LAMINATED FABRICS

ADVANCED LAMINATED FABRICS FOR PROFESSIONAL PERFORMANCE

ADVANCED LAMINATED FABRICS FOR PROFESSIONAL PERFORMANCE

At Concordia Textiles, we take pride in being a vertically integrated European manufacturer. We maintain full control over every stage of production, starting from weaving and knitting, through dyeing and printing, to coating, lamination and finishing. This ensures consistent quality, traceability, and the flexibility to meet the most demanding specifications in the PPE, military, police, and corporate wear sectors.

Our state-of-the-art facility is equipped for:

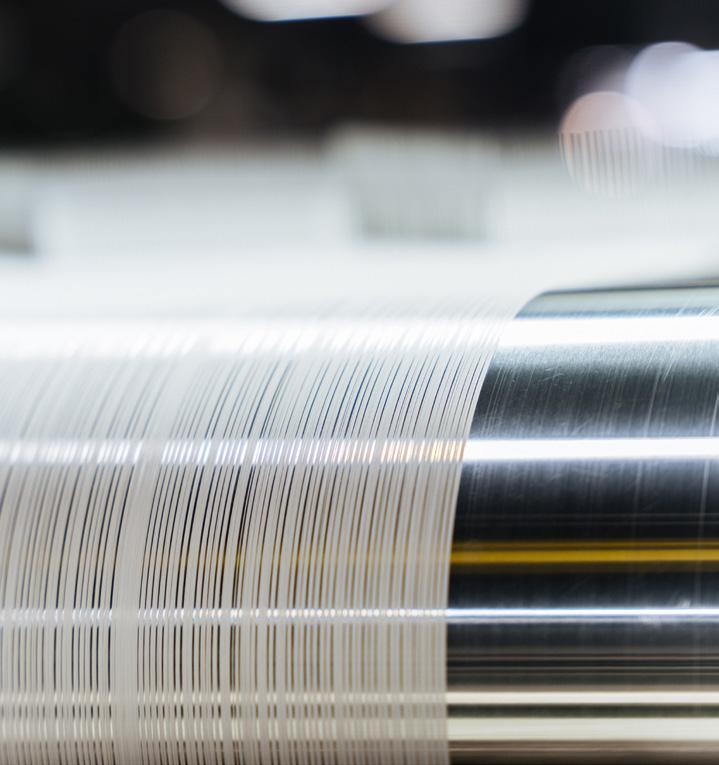

• Weaving High-performance base fabrics

• Knitting Circular knitting

• Dyeing & finishing With advanced chemical treatments

• Printing State of the art printing machine

• Coating Capabilities for additional protection and performance

• Dot lamination & foam lamination For enhanced functionality

• In-House accredited Lab Performance validation (e.g. hydrostatic head, Ret, domestic and industrial wash resistance,...) Seam-sealing compatibility testing

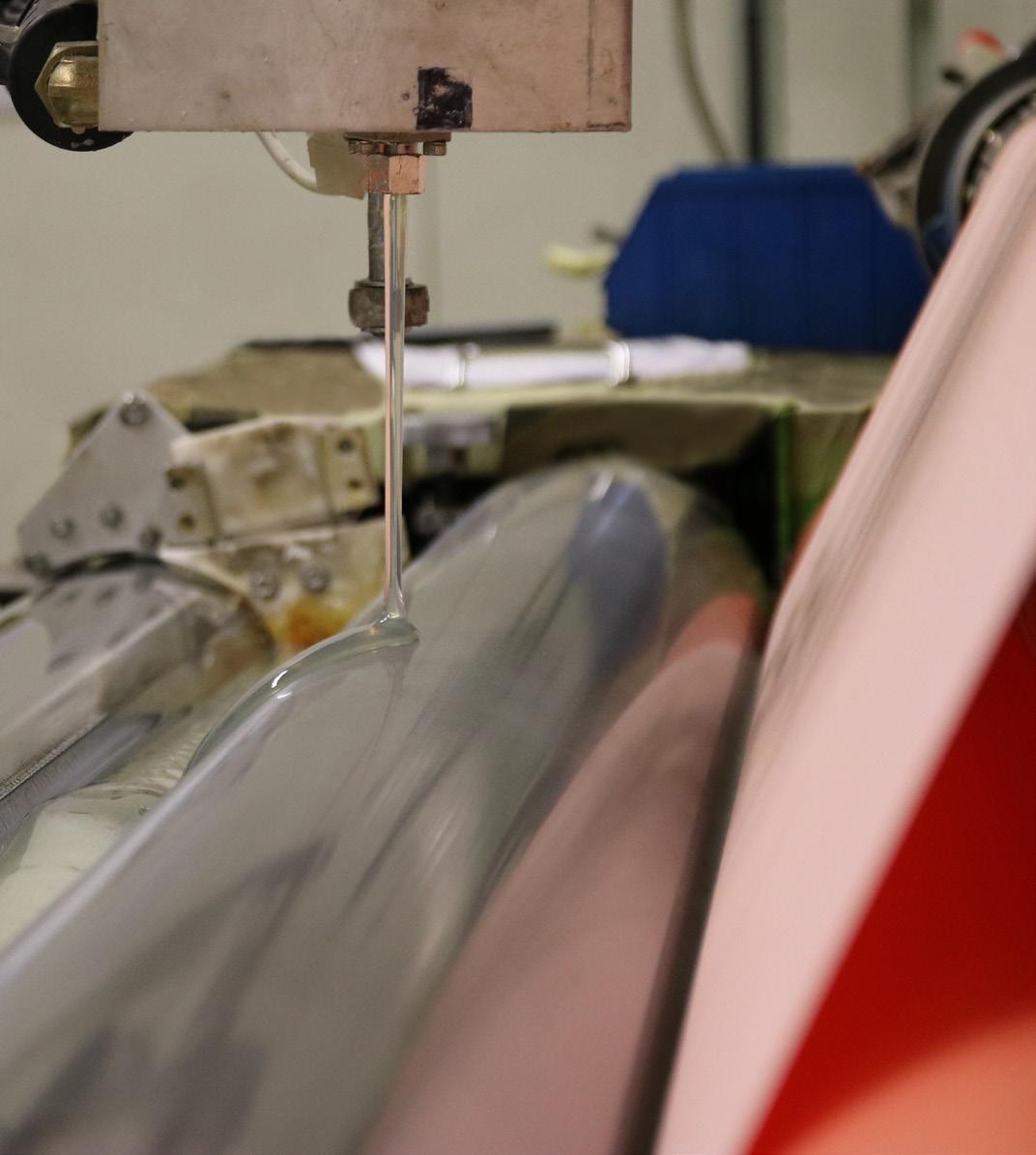

This unique technology applies a foamed layer to the fabric, followed by stenter drying and membrane application pressure roller. During this step, the foam partially collapses, creating a porous structure that enables moisture vapor transmission.

Unlike dot lamination, this method applies chemistry over the entire fabric surface. The result is stronger adhesion, a higher add-on, improved wash resistance (ISO 6330), and longer durability. It is OekoTex® Class 3 certified and specially developed for PU membranes This process enhances arc protection and insulation in flame-retardant products, delivering fabrics that are both stronger and more comfortable. It is mostly used in 2-layer systems.

Dot lamination uses a range of reactive, solvent-free polyurethane that is melted and applied in a dot pattern via gravure rollers. The adhesive is applied in a controlled pattern that only partially covers the fabric, preserving breathability. A membrane is then laminated on top, with the process carefully regulated through optimized tension and pressure.

Different gravure patterns can be used to adjust dot density and volume, resulting in lower add-on and fabrics that are lighter and softer, tailored to the enduse. The process supports both 2- and 3-layer systems and requires no heat during curing, making it more ecological. In addition, it offers full flexibility in the choice of membrane. It also allows efficient finishing, whether fluorine-containing or fluorine-free, on one side of the fabric. This improves adhesion, taping performance, and reduces overall chemical use.

TPU

Flexible, durable, and waterproof.

Thermoplastic Polyurethane Offers good elasticity and abrasion resistance. Often used in breathable and stretchable garments.

PES

Cost-effective and chemically stable. Polyester Membrane Less breathable but good for basic waterproofing and durability. Does not support industrial laundering.

PU

Soft, breathable, and lightweight. Polyurethane Widely used in PPE for comfort and microporous / compact hydrophilic moisture management.

ePTFE Highly breathable and waterproof.

Expanded Polytetrafluoroethylene Used in high-performance microporous PPE and mostly combined with fleece.

ePTFE / PU

Combines the breathability of ePTFE

Expanded Polytetrafluoroethylene with the softness and tapeability of PU, microporous / PU compact hydrophilic ideal for multi-layer systems that demand both comfort and protection. Also resistant to chemicals.

Possible to create 3-layer systems by combining the membrane with various inner liners. These can include knitted fabrics, both warp and circular knit, made from polyester, polyamide or... offering stretch, comfort, and durability. For improved insulation, fleece can be used or for reinforcement an additional fabric can be added.

This versatility allows tailoring the final laminate to specific PPE applications, from lightweight rainwear to insulated protective gear for military and police.

COMPOSITION

55% MA / 44% CO / 1% AS + PU Foam Laminated

WEIGHT

275 g/m²

COMPOSITION

51% MA / 42% CO / 6% EOL / 1% AS + PU Laminated

WEIGHT

315 g/m²

COMPOSITION

55% MA / 44% CO / 1% AS + PES Laminated + MA / CO Fleece

WEIGHT

440 g/m²

COMPOSITION

100% PA 6 + PU Laminated WEIGHT 135 g/m²

COMPOSITION

100% PA 6 + PU Laminated

WEIGHT

140 g/m²

COMPOSITION

100% PA 6 + PU Foam Laminated

WEIGHT

165 g/m²

COMPOSITION

100% PA 6 + PU Foam Laminated

WEIGHT

235 g/m²

breathable waterproof

COMPOSITION

100% PA 6 + PU Coated + PES Fleece

WEIGHT

315 g/m²

T22987.150 I0007

COMPOSITION

100% PA 6.6 + mPTFE Laminated

WEIGHT

90 g/m²

COMPOSITION

100% PA 6.6 + PU Laminated + PA 6 Knit

WEIGHT

100 g/m²

COMPOSITION

99% PA 6.6 / 1% AS + ePTFE Laminated

WEIGHT

115 g/m²

COMPOSITION

100% PA 6.6 + PU Laminated + PA 6 Knit

WEIGHT

150 g/m²

COMPOSITION

100% PA 6.6 + ePTFE Laminated + PA 6.6 Knit

WEIGHT

185 g/m²

COMPOSITION

100% PA 6.6 + ePTFE Laminated + PA 6.6 Knit

WEIGHT

190 g/m²

COMPOSITION

85% PA 6.6 / 15% EOL + PU Laminated + PA 6.6 Knit

WEIGHT

195 g/m²

COMPOSITION

100% PA 6.6 + ePTFE Laminated + PA 6.6 Knit

WEIGHT

200 g/m²

COMPOSITION

100% PA 6.6 + PU Laminated

WEIGHT

240 g/m²

COMPOSITION 88% PA 6.6 / 12% EL + PU Laminated + PA 6.6 Knit

WEIGHT

240 g/m²

COMPOSITION

100% PA 6.6 + mPTFE Laminated + PES Fleece

WEIGHT

250 g/m²

breathable waterproof

COMPOSITION

100% PA 6.6 + mPTFE Laminated + PES Fleece

WEIGHT

300 g/m²

COMPOSITION

100% PES + ePTFE Laminated

WEIGHT

105 g/m²

COMPOSITION

100% PES + PU Laminated

WEIGHT

130 g/m²

COMPOSITION

100% PES + ePTFE Laminated

WEIGHT

145 g/m²

COMPOSITION

100% PES + ePTFE Laminated + PA 6.6 Knit

WEIGHT

165 g/m²

breathable waterproof

COMPOSITION

100% PES + PU Laminated + PES Knit

WEIGHT

185 g/m²

COMPOSITION

100% PES + ePTFE Laminated + PES Knit

WEIGHT

190 g/m²

COMPOSITION

80% PES / 19% EME / 1% AS + PU Laminated + PES Knit

WEIGHT

200 g/m²

CLIMASPRINTER PU CP

COMPOSITION

100% EME + PU Laminated + PES Knit

WEIGHT

200 g/m²

COMPOSITION

100% PES Recycled + PU Laminated

WEIGHT

215 g/m²

COMPOSITION

100% PES + PU Laminated

WEIGHT

225 g/m²

waterproof

COMPOSITION

100% PES + PES Fleece

WEIGHT

235 g/m²

COMPOSITION

100% PES + PES Fleece

WEIGHT

250 g/m²

100% PES Repreve® + PU Laminated + PES Knit WEIGHT 250 g/m

96% PES / 4% AS + PU FR Coated + MA / CO Knit WEIGHT 265 g/m² COMPOSITION

COMPOSITION

100% PES + PU Laminated + PES Fleece

WEIGHT

285 g/m²

breathable waterproof

COMPOSITION

100% PES + mPTFE Laminated + PES Fleece

WEIGHT

295 g/m²

COMPOSITION

100% EME + PES Fleece

WEIGHT

310 g/m²

COMPOSITION

94% PES / 6% EL + PU Laminated + PES Fleece

WEIGHT

310 g/m²

COMPOSITION

80% PES / 19% EME / 1% AS + PES Fleece

WEIGHT

350 g/m²

COMPOSITION

99% PES / 1% AS + MA / CO Fleece

WEIGHT

390 g/m²

OMNIPROTECTOR LIGHT

OMNIFLAMACRYL STRETCH PU FF

FLAMACRYL SOFTSHELL

NAUTICA RIPSTOP PU FF CP

NAUTICA PU FF CP

OMNIMAN

OMNITRAFFIC

POLARMAN

T22987.150 I0007

CLIMANAVIGATOR LITE PU GREY

OMNICOVERMAT AS PTFE

CLIMAHASTA LITE PU KHAKI

CLIMASERICUM PTFE

CLIMALORICA PTFE BL

CLIMALORICA STRETCH PU

CLIMASCUTUM PTFE

OMNI ADAMAS PU

CLIMALANA STRETCH PU

POLARCETRATUS mPTFE

POLELORICA mPTFE BL IR

OMNIWALKER PTFE CP

OMNIBRICK DULL PU

OMNIBRICK PTFE

OMNITUNICA PU

ICEBERG DULL PTFE

ICEBERG DULL PU

ICEBERG PTFE BL

CLIMAGRID PU CP

CLIMASPRINTER PU CP

OMNIGASTON PU FF CP

OMNIGARDIA PU

SOFTCRAWLER FF CP

SOFTBRICK BL

CLIMAPIQUE REPREVE® 260 PU FF

CLIMASECURE

OMNICOTTONESTER 265 AS NEW PU

POLEBRICK DULL PU

POLEBRICK mPTFE BL

SOFTJOGGER CP

POLARTUNICA PU

SOFTGRID CP

SOFTSHELL FR 390

55% MA / 44% CO / 1% AS + PU Foam Laminated

51% MA / 42% CO / 6% EOL / 1% AS + PU Laminated

55% MA / 44% CO / 1%AS + PES Laminated + MA / CO Fleece

100% PA 6 + PU Laminated

100% PA 6 + PU Laminated

100% PA 6 + PU Foam Laminated

100% PA 6 + PU Foam Laminated

100% PA 6 + PU Coated + PES Fleece

100% PA 6.6 + mPTFE Laminated

100% PA 6.6 + PU Laminated + PA 6 Knit

99% PA 6.6 / 1%AS + ePTFE Laminated

100% PA 6.6 + PU Laminated + PA 6 Knit

100% PA 6.6 + ePTFE Laminated + PA 6.6 Knit

100% PA 6.6 + ePTFE Laminated + PA 6.6 Knit

85% PA 6.6 / 15% EOL + PU Laminated + PA 6.6 Knit

100% PA 6.6 + ePTFE Laminated + PA 6.6 Knit

100% PA 6.6 + PU Laminated

88% PA 6.6 / 12% EL + PU Laminated + PA 6.6 Knit

100% PA 6.6 + mPTFE Laminated + PES Fleece

100% PA 6.6 + mPTFE Laminated + PES Fleece

100% PES + ePTFE Laminated

100% PES + PU Laminated

100% PES + ePTFE Laminated

94% PES / 6% EL + PU Laminated

100% PES + ePTFE Laminated + PA 6.6 knit

100% PES + PU Laminated + PES Knit

100% PES + ePTFE Laminated + PES Knit

80% PES / 19% EME / 1% AS + PU Laminated + PES Knit

100% EME + PU Laminated + PES Knit

100% PES + PU Laminated + PES Knit

100% PES + PU Laminated

100% PES + PES Fleece

100% PES + PES Fleece

100% PES Repreve® + PU Laminated + PES Knit

96% PES / 4% AS + PU FR Coated + MA / CO Knit

99% PES / 1% AS + PU Laminated

100% PES + PU Laminated + PES Fleece

100% PES + mPTFE Laminated + PES Fleece

100% EME + PES Fleece

94% PES / 6% EL + PU Laminated + PES Fleece

80% PES / 19% EME / 1% AS + PES Fleece

99% PES / 1% AS + MA / CO Fleece

Protective suits

Waterproof, breathable, highly visible and flameretardant.

Tactical gear and outerwear

Rugged, weatherproof, and mission-ready.

Branded uniforms and outer shells

Stylish, durable, and built for performance.

• Certified & Compliant Meeting global standards

• Diverse Product Range Solutions for every sector

• Accredited Lab ISO 17025 Testing and validation