: 2665

Client: Auckland Transport

64

66

67

68

69

Revision: 05, Date: 21 March 2016

(i) Procedures for, where practicable, limiting dust and odour nuisance and the methods for monitoring these procedures including Identification of contingency measures to address identified and verified adverse effects on sensitive receptors. Contingency measures may include options such as:

(i) Cleaning of air filtration intakes; or N/A

(ii) Cleaning of other buildings and infrastructure; and N/A

(j) Procedures for responding to any complaints received and the timeframes for response to complaints and reporting; 7

(k) Cross references to the specific sections in the Communication and Consultation Plan which detail how the communities in the vicinity of construction works are to be communicated with on the management of the adverse effects relating to air quality.

70

This resource consent shall expire 15 years after the consent commences unless it has been surrendered or been cancelled at an earlier date pursuant to the RMA.

The Consent Holder shall ensure that all processes on the Project worksite shall be implemented, operated, maintained, supervised, monitored and controlled so that any emissions authorised by this consent are maintained at the minimum practicable level.

Unless provided for by Condition 67, there shall be no dust or odour beyond the boundary of the Project worksite caused as a result of on-site processes which, in the opinion of Council, is noxious, offensive or objectionable.

All offensive or objectionable dust or odours beyond the boundary of the Project worksite caused as a result of construction and earthworks activities associated with the Project shall be mitigated as soon as practicable in accordance with the requirements of the certified Air Quality Management Plan as required by Condition 69.

The Consent Holder shall ensure that beyond the boundary of the Project worksite, there shall be no hazardous air pollutant, caused as a result of construction and earthworks activities associated with the Project that causes, or is likely to cause, adverse effects on human health, environment or property.

The Consent Holder shall review the draft Air Quality Management Plan –Britomart to Wyndham dated December 2014 (“draft AQMP”), prepared by Golder Associates (NZ) Limited and submit to Council (Team Leader Central Monitoring) a final AQMP(s) which is (are) generally consistent with the draft AQMP provided in support of the application material.

The final AQMP(s) shall be prepared by a senior qualified person, provided to the Council (Team Leader Central Monitoring) for certification at least 20 working days prior to the commencement of construction and shall include:

a. a clear identification of the type and location of the controls proposed; 6

b. a detailed framework for the management, mitigation and monitoring of construction and earthworks activities associated with the Project; 5, 6, 8

Project #: 2665

Client: Auckland Transport

c. a focus principally on the sources of dust discharges, and

Revision: 05, Date: 21 March 2016

d. an assessment of the risk of discharges from each Active Construction Zone and the associated Construction Support Areas.

The final AQMP(s) shall also provide detailed methods including, but not limited to, the following matters:

a. methods to ensure the exposed surfaces remain dampened to minimise dust emissions (possible examples include a suspended water spray system or other suitable system, water carts and other suppression methods);

b. a 20 km/hr vehicle speed limit within the Active Construction Zones and Construction Support Areas;

c. installation of wheel washes;

d. regular sweeping of public roads around the exit points of Active Construction Zones and Construction Support Areas and sealed vehicle accessways within these areas;

e. measures for dampening any temporary stock piles (which are to be limited to no more than 24 m³ of spoil at any one time in each Active Construction Zone);

f. measures for the handling of cement associated with forming of cement stabilised columns, including filter systems and high level alarms where a silo is used;

g. covering of loads of material being delivered and removed from the site;

h. instrumental monitoring of dust concentrations (identification of a monitoring methodology, monitoring network and appropriate alert thresholds) to ensure that any significant dust effects arising from the Active Construction Zones or Construction Support Areas are identified and remedied as soon as practicable throughout the Project;

i. the locations of instrumental dust monitoring sites, including one re-locatable monitor to be associated with Active Construction Zones A to D and fixed monitors associated with Active Construction Zone E;

j. measures for responding to continuous instrumental dust monitoring trigger alarms, including contingency measures to reduce measured concentrations below the trigger thresholds and provisions for responding after standard operating hours;

k. measures for undertaking meteorological observations and visual inspections of dust or other air discharges from the Project, to be completed at least on a daily basis, with all relevant information logged; and

l. information regarding complaint logging, investigation and response procedures, training and roles and responsibilities.

72 The Consent Holder shall request the Council’s (Team Leader Central Monitoring) provides its determination as to whether the AQMP(s) can be certified, in writing, within 10 working days of receipt of the AQMP(s).

73

Any change to the AQMP(s) shall be submitted to the Council (Team Leader Central Monitoring) for certification. No activity reliant upon a change to the AQMP can be undertaken until the change has been certified. The Consent Holder shall request the Council’s (Team Leader Central Monitoring) determination as to whether the change can be certified, in writing, within 10 working days of submission of the change. 10

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

74 All works shall be undertaken in accordance with the certified AQMP(s). All

75 Prior to construction commencing, and for the duration of excavation and construction associated with the Project which have the potential for significant dust emissions, the Consent Holder shall install, operate and maintain mobile instrumental continuous dust monitors for the purposes of monitoring Total Suspended Particulates (TSP) and/or fine particulate matter (PM10). The monitors shall be operated at locations and according to methods detailed in the certified AQMP(s) required by Condition 69.

76

The instrumental dust monitoring equipment shall be fitted with an alarm system that, when dust concentrations exceed alert levels specified by the certified AQMP(s), send a warning to the responsible person identified by the AQMP(s). The Consent Holder shall ensure that the responsible person, or other nominated person, is available at all times to take immediate action to reduce dust emissions from the site.

AT is seeking an Infrastructure Sustainability Council of Australia (ISCA) Infrastructure Sustainability (IS) rating for the Project. Full details are included in the Project’s Sustainability Management Plan. Project sustainability requirements that relate directly to the AQ DWP are included in Appendix A.

In preparing this AQ DWP, information has been drawn from practical experience with the management of air quality emissions from large construction processes as well as the following documents:

Draft Air Quality Management Plan prepared by Golder Associates1

The Good Practice Guide for Assessing and Managing the Environmental Effects of Dust Emissions prepared by the Ministry for the Environment; September 2001;

Draft Guide for Assessing Air Quality Effects for State Highway Asset Improvement Project, prepared by the NZ Transport Agency; Version 0.6 September 2012; and

NZ Transport Agency Draft Erosion and Sediment Control Field Guide for Contractors.

Connectus Air Quality Delivery Work Plan

Project #: 2665

Client: Auckland Transport

Doc. No. CRL-PAT-ENV-CON-PLN-000899

Revision: 05, Date: 21 March 2016

This section presents a summary of the Project works that relate to the matters required to be addressed by the AQ DWP. A detailed description of the construction methodology is provided in the Project CEMP.

Connectus will use a cut and cover method to construct two parallel rail tunnels within the Albert Street road corridor between Customs Street and Wyndham Street. The total length of the tunnel for the Project will be 340 m. A number of utilities are required to be removed, relocated, or supported during construction.

Generally, the Project works will consist of:

1. Utilities relocation and exposure

2. Piling and capping beam construction within Albert Street;

3. Piling and road deck construction within the Customs Street Intersection;

4. Trench Excavation;

5. Construction and waterproofing of the rail tunnels; and,

6. Backfill of the trench, including construction of the new road pavement. These activities will be undertaken in the active construction zones (ACZ) as shown in Figure 2

The Project makes use of three of the Construction Support Areas (CSA) identified during the consenting process. These are located at:

Wyndham Street (CSA6)

Lower Albert Street (CSA4)

Customs Street (CSA5)

2.1.1 Utilities relocation and exposure

The location of utility service cables/pipes/ducts (gas, electricity, phone, wastewater, stormwater) (herein collectively referred to as utilities) within the Project footprint have been identified through site inspections and liaison with Network Utility Operators, including Vector Electricity, Vector Gas, Vector Communications, Chorus, Auckland Council and Vodafone. It is not feasible to completely avoid all utilities, although wherever possible piling locations and other construction activities have been

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

selected to avoid conflict with services. This CNV DWP covers only those utility works within the designation footprint and separate provision has been made for utility works required outside of the designation footprint.

Utility relocation works required for Project construction includes works both inside and outside of the trench alignment. All works outside of the trench will be completed prior to excavation works, while the works within the trench will be completed during trench excavation or as the trench is being backfilled on completion of tunnel construction.

Further detail on utilities relocation can be found in the Enabling Works Contract 2 Project CEMP.

Piling is required as the initial stage of construction for the Project. It includes the installation of cased continuous flight auger (CFA) piles and the construction of the pilecap on the western side of Albert Street. Figure 3 shows the location and staging of the piling. The asphalt surface of the road reserve will be removed and the utilities relocated. Piling will then occur, and a Pile-Cap constructed to connect the piles along the western side of Albert Street. Reinforcing will be installed and concrete placed.

Continuous steel traffic decks will be installed along each side of the main trench along Albert Street during the piling and capping stage of construction. The traffic deck along the western side of the trench will extend between Swanson Street and Customs Street, and will be used by general traffic along Albert Street. The traffic deck along the eastern side of the trench will extend between Wyndham Street and Customs Street and will be limited to use by construction traffic only. The eastern deck (construction traffic deck) will provide continuous access into the excavation along the length of the trench and additional construction site set down and plant space to supplement the southern and northern compounds. In addition to the continuous traffic decks, two pedestrian bridges will span the trench, located on the north side of the Wyndham Street and Swanson Street intersections.

Piling and construction of a temporary deck structure at the Customs Street/Albert Street intersection that permits traffic to cross over the tunnel construction underneath will be undertaken. The deck will be constructed in four stages as shown in Figure 4 This will enable traffic to utilise the intersection during construction and avoids closing the intersection completely. Each stage requires pile installation and jet-grouting followed by excavation to approximately 2m depth to allow the construction of the concrete deck. Once all four piling and deck sections are complete, excavation and tunnel construction can commence beneath the live intersection.

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

In addition to supporting the traffic deck, the piles and jet-grout columns hold back the soil during excavation beneath the deck and stop water from entering the excavation site. After tunnel construction the area under the deck will be backfilled, and the deck structure ‘buried’ (i.e. the deck will no longer be a separate deck structure and will be incorporated in the area immediately below the intersection pavement).

Trench excavation will be carried out in layers (starting at the southern end) as shown in Figure 5 with installation of temporary struts and ground anchors as the depth increases.

As excavation progresses, steel waler beams and struts will be installed in combination with ground anchors to support the piled trench walls. In addition, shotcrete and/or rockfall mesh with pins will be applied to the sides of the trench to stabilise the excavation face. Shotcrete will be spray applied, rockfall mesh is installed by driving short pins into the soil and attaching the mesh to the pins.

As the trench becomes deeper, excavators and loaders will be located inside the trench to break material from the natural face of the trench and transport material to stockpiles. On the construction deck above, cranes and excavators will reach down to remove material from the trench to load onto trucks for offsite disposal.

Client: Auckland Transport 21 March 2016

The construction of the rail tunnels will be a rolling process with multiple work faces progressing simultaneously. The tunnel works will start at the southern end of Albert Street when the excavation plant is clear of the base of the tunnel.

Tunnel construction will be broken into 12m lengths, and comprises the following tasks:

Base drainage and blinding.

Waterproofing.

Base foundation and construction.

Wall construction

Roof construction.

Roof waterproofing.

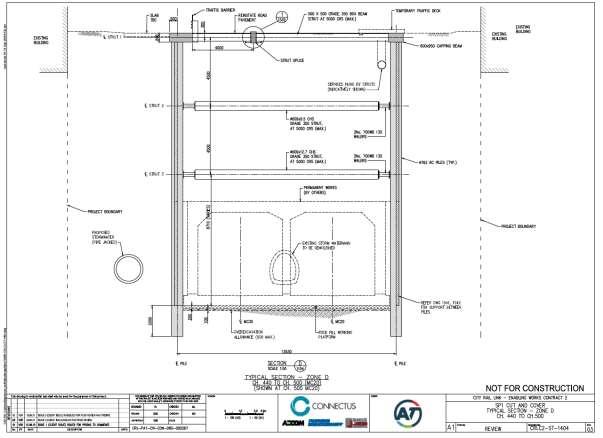

Figure 6 shows a typical cross section for the cut and cover tunnels.

Concrete will be pumped to the works by pump machinery that is initially located at the compound on the southern side of Albert Street. The pump machinery is moved onto the construction deck s the works proceed further north.

Project #: 2665

Client: Auckland Transport

Figure 6 Typical cross section for the Albert Street Cut and Cover Tunnels

Revision: 05, Date: 21 March 2016

As the construction of the tunnels progresses, back filling of the cut and cover excavation in the Custom Street Intersection and Albert Street trench will occur. The trench backfill will be placed on top of the tunnel structure after construction has been completed for a sufficient length (approximately 50 m), including the installation of the waterproofing membrane, and will continue to follow the tunnel construction as it progresses. A layer of concrete blinding (or similar) will be placed over the roof membrane for protection from the trench backfill works. Material will be delivered to site by trucks on the construction deck. Trucks will deposit the fill material onto the floor of the deck structure and it will be collected and tipped into the trench by a loader.

Works to complete new utility routes or reinstate existing utilities will be co-ordinated with the filling operation as it reaches the upper layers. Finally, the construction of the new permanent road pavement will occur in stages after the trench backfill has been completed.

Where required in order to maintain traffic movements, it will be necessary to put down a temporary pavement. Temporary pavements will consist of unbound granular material with a bituminous seal, concrete panels or steel plates on the surface.

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

The main discharge to air arising from the construction activities discussed above is particulate matter (dust). The following dust generating activities from the Project have been identified:

Drilling holes for piles;

Breaking up and excavating existing road surface concrete and asphalt;

Storage of excavated spoil and imported fill (up to 150 m³, if necessary);

Batching grout for jet grouting cement stabilised columns in Customs Street Intersection;

Excavation and spoil removal;

Movement of vehicles in the trench (this includes trucks, loaders and excavators for the trench excavation and spoil removal, as well as trucks that will travel along the trench for the delivery of tunnel construction materials – e.g., concrete and steel);

Backfilling of the trench

In addition, there will also be discharges of combustion related air pollutants from mobile plant and diesel generators. These include oxides of nitrogen (nitric oxide (NO) and nitrogen dioxide (NO2)), carbon monoxide (CO) and volatile organic compounds (VOC).

The location of activities that have the potential to cause air discharges are as follows:

Piling and road surface removal is performed between the Downtown Shopping Centre redevelopment site up to 20m south of Wyndham Street.

Small stockpiles of excavated material will be located in all areas of the project

A larger stockpile of fill material will be located in the CSA just south of Wyndham Street

Jet grouting will be performed in the Customs Street Intersection

Excavation and spoil removal as well as vehicle movement and backfilling will occur along the full length of the Project, from the Downtown Shopping Centre redevelopment site through to 20 m south of Wyndham Street.

As the piles are cased CFA there is limited potential for dust from these activities.

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

The key management roles in relation to environmental management during construction are outlined in the Project CEMP. Specific roles relating to this AQ DWP are detailed in Table 2

Table 2 Environmental management responsibilities Organisation

Requiring Authority, Consent Holder and Project Manager

Overall responsibility for project compliance and performance in relation to environment, quality assurance and incident management.

Obtaining any additional consents required during construction.

Auckland Transport

Connectus

Health & Safety Manager

Project Director

Cut and Cover Tunnel Manager

Environment and Sustainability Manager (ESM)

Key contact for monitoring compliance. Attendance at monthly meetings with Connectus ‘Key contact’ and Auckland Council Consent Monitoring Officers.

Compliance with Health & Safety and incident management.

Overall responsibility for site environmental management.

Review and approve CEMP, including AQ DWP and other sub-plans.

Reviewing and reporting on environmental performance.

Inspection of works to assess compliance with the AQ DWP

Assess the requirement for odour monitoring.

Inspections, auditing and checking of environmental management practices and procedures.

On-site compliance with AQ DWP, consent conditions and other requirements and tracking compliance information.

Report to Auckland Transport changes to construction techniques or natural environmental changes which require alterations to existing consents or new resource consents.

Prepare, review and update of CEMP, including AQ DWP and other sub-plans.

Facilitate and oversee environmental monitoring.

Update and maintain the environmental portion of the Project Risk Register.

Training of all staff including subcontractors.

Key contact for monitoring compliance. Attendance at monthly meetings with Connectus ‘Key contact’ and Auckland Council Consent Monitoring Officers.

Project & Site Engineers

Odour scout

Subcontractors Site Managers

Development, management and monitoring of Construction Execution Procedures (CEPs). Including incorporating environmental and sustainability requirements into the detailed CEPs developed on site.

Overseeing subcontractors.

Undertake odour monitoring as required to assess site odours on the intensity scale set out in Table 6

Record odour monitoring results in Project file.

Adherence to the CEMP and sub-plans.

Connectus Air Quality Delivery Work Plan

Project #: 2665

Client: Auckland Transport

Doc. No. CRL-PAT-ENV-CON-PLN-000899

Revision: 05, Date: 21 March 2016

The key personnel responsible for the AQ DWP are identified in Table 3. However, all site personnel are responsible for following the requirements of the AQ DWP.

Table 3 Key Contacts

Role

Person Responsible for AQ DWP

Alasdair Mawdsley –ESM

Connectus (021) 240 4153

alasdair.mawdsley@mcdgroup.com

Project Director Chris Powell Connectus (021) 596 036 chris.powell@mcdgroup.com

Communication and Consultation Manager

Auckland Council –Team Leader Central Monitoring

Public complaint contact number -

Allan HowardSmith Connectus (021) 361 158 alan.howard-smith@hawkins.co.nz

Fiona Harte Auckland Council (021) 828 369 fiona.harte@aucklandcouncil.govt.nz

Auckland Transport (09) 447 4343 CRLProject@aucklandtransport.govt.nz

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

As required by the designation and resource consent conditions, the intention of this AQ DWP is to ensure that construction air quality effects are kept to a practical minimum and that this recognises the sensitivity of the environment within which the works are being undertaken.

Generally the compliance measure used in construction processes is that dust and other air discharges do not result in “off-site” nuisance, where off-site in this case is defined as being outside of the CRL designation. Due to the proximity of pedestrians, and businesses to the works, all locations outside of the designation are considered sensitive2 to the effects of dust

Because a “dust nuisance” cannot necessarily be identified until it has occurred, there are numerical guidelines that can be used in conjunction with Total Suspended Particulate monitoring to identify levels of dust that are likely to be considered a nuisance. These values, developed by the Ministry for the Environment (MfE), are set out in Table 4, together with additional values to deal with short term emissions that are most likely to result in effects. Table 4 also contains Trigger levels for odour, wind and dust deposition.

Table 4 Environmental Trigger Levels for Air Discharges

Monitoring

Maximum Values not to be exceeded:

80 μg/m³ (24 hour average) – sensitive area Upper Limit

Trigger values for Action

μg/m³ (1 hour average) 60 μg/m³ (24 hour average)

Wind Speed Wind warning level (3 second gust) 10 m/s (measured at 10 m above ground level or equivalent value for other monitoring heights)

Dust Deposition

Odour

Evidence of dust on windows (a finger run down the glass leaves a clear line)

Dirt on clean washing

Presence of odour that is out of character with environment (e.g. smell of refuse in a residential area)

Implement requirements of Section 5.3.3 and any additional mitigation measures identified in Section 6.

Implement requirements of Section 5.3.4 and mitigation measures set out in Section 6.

Implement any required mitigation set out in Section 6.

Implement any monitoring in Section 5.7 and mitigation set out in Section 6.

2 The MfE has defined the sensitivity of different land uses in its Good Practice Guide for Assesing and Managing Odour in New Zealand. These definitions apply equally to the effects of dust, with both high density residential and commercial/retail areas considered to have high sensitivity.

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

The overall approach to dust control is primarily based on visual monitoring in combination with targeted ambient dust monitoring; good management of the construction areas; and a rapid response to any of the triggers outlined in Table 4 and/or to any complaints received. Good practice focusing on pre-emptive measures will aid in the avoidance of significant dust emissions, or if dust emissions occur, the subsequent mitigation or remediation of any adverse effects.

General visual monitoring of all construction areas will be undertaken on a daily basis or potentially more frequently, if conditions change. This type of monitoring relates to the control measures described in Section 6 of this AQ DWP and will include pre-emptive measures to avoid dust emissions. Table 5 below describes the monitoring programme.

Table 5 Visual Dust Monitoring Programme

Monitoring Activity

Check weather forecasts for strong winds and rainfall to plan appropriate work schedule and dust management response.

Inspect construction exits and adjoining roads for the presence of dust deposition.

Observe weather conditions including wind and rain via observations and data outputs from weather stations.

Inspect all exposed surfaces for dampness

Daily

Twice daily

Daily and as conditions change

Daily and as conditions change Inspect stockpiles to ensure enclosure, covering, stabilisation or dampness. Ensure stockpile height is less than 3 m where possible or appropriate.

Inspect dust generating activities to ensure dust emissions are effectively controlled.

Inspect watering systems (sprays and water carts) to ensure equipment is maintained and functioning to effectively dampen exposed areas

Daily and as conditions change

Daily and as new activities are commenced

Weekly

Monitor dust generating activities and water application rate. In winds over 5.5 m/s (11 knots or Beaufort Scale 3)

Check for dust on local roads being used to access the site. Daily Inspect any wheel wash equipment to ensure effective operation. Weekly

5.3.1 Dust

Continuous dust monitoring will be carried out alongside the trench on Albert Street in order to provide real-time information on dust levels that can be used for managing dust events as they occur. This monitoring is to complement the visual inspections described above. As discussed in the Air Quality Assessment (Golder 2014a), the trench along Albert Street is expected to be the main potential source of dust emissions. As required by Condition 75, ambient dust monitoring will commence at least 12

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

weeks prior to excavation of the trench, to provide background data against project monitoring can be compared. The early start will ensure that there is sufficient time to revise the trigger levels in the event that the initial values are too low, i.e. they are being exceeded by existing activities such as traffic emissions.

Instrumental monitoring for the Project will include:

Continuous instrumental TSP monitoring at two fixed locations (refer Figure 8)

Three mobile dust monitors which can be used at any location along the excavation works;

Calculation of 1 hour and 24 hour average concentrations from real-time monitoring data;

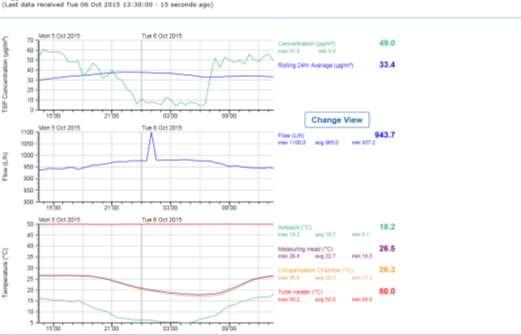

Remote display of real-time TSP and meteorological data (e.g. via the internet using a Harvest system (www.harvest.com) or similar (Figure 7);

Figure 7 Example of remote display of real-time TSP and meteorological data

Provision for alarms on 24-hour and 1-hour average concentrations and wind measurements (visual and/or via internet, email and mobile phone);

Recording/logging of monitoring data; and

Where practicable the monitors will be located in accordance with AS/NZ 3580.1.1:2007 Method for Sampling and Analysis of Ambient Air – Guide to Siting Air Monitoring Equipment; and AS 3580.14 -2011 Ambient Air – Guide for the Measurement of Horizontal Wind for Air Quality Applications, as far as is practicable.

Examples of continuous TSP monitors that could be employed include:

Continuous particulate monitoring in accordance with United States Code of Federal Regulations, Title 40-Protection of Environment, Volume 2, Part 50, Appendix O-R Reference Method for the Determination of Coarse Particulate Matter as PM in the Atmosphere (e.g. Beta- Attenuation Monitor); and,

Optical analysis methods with gravimetric calibration (e.g. E-Sampler).

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

A meteorological station which can continuously measure the following parameters will be installed at one location (to be determined) on Albert Street:

wind direction;

wind speed;

rainfall; and

temperature

The monitoring equipment will be set up with text alerts to key personnel in the relevant work zone, when dust concentrations exceed the Trigger values set out in Table 4. At a minimum this will include:

The Project Manager;

The ESM;

The Construction Manager; and

Site Manager.

If personnel change then the Instrument Technician will be contacted to update the alerts.

If a dust trigger alert is sent, one of the above staff members should immediately (within 30 minutes) respond and investigate the cause of the alert. This investigation should: determine if the alert is real and not caused by equipment malfunction, identify the source of dust and check to see that all of the required mitigation measures are being implemented. If it is determined that construction activities are the cause of dust and that mitigation measures are not effective at controlling dust, the contractor should implement the Dust Contingency Measure outlined in section 6.8 of this DWP. If these measures fail to effectively manage dust to acceptable levels, works should be halted until it can be determined why dust emissions are occurring and what additional mitigation measures are required to control ambient dust to acceptable levels. The findings of the investigation should be recorded in the Air Quality Diary

In the event that wind speeds exceed the trigger values set out in Tables 4 and 5, then there will be text alerts to key personnel in the relevant work zone, at a minimum this will include:

The Project Manager;

The ESM;

The Construction Manager; and

Site Manager.

If wind speeds exceed 5.5 m/s then the Site Manger will designate a person to undertake visual monitoring of the work area, and ensure that all appropriate mitigation is being implemented. If wind speeds exceed 10 m/s, all work that could give rise to dust will cease, unless the TSP monitoring demonstrates that TSP trigger levels are not being exceeded.

Indicative monitoring locations for the two fixed monitors are shown in Figure 8 below A total of up to five (5) portable and continuous Total Suspended Particulate (TSP) monitors will be deployed. The

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

exact location of the two fixed monitors will be determined once work plans are finalised. The mobile monitors will be deployed along Albert Street as the works progress

The exact locations will be determined taking into consideration the following:

Prevailing winds.

Location of most sensitive neighbours located closest to the site, where a high or medium risk of dust impact has previously been determined.

The location of construction activities with potential for dust emissions occurring on the site.

The objective in siting the monitors is to ensure they are located close to sensitive off-site neighbours and adjacent to construction activities (e.g. trench excavation) as they occur – most likely along the top of the traffic barrier fence that runs along the edge of the trench. This will allow the monitoring to pick up on high dust levels as they occur and allow a response to reduce the dust before it becomes a nuisance for neighbours.

Figure 8 Approximate location of the fixed continuous dust monitors (green circles)

All monitoring data from the dust monitors and the onsite weather stations will be available to project staff on-line.

The TSP monitoring equipment and meteorological equipment will require periodic maintenance. The monthly maintenance of the equipment will be carried out by either site personnel, who have received appropriate training, or an Instrument Technician.

Quarterly maintenance and calibration will be carried out by an Instrument Technician familiar with the equipment installed.

In the event that there is an equipment malfunction, or the equipment needs to be relocated for some reason, then the Instrument Technician will attend to this

Odour monitoring will be undertaken when it is considered likely that odorous material will be encountered (such as the excavation of contaminated materials), during excavations. This decision to undertake monitoring will be made by the Cut and Cover Tunnel Manager.

The frequency of monitoring will be dependent on the nature / scale of the source, location in relation to sensitive receptors, and meteorological conditions during exposure. Odour scouting will occur:

When potentially contaminated material is excavated and loaded onto heavy vehicles; and

Project #: 2665

Client: Auckland Transport

When odour complaints have been received.

Revision: 05, Date: 21 March 2016

The ESM will ensure that at least one person in each work area is trained as an odour scout.

This monitoring will involve the odour scout being downwind of the works and assessing odours on the intensity scale set out in Table 6. Where odours are identified as being “Distinct” and above, and the odour characteristic unpleasant, mitigation measures will be implemented (refer Section 6.6 of this plan). All observations are to be recorded in the daily Air Quality Diary (refer Section 9.1 of this Plan)

Table 6 Odour Intensity Scale

The odour scout will reassess the level of odour once the mitigation measures have been implemented. If the odours are still ‘Distinct’, further mitigation will be implemented, and / or the works halted until more conducive meteorological conditions are present, i.e. not blowing towards the sensitive receptor.

If it is suspected that sources upwind of the works are responsible for any odour then the odour scout will make appropriate observations and document this also.

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

There are a range of routine measures that will be used on the site to manage and mitigate the effects of discharges of dust, odour or construction vehicle exhaust emissions. Additional mitigation may also be required in the event that:

Monitoring indicates that abnormal discharges of dust are occurring;

Weather conditions are changing such that dust or odour discharges are more likely as determined using the Dust Risk Index; and / or

Complaints are received regarding discharges of dust, odour or construction vehicle exhaust emissions.

All processes on the Project worksite will be implemented, operated, maintained, supervised, monitored and controlled so that any emissions authorised by the resource consent are maintained at the minimum practicable level. If the available mitigation methods are unsuccessful in controlling discharges (i.e. dust and odour) that cause significant adverse effects on receptors beyond the Project boundary, then activities causing the discharge will be suspended until adequate mitigation can be put in place.

Dust control methods are generally associated with either reducing the potential for dust generation and transport associated with the activity factors described in Section 2 of this AQ DWP that may reduce dust generation and transport potential.

General measures that will be employed to control dust from construction activities include:

Controlling dust from stockpiles: utilising windbreaks around stockpiles;

Controlling dust from exposed surfaces: Placing limits on vehicle speeds;

Limiting disturbance of soil or dusty materials: Reduction in vehicle movements and speeds and the use of lighter vehicles will also reduce disturbance and dust generation;

Limiting area of exposed materials: Staging of works and minimisation of material exposure in works areas will reduce the potential for wind erosion;

Temporary stabilisation of unpaved roading surfaces or yard areas through the use of dust suppressants can also provide an alternative to wet suppression as a dust control method;

Maintenance of surface moisture content: Watering or wet suppression is used to dampen dry or dusty exposed areas; and,

Removing excavated spoil from site on a regular basis

One of the main potential air quality impacts comes from dust associated with the construction process. To provide better guidance to the Cut and Cover Tunnel Manager, and area supervisors on the implementation of dust mitigation, this project will use a Dust Risk Index (DRI). The DRI process is described in Appendix B.

A simple “traffic light” indication of dust risk will be posted in each work area, so that both Connectus staff and members of the public are aware of the dust risk.

Project #: 2665

Client: Auckland Transport

This system will indicate that dust risk on a particular day is:

Low (Green Light)

Moderate (Orange Light)

High or Extreme (Red Light)

Revision: 05, Date: 21 March 2016

The dust prevention methods recommended in Table 7 are methods that have been found to be effective for many sites across New Zealand. These methods can be used alone or in combination depending on the circumstances. Alternate methods may be employed after the effectiveness of those methods is demonstrated and this AQ DWP updated accordingly. The scale of dust prevention methods required in a particular area will be dependent on the degree of risk that the dust would cause adverse effects on the surrounding area. The dust control methods for the various degrees of risk are described below. Effects of dust on affected parties in proximity to the Project are further mitigated through Sections 4.2 and 5.6 of the Project Social Impact and Business Disruption Delivery Work Plan (Appendix D of the Project CEMP).

6.3.1

The dust prevention methods outlined in Table 7 will be used, as applicable, in all areas of the Project. The list is not exhaustive and additional methods may be found to be effective. Table 7 Dust management measures for all areas (low Risk)

Stockpiles

Unpaved Surfaces such as Roads and Yards

Limit the height and slope of stockpiles to reduce wind entrainment. Stockpiles exceeding 3 m in height have a higher risk of discharging dust;

Ensure that stockpiles do not exceed 24 m3 in size;

Orientate stockpiles away from intersections where possible in order to maximise wind sheltering as much as possible;

Maximise shelter from winds as far as practicable;

Keep active stockpiles damp at all times or bunker or cover stockpiles of fine materials;

Dampen inactive stockpiles if they are producing visible dust emissions

Limit the amount of exposed surfaces as much as possible;

Keep exposed surfaces damp. Typical water requirements for most parts of New Zealand are up to 1 litre per square metre per hour;

Cover surfaces with coarse materials where practicable (e.g. ballast);

Stabilise cleared areas not required for construction, access or for parking if liable to cause excessive dust during windy conditions. Methods may include placing metal on surfaces.

Sealed surfaces

Cement Handling

Vehicles

Regular removal of dust through washing or vacuum sweeping – the frequency determined by visual inspection;

Clear all spillages on sealed surfaces as soon as practicable.

Ensure that any cement silos have appropriate dust treatment and that this equipment is maintained appropriately.

Limit vehicle speeds to 20 km/h;

Limit load sizes to avoid spillages;

Cover loads of fine materials;

Minimise travel distances through appropriate site layout and design;

Project #: 2665

Client: Auckland Transport

Piling

Ground stabilisation

Miscellaneous

Earthmoving and Construction

6.3.2

Revision: 05, Date: 21 March 2016

Minimise mud and dust track out from unsealed areas to sealed areas by using wheel cleaning facilities at site exits to sealed roads.

Remove drill spoil regularly from site;

Use CFA casing to minimise dust;

Add water to drill spoil if it appears dry and is generating excessive dust

Control grout batching to minimise cement dust

Ensure sufficient water is available on site;

Take account of daily weather forecast wind speed, wind direction and spoil conditions before commencing an operation that has a high wind potential;

Install hoardings sooner rather than later to assist by acting as wind breaks;

Minimise the area of surfaces covered with fine materials.

During periods of extreme dust risk, dampen areas that are to be earthworked prior to any earthwork commencing. Allow time for penetration of the soil;

Employ additional measures where dropping material from height, such as the use of watersprays;

Stabilise exposed areas not required for construction, access or parking, along with completed fill and spoil areas as soon as practicable.

Moderate risk conditions require a greater level of dust control and attention to dust suppression. The methods outlined in Table 8 will be implemented in addition to the methods outlined in Table 7 during conditions presenting a medium risk

As above this list is not exhaustive and other methods may also be employed to control dust.

Vehicle Movements on unsealed surfaces

Loading, unloading and transport of dusty materials

Stockpiling

Further limit vehicle speeds on unsealed surfaces;

If wind speeds at the level of the unsealed surface are predicted in excess of 8 m/s (16 knots or Beaufort Scale factor 5), maintain unsealed surfaces in regular use in damp condition through surface watering (e.g. with water carts or fixed irrigation);

Where a suitable water supply is not available for surface watering, synthetic dust suppressants may be used as an alternative. The use of recycled oil-based suppressants is expressly prohibited.

Limit loading or unloading during windy conditions that cause dust to be emitted beyond the site boundary;

Limit vehicle speeds on unsealed surfaces.

Bunker or cover stockpiles of fine, dry materials.

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

6.3.3 Further Methods of Dust Control – High and Extreme Risk Conditions

The greatest attention to dust control will be paid in extreme risk conditions and this is reflected in the further control measures outlined in Table 9. These methods should be employed in addition to the measures outlined in Table 7 and Table 8 during high and extreme risk conditions

As above this list is not exhaustive and other methods may also be employed to control dust.

Table 9 Potential dust sources and control methods for high and extreme risk areas

Source of Dust Controls (in addition to Low and Moderate Risk Controls)

Vehicle Movements on unsealed surfaces

Earthmoving, excavation and construction

Stockpiling

Maintain regularly used unsealed road surfaces in damp condition through surface watering in all wind conditions.

Maintain surfaces of active earthworks areas in damp condition. This should include pre-watering of earthworks surfaces, prior to excavation allowing enough time for moisture to penetrate the soil;

Maintain active stockpiles in damp condition with regular watering;

Dampen inactive stockpiles if they are producing visible dust emissions;

Utilise windbreak fences or temporary bunkers if they are producing visible dust.

6.3.4

A grouting plant may be set up on the site to facilitate jet grouting, as outlined in the Project CEMP. This plant will have cement silos which are a component of the grouting process. Cement silos will be fitted with dust control, primarily to deal with silo filling operations, but also any transfer of cement to the mixing unit. Information on dust control equipment will be updated in Appendix D once a supplier is selected. This information will include the following:

Procedures for equipment inspection (including timeframes for regular inspections), maintenance, monitoring and recording, including baghouses, pressure relief valves and high level alarms to mitigate dust emissions

6.3.5 Equipment Malfunction

If construction equipment fails and causes accidental dust discharges, it will be shut-down immediately and the fault repaired and tested prior to being allowed to continue operation.

If equipment associated with dust control fails (such as a cement silo baghouse) the activities reliant on the equipment will be suspended until the fault can be repaired.

The location, duration and time of any dust discharge caused by equipment failure will be recorded in the environmental dairy.

When site operators are alerted to a potential off-site dust nuisance through any of the monitoring techniques described in Section 6 of this AQ DWP, or as a result of a complaint from a third party, the Site Supervisor will immediately undertake a review of site activities to determine the source of the dust and implement such further mitigation as may be required in order to reduce the dust generation to acceptable levels. As appropriate the Site Manager will notify the Environment Manager.

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

In general, the additional mitigation will be those measures set out in Tables 7-9

Once the additional mitigation has been implemented the Site Manager will review the monitoring data to ensure that it has been effective.

The following are locations where information necessary for determining the DRI and general dust control can be obtained:

Site specific monitoring web site where TSP and meteorological data can be accessed (to be established); and,

Met Service: http://www.metservice.com/towns-cities/auckland/auckland-central

While no areas have been identified that are expected to contain contaminated material, the Contamination DWP (Appendix G of the Project CEMP) sets out in detail how contaminated material will be dealt with should it be discovered. Set out below is further clarification on the specific mitigation measures that can be used to minimise the potential for any effects associated with discharges to air from contaminated material

In general it is considered that the dust generation, monitoring and control procedures described above are also suitable for use during the excavation, handling and transportation of any contaminated soils encountered during the works. Because of the increased potential for effects associated with dust from contaminated material, it is assumed that there is an extreme dust risk associated with these works, and all appropriate mitigation measures will be implemented to minimise effects. Dependent on the location and the size of the excavation and nature of the contaminant this may include:

Pre-wetting the area to eliminate the potential for dust generation, while taking care not to overwater and cause contaminated run-off;

Where practical, directly loading contaminated soils into trucks for transport to off-site disposal locations, and ensuring that all trucks are covered;

If stockpiling is necessary, ensuring they are damped or otherwise covered, particularly in dry windy weather conditions; and

Carrying out ambient dust monitoring to assess the effectiveness of the control measures.

Discharges of odour are most likely to occur from any contaminated material encountered during the project works. Odour emissions are to be monitored by the odour scout during the excavation of such material and the following techniques utilised if necessary:

Limiting the time that the odorous material in the excavation is exposed;

Removing excavated odorous material from site as quickly as possible in covered trucks; and

The use of odour masking agents, chemical counteractants or digestive deodorant sprays. If significant odour is detected and the odorous material cannot be removed quickly, and odour masking agents, chemical counteractants or digestive deodorant sprays are not immediately available, the odorous material will be covered, and work in that area suspended until suitable mitigation measures can be put in place.

Section 5.7 sets out the odour monitoring procedure.

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

Effects of odour on affected parties in proximity to the Project are further mitigated through sections 4.2 and 5.6 of the Project Social Impact and Business Disruption Delivery Work Plan.

Further to operational controls mentioned in Section 6.3 , the following key actions will be carried out to minimise emissions from vehicle exhausts:

All construction machinery used on the site will be maintained in accordance with manufacturers’ requirements;

Where excessive exhaust smoke is identified from any construction vehicle that vehicle will be serviced as soon as is practicable and taken out of use until such maintenance has been completed; and

Unless warm-up or turbo maintenance procedures require it, construction vehicles will not be left idling while parked or unattended.

In the event that there is a significant dust emission that results in either complaints or concentrations of dust that are significantly greater than the trigger values set out in Table 4, Connectus will undertake contingency measures as follows, dependent on the nature of the complaint. These measures would be undertaken as a last resort if the source of the dust cannot be eliminated, in order to prevent build up.

1. Dust inside buildings or at a level which prevents windows being opened

Following discussions with the building owner and/or occupiers, arrange to fit or retrofit dust filters to any building/apartment air supply systems. Where a building or specific apartment does not have an existing air supply system, then such a system will be installed, and all reasonable costs associated with the installation, operational and maintenance costs while the project is occurring.

2. Dust on the outside of buildings

Arrange for the exterior of the building to be cleaned.

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

Communication and consultation with affected parties and the wider community in vicinity of the Project will be regular and ongoing. Methods to facilitate communication will be through the Community Liaison Group (CLG), which will meet at least every three months during the construction of the Project, and through the methods discussed in Section 6 of the Communication and Consultation Plan (Appendix O of the Project CEMP). These measures include engagement tools such as publications, phone calls, use of the CRL website to provide updates, signage, and advertising material. One on one engagement may also be used for affected parties.

Although the measures described in this AQ DWP are aimed at avoiding complaints regarding discharges to air, complaints may in practice be made on occasion by members of the public. It is important to ensure that any complaints are recorded and promptly investigated to identify and resolve the cause of the complaint. The requirements and procedures relating to complaints are detailed within the Project Communication and Consultation Plan.

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

To achieve an effective AQ DWP and to ensure off site air quality impacts comply with designation and resource consent requirements, all Project staff (contractors and subcontractors) will undergo general environmental awareness training and training about their responsibilities relating to the activities under this AQ DWP Training requirements are described in full detail within the CEMP. Specific training requirements relating to this AQ DWP are outlined in Table 10.

Table 10 Specific Training requirements in relation to AQ DWP

Introduction to the on-site monitoring equipment

Responding to continuous dust monitoring trigger alarm alerts

Responding to complaints regarding dust and air quality concerns

As required & during new staff induction All new staff members

As required & during new staff induction Site manager, delegated staff member and duty managers

As required & during new staff induction Site manager, delegated staff member and duty managers

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

Construction activities can be affected by a number of different external and internal factors, such as weather conditions or equipment malfunction, which can contribute to an increase of dust emissions. Various control and mitigation measures are to be carried out on the site in order to prevent such effects, and monitoring and inspection procedures will be used to assess the level of dust emissions both on the Project site and beyond its boundary. Recording relevant monitoring and inspection results, as well as the conditions of external and internal factors, can help to assess if control measures are being effective and to define appropriate corrective or preventive actions in case any undesirable effects are detected.

The procedures for recording a daily Air Quality Diary are detailed below:

The site manager will fill out the daily diary each day and maintain the record on site.

The following information will be recorded in the daily diary:

o Records of TSP monitoring exceedances of the trigger levels specified by this AQ DWP, including identification of the monitor ID which registered the exceedance, the time and the averaging period of the TSP exceedance (e.g., 1-hour or 15-minute average concentration);

o Any dust control equipment malfunctions and any remedial action(s) taken;

o Results of the Visual Inspections of dust emissions;

o General weather conditions during the day (i.e., windy, calm, warm, rain, etc.);

o The frequency of watercart and/or water sprinkling system use; and,

o The date and signature of the person entering the information.

A copy of the daily Air Quality Diary will be kept in the Project filing system.

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

This AQ DWP will be updated throughout the course of the Project as required to reflect material changes associated with a new or changed activity, equipment or location of activities.

Approval from AC will be required for any relevant revisions of a material nature to the AQ DWP No activity reliant upon a change to the AQ DWP can be undertaken until the change has been certified

A review of the CEMP (including this AQ DWP) will be undertaken annually by the Project Management team. The management review process is detailed within section 5.7 of the Project CEMP and will be organised by the ESM.

Project #: 2665 Doc. No. CRL-PAT-ENV-CON-PLN-000899

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

AT and Connectus are seeking an Infrastructure Sustainability Council of Australia (ISCA) Infrastructure Sustainability (IS) Rating for the CRL Enabling Works. This appendix details IS requirements that are different, or additional to the Project’s Consent Requirements. It is essential that these requirements are met to achieve the Project’s sustainability goals; however they are not consent requirements to be certified by Auckland Council. These IS rating requirements are included as an appendix because they are not yet fixed. They remain subject to change as the Project’s sustainability program evolves.

Applicable ISCA requirements that relate to this AQ DWP are listed below along with their associated target Levels.

Measures to minimise adverse impacts to local air quality during construction have been identified and implemented.

AND

Monitoring of air emission and / or air quality is undertaken at appropriate intervals and in response to complaints during construction.

AND Monitoring and modelling demonstrates no recurring or major exceedances of air emission or air quality goals.

Section 6

Section 5

The weekly site inspection checklist will be amended to require inspection staff to proactively inspect surfaces (window sills etc.) adjacent to the work sites for evidence of dust build up.

Section 5

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

One of the main potential air quality impacts comes from dust associated with the construction process The foregoing discussion sets out some of the mitigation measures that can be used to control this. However there are work activities and locations where the need for dust mitigation is minimal and others where it is extremely important. To provide better guidance to the Construction Manager, and area supervisors on the implementation of dust mitigation, this project may use, when deemed necessary by the Connectus Environmental Manager, a Dust Risk Index (DRI). This is a technique recently developed for the construction phase of the Cambridge Expressway and Transmission Gully. The full NZTA version is detailed below at present. Connectus may develop a simplified, project specific version going forward.

The objectives of using the DRI are to highlight those areas and activities that are of higher risk of generating dust issues by:

A systematic and consistent approach to risk identification in relation to dust generation;

A simplification of decision making in relation to the application of dust mitigation techniques and procedures; and

Improved Stakeholder satisfaction and a reduction of dust related complaints from them.

The DRI uses a simple approach to generate a number that identifies the risk of dust generation and potential issues. The greater the number, the higher the likelihood of dust related issues. The formula involves combining a number of factors together in the following ways:

DRI = Sum(E+S+M+WS+D+A)*R*WD

Where:

E = Surface exposure.

S = Stabilisation.

R = Rainfall.

M = Month of the Year.

WS = Wind Speed.

WD = Wind Direction

D = Distance to nearest receiver.

A = Construction Activity.

10.1.2

This factor recognises that where material has been removed from the surface of the ground that dust is more likely to be generated than if the original surface is still in place. As such a value of 0 is used where the surface remains untouched and a value of 10 is used where the surface has been exposed and the vegetation removed, and a value of 50 is used when the exposed surface has been significantly disturbed.

Project #: 2665

Client: Auckland Transport

10.1.3

Revision: 05, Date: 21 March 2016

This factor recognises that surfaces that have been exposed, in the manner referred to above and then subsequently stabilised are less likely to generate dust.

Stabilisation measures associated with this project include:

Water;

Chemical dust suppressant; and,

Aggregate covers such as Gap TNZ40, Gap 65, Drainage 200.

As such a value of 0 is used where the surface is fully stabilised in a manner described above, 5 when there is some degree of stabilisation and a value of 10 when no form of stabilisation has been used.

10.1.4

This factor recognises that dust issues are neutralised by the presence of sufficient rainfall, or the receipt of sufficient rainfall within the previous 24-48 hours. As such a value of 0 has been assigned where it is currently raining and 1 where 5 mm or more of rainfall has been received in the previous 24 hours. A value of 1.5 has been assigned where 5 mm or more of rainfall has been received in the previous 48 hours. A value of 2 is assigned when it has not rained for more than 2 days.

10.1.5

This factor recognises that certain periods of the year are more likely to be periods of higher risk due to low soil moisture levels or higher wind speeds. As such the winter and spring months of June to September are assigned a value of 0; a value of 5 is used for April, May, October and November; and a value of 10 for the months of December to March.

10.1.6

Wind speed is recognised as a significant factor. Increases in dust issues coincide with an increase in wind speed. The following weightings have been applied to the wind speed groupings:

0-9 km/h 0

10-18 km/h 10

19-27 km/h 50

28-36 km/h 200

Greater than 36 km/h 500

10.1.7

This factor recognises that the degree to which a stakeholder or sensitive receiver adjacent the Project is effected by dust is strongly influenced by the direction of the wind in relation to their position. Where the wind direction is such that the receiver is downwind of the works then a value of 1 has been assigned to the factor. However where the wind is blowing away from the sensitive receiver then the value assigned is 0. Given the narrow nature of the Project alignment it is accepted that a value of 0 is highly unlikely for most areas due to the close proximity of sensitive receptors.

Project #: 2665

Client: Auckland Transport

10.1.8

Revision: 05, Date: 21 March 2016

Closely related to the direction and speed of wind, as determining factors for dust issues, it is recognised that the distance to the nearest sensitive receiver also contributes to the risk involved. As such a value of 100 has been assigned to this factor.

The final factor recognises that certain construction activities are more or less likely to contribute to dust related issues. As such the following groups of construction activities have been assigned differing values. Where there are other activities occurring, choose the most similar activity or contact the Environment Manager for guidance.

10.1.10

Once the DRI has been calculated for a particular location it needs to be assigned to a risk value using Table 11

Table 11 Conversion Values for DRI to Dust Risk

10.1.11

At the beginning of each week on a Monday morning a DRI forecast will be carried out in order to assist with planning of dust management mitigation measures for that week. The forecast will identify the likely DRI for each day Monday through Saturday. The forecast will then be disseminated to the construction teams and staff responsible for dust mitigation such as supervisors and water cart drivers. The information will allow a more focussed and proactive approach to dust control and mitigation.

At the conclusion of each month, as part of the monthly environmental reporting the Environment Manager will review the performance the Project in terms of dust management. As part of this review, the effectiveness of the DRI will be assessed and any amendments to the DRI advised and commented on.

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

One means of communicating the DRI to construction staff is via a warning board similar to that used to convey fire danger in rural areas. Therefore each work area will have a board in a prominent location such as beside the site office or canteen where the current DRI value is displayed.

Project #: 2665

Client: Auckland Transport

Revision: 05, Date: 21 March 2016

Project #: 2665

Transport Revision: 05, Date: 21 March 2016

7 27/10/2015 1730-1900 CLG Meeting Ross Will the data collected by dust monitoring equipment be made available to the public?

8 27/10/2015

A summary of dust monitoring data can be made public via the project communications team at their discretion at intervals deemed appropriate (for instance, a monthly summary).

No change is proposed to the AQ

Would it be worth putting the dust monitoring equipment in place early so people can compare the pre-construction data with during construction data. Noted

9 27/10/2015 Will the project provide the calculated dust risk index to the public.

The dust risk index calculation is intended as a tool to inform construction staff of the risk of dust emissions if appropriate mitigation measure are not put in place. It does not reflect the risk of discharge of dust from the site. It is conceivable that providing the dust risk figure to the public, who are by and large unfamiliar with the process for calculating the figure and its implications, may cause the public to take unnecessary action to protect themselves or result in undue stress and concern.

No change is proposed to the AQ DWP

Project #: 2665

Client: Auckland Transport

Peer Reviewer: Carol McSweeney (Air Matters Ltd)

Date: 29th January 2016

59.1 An Air Quality DWP shall be prepared to avoid, remedy or mitigate the adverse effects on air quality during the construction of the City Rail Link or any part of it.

59.2 The objective of the Air Quality DWP is to detail the best practicable option to avoid dust and odour nuisance being caused by construction works and to remedy any such effects should they occur.

59.3 To achieve the above objective the following shall be included in the Air Quality DWP and implemented as required:

(a) The procedures to be implemented for the continuous monitoring of Total Suspended Particulate (TSP) concentrations and meteorology including, but not limited to, the establishment of two monitoring sites (to the north and south of the site);

(b) Identification of the sensitive locations, and the specific methods for monitoring, including trigger limits to determine whether further action (such as implementation of the mitigation measures discussed below or other mitigation measures) is required;

Consider including provision for monitoring of TSP before construction occurs as per Comment 8 of the CLG meeting.

Sensitive receptors not identified

Table 4: Trigger levels. It would be useful to see on this table what action these trigger levels activate. Relate to condition b) more directly

Revision: 05, Date: 21 March 2016

Noted. No change to monitoring programme proposed at this time.

Text clarified to indicate that all locations adjacent to designation considered sensitive to potential dust effects.

Table 4 has been updated to clarify the trigger actions.

(c) Procedures for responding to malfunctions with construction machinery or works causing accidental dust discharges including, but not limited to, the requirement to remedy any malfunction within 24 hours;

(d) Procedures for monitoring weather conditions and the requirement that water spray is used on soil stockpiles, any non-

Text clarified to explain the difference purposes associated

Project #: 2665

Client: Auckland Transport

paved construction areas, and the wheels of trucks where dust may disperse beyond the site;

5.2 (Table 5)

(e) Procedures for establishing when the covering of trucks will be required;

Table 7

(f) Procedures for determining when hard surfaced areas in construction yards and active construction areas should be cleaned including, but not limited to, the requirement that such areas be cleaned whenever dust generation occurs due to traffic on these surfaces;

(g) Procedures for responding to discharges of odour (including in the event of excavation of contaminated sites) including, but not limited to, the requirement to address discharge of objectionable odour by immediately ceasing the activity causing the discharge;

(h) Procedures for equipment inspection (including timeframes for regular inspections), maintenance, monitoring and recording,

Doc. No. CRL-PAT-ENV-CON-PLN-000899

Revision: 05, Date: 21 March 2016

with the two trigger values.

Table 5 (item 8) discusses wind speed and water application. This is not consistent with the wind speed “trigger level” in Table 4. As the wind speed for water application in Table 5 is lower than the trigger level in Table 4. It is recommended that the lower level is used as the trigger.

The procedure in Table 7 requires covering of all loads of fine materials. There is no procedure for other situations.

There was a requirement for covering contaminated loads (Section 6.5 and section 6.6 has be modified to make it explicit that odorous loads must also be covered).

Given the wet nature of the material being removed it is not considered that there are other reasons why loads need to be covered.

Table 7 Nil n/a