Mt Eden Main Works

Air Quality Delivery Work Plan

CRL-MTE-RME-LKA-PLN-800039

Revision: 001

Date: 29 June 2020

Air Quality Delivery Work Plan

CRL-MTE-RME-LKA-PLN-800039

Revision: 001

Date: 29 June 2020

CRL-MTE-RME-LKA-PLN-800039

This document is uncontrolled when printed. This document should be printed in colour

Revision Status

Rev 001 29 June 2020 Final for submission

Approval Status

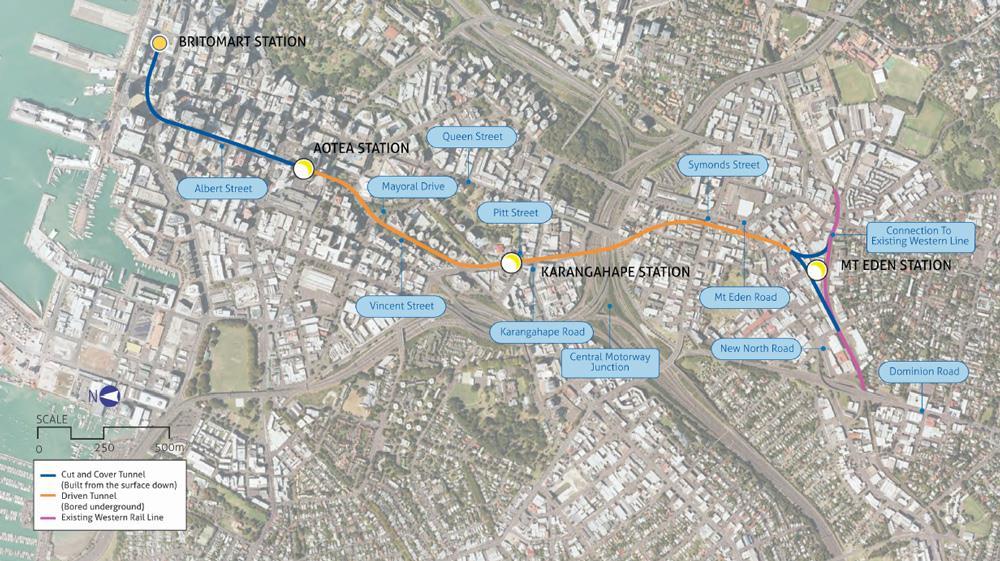

The City Rail Link (CRL) project comprises the construction, operation and maintenance of a 3.4 km underground passenger railway, running between Britomart Station and the North Auckland Rail Line (NAL) in the vicinity of Mt Eden Station. The CRL also involves the construction of two new underground stations at Aotea and Karangahape, and a redeveloped Mt Eden Station (refer to Figure 1-1). The design and construction of the CRL infrastructure between Aotea and Mt Eden Stations is being delivered by the Link Alliance.

This Air Quality Delivery Work Plan (AQ DWP) has been prepared in relation to the Mt Eden Main Works (“main works”).

CRL works in the Mt Eden area involve the construction of the southern section of the tunnel structures and the tie-in of the CRL railway to the existing NAL, including the construction of the redeveloped Mt Eden Station. The Mt Eden Active Construction Zone (ACZ) and Construction Support Areas (CSAs) is generally located between Nikau Street to the north, State Highway 1 (SH1) to the east, Dominion Road to the west and the existing NAL to the south.

The works in this area include:

Operational activity required to support the tunnel boring machine (TBM) drive, including control room and plant, storage and spoil handling;

Construction of a new Mt Eden Station building, incorporating passenger linkages between the new CRL platform and the modified existing NAL platform; Road over rail bridges at Mt Eden Road, Normanby Road and Ruru Street with sections of road realignment;

Grade separation structures for the existing and new rail lines to pass-over and connect with each other, including the Newton Junction Grade Separation Structure, the Eastern Facing Connection and the Western Facing Connection; Construction of a portal vent house building structure; Installation of retaining walls and utilities; Pedestrian and cyclist bridge structures at Fenton Street and Porters Avenue; and New road linkages within the reinstated area post-construction.

Given the nature and scale of CRL construction works in Mt Eden, works are being undertaken in a staged manner, involving:

Enabling and early works (demolition, network utility relocation and site establishment work) – early works have commenced and will continue to end of 2020; Main construction works (construction of the underground CRL cut and cover tunnels, grade separation structures and trenches, station building and platforms, and tie-ins to the NAL) to be undertaken from mid-2020 through to mid-2023; and

Public realm reinstatement – likely to be undertaken from 2021 to early 2024.

This AQ DWP has been prepared to identify measures that will be implemented to mitigate and manage the potential adverse effects on air quality during the main works. The objectives of the AQ DWP are:

• To address requirements specified in the conditions of the CRL designation and construction air discharge permit for the Aotea to NAL (A2N) section;

• Detail various sources of dust, odour and combustion air pollutants that may be created during the works;

• Highlight specific sensitive locations;

• Identify dust and odour mitigation methods;

• Describe methods to minimise the discharge of combustion emissions from vehicles;

• Describe monitoring methods; and

• Set out methods for managing complaints regarding discharges into air and keeping compliance records.

The CRL designation 2500-6 (condition 59) requires the preparation of an AQ DWP, while conditions 217 to 228 of the discharge permit (R/REG/2016/1899) require an Air Quality Management Plan (AQMP). These two separate requirements have been combined and are addressed in this single AQ DWP.

This AQ DWP has been prepared in consultation with the CRL Mana Whenua Forum, Mt Eden Community and Business Liaison Group (CLG) and reviewed by Independent Peer Review (IPR) prior to submission to Auckland Council (as per designation conditions 7 and 11, and resource consent condition 19). A record of the consultation and review outcomes, including the Link Alliance’s response to matters raised, is provided in Appendix E.

Resource consent DIS60354169 was granted for discharges to air from concrete and aggregate crushing not already authorised by the designations and A2N resource consents on 13 May 2020. The DWP also incorporates the dust management and monitoring requirements of this resource consent.

This AQ DWP has been prepared by a team of air quality specialists.

• The DWP has been authored by Jason Pene, a Senior Environmental Engineer and Principal of Tonkin & Taylor Ltd (T+T), with support from other T+T air quality specialists. Jason has over 18 years of experience in the assessment and management of air quality impacts, including management and monitoring of dust associated with linear infrastructure construction projects.

• The DWP has been reviewed by Richard Chilton, a Senior Air Quality Specialist of T+T. Richard has 21 years of experience assessing and managing air quality impacts, and was the technical lead for the assessment of air discharges associated with the regional consenting process for the CRL project.

Table 1-1 identifies the designation and resource consent conditions relevant to this DWP and where they are addressed in the document.

Table 1-1: Relevant conditions and location in DWP

59.1 An Air Quality DWP shall be prepared to avoid, remedy or mitigate the adverse effects on air quality during the construction of the City Rail Link or any part of it.

59.2 The objective of the Air Quality DWP is to detail the best practicable option to avoid dust and odour nuisance being caused by construction works and to remedy any such effects should they occur. This document

59.3 To achieve the above objective the following shall be included in the Air Quality DWP and implemented as required:

(a) The procedures to be implemented for the continuous monitoring of Total Suspended Particulate (TSP) concentrations and meteorology including, but not limited to, the establishment of two monitoring sites (to the north and south of the site);

(b) Identification of the sensitive locations, and the specific methods for monitoring, including trigger limits to determine whether further action (such as implementation of the mitigation measures discussed below or other mitigation measures) is required;

(c) Procedures for responding to malfunctions with construction machinery or works causing accidental dust discharges including, but not limited to, the requirement to remedy any malfunction within 24 hours;

(d) Procedures for monitoring weather conditions and the requirement that water spray is used on soil stockpiles, any non-paved construction areas, and the wheels of trucks where dust may disperse beyond the site;

Section 6.3

Sections 3.3, 6

Sections 5.4, 6.5

Sections 5.2, 6.3.3,

(e) Procedures for establishing when the covering of trucks will be required;

(f) Procedures for determining when hard surfaced areas in construction yards and active construction areas should be cleaned including, but not limited to, the requirement that such areas be cleaned whenever dust generation occurs due to traffic on these surfaces;

(g) Procedures for responding to discharges of odour (including in the event of excavation of contaminated sites) including, but not limited to, the requirement to address discharge of objectionable odour by immediately ceasing the activity causing the discharge;

(h) Procedures for equipment inspection (including timeframes for regular inspections), maintenance, monitoring and recording, including baghouses, pressure relief valves and high level alarms to mitigate dust emissions;

(i) Procedures for, where practicable, limiting dust and odour nuisance and the methods for monitoring these procedures including Identification of contingency measures to address identified and verified adverse effects on sensitive receptors. Contingency measures may include options such as:

i. Cleaning of air filtration intakes; or

ii. Cleaning of other buildings and infrastructure; and

(j) Procedures for responding to any complaints received and the timeframes for response to complaints and reporting;

(k) Cross references to the specific sections in the Communication and Consultation Plan which detail how the communities in the vicinity of construction works are to be communicated with on the management of the adverse effects relating to air quality.

Discharge permit (air – construction) R/REG/2016/1899

Section 5

Sections 5.2, 6.2

Section 6.6

Section 5.3

Section 5

Section 7.2

Section 7

217 This resource consent shall expire 15 years after the consent commences unless it has been surrendered or been cancelled at an earlier date pursuant to the RMA. Noted

218 The Consent Holder shall ensure that all processes on the Project work site shall be implemented, operated, maintained, supervised, monitored and controlled so that any emissions authorised by this consent are maintained at the minimum practicable level.

219 Unless provided for by Condition 220, there shall be no dust or odour beyond the boundary of the Project work site caused as a result of on-site processes which, in the opinion of Council, is noxious, offensive or objectionable.

220 Any noxious, offensive or objectionable dust or odour beyond the boundary of the Project work site caused as a result of construction and earthworks activities associated with the Project shall be mitigated as soon as practicable in accordance with the requirements of the certified Air Quality Management Plan as required by Condition 222.

221 The Consent Holder shall ensure that beyond the boundary of the Project worksite, there shall be no hazardous air pollutant caused as a result of

This document

This document

This document

This document

Condition

construction and earthworks activities associated with the Project that causes, or is likely to cause, adverse effects on human health, environment or property.

222 The Consent Holder shall review the draft Air Quality Management Plan –Aotea Station to North Auckland Line dated May 2016, and submit to Council (Team Leader Central Monitoring) a final AQMP/s which is generally consistent with the draft AQMP provided in support of the application.

223 The final AQMP/s shall be prepared by a Senior Qualified Person, provided to the Council (Team Leader Central Monitoring) for certification at least 20 working days prior to the commencement of construction and shall include:

a. a clear identification of the type and location of the controls proposed;

b. a detailed framework for the management, mitigation and monitoring of construction and earthworks activities associated with the Project;

c. a focus principally on the sources of dust discharges, and

d. an assessment of the risk of discharges from each ACZ and the associated CSA.

224 The final AQMP/s shall also provide detailed methods including, but not limited to, the following matters:

a. methods to ensure exposed surfaces remain dampened to minimise dust emissions (possible examples include a water spray system or other suitable system, water carts and other suppression methods);

b. ensuring a 20 km/hr vehicle speed limit within the ACZs and CSAs;

c. operation of wheel washes;

d. regular sweeping of public roads around the exit points of ACZs and CSAs and sealed vehicle accessways within these areas;

e. measures for supressing dust from any temporary stock piles (demonstrating how they are to be limited to no more than 24 m³ of uncovered spoil at any one time in each ACZ);

f. measures for the handling of cement associated with the forming of cement stabilised columns, including filter systems and high level alarms where a silo is used;

This document

Section 5

Section 5

Section 5

Section 5.1, Appendix B

Section 5

Section 5.2

Section 5.2

Section 5.2

Section 5.2

Section 5.2

g. covering of loads of material being delivered and removed from the site; Section 5.2

h. instrument monitoring of dust concentrations (including identification of a monitoring methodology, monitoring network and appropriate alert thresholds) to ensure that any significant dust effects arising from the ACZs or CSAs are identified and remedied as soon as practicable throughout the Project;

i. the locations of instrument dust monitoring sites, including at least three re-locatable and/or fixed monitors to be associated with each of ACZs A, K and M, and the duration of this monitoring;

j. measures for responding to continuous instrument dust monitoring trigger alarms, including contingency measures to reduce measured concentrations below the trigger thresholds and provisions for responding after standard operating hours;

Section 6.3

Section 6.3

Section 6.3

k. measures for undertaking meteorological observations and visual inspections of dust or other air discharges from the Project, to be completed at least on a daily basis, with all relevant information logged; and

l. information regarding complaint logging, investigation and response procedures, training and roles and responsibilities.

Section 6.3

The Team Leader Central Monitoring shall be requested to respond to the AQMP/s with any suggested changes within 10 working days from receipt of the AQMP; otherwise the AQMP may be considered by the Consent Holder to be certified by the Council. Section 7.2

225 Any change to the AQMP shall be submitted to the Council (Team Leader Central Monitoring) for certification. No activity reliant upon a change to the AQMP can be undertaken until the change has been certified.

The Team Leader Central Monitoring shall be requested to respond to the proposed change within 10 working days from receipt of the change; otherwise the AQMP may be considered by the Consent Holder to be certified by the Council.

Section 6.7 of the CEMP

226 All works shall be undertaken in accordance with the certified AQMP/s. Noted

227 Prior to the commencement of construction, and for the duration of excavation and construction associated with the Project which have the potential for significant dust emissions, the Consent Holder shall install, operate and maintain continuous dust monitoring undertaken using mobile instruments for the purposes of monitoring Total Suspended Particulates (TSP).

The locations, durations and methods of TSP monitoring at each of ACZs A, K and M shall be in accordance with the details in the certified AQMP(s) required by Condition 222.

228 The dust monitoring instruments shall be fitted with an alarm system that sends a warning to the responsible person identified by the AQMP/s when dust concentrations exceed alert levels specified by the certified AQMP/s.

The Consent Holder shall ensure that the responsible person, or other nominated person, is available at all times to take immediate action to reduce dust emissions from the site.

Section 6.3

Section 6.3

The Link Alliance is seeking an Infrastructure Sustainability Council of Australia (ISCA) Infrastructure Sustainability (IS) Rating. Further details can be found in the main works Construction Environmental Management Plan (CEMP) and Sustainability Management Plan. Main works sustainability requirements that relate directly to this AQ DWP are included in Appendix A These requirements are imbedded within the Delivery Work Plans and Management Plans for the main works to ensure that sustainability is a key focus and ‘the way we do things’.

In some cases, the IS requirements and sustainability goals enhance the designation and consent requirements.

This AQ DWP is a live document that will be reviewed and updated at least annually, or as a result of a material change to the main works, identification of increasing dust levels or potential for nuisance identified in monitoring required under this DWP, or to address unforeseen adverse air quality effects arising from construction, or unresolved complaints. Refer to sections 1.9 and 6.7 of the CEMP for further detail on the review and updating process.

The main works involve construction along several active work fronts concurrently within the Mt Eden area at any one time, to enable the redevelopment of Mt Eden Station and establish the CRL tie-ins to the NAL. Works will be carried out in a staged fashion. The construction staging, and methodologies are described in greater detail in the CEMP.

Within the main works area, there are already other works occurring in accordance with the Mt Eden Enabling Works (OPW60350039) and Normanby Road Early Works (OPW60351423) outline plan packages.

In summary, the main works involve:

• Ground improvements, in the form of deep soil mixing (contiguous piling and grout injection), within the NAL corridor between Mt Eden Road Bridge and Normanby Road;

• Bulk excavations and construction of retaining walls along the NAL to provide for the rail trenches and installation of new tracks. The excavation will encounter basalt, which will be removed via rock-breaking and blasting. In places, softer ground conditions are anticipated to be encountered, which may require the use of sheet piles;

• Construction of the eastern and western crossover structures that enable the CRL rail lines to tie-in to the NAL;

• Construction of the Porters Avenue and Fenton Street pedestrian and cyclist bridges.

• Construction of the Normanby Road grade separation bridge, including regrading of Normanby Road and realigning the Boston Road roundabout;

• Redevelopment of the existing NAL platform;

• Construction of the CRL platform and the foundations for the Mt Eden Station building and the ventilation building; and

• Operation of the TBM, including the conveying of spoil material from the tunnels and the refuelling and general maintenance of the TBM within CSA 4.

The main works will be divided into several stages within the various work areas.

Generally, the works along the NAL are divided into two stages to allow works on the northern (downmain) or southern (upmain) sections to correspond with the ‘Single Line Running’ of train services through the construction area.

Works within the Mt Eden station area are divided into 12 stages. Stages 1-4 have already been addressed in the Mt Eden Enabling Works outline plan package, and stages 5-12 will be undertaken as part of the main works. For the new Mt Eden Station building and ventilation building, construction of the foundations and building structures will be undertaken as part of stages 5-12, while the finishing of the buildings, including internal and external fittings, will be completed as part of the future public realm reinstatement.

The construction staging, and methodologies are described in sections 2.3 and 2.4 of the CEMP.

The main discharge to air from the construction activities outlined will be particulate matter (dust). Dust has the potential to cause nuisance or soil property if deposited in sufficient quantities in the environment.

Fine particles present in dust emissions have the potential to affect respiratory heath while suspended in air. Bentonite powder used in the construction of diaphragm walls, fly ash and cement used in grout and concrete removed from excavation areas may contain respirable crystalline silica (RCS), which can also have respiratory health effects with sufficiently high exposure. Waitakere Group rocks containing erionite may be encountered during excavations though the main work’s geological specialists have indicated that this risk is very remote. Erionite can also have respiratory health effects if inhaled in suspended dust in sufficient quantities

The following activities have the potential to result in discharges of particulate matter to air:

• Demolition activities (such as knocking down and breaking up of building material including plasterboard and blockwork, and cutting, breaking and crushing of concrete);

• Excavation and backfilling;

• Piling, deep soil mixing and drilling;

• Outdoor spoil handling/removal;

• Wind erosion of spoil and other stockpiled material;

• Basalt blasting;

• Basalt crushing;

• Conveyance of cement, fly ash and bentonite powder to silos and mixing of these materials to form grout or bentonite slurry; and

• Movement of vehicles over unsealed surfaces (this includes trucks, loaders and excavators required for the tunnel excavation and spoil removal, and the delivery of construction materials such as concrete and steel).

Other minor discharges to air could include:

• Combustion emissions from vehicle, equipment or generator engines on site, which can affect respiratory health in the environment with sufficient exposure;

• Odour and emissions from spray painting/coating of bridges and other structures; and

• Odour from excavation or disturbance of contaminated soil (if encountered), which has the potential to cause nuisance

This section of the AQ DWP describes the environment surrounding the main works site in terms of meteorological influences on the transport of air contaminants and sensitivity of adjacent activities to those discharges.

The main works will be undertaken near the existing Mt Eden Station and along the NAL, in an existing urban environment. The main works area is generally bounded by the NAL (south), State Highway 1 (east), Dominion Road (west), and Nikau Street (north) (refer Figure 3-1). The main works will include construction activity along Nikau Street, Ruru Street, Porters Avenue, Fenton Street, Haultain Street, Ngahura Street, Flower Street, Shaddock Street, Mt Eden Road, Normanby Road, Boston Road and Nugent Street.

Additional areas of land outside the CRL designation boundaries may also be required to provide construction access to the NAL corridor.

CRL Designation 2500-6 KiwiRail Designation 6300

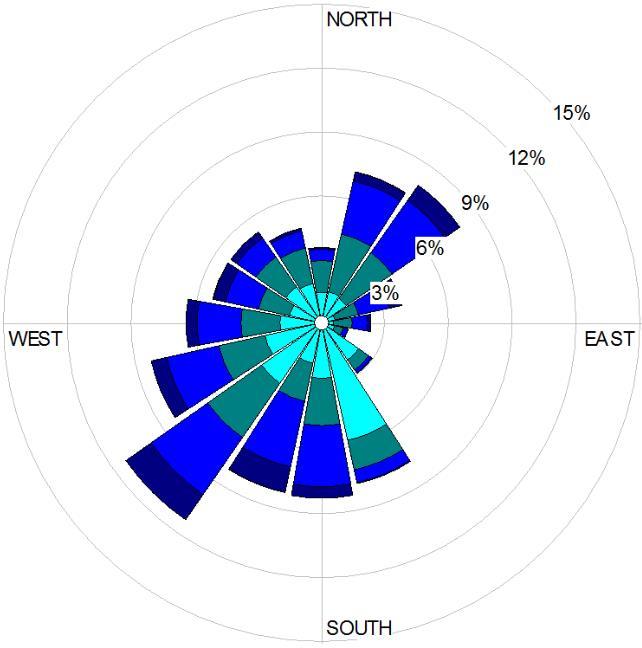

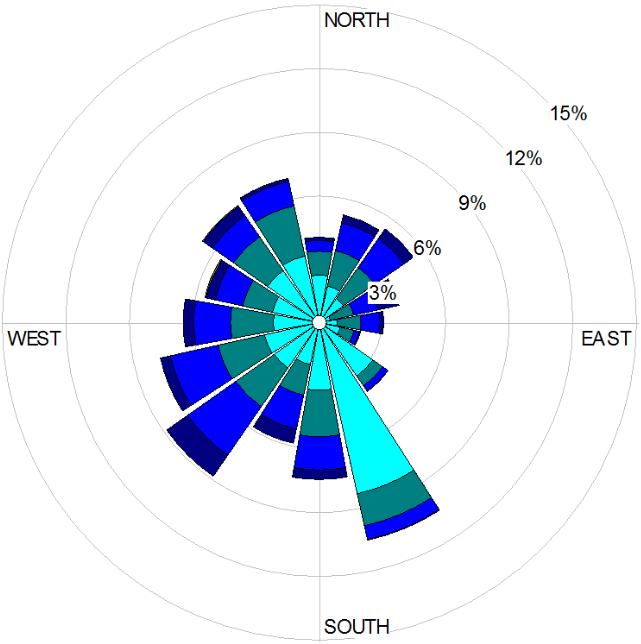

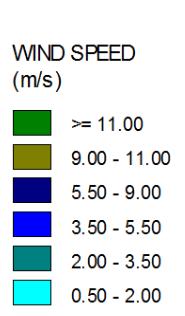

Figure 3-2 shows wind roses of wind speeds and directions measured at the NIWA weather station at the Auckland Museum of Transport and Technology (MOTAT), Western Springs over year round, summer (December to February) and winter (June to August) periods.

The weather station is located approximately 2.85 km to the west of the CRL Mt Eden site. Wind measurements at this station are considered to be generally representative of conditions over the Auckland isthmus as it is relatively free from nearby obstructions or eddies created by adjacent buildings.

Although localised topographical features and adjacent buildings at the Mt Eden site are likely to alter wind conditions, the wind direction frequency trends illustrated below are likely to be broadly similar to those experienced at the site

Based on the wind roses in Figure 3-2, winds are predominantly from the southwest and northeast, and therefore sensitive locations to the northeast and southwest of the site, respectively, are likely to be most frequently exposed to any off-site dust emissions from site activities. The amount of dust generated is also highly dependent on whether conditions are dry, and the wind speeds, with faster wind speeds increasing effect of wind erosion and the distance that the dust travels.

All months, 2016-2019, Calms = 5.52%

Winter months, 2016-2019, Calms = 6.28%

Summer months, 2016-2019, Calms = 2.25%

Figure 3-2: Wind rose frequency analyses of wind speeds and directions at the Auckland MOTAT weather station for August 2016 to August 2019, year round, winter and summer months Source: NIWA Cliflo database.

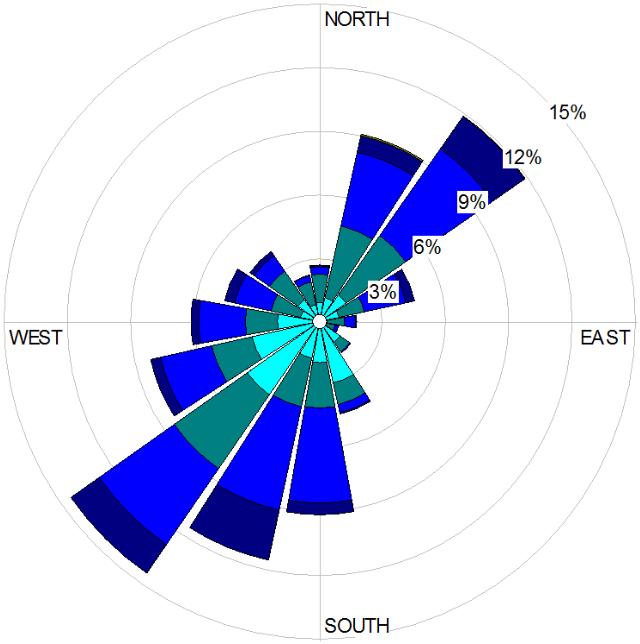

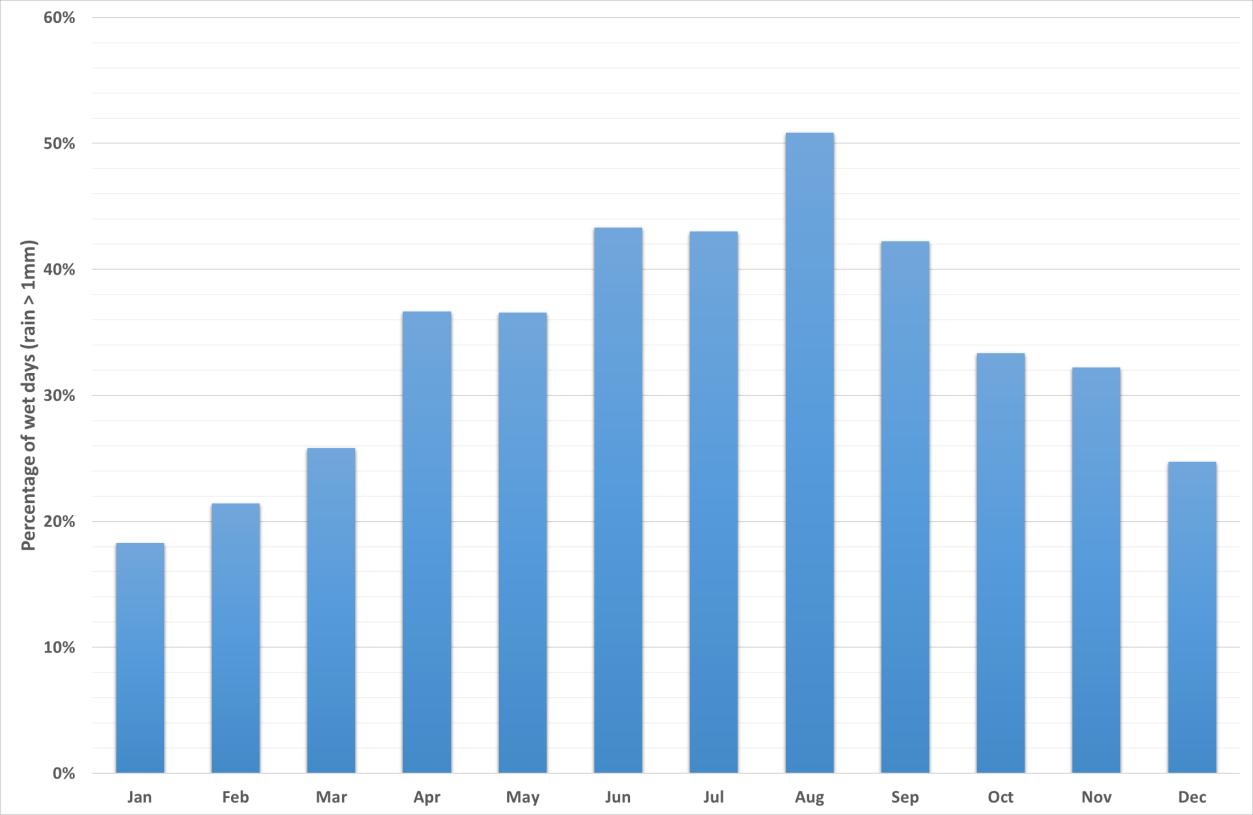

Figure 3-3 shows that the expected drier months are during summer, when wind speeds also tend to be higher. Summer winds are dominated by a south-westerly wind which will transport any emitted dust towards sensitive receptors to the northeast of site.

3-3: Percentage of wet days (rain exceeding 1 mm) over each month of the year at MOTAT. Source: NIWA Cliflo database.

The main works are situated within a ‘business – mixed use zone’. Neighbouring zones include residential (single house and mixed housing urban and suburban), open space (conservation and informal recreation) and more business (including city centre). Adjacent land use therefore comprises a range of commercial, residential, and recreational activities. Due to the density and nature of development and human occupation in surrounding areas the sensitivity of the local environment to air pollution in general is relatively high.

Examples of nearby activities that may be sensitive to dust and other air contaminants include:

• Residential apartments such as on Flower Street, Nikau Street, Fenton Street, Ngahura Street, Korari Street, Akiraho Street, Enfield Street and Normanby Road.

• Residential houses such as those along Akiraho Street, Ruru Street and Sylvan Avenue.

• Education centres such as the Bear Park Early Childcare Centre at the western end of Akiraho Street.

• Pedestrian access (to offices and other places of work) and parked vehicles along roads.

• Bars and restaurants, particularly where premises include outdoor dining or entertainment areas.

• Retail, office and commercial premises.

• Cityside Baptist Church, Mt Eden Road.

• Mt Eden Prison

As required by the CRL designation conditions and the A2N resource consent conditions, the purpose of this AQ DWP is to ensure that construction air quality effects are kept to a practical minimum, recognising the sensitivity of the environment within which the works are being undertaken.

The key air quality compliance requirement for construction activities is that dust and other air discharges from the activities do not cause offensive or objectionable levels of dust or other contaminants beyond the site boundary.

A range of air quality management and monitoring measures are specified in Sections 5 and 6 of this AQ DWP to minimise the potential for adverse air quality effects and avoid the occurrence of offensive or objectionable dust or contaminants in the surrounding environment.

These measures include monitoring trigger levels and response actions, which are intended to provide operational feedback to improve air quality management. The monitoring trigger levels are not intended as environmental performance standards in and of themselves

A range of routine measures will be used to manage and mitigate the effects of discharges of dust, odour and construction engine exhaust emissions during the main works. An adaptive approach to management of dust, including additional mitigation may be required in the event that:

• Monitoring indicates that abnormal discharges of dust are occurring;

• Weather conditions are changing such that dust or odour discharges are more likely as determined using the Dust Risk Assessment; and / or

• Complaints are received regarding discharges of dust, odour or construction vehicle exhaust emissions.

If the available mitigation methods are unsuccessful in controlling discharges (i.e. dust and odour) that cause significant adverse effects on receptors beyond the site boundary, the activities causing the discharge shall be suspended until adequate mitigation can be put in place.

To provide guidance to the Environmental and Sustainability Manager and area supervisors (refer Section 9 of this AQ DWP) on implementing dust mitigation, the amin works will use a Dust Risk Assessment (DRA) approach.

The DRA is described in Appendix B and assigns a risk classification to each proposed activity with the potential to generate dust based on the scale of potential dust emissions and local environmental conditions (including sensitivity of adjacent activities and weather conditions).

As the dust risk is dependent on local environmental conditions, the dust risk associated with activities should be re-calculated as conditions change.

A “traffic light” indication of dust risk will be posted in each work area so that main works staff are aware of the dusk risk. The dust risk will be indicated as:

• Low risk (green).

• Moderate risk (orange).

• High or extreme risk (red).

Dust management measures are specified for proposed main works activities in Table 5-1. Dust management measures may differ based on the dust risk of the activity calculated in accordance with the DRA in Appendix B.

The control measures specified for the calculated dust risk level should be employed in addition to the measures for all preceding levels– e.g. a medium risk activity requires application of measures applicable to the corresponding low risk activity as well as measures specified for medium risk.

Alternate methods may be employed after the effectiveness of those methods is demonstrated and this AQ DWP updated accordingly. The list of control methods is not exhaustive and additional methods may be found to be effective.

Stockpiles Low

Medium

• Store stockpiled material containing a high content of fine material indoors or undercover where practicable.

• Outdoor stockpiles of spoil are to be maintained in damp condition with regular application of water (such as via water sprays).

• Limit the height of any outdoor stockpiles to reduce wind entrainment (generally no greater than 3 m).

• Orientate outdoor stockpiles to maximise wind sheltering as much as practicable.

• Dampen, cover or stabilise inactive stockpiles if they are producing visible dust emissions.

• Stabilise stockpiles using various means depending on the length of inactivity (e.g. soil binders if inactive for 28 days).

• Minimise handling of stockpiled material and drop heights to stockpiles during unloading to decrease potential for dust generation.

• Bunker or cover stockpiles of fine, dry materials if stockpile is existing for prolonged periods (greater than 1 month).

• Utilise windbreak fences or temporary bunkers if they are producing visible dust.

Personal responsible

Environment and Sustainability Manager or delegated person

1 Dust risk levels for each activity will be dependent on environmental conditions and are to be calculated in accordance with the procedure described in Appendix C.

Vehicle movements (over sealed and unsealed surfaces)

Low and medium

• Limit vehicle speeds to 20 km/h.

• Limit load sizes to avoid spillages.

• Cover loads of fine materials leaving or entering the site.

• Minimise on-site travel distances through appropriate site layout and design.

• Minimise mud and dust track out from unsealed areas to sealed areas by using wheel cleaning facilities at site exits to sealed roads.

• Wheels of all trucks exiting the site to public roads are to be inspected and washed as required to prevent tracking of material off-site.

• Any material identified to be tracked onto public roadways during regular inspections (or via notification from the public) is to be cleaned with a vacuum sweeper truck.

• Sealed access routes are to be cleaned with a vacuum sweeper truck on a daily basis (at a minimum).

• In dry conditions (e.g. less than 1 mm of rain in the preceding 48 hours), maintain unsealed surfaces in regular use in damp condition through surface watering (e.g. with water carts or fixed irrigation).

• If water suppression is ineffective, synthetic dust suppressants may be used as an alternative. The use of recycled oil-based suppressants is expressly prohibited.

High

Demolition Low

Medium

• Maintain regularly used unsealed road surfaces in damp condition through surface watering in all wind conditions.

• As required water sprays or fogging systems are used to dampen material to avoid dust generation.

• Only wet cutting of concrete should be undertaken.

• Any breaking of concrete should be done under wet conditions (such as a water spray or fog directed at where the breaking is occurring).

Environment and Sustainability Manager or delegated person

High

• Dust from the removal of plaster board is controlled by wetting the plaster board as it is broken up.

• Dust from knocking down and breaking up of blockwork or concrete, and from the removal of rubble will be controlled using water sprays or fogging systems directed onto the activity during dry and windy weather.

Environment and Sustainability Manager or delegated person

Earthworks including excavation and removal of hard stand or structures

Low

Medium and High

Loading and unloading of dry material

Medium and high

Blasting

Medium

Crushing (concrete and basalt)

High

Medium and High

• Limit the extent of excavation, mining and material handling activities in exposed areas carried out during dry and/or windy conditions as far as practicable.

• Limit drop heights of material during handling, including from any conveyor transfer points.

• Stabilise exposed areas not required for construction, access or parking, along with completed fill and spoil areas as soon as practicable.

• Maintain surfaces of active earthworks areas in damp condition during excavations in dry weather. This should include pre-watering of dry soil surfaces, prior to excavation allowing enough time for moisture to penetrate the soil.

• Remove excavated spoil from site on a regular basis.

• Maintain surfaces of active earthworks areas in damp condition during dry weather. This should include pre-watering of earthworks surfaces, prior to excavation allowing enough time for moisture to penetrate the soil.

• Only wet cutting of concrete shall be undertaken.

• Any breaking of concrete shall be done under controlled conditions (e.g. using water sprays or fog cannons directed at where the breaking is occurring).

• Limit loading or unloading during windy conditions that cause dust to be emitted beyond the site boundary.

• Cover loads of fine materials.

• Minimise drop heights when loading and unloading dry material.

• Blasting is to be carried out in accordance with dust management measures Blasting Management Plan

• Topsoil and loose material overlying the rock shall be removed prior to blasting.

• If the rock and adjacent material is dry, dampen with water where practicable.

• Use a fog canon on the area that is being blasted during the blast

• Only crushers fitted with water sprays or fogging systems are be used and those systems are to be operated at all times when crushing occurs.

• Feed material is to be pre-wet prior to loading to the crusher feed hopper.

Environment and Sustainability Manager or delegated person

Environment and Sustainability Manager or delegated person

Environment and Sustainability Manager or delegated person

Environment and Sustainability Manager or delegated person

Unpaved surfaces (including roads and yard areas)

Low

Piling and deep soil mixing Low and Medium

Storage, handling and mixing of cement and bentonite (including pneumatic conveyance)

All dust risk levels

Rock drilling Medium and High

Miscellaneous All dust risk levels

• Where practicable, the crusher plant is to be located to minimise the potential for wind to transport dust off-site (towards downwind off-site sensitive activities in particular).

• Limit the amount of exposed surfaces as much as possible.

• Use water sprays or watering trucks to dampen dry exposed surfaces.

• Stabilise cleared areas not required for construction, access or for parking if liable to cause excessive dust during windy conditions. Methods may include placing metal or other coarse material on surfaces.

• All spoil to be placed in a pre-identified stockpile location and removed from site as soon as possible.

• Any spilt material to be cleaned up immediately.

• Cement silos are to have either an automated remote filling system or be fitted with a high level alarm that has both an audible and visual indicator and when the alarm is triggered it will stop the filling of the silo.

• Each cement silos is to be fitted and operated with a filtration system with a filter surface area of at least 24 m2 .

• Mixing of grout and bentonite slurry is to occur in enclosed mixers or within a mixing enclosure.

• Drills used on rock or concrete in exposed areas should be fitted with dust suppression mechanisms where practicable.

• Ensure sufficient water is available for dust sprays on-site.

• Taking account of daily weather forecast wind speed and wind direction, and the condition of any excavated spoil (such as its dampness) before commencing an operation that has a high wind potential.

• Installing wind fences where practicable and appropriate. Effectiveness is greatest where fencing is perpendicular to the prevailing northeast and southwest winds with porosity of about 50%.

• Maintenance of surface moisture content: Watering or wet suppression is used to dampen dry or dusty exposed areas.

Environment and Sustainability Manager or delegated person

Environment and Sustainability Manager or delegated person

Environment and Sustainability Manager or delegated person

Environment and Sustainability Manager or delegated person

Environment and Sustainability Manager or delegated person

Information will be sourced from the dust control equipment supplier on the following:

• Procedures for equipment inspection (including timeframes for regular inspections), maintenance, monitoring and recording, including dust filters, pressure relief valves, high level alarms and dust suppression mechanisms such as fog canons or sprays.

If construction equipment fails and causes accidental dust discharges, it will be shut-down immediately and the fault repaired and tested prior to being allowed to continue operation.

If equipment associated with dust control fails (such as a baghouse) the activities reliant on the equipment will be suspended until the fault can be repaired.

The location, duration and time of any dust discharge caused by equipment failure will be recorded in the Air Quality Log (log sheet template provided in Appendix D)

When site operators are alerted to a potential off-site dust nuisance through any of the monitoring techniques described in Section 6 of this AQ DWP, or as a result of a complaint from a third party, the Site Engineer will immediately undertake a review of site activities to determine the source of the dust and implement further mitigation measures as required in order to reduce the dust generation to acceptable levels. As appropriate the Site Engineer will notify the Environment and Sustainability Manager.

In general, the additional mitigation will be those measures set out in Table 5.1.

Once the additional mitigation has been implemented the Site Engineer will review the monitoring data to ensure that it has been effective.

The following are locations where information necessary for determining the Dust Risk Level and general dust control can be obtained:

• Site Specific monitoring web site where TSP and meteorological data can be accessed (to be established); and

• Met Service: http://www.metservice.com/towns-cities/auckland/auckland-central

• MetVUW North Island forecast charts: http://metvuw.co.nz/forecast/

Odour may be emitted if contaminated soil is encountered during the excavation works, depending on the nature of the contamination. This section of the AQ DWP sets out the mitigation required by CRL designation condition 59.3(g) for minimising any potential for odour if contaminated material is encountered.

Odour emissions will be monitored in accordance with Section 6.6 of this AQ DWP during the excavation of contaminated material and the following techniques considered if necessary:

• Limiting the time that the odorous material in the excavation is exposed;

• Applying inert, non-odorous fill material to cover exposed odorous material where excavations are to be left incomplete overnight (to a minimum depth of 150 mm);

• Removing excavated odorous material from site as quickly as possible in covered trucks; and

• The use of odour masking agents, chemical counteractants or digestive deodorant sprays.

As there is a potential that exposed odorants may also be hazardous air pollutants and their inhalation could potentially present a health risk, the procedures outlined in Section 7.1 of the Contamination DWP for unexpected discovery of contamination should also be followed.

If significant odour is detected and the odorous material cannot be removed quickly and odour masking agents, chemical counteractants or digestive deodorant sprays are not immediately available, the odorous material shall be covered with uncontaminated soil or other suitable material to suppress odour emissions, and work in that area suspended until suitable mitigation measures can be put in place.

The following key actions shall be carried out to manage potential off-site impacts of exhaust emissions from vehicle and stationary engines:

• Electrical generators or other stationary engines are to be sited and associated exhaust discharges are to be oriented to avoid exhaust discharges towards adjacent site boundaries (particularly windows, balconies, accessible terrace areas and air intakes) as far as practicable;

• All engines used on the site will be maintained at least in accordance with manufacturers’ requirements;

• Where excessive exhaust smoke is identified from any engine, it is to be serviced as soon as is practicable and the vehicle or piece of equipment is to remain out of service until such maintenance has been completed; and

• Unless warm-up or turbo maintenance procedures require it, construction vehicles are not to be left idling while parked or unattended.

Construction of bridges and other structures may require application of paint or other coating materials. Spray coating application may be required where pre-installation application (off-site) or application by brush is not practicable, which can result in overspray, spray drift and property damage or nuisance effects in adjacent areas if not well managed.

The following key actions shall be carried out to manage potential off-site impacts of emissions from spray coating activities:

• Application of spray coatings prior to installation or application by brush/roller (where practicable);

• Using high volume-low pressure or airless spraying systems where spray application is required (where practicable);

• Avoiding spray application in windy conditions (refer wind trigger levels described in section 6.3.4 below);

• Maintaining an exclusion zone around spray application of at least 10 metres from off-site property and public access. Where this exclusion is not able to be maintained or in other

circumstances where spray drift beyond the Site is possible, screening of the spray application area and/or sheltering of off-site property should be applied.

In the event of significant on-going dust emissions that are unable to be mitigated through the measures described in section 5.2 and are verified to have caused offensive or objectionable dust deposition on property surrounding the works area, the Environment and Sustainability Manager (or delegated person) shall investigate the implementation of dust contingency measures. The investigation is to consider the nature and scale of dust exposure and adverse effects at adjacent properties and the practicability of implementing contingency measures, including:

Commercial cleaning of buildings and infrastructure, including air ventilation intakes, at adjacent properties that are affected by adverse effects of dust; and Cleaning of vehicles or other property subject to dust deposition from main works activities.

In the event that instrumental monitoring, dust observations or investigation of complaints indicates that further control of dust from outdoor stockpiling is required, the following measures shall be implemented:

Windbreak fencing or other wind reduction structures shall be installed along the periphery of outdoor spoil storage areas (except at vehicle entrances). The height of fencing should be of the same height of stockpiles (at a minimum) and porosity of fencing material should be in the order of 50%.

If outdoor stockpiling activities result in visible dust emissions beyond the site boundary outside of operating hours, automation of water sprays to maintain surface material in dry windy conditions may be required.

In the event that water application is required to suppress dust from main works activities (in accordance with section 5.2), but that water availability is restricted or limited (e.g. during droughtinduced water restriction periods), alternative dust mitigation measures are to be investigated and implemented, where practicable, in place of wet suppression dust measures. Potential alternative measures include:

Use of chemical dust suppressants.

Stabilisation of access routes and other exposed surfaces (e.g. through application of metal, geotextile material or paving).

Use of covers, enclosures, wind breaks and other methods to reduce wind exposure of exposed surfaces.

The overall approach to dust control for the main works is based on visual monitoring combined with targeted ambient dust monitoring; good management of the construction areas; and a rapid response to any of the triggers outlined in Sections 6.3.2 or 6.3.4, or complaints received. Good practice focusing on proactive measures will aid in avoiding significant dust emissions, however if dust emissions do occur, the monitoring will help to identify such occurrences and enable a prompt response.

Visual monitoring of all construction areas will be undertaken by the Environment and Sustainability Manager (or delegated person) on a daily basis, or more frequently if conditions change. This type of monitoring relates to the control measures described in Section 5 of this AQ DWP and will include proactive measures to avoid dust emissions.

Table 6-1 below describes the visual dust monitoring activities to be undertaken during construction. Outcomes of visual inspections are to be recorded in the Air Quality Log (log sheet template provided in Appendix D).

Table 6-1: Visual Dust Monitoring Programme

Monitoring

Check weather forecasts for strong winds (winds that may exceed the trigger levels described in section 6.3.4) and absence of rainfall to plan appropriate work schedule and dust management response.

Inspect land adjacent to the site, construction exits and adjoining roads for the presence of dust deposition and/or accumulation of dust material.

Observe weather conditions including wind and rain via observations and data outputs from weather stations.

Inspect all exposed un-stabilised surfaces for dampness and that the extent of those areas is being minimised

Inspect stockpiles for dampness and height of no more than 3°m (or enclosure, covering or stabilisation where required).

Inspect dust generating activities for effectiveness of dust management measures and avoidance of visible dust emissions beyond the boundary of the site.

Inspect watering systems (sprays and water carts) to ensure equipment is maintained and functioning to effectively dampen exposed areas.

Monitor dust generating activities and water application rate (for effective dampening).

Inspect wheels of all trucks exiting the Site to public roads for evidence of tracked material (to be washed and removed as required)

Check for dust on local roads being used to access the site.

Frequency

Daily

Twice daily

Daily and as conditions change

Daily and as conditions change

Daily and as new activities commenced

Daily and as new activities are commenced

Weekly

In winds over 5 m/s (1-hour average)

All truck departures

Daily

Inspect vehicle exits to ensure that wheel inspection and washing is effective and dust or sediment laden water is not being tracked off site by vehicles.

Inspect sealed vehicle access routes within the Site for deposition of material (to be removed via vacuum sweeper truck)

Inspect spray coating application locations for potential spray drift beyond Site

Monitoring that water sprays/fogs are being operated when crushing activities are being undertaken, and that control measures to minimise dust from drilling when setting charges are being implemented and effective.

6.3.1.

Frequency

Daily

Daily

Daily and as new activities are commenced

When crushing activities are being undertaken.

Continuous instrumental dust monitoring will be carried out at representative locations adjacent to sensitive areas when in the vicinity of dust generating activities. It is expected that at least three dust monitors are to be used to monitor dust from the site, in accordance with Condition 224 (i) of the A2N resource consents.

The locations of the two monitors initially installed to monitor dust from the site are as follows:

• At the Mediaworks building at the corner of Nikau Street and Flower Street adjacent (to the north of) the proposed portal location. This site is intended to monitor particulate levels downwind of the Mt Eden ACZ in prevailing southwest winds.

• At the existing Mt Eden Station platform. This site is intended to monitor particulate levels adjacent to residential and commercial activities on Akiraho Street. This monitor will be relocated prior to deconstruction of the station platform and adjacent structures.

An additional monitor is proposed to monitor dust near sensitive receptor locations adjacent to earthworks or other dust generating activities along the NAL corridor. This monitor is intended to be moved as works progress along the NAL.

The location of the monitors will be re-evaluated by the Environment and Sustainability Manager (or delegated person) with advice from the Air Quality subject matter expert, and potentially moved, as the construction stages progress and the location of dust generating activities shifts. For example, the Mt Eden station platform

As required by condition 227 of the A2N resource consents, ambient dust monitoring will commence prior to activities that have the potential for significant dust emissions. The two initial dust monitors described above have been commissioned as a consequence of the Mt Eden demolition and enabling works. The third monitor will be required to be commissioned prior to commencement of bulk earthworks or other activities with a potential for significant dust emissions associated with the NAL modification works.

Particulate instrumental monitoring for the main works will include:

• Continuous instrumental monitoring of dust concentrations;

• Calculation of 1-hour average concentrations from real-time monitoring data;

| Mount Eden Enabling Works

• Remote display of real-time particulate data (e.g. via the internet);

• Provision for alarms on 1-hour average concentrations measured above dust trigger levels (visual and/or via internet, email and mobile phone);

• Recording/logging of monitoring data; and

• The monitors shall be located in accordance with AS/NZ 3580.1.1:2007 Method for Sampling and Analysis of Ambient Air – Guide to Siting Air Monitoring Equipment, except where the presence of buildings or structures in the urban environment precludes complete accordance.

Two Dust Profiler particle counter monitors, manufactured by Aeroqual, have been installed to monitor dust at the site. The third monitor is likely to be of the same model but other monitor options that meet the requirements of the CRL designation and resource consent conditions include:

• Remote nephelometers; or

• Beta attenuation monitors.

Dust monitoring results are to be compared with trigger levels to indicate where dust levels may have the potential to cause adverse air quality effects and where modification to dust management measures may be required to avoid this outcome.

In the first instance, trigger levels published by the Ministry for the Environment (MfE) 2 are adopted as operational dust trigger levels. In the event of monitoring results exceeding the trigger level, response actions are to be taken as outlined below. The trigger level values are described in Table 6-2

Table 6-2: Dust Trigger Levels

Monitored

Instrumental dust monitoring*

Dust emissions and deposition

• MfE recommended trigger values for TSP concentrations: 200 µg/m3 (rolling 1-hour average)** OR

• MfE recommended trigger values for PM10 concentrations: 150 µg/m3 (rolling 1-hour average)**

• Visible dust emissions beyond the boundary of the site

• Evidence of dust on windows or cars (a finger run down the glass leaves a clear line)

• Dirt on clean washing

*The dust monitoring trigger levels should be updated to reflect the method of monitoring employed, if required (refer below).

** The MfE recommended trigger values do not relate specifically to rolling averages, which are specified in this case to provide instantaneous feedback on dust levels.

The dust monitoring trigger levels should be reviewed through regular (at least monthly) review of monitoring results. The regular review should include comparison with:

• The trigger alerts specified in Table 6-2;

2 Ministry for the Environment. 2016. Good Practice Guide for Assessing and Managing Dust: Ministry for the Environment.

29 | Mount Eden Enabling Works

• A review criterion for 24-hour average particulate TSP concentrations of 60 µg/m3 for TSP or of 50 µg/m3 for PM10 (if TSP is not measured)3;

• Visual monitoring records;

• Dust complaints.

If review of monitoring results indicates the triggers specified in Table 6-2 have not provided suitable advance indication of potential adverse air quality effects, the triggers may require modification.

The monitoring equipment will be set up with text alerts to key personnel in the relevant work zone, when dust concentrations exceed the trigger values set out in Table 6-2. At a minimum this will include:

• The Project Manager;

• The Environment and Sustainability Manager;

• The Construction Manager; and

• Site Engineer

If main works personnel change, the Instrument Technician will be contacted to update the alerts.

If a dust trigger alert is sent, one of the above staff members will immediately (within 30 minutes) respond and investigate the cause of the alert. This investigation will:

• Determine if the alert is real and not caused by equipment malfunction; and

• Identify the source of dust and check to see that all of the required mitigation measures are being implemented.

If it is determined that construction activities are the cause of dust, and that mitigation measures outlined in Section 5 of this AQ DWP are not effective for controlling dust, the contractor will implement the dust contingency procedures outlined in Section 5.8 of this AQ DWP. If these measures fail to effectively manage dust to acceptable levels, works shall be halted until it can be determined why dust emissions are occurring and what additional mitigation measures are required to control ambient dust to acceptable levels.

The findings of the investigation will be recorded in the Air Quality Log (refer to Section 9.1 of this AQ DWP).

Continuous instrumental monitoring of local weather conditions will provide information for dust management. A meteorological station that can continuously measure the following parameters is to be installed at the Site:

• Continuous instrumental monitoring of wind speed and direction;

• Recording of 1-minute and calculation of rolling 1-hourly averaged data;

• Provision for alarms on wind speed data measured above wind speed trigger levels (visual and/or via internet, email and mobile phone);

• Remote display of real-time meteorological data (e.g. via the internet); and

3 The MfE Good Practice Guide (2016) does not recommend a 24-hour average trigger for PM10 and the threshold concentration for 24-hour average PM10 concentrations specified in the National Environmental Standards for Air Quality has been specified as the PM10 review criterion (where TSP concentrations are not measured).

Page 30 | Mount Eden Enabling Works

• Recording/logging of monitoring data

Additionally, at least one meteorological station that can continuously measure rainfall, relative humidity and temperature is to be installed.

Where practicable the monitor(s) shall be located in accordance with AS 3580.14 -2011 Ambient Air – Guide for the Measurement of Horizontal Wind for Air Quality Applications. It will preferably be located to avoid adjacent buildings and other obstructions, where possible.

In the absence of on-site weather monitoring data, information of current and preceding wind conditions may be obtained from:

• Weather observations from other CRL works areas (if available);

• Weather observations from other weather stations in Central Auckland (if available);

• Current wind observations are displayed by the Met Service at www.metservice.com

The Trigger Levels proposed for wind speed measurements are detailed in Table 6-3

Table 6-3: Wind speed trigger levels

Discharge

Wind speed

• Wind warning level:

5 m/s (1-hour average)

10 m/s (1-minute average occurring twice in 20 minute period)

In the event that wind speeds exceed the trigger values set out in this AQ DWP, text alerts will be sent to nominated main works personnel in the relevant work zone. As a minimum, the nominated personnel will include:

• The Project Manager;

• The Environmental and Sustainability Manager;

• The Construction Manager; and

• The Site Engineer.

If 1-hour average wind speeds exceed 5 m/s then visual monitoring of the work area will be undertaken and recorded in the air quality log, to ensure that all appropriate mitigation outlined in this AQ DWP is being implemented and are effective.

There is the potential that continuous instrumental measurement of particulate concentrations may be influenced by either background particulate emission sources (not associated with the Mt Eden Main Works, such as other construction activities, domestic home heating or motor vehicle emissions) or rainfall/high humidity conditions that can affect dust monitoring instruments.

Previous experience at other CRL construction sites has shown that comparison of continuously measured ambient particulate concentrations with defined trigger levels may not always be indicative of adverse dust effects or a potential for dust nuisance experienced beyond the site boundary.

31 | Mount Eden Enabling Works

If investigations of exceedance trigger levels establish that trigger events are not associated with onsite dust generation, an alternative dust risk assessment approach can be implemented. In that instance and if required by the Environment and Sustainability Manager in consultation with the Auckland Council Monitoring and compliance team, the following alternative approach will be taken:

• A response to individual dust trigger alerts in accordance with Section 6.3.2 will not be mandatory and instrumental dust monitoring results will instead be reviewed against the trigger levels specified in by the Environment and Sustainability Manager (or delegated person) on a daily basis.

• Visual dust inspections are to continue in accordance with Section 6.2. If identified by the Environment and Sustainability Manager as a result of a review of instrumental dust monitoring results, visual inspections may be required at an increased frequency.

• Dust risk is calculated each morning by site engineers in accordance with Section 5.1 and Appendix B and used to inform appropriate management procedures.

All monitoring data from the dust monitors and the on-site meteorological station will be available to main works staff on-line, and electronically recorded for future reference.

The dust monitoring equipment and meteorological equipment will require periodic maintenance and calibration checks These will be done at a frequency and as per manufacture specifications by either site personnel, who have received appropriate training, or an Instrument Technician.

Unless the instrument recommends a higher frequency, at least quarterly maintenance and calibration will be carried out by a qualified Instrument Technician familiar with the equipment installed.

In the event that there is an equipment malfunction, or the equipment needs to be relocated for some reason, then the Instrument Technician will attend to this. If equipment malfunction results in on-going dust emissions (during the malfunction), the equipment is to be repaired, replaced or other measures are to be taken to minimise those emissions within 24 hours of the malfunction being identified.

Odour monitoring (observations) will be undertaken when it is considered likely that odorous material may be encountered (such as contaminated soil materials) during excavations. The decision to undertake monitoring by a suitable experienced odour observer will be made by the Environment and Sustainability Manager.

The frequency of odour monitoring will be dependent on the nature/scale of the source, location in relation to sensitive receptors, and meteorological conditions during exposure. Odour observations will occur:

• When potentially odorous contaminated material is excavated and loaded onto trucks; and

• When odour complaints have been received or odour is detected by main works staff.

The Environment and Sustainability Manager will ensure that a trained odour scout is available to undertake odour observations as required.

Monitoring will involve the odour observer being positioned downwind of the works and assessing odours on the intensity scale set out in Table 6-4. Where odours are identified as being “Distinct” and above, and the odour characteristic unpleasant, mitigation measures will be implemented. All observations will be recorded in the Air Quality Log (refer Section 9.1 of this AQ DWP).

The odour observer will reassess the level of odour once the mitigation measures have been implemented. If the odours are still ‘Distinct’, further mitigation will be implemented, and / or the works halted until more conducive meteorological conditions are present, i.e. not blowing towards the sensitive receptor.

If it is suspected that sources upwind of the works are responsible for any odour, the odour observer shall make appropriate observations and document these also.

As exposed odorants may potentially also present health risks, the procedures outlined in Section 7.1 of the Contamination DWP for unexpected discovery of contamination should also be followed.

Section 7 of the Communication and Consultation Plan (CCP) details how communities in the vicinity of the construction works will be communicated with in relation to the management of adverse effects relating to air quality. Communications will focus around informing communities of dust management and monitoring measures to be implemented during the main works and providing updates on these aspects as appropriate during the construction works.

Although the mitigation measures described in this AQ DWP are aimed at avoiding discharges to air, complaints may be received by members of the public. It is important to ensure that any complaints are recorded and promptly investigated to identify and resolve the cause of the complaint. The requirements and procedures relating to complaints are detailed below.

A complaint may be received from a member of the public via the following:

• Direct call to the main works Hotline.

• Complaint received by Auckland Council which notifies the Link Alliance of the complaint.

• Written or email correspondence.

In all circumstances, correct and accurate information needs to be recorded by the person receiving the complaint in order to help investigate the cause of the complaint, and ensure appropriate mitigation has or will be undertaken.

Any complaints received should be recorded in a complaints file, and an investigation undertaken as outlined in the CEMP and CCP The following guide should be followed when a complaint is received:

• Record the details provided about the incident by the complainant.

• The name and contact details of the person(s) who raised the complaint (unless they elect not to provide this).

• Acknowledge receipt of the concern or complaint and assure that an initial response shall be undertaken within 24 hours of receiving a complaint and resolved as soon practicable.

• Known construction activities at the time and in the vicinity of the complainant during the concern or complaint period.

• Remedial actions undertaken (if any) and the outcome of these, including monitoring of the activity.

• Weather conditions at the time of the concern or complaint, including wind direction.

• Reporting of the investigation in the complaints file.

The investigation of all complaints relating to air discharges will involve the following:

• Information about the incident as described by the complainant.

• Weather conditions at the time of the complaint, including wind direction and speed, and rainfall (if any)

• Reporting the findings and recommendations.

• Actions and time taken to close-out complaint.

• Communication with the complainant.

• Ensure reporting of the investigation is recorded in the complaints file.

An investigation of the complaint will require the Site Engineer or delegated staff member to go around the whole site and make visual observations about activities occurring on site. This may also include going to the location where the complainant observed the impact.

At all times during the complaints investigation, appropriate health and safety procedures must be followed

All main works staff (contractors and subcontractors) will undergo general environmental awareness training and training about their responsibilities relating to this AQ DWP. Training requirements are described in full detail within the CEMP. Specific training requirements relating to this AQ DWP are outlined in Table 8-1

Table 8-1: AQ DWP specific training requirements

Training requirements

Introduction to the on-site monitoring equipment, visual inspection procedures, odour monitoring procedures, air quality management measures and dust risk assessment procedure

Responding to dust monitoring trigger alarm alerts

Investigations in response to complaints regarding dust and air quality concerns

Frequency

As required and during new staff induction

Attendance

Site Engineer, Environment and Sustainability Manager, delegated staff member and Site Engineers

As required and during new staff induction Site Engineer, Environment and Sustainability Manager, delegated staff member and Site Engineers

As required and during new staff induction Site Engineer, Environment and Sustainability Manager, delegated staff member and Site Engineers

Construction activities can be affected by a number of different external and internal factors, such as weather conditions or equipment malfunction, which can contribute to an increase in dust emissions. Various control and mitigation measures will be carried out on-site to prevent such effects, and monitoring and inspection procedures will be used to assess the level of dust emissions both on the main works site and beyond its boundary. Recording relevant monitoring and inspection results, as well as the conditions of external and internal factors, can help assess if control measures are being effective, and to define appropriate corrective or preventive actions in case any undesirable effects are detected.

The procedures for recording daily air quality inspections are detailed below:

• The Construction Manager (or delegated person) will fill out an Air Quality Daily Log (refer Appendix D) form each day and maintain the record on site.

• The following information will be recorded:

o Records of dust monitoring trigger events specified by this DWP, including identification of the monitor ID which registered the trigger event, the time and the averaging period of the TSP trigger event;

o Any dust control equipment malfunctions and any remedial action(s) taken;

o Results of the Visual Inspections of dust emissions (refer section 6.2);

o General weather conditions during the day (i.e. windy, calm, warm, rain, etc.);

o The frequency of watercart and/or water sprinkling system use; and

o The date and signature of the person entering the information.

The key management roles in relation to environmental management during construction are outlined in Section 4.1 of the CEMP. Specific roles relating to this AQ DWP are detailed in Table 10-1

Table 10-1: AQ DWP Environmental Management Roles

Organisation Role

Link Alliance NAL Deputy Construction Manager and Project Managers

Environment and Sustainability Manager or delegated staff member

Responsibilities

Overall responsibility for site environmental management. Reviewing CEMP and sub-plans, including the AQ DWP.

Reporting on environmental performance.

Inspection of works to assess compliance with the AQ DWP and sub-plans.

Assess requirement for alternative dust management approach. Update and maintain the environmental portion of the Project Risk Register.

Assess the requirement for odour monitoring.

Construction Manager or delegated staff member

Air Quality Subject Matter Expert

Report to CRLL any changes to construction techniques or natural environmental changes which require alterations to existing consents or new resource consents.

Maintain Daily Logs and Complaint Records. Training of all staff including subcontractors.

Prepare, review and update AQ DWP.

Provide advice for dust management/monitoring measure reviews, dust investigations, odour monitoring and AQ DWP specific training requirements

Review dust and meteorological monitoring results

Site Engineers Supervise subcontractors to ensure implementation of environmental controls.

Undertake daily site inspections and environmental monitoring. Coordinate and implement mitigation actions (e.g. in relation to trigger values exceedances or complaint).

Ensure environmental erosion and sediment control works are installed and maintained.

Ensure all staff are aware of environmental requirements and management measures are implemented and maintained to ensure ongoing effectiveness.

Auckland Council Monitoring and Compliance Team

Approve the CEMP, including the AQ DWP and other sub-plans. Auditing to assess that compliance with the AQ DWP.

This AQ DWP is a live document that will be reviewed and updated at least annually, or as a result of a material change to the main works, identification of increasing dust levels or potential for nuisance identified in monitoring required under this DWP, or to address unforeseen adverse air quality effects arising from construction, or unresolved complaints. Refer to sections 1.9 and 6.7 of the CEMP for further detail on the review and updating process

Approval from Auckland Council will be required for any relevant revisions of the AQ DWP that are of a material nature.

A annual review of the AQ DWP will take into consideration:

Compliance with the designation or consent conditions, the CEMP, DWPs and MPs (including site specific plans) and material changes to these plans

Any significant changes to construction activities or methods

Key changes to roles and responsibilities within the main works team

Changes in industry best practice standards

Changes in legal or other requirements (social and environmental legal requirements, consent conditions, relevant policies, plans, standards, specifications and guidelines)

Results of inspections, monitoring and reporting procedures associated with the management of adverse effects during construction

Comments or recommendations from Auckland Council regarding the CEMP, DWPs and MPs

Unresolved complaints and any response to complaints and remedial action taken to address the complaint

Any further information obtained in relation to the presence of hazardous material in dust emissions from construction activities at the Site including composition levels of silica, asbestos, erionite or other hazardous material4

Reasons for making changes to the AQ DWP will be documented. A copy of the original AQ DWP document and subsequent versions will be kept for the main works records and marked as obsolete. Each new / updated version of the AQ DWP documentation will be issued with a version number and date to eliminate obsolete AQ DWP documentation being used.

A summary of the review process will be provided annually to Auckland Council and made available to Council on request.

4 Receipt of further information relating to increased levels of hazardous material in dust emissions from the Site may initiate a review of this DWP.

Table A identifies the ISCA Credit Requirements relevant to this AQ DWP and where they are addressed in the document.

Table A: ISCA requirements

Credit

DIS-4

Level 1

DIS-4

Level 1

DIS-4

Level 1

DIS-4

Level 3

Measures to minimise adverse impacts to local air quality identified and implemented

Monitoring of air emission and/or quality is undertaken at appropriate intervals

Monitoring of air emission and/or quality is undertaken in response to complaints

Monitoring and Modelling demonstrates no exceedances of air emission or air quality goals

Table 5-1

Section 6

Section 7.2

Section 6

Also refer to main works Erosion and Sediment Control Plan

Note dust trigger levels specified in section 6.3.2 are not intended as air quality goals.

Also refer to Monitoring Results and Reports.

The risk of adverse off-site dust impacts and the level of dust mitigation and management processes required to minimise will vary depending on various factors including:

• Proximity of activity to sensitive locations in the surrounding environment;

• Weather conditions such as wind speed and whether the ground is dry; and

• The dust emission potential associated with the type of activity being undertaken

The objective of this dust risk assessment (DRA) procedure is to provide guidance to the Environmental and Sustainability Manager, and site supervisors of the level of dust management procedures that should be implemented depending on what activity is being undertaken on site. The DRA procedure is based on those implemented by London Council and is outlined in Figure C1 below5,6

Calculate environmental dust senstiivity from local weather conditions and proximity of sensitive receptors (Table C-1).

Calculate dust risk for each activity to be undertaken (Table C-2).

Ensure the appropriate level of dust management processes are implemented (section 5.2), and that the dust risk is displayed on-site.

The calculation of environmental dust sensitivity (and potential fort dust transport) requires identification of the following:

1. Identify location of nearest residential activity to the works activities to be undertaken and identify approximate separation distance for each works activity.

2. Review local weather forecast over works period for wind speeds (e.g. via https://www.metservice.com/towns-cities/auckland/auckland-central) and on-site meteorological data for rainfall in preceding 48 hours.

With this information the environmental dust sensitivity rating can be calculated from Table A-1 below.

5 The Control of dust and Emissions During Construction and Demolition. Greater London authority, July 2014.

6 Guidance on the assessment of dust from demolition and construction, Version 1.1, Institute of air Quality Management, February 2014.

Table C-1 Environmental Dust Sensitivity Calculation

Environmental dust sensitivity

Meteorological influences

Predicted 1-hourly average wind speeds

>5 m/s AND <1 mm of rain in the preceding 48 hours

Predicted 1-hourly average wind speeds

>5 m/s OR <1 mm of rain in the preceding 48 hours

Predicted 1-hourly average wind speeds

<5 m/s AND >1 mm of rain in the preceding 48 hours

Receptor sensitivity

Residential receptor within 100 m of activity

Residential receptor within 200 m OR other activities within 100 m of activity

The dust risk is subsequently derived from the dust emission potential of each prescribed activity associated with the works and the calculated environmental risk.

Table C-2 Overall dust risk calculation

Overall dust risk of activity

Activity

Earthworks (including excavation and handling of spoil)

Vehicle movements over unpaved surfaces

Demolition/removal of hardstand

Handling of cement and bentonite (or other bulk solid/powder materials including pneumatic conveyance)

Vehicle movements over paved surfaces

* Each activity has a different dust emission potential

The calculated dust risk should be displayed on-site to ensure site staff implement the appropriate level of dust management procedures as specified in section 5.2 The dust management procedures for each activities’ risk level is described in Appendix C.

Page 42 | Mount Eden Enabling Works

To be completed by the construction manager or others involved in the implementation of controls based on the requirements of section 5.2