Glass fusion technology with extended functionality and flexibility for unrivalled performance

The Cleanfire® HRx burner can operate safely with an oxygen level above 95 per cent, offering the following benefits over air-fuel technology:

• Increased flame radiation for high fuel efficiency

• Ultra-low NOx emissions

• Foam reduction capability for higher quality glass production

• Improved productivity

For further information, please contact us

proposta@gasin.com

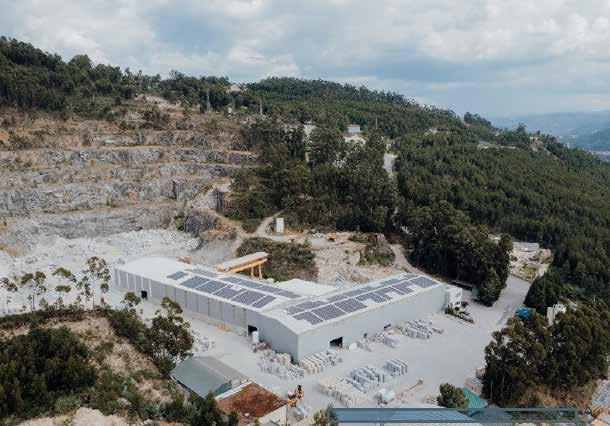

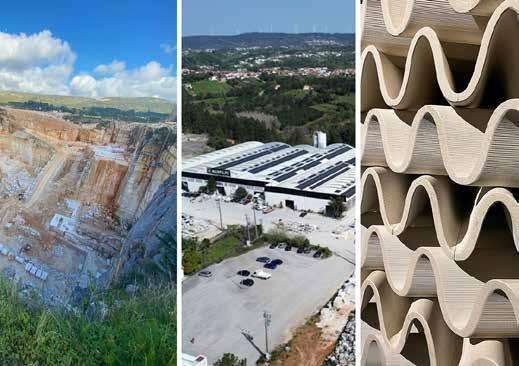

The Natural Stone industry is a pillar of the country's economy, ranking as the second-largest per capita exporter in the world and the seventh-largest producer worldwide, where exports, relative to imports, amount to more than 550%, totalling 470 million euros, with China, France, the USA, Germany and the United Kingdom as main destinations. The Portuguese Natural Stone Industry also employs around 14500 jobs, making a significant contribution to the national economy.*

This sector combines the tradition and inherent beauty of Natural Stone with technological modernisation, increasingly stringent performance requirements in modern construction, design and high standards of sustainability, resulting in a product with high commercial value that is recognised internationally.

One of the world's leading showcases for Natural Stone is MARMOMAC in Italy, where innovation, tradition, design and engineering come together. It is also a privileged showcase to affirm the identity and competitiveness of an industry that, in Portugal, has managed to combine experience, technical competence and international reach.

In this context, CTCV, in close partnership with ASSIMAGRA, presents this special edition of TÉCNICA magazine, dedicated to the Portuguese presence at this international exhibition. This publication aims to showcase the talent, versatility, design and sustainability that define the national Natural Stone industry, highlighting the companies that transform it into a product of excellence daily and reinforce Portugal's international reputation in this sector.

With a clear commitment to sustainability and decarbonisation, the national Natural Stone industry wants to position itself as a leader in sustainable production. By focusing on a detailed analysis of the life cycle and carbon footprint, it is important to quantify carbon emissions, resource management and consumption at all stages of the product life cycle, certifying it with strict environmental performance criteria through Environmental Product Declarations (EPDs) in line with the requirements of the new construction product regulations and the future Digital Product Passport (DPP).

It also follows a progressive path of decarbonisation until 2050, with important milestones along the way, including a reduction in GHG emissions of between 30% and 40% by 2030, through greater investment in energy efficiency and partial electrification, a reduction by 2040 through the adoption of renewable energies and low-carbon fu-

* Source: ASSIMAGRA

els, until carbon neutrality is achieved with CO2 removal technologies and complete process electrification by 2050.

CTCV, with its mission to support industry in technological innovation and the implementation of more sustainable and decarbonised processes, is a unique partner of this industry, supporting its transition and enhancing competitiveness in highly demanding markets.

Jorge Marques dos Santos Chairman of the Board of CTCV

PORTUGUESE NATURAL STONE AT MARMOMAC: A JOURNEY OF EXCELLENCE AND GLOBAL RECOGNITION

STONEBYPORTUGAL: THE GLOBAL SIGNATURE OF PORTUGUESE NATURAL STONE

ROAD TO 2050: Towards carbon neutrality of the Natural Stone sector by 2050

ENVIRONMENTAL FOOTPRINT IN THE NATURAL STONE SECTOR: A CHALLENGE AND AN OPPORTUNITY

Pride of Stone. Raw Dialogues.

BROOT - A FERTILE DIALOGUE BETWEEN ANCESTRAL TRADITIONS AND CONTEMPORARY DESIGN

TECHNICAL GUIDE TO NATURAL STONE: FROM DESIGN TO MAINTENANCE IN CONSTRUCTION

The New Construction Products Regulation (EU) 2024/3110: Sector Context and New Requirements for the Natural Stone Industry

BIM Methodology: An Irreversible Opportunity for the Natural Stone Sector in Portugal

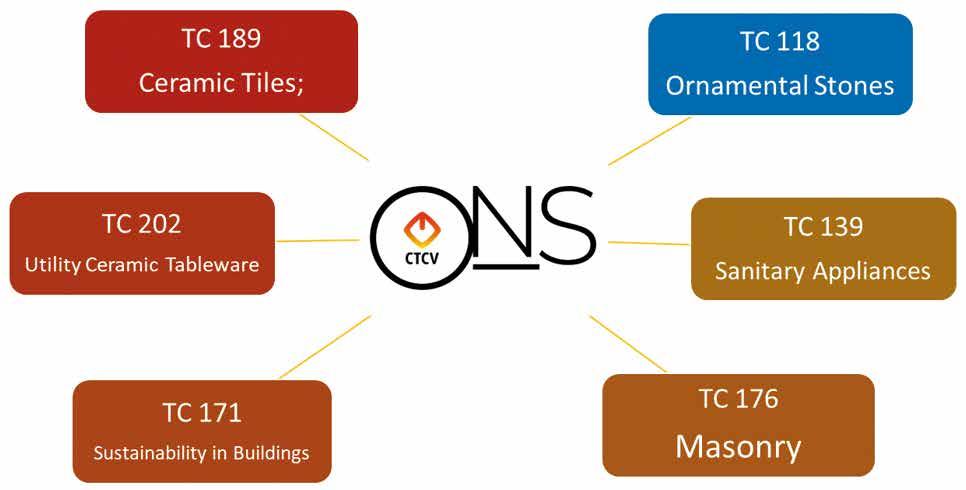

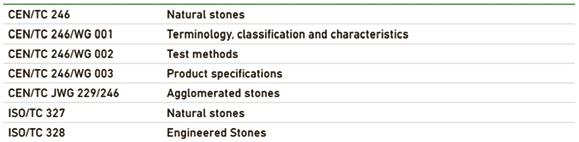

CTCV – Innovation and Technological Centre and Standardization in the Natural Stone Sector

Environmental Product Declarations and the Future of Sustainable Construction: Insights from the Stone Sector

EN 12440: A NECESSARY REVIEW OF THE DENOMINATION CRITERIA STANDARD TO ELEVATE EU NATURAL STONE IN A DIGITAL AND SUSTAINABLE MARKET

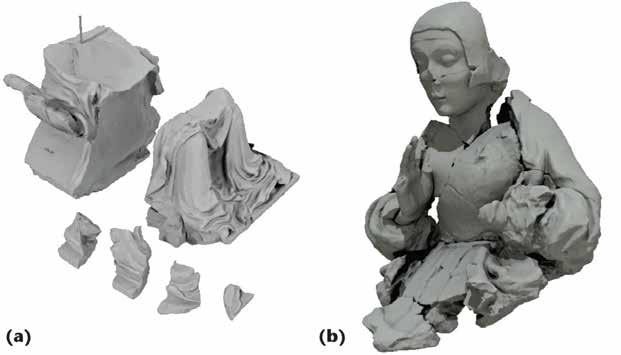

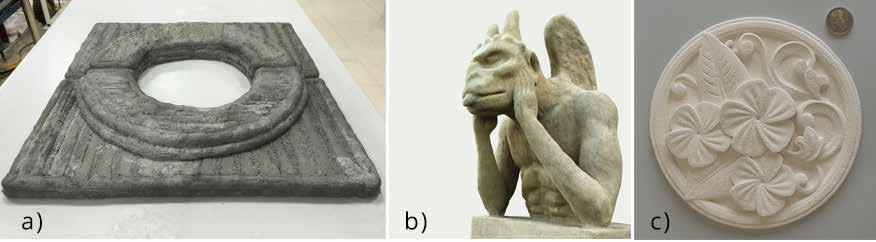

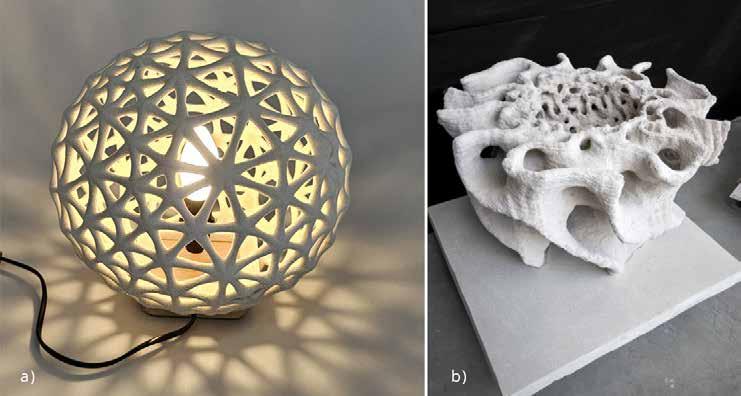

Cultural heritage in stone: potential of the use of additive manufacturing in restoration

STONE BYPORTUGAL AWARDS - EXCELLENCE AND INNOVATION IN THE INTERNATIONAL PROJECTION OF PORTUGUESE NATURAL STONE

Companies at MARMOMAC 2025

Ownership, Publishing and Editorial Office

CTCV - Innovation and Technological Centre

Rua Coronel Veiga Simão, 3025-307 Coimbra (T) 239 499 200 (E) comunicacao@ctcv.pt (W) www.ctcv.pt

VAT No.: 501632174

Director Deputy Director

António Baio Dias Sofia David

Associate Director Editor

Sandra Carvalho Jorge Marques dos Santos

Coordinator

Nuno Nossa

Contributors

Anabela Amado, A. Silva, A. Magalhães, Ana Sofia Amaral, A. Vinagre, C. Carvalho, Carlos Costa, Célia Marques, Cláudia Paiva Silva, G. Matias, Guilherme Ascensão, Helena Teixeira, Hélio Jorge, Hugo Rodrigues, Isabel Antunes, Inês Rondão, J. Carvalho, Marisa Almeida, Milene Lopes, Pedro Frade, Pedro Oliveira, P. Rebola, R. Alves, Sandra Carvalho, Sandra Chambel, Sofia Ferreira, Victor Francisco, Victor Ferreira

Design and Layout

José Luís Fernandes

Cover

Designed using Gemini AI capabilities

Printing

Gráfica Almondina - Progresso e Vida; Empresa Tipográfica e Jornalistica, Lda Rua da Gráfica Almondina, Zona Industrial de Torres Novas, Apartado 29, 2350-909 Torres Novas (T) 249 830 130 (E) geral@grafica-almondina.com (W) www.grafica-almondina.com

Print Run

500 copies

This is a registered periodical publication with ERC (Regulatory Entity for the Media) under nº 127420.

Editorial Statute available at: https://www.ctcv.pt/estatuto-editorial.pdf

Reproduction of texts, in whole or in part, is prohibited without citing the source. Signed articles reflect the views of their authors.

Start: October 2025 Duration: 120 hours.

Aimed at industry professionals, recent graduates, students, and all those who wish to deepen their knowledge of the sector.

Participants will be able to deepen their knowledge in the eld of ornamental stone industry technologies, covering processes ranging from extraction to transformation and valorisation.

This course o ers a comprehensive approach across the entire value chain, also integrating topics related to quality, innovation, and sector sustainability.

• General geology

• Occurrences in Portugal

• Geomorphological, structural, and environmental constraints of mining

• Methods and techniques of extraction processes

• Performance assessment and physical-mechanical characterisation

• Legal framework for research and mining licensing

• Processing and enhancement techniques

• Pathologies, maintenance, and restoration

• Standardisation, certi cation, and product quality

• Management systems, valorisation, and market requirements

• Circular economy, industrial symbioses, and decarbonisation

• Innovation, development, and digitalisation

Célia Marques

ASSIMAGRA – Portuguese Association of the Mineral Resources Industry

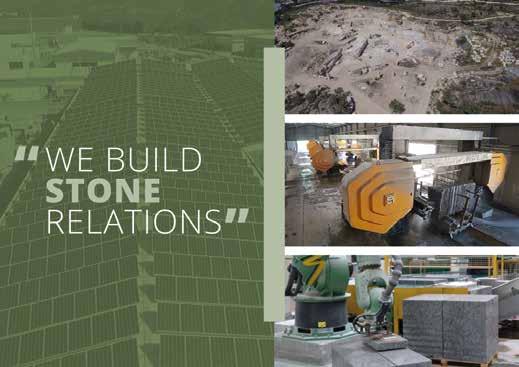

As the natural stone industry converges once again in Verona for MARMOMAC 2025, Portugal's presence stands as a testament to more than two decades of strategic vision, collaborative effort, and unwavering commitment to excellence. Our participation in this prestigious international exhibition represents far more than a commercial endeavor—it embodies the transformation of Portuguese natural stone from a regional industry into a globally recognized symbol of quality, innovation, and sustainability.

The journey of Portuguese natural stone at MARMOMAC reflects the broader evolution of our industry's internationalization strategy. Under the leadership of ASSIMAGRA—Portuguese Association of Mineral Resources Industry—for over 25 years, what began as individual company participations has evolved into a sophisticated, coordinated presence that positions Portugal among the world's leading natural stone nations. This transformation has been neither accidental nor effortless; it represents the culmination of strategic planning, collective investment, and an unwavering belief in the exceptional quality of Portuguese stone.

This remarkable presence at MARMOMAC serves multiple strategic purposes that extend far beyond immediate commercial transactions. The exhibition provides Portuguese companies with unparalleled access to global buyers and specification professionals, enabling direct engagement with decision-makers from markets spanning every continent. Simultaneously, it offers invaluable opportunities to observe emerging market trends, analyze competitor strategies, and identify new business opportunities that might otherwise remain invisible from our domestic perspective.

The evolution from individual company participation to coordinated brand presence under StonebyPORTUGAL, created by ASSIMAGRA, represents a strategic maturation that reflects our industry's sophisticated understanding of global marketing dynamics. This unified approach allows smaller Portuguese companies to benefit from collective marketing strength while maintaining their individual identities and specializations.

The brand serves as a quality guarantee that communicates Portuguese excellence to international markets, facilitating market entry and relationship development in regions where individual companies might face significant barriers to recognition.

Portugal's achievements at MARMOMAC are particularly remarkable when considered within the context of our nation's size and resources. As the 7th largest natural stone producer globally, despite having only 10.3 million inhabitants, Portugal demonstrates that excellence transcends scale. Our industry's export performance—with over 80% of production destined for international markets and export values reaching €470 million in 2024—provides the foundation for sustained investment in international marketing initiatives like MARMOMAC participation.

Looking toward the future, Portugal's participation in MARMOMAC will continue to evolve in response to changing market dynamics and emerging opportunities. The integration of digital technologies, sustainability initiatives, and design innovation will shape how Portuguese companies present themselves and engage with global markets. The foundation of excellence, collaboration, and strategic vision that has driven our success over the past decades provides the platform for continued growth and recognition.

The story of Portuguese natural stone at MARMOMAC continues to unfold, with each edition building upon the successes of previous years while opening new chapters of opportunity and achievement. As we look ahead, we do so with the knowledge that our foundation is solid, our vision is clear, and our commitment to excellence remains unwavering.

Digital Maturity Diagnosis; Natural Stone Slab Digitization and Integrated Digital Design; Quarry and Shop Floor Sensorization; Advanced Training for Professionals

ASSIMAGRA - Portuguese Association of the Mineral Resources Ind ustry

As we gather in Verona for MARMOMAC 2025, one of the world's most prestigious natural stone exhibitions, it is with immense pride that we present this special edition of CTCV's Technical Publication, entirely dedicated to Portugal's thriving natural stone industry. This publication stands as a testimony to the remarkable journey of an industry that has transformed itself into a global benchmark for quality, innovation, design, and sustainability.

The Portuguese natural stone sector exemplifies the power of international markets as a catalyst for industrial excellence. As a predominantly export-oriented industry, internationalization has not merely been a growth strategy – it has been the fundamental driver that has shaped our sector's identity, competitiveness, and continuous evolution. With over 80% of our production destined for international markets, the sector has developed an acute understanding of global standards, diverse cultural preferences, and the most demanding technical specifications.

This export-driven approach has cultivated a culture of innovation within Portuguese companies, compelling them to continuously invest in advanced technologies, sustainable practices, and design excellence. The result is an industry that does not simply extract and process stone, but creates solutions that enhance architectural projects worldwide, from the most iconic buildings in major capitals to intimate residential spaces that demand the highest levels of craftsmanship.

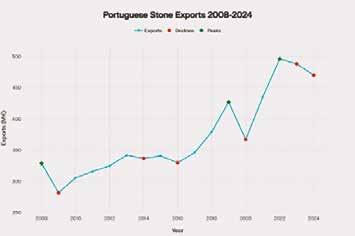

The statistical performance of Portuguese natural stone exports since 2008, year when ASSIMAGRA started to have sectorial statistics, tells a compelling story of resilience, adaptation, and strategic growth. Despite facing significant global challenges, including the 2008 financial crisis, European debt crisis, and the recent pandemic, the sector has demonstrated remarkable stability and growth momentum.

From an export value of 329 million Euros in 2008, the industry achieved its historical peak of 496 million Euros in 2022, representing

a 51% increase over this period. Even with the natural market adjustments of recent years, exports maintained strong performance at 470 million Euros in 2024, demonstrating the sector's fundamental strength and market positioning.

The sector's export resilience is further evidenced by its consistent trade surplus, maintaining coverage rates that have ranged from 438% to over 924%, meaning Portugal exports between four to nine times more natural stone than it imports. This extraordinary performance reflects not only the superior quality of Portuguese stone but also the industry's capacity to create value-added products that command premium prices in international markets.

Volume performance has been equally impressive, with exports reaching peak quantities of 2.2 million tons in 2019, stabilizing around 1.8 million tons in recent years. This combination of value and volume growth indicates a successful strategy of market diversification and product sophistication.

Portugal has earned its position as the seventh-largest producer and extractor of natural stone worldwide, a remarkable achievement

for a country of 10.3 million inhabitants, and a very small footprint area. This ranking reflects not just natural geological advantages, but decades of investment in technology, expertise, and market development.

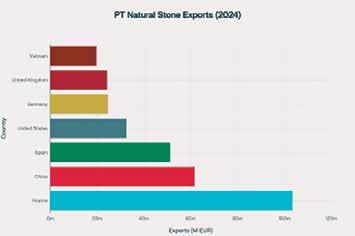

The global reach of Portuguese natural stone is exemplified by its diverse export destinations. France remains our leading market with 103.4 million Euros in imports, followed by China at 61.6 million Euros and Spain at 51.2 million Euros. The presence of markets as varied as the United States, Germany, the United Kingdom, and Vietnam demonstrates the universal appeal and adaptability of Portuguese stone products.

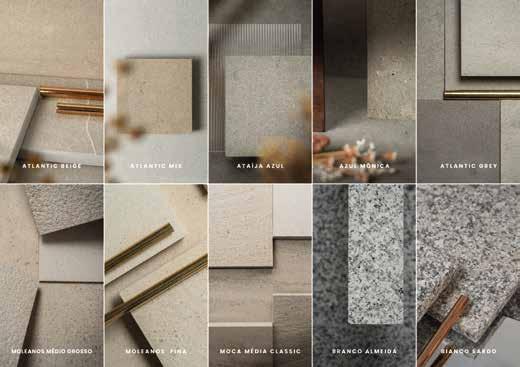

The international recognition of Portuguese stone extends beyond commercial success. Five Portuguese stones have been officially recognized as "Heritage Stones" by the International Union of Geological Sciences (IUGS): Ançã limestone, Estremoz marble, Lioz limestone, Arrábida breccia, and Porto granite. This recognition underscores the cultural and historical significance of Portuguese natural stone in global architectural heritage.

ASSIMAGRA: Over 25 Years of Internationalization Leadership

For more than two and a half decades, ASSIMAGRA – Portuguese Association of Mineral Resources Industry – has been the driving force behind the sector's internationalization strategy. Founded in 1964 as the National Guild of Marble, Granite and Similar Rock Industries, ASSIMAGRA transformed in 1974 and has since evolved into a sophisticated organization that combines sectoral representation with strategic market development.

The association's internationalization efforts are embodied in successive INTERSTONE projects, comprehensive programs that combine traditional trade fair participation with innovative digital marketing strategies. The current INTERSTONE 2025/2026 project, with a total

eligible investment of €3.8 million and €1.87 million in incentives, demonstrates the scale and ambition of these coordinated efforts.

These projects include participation in major international fairs across different continents, in strategic regions, development of digital content and platforms, access to online marketplaces and the support for the companies to create their own webstores, with the objective to support Portuguese companies in their global expansion. The collaborative approach allows small and medium enterprises to access international markets that would be prohibitively expensive to approach individually.

ASSIMAGRA's commitment to internationalization extends beyond traditional commercial activities. Initiatives like the First Stone with a disruptive approach involving architects, designers and artists to work with Portuguese Natural Stone, as never before and more recently BROOT, to create innovative dialogues between Portuguese stone and other sustainable materials, are examples of excellence of what is also developed by ASSIMAGRA to step forward to the future of the Portuguese Natural Stone.

The internationalization strategy of Portuguese natural stone is fundamentally anchored in the StonebyPORTUGAL brand, a sophisticated marketing platform that encapsulates the sector's commitment to quality, innovation, and sustainability. This sectoral brand represents far more than a commercial identifier – it embodies a comprehensive value proposition that communicates Portuguese excellence to global markets.

StonebyPORTUGAL was developed to address a critical need in international markets: the ability to communicate coherently and credibly the unique attributes of Portuguese stone products and companies. The brand serves as a unifying element that allows individual companies to benefit from collective marketing strength while maintaining their individual identities and specializations.

The brand strategy includes multiple dimensions of value creation. It emphasizes the geological uniqueness of Portuguese stones, the advanced technological capabilities of processing companies, the design innovation that characterizes Portuguese applications, and the environmental sustainability that guides modern extraction and processing practices. This multifaceted approach enables Portuguese companies to compete effectively in premium market segments where value exceeds price considerations.

Digital integration is a cornerstone of the StonebyPORTUGAL strategy. The brand's digital platform serves as a comprehensive resource for architects, designers, and specification professionals worldwide, providing technical information, case studies, and direct connections to Portuguese companies. This approach recognizes that modern

commercial success requires sophisticated digital presence combined with traditional relationship-building.

The brand's effectiveness is demonstrated through its adoption by Portuguese companies participating in international fairs and its recognition by global industry professionals. StonebyPORTUGAL has become synonymous with quality and reliability, facilitating market entry and relationship development in regions where Portuguese companies might otherwise face significant barriers to recognition.

As this special edition of TECNICA demonstrates through its comprehensive coverage of technical innovations, sustainability initiatives, and company showcases, the Portuguese natural stone industry stands at a remarkable inflection point. With 60 years of ASSIMAGRA leadership, over 25 years of systematic internationalization efforts, and a proven track record of export excellence, the sector is uniquely positioned for continued global expansion.

The industry's 14,000 professionals, working across more than 2,000 companies, represent a formidable combination of traditional craftsmanship and modern technological capability. The sector’s €1.2 billion annual turnover and consistently strong export performance provide a solid financial foundation for ongoing investment in innovation, sustainability, and market development.

Portuguese natural stone has increasingly captured the attention of architects, designers, and developers seeking authenticity, durability, and sustainability. Strategic initiatives like StonebyPORTUGAL have helped redefine the global perception of Portuguese stone — not just as a construction material, but as a medium for culture, art, and design.

Projects such as First Stone have exemplified this shift, bringing together renowned international architects and artists to explore the creative and structural potential of Portuguese stone. Similarly, the Life of Marbel project has showcased how stone can be integrated into contemporary architecture and sustainable design narratives, bridging heritage with future-forward thinking. More recently, BROOT has pushed boundaries by combining digital design, sustainability, and biomimicry to present Portuguese stone in radically new formats and environments — from urban interventions to experimental pavilions.

These initiatives are more than showcases; they are strategic instruments that open new markets, attract new audiences, and elevate the Portuguese natural stone sector to new realms of visibility and prestige.

Looking ahead, the challenges and opportunities are clearly defined. Global demand for natural materials continues to grow, driven by environmental awareness and a design shift towards authenticity and

longevity. Portuguese companies are exceptionally well-positioned to respond to this demand, leveraging their unique geological resources, advanced processing expertise, and growing design culture.

The path forward will require continued commitment to the principles that have driven success: international focus, collaborative action through ASSIMAGRA, strategic brand development through StonebyPORTUGAL, and unwavering dedication to quality and innovation. As we continue to build on these solid foundations, the Portuguese natural stone industry is poised not only to grow — but to lead — bringing the timeless beauty and enduring value of Portuguese stone to visionary projects around the world.

Manufacturing of components in limestone, granite and marble Development using new materials and applications

Contact: inovacao@ctcv.pt

CTCV materials : habitat | iParque Parque Tecnológico de Coimbra, 3040-540 ANTANHOL (T) 239 499 200 (E) centro@ctcv.pt

Isabel Antunes, Inês Rondão, Marisa Almeida, Pedro Frade, Anabela Amado, Milene Lopes, Carlos Costa, Sandra Chambel, Victor Francisco, Sandra Carvalho

CTCV - Innovation and Technological Centre

ROAD TO 2050 – Roadmap for the Decarbonization of the Natural Stone Sector, is a two-years project led by ASSIMAGRA – Portuguese Mineral Resources (assimagra.pt) with the support of Technological Centre of Ceramics and Glass (CTCV), and funded by Recovery and Resilience Plan (NextGenerationEU). It is the only sector-specific initiative in Portugal dedicated to the Natural Stone sector, with the aim of outlining a roadmap to achieve carbon neutrality.

The main objective of Roadmap for the Decarbonisation of the Natural Stone Sector is to develop a reference document that provides guiding and feasible solutions to support the Natural Stone sector in decision-making on its path to decarbonization, aligned with national and European climate goals.

The roadmap addresses the most relevant decarbonisation vectors for the sector, along with the most relevant technologies and measures of decarbonisation currently available. It also takes into account technologies that, while currently at an early stage of development, show potential for implementation in the medium to long term. The roadmap further seeks to assess the effectiveness of the proposed decarbonisation strategies on the reduction of GHG emissions projected for this sector by 2050, while evaluating the associated economic impacts through the definition of cost-effective pathways. Among the decarbonisation strategies addressed for the sector, particular emphasis is given to energy efficiency, use of renewable energy and electrification of vehicles and equipment, the use of low-carbon fuels, industrial process digitalisation and adoption of circular economy strategies.

Alongside the development of the roadmap, a training and knowledge dissemination plan was carried out to ensure the involvement of all stakeholders and to encourage a sector-culture that supports the implementation of the identified measures, through the discussion and dissemination of decarbonisation strategies. Among the central actions outlined in the plan were included:

• creation of the project platform (roadto2050.assimagra.pt) for

dissemination of roadmap and the initiatives promoted within the scope of the project, and to serve as a decarbonization observatory, through technological monitoring in energy transition theme and environmental sustainability of Natural Stone sector.

• dissemination of project results, training, activities and educational resources, developed within the scope of the project, through traditional media, digital platforms and social media.

• organization of an Open Day involving the local community,

• development of Carbon Emissions Calculation Tool, available on the project website, designed to calculate the carbon emissions of companies operating in the Natural Stone sector. This tool also provides guidance on measures and techniques to help reduce companies’ carbon emissions, supporting them in the development and implementation of the decarbonisation roadmap for their industrial facilities.

• development of a Course on Decarbonisation of the Natural Stone Sector, aimed at training professionals within the industry, delivered in a MOOC (Massive Open Online Course) format.

• organisation of events and workshops designed to promote the project, presents its results, and engaging stakeholders in the sector decarbonation, with emphasis on the key strategies needed to achieve carbon neutrality.

The kickoff event of the ROAD TO 2050, held on 27 October 2023 in Alcobaça, officially marked the beginning of the project and saw

strong participation from various stakeholders in the Natural Stone sector. The programme featured several presentations focused on key topics for the sector’s decarbonisation, such as product life cycle assessment and its environmental footprint, Environmental Product Declarations (EPDs), and the role of digital transition in empowering companies to face new challenges.

Throughout the project, a set of regional workshops sessions was held, bringing together industry representatives, technologies pro-

viders and researchers. These sessions aimed to discuss short-, medium- and long-term decarbonisation solutions for the sector, and to gather input from industry stakeholders on the main challenges they face in the decarbonisation of their companies.

Also, as part of ROAD TO 2050 initiative, an event entitled Green Horizon: Sustainability in the Mineral Resources Sector, was held at Stone Ibérica 2025, on 28 March 2025. The event began with the presentation on the main target and decarbonization vectors outlined in the

roadmap. This was followed by the roundtable discussion Strategies for Carbon Neutrality – Challenges of the Green Transition, featuring

portunities for the sector within the context of the energy transition.

The project’s closing event was held on September 18th at Sesimbra Natura Park. One of the key moments was the presentation of the results from the Decarbonization Roadmap of Natural Stone Sector. In addition to this, the several outputs developed throughout the project were showcased. Among them was the Carbon Emissions Calculation Tool, demonstrated through a practical case study to illustrate its application.

The event also featured the official launch of the Decarbonization Course for the Natural Stone Sector, which included the screening of an explanatory video detailing the structure and functioning of the course. Furthermore, the Executive Summary of the roadmap was unveiled, with both the video and summary made accessible through the project’s official website.

ROADTO2050 arises within the framework of national and European commitments to achieve carbon neutrality by 2050. Through this roadmap, companies have access to information that guides them in finding the most effective solutions for decarbonizing their processes. More than just a regulatory obligation, the decarbonisation of the Natural Stone sector represents a strategic opportunity to modernize the sector, enhance the global competitiveness of companies, and establish Portugal as a leader in sustainable Natural

January 2026 to December 2028

Efficient and safe workplaces

Leadership

Sustainability and Decarbonisation

Circular economy

Environmental, social and corporate governance (ESG)

Energy efficiency and transition

Critical technical skills for business

Improved productivity, operational efficiency and logistics

Innovation: productive, technological and organisational

Digital economy

Industry 4.0

Artificial intelligence

Digital marketing

International markets

Business intelligence Promoted by

ASSIMAGRA - Portuguese Association of the Mineral Resources Ind ustry

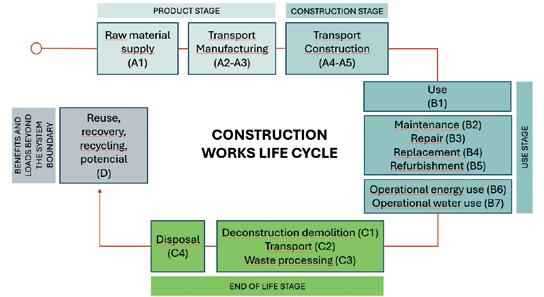

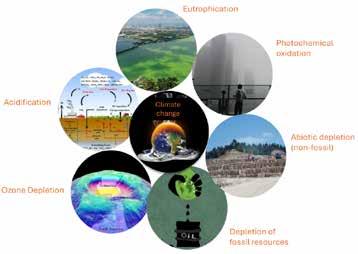

The natural stone sector today faces an unavoidable challenge - responding to the growing demands for environmental sustainability. It is within this context that the "Environmental Footprint of the Natural Stone Sector" Project emerges, promoted and coordinated by ASSIMAGRA under the Sustainable Stone by Portugal Agenda, which aims to guide the sector towards more responsible and conscious practices. By focusing on detailed analysis of carbon and water footprints, the project provides a rigorous methodology for quantifying carbon emissions and water consumption throughout all phases of the product lifecycle. This approach offers companies in the sector the necessary tools to identify critical points in their production processes, optimise them, and implement more efficient solutions, both from an operational and environmental perspective.

The credibility of the results obtained is ensured by the adoption of international standards, such as ISO 14040, ISO 14044, and EN 15804, which guarantee not only technical consistency but also the comparability of collected data. The main objective of this initiative is to equip the sector with technical and strategic knowledge, promoting proactive environmental management that, whilst reducing negative impacts, reinforces companies' image as leading agents in the transition to a more sustainable economic model.

In this transformation process, digitalisation emerges as a fundamental element for accelerating the adoption of sustainable practices. The DIGITALbuilt project represents an innovative response to the sector's needs, offering companies specialised support for digitalisation and optimisation of their production processes. This initiative recognises that the transition to sustainability cannot be dissociated from technological modernisation, providing companies with the digital tools necessary to monitor, analyse, and continuously improve their environmental performance.

Through DIGITALbuilt, companies in the natural stone sector can access advanced technological solutions that enable the integration of environmental management systems with intelligent digital platforms. These tools facilitate automated data collection on energy and water consumption, real-time analysis of sustainability indicators,

and the implementation of optimisation strategies based on scientific evidence. The digitalisation of processes not only increases operational efficiency but also ensures the precision and reliability of data necessary for rigorous calculation of environmental footprint.

Mastery of technical knowledge about the environmental footprint of natural stone today constitutes a decisive competitive advantage in the global market. This specialised knowledge enables the Portuguese sector to position itself distinctively against competing materials, demonstrating with scientific rigour and technical credibility that natural stone has always been and continues to be a genuinely sustainable material.

The ability to quantify and transparently communicate the environmental impacts of stone products represents a fundamental strategic asset. When companies master the methodologies for assessing carbon and water footprints, they can not only optimise their processes but also present concrete and verifiable data about the sustainability of their products to international markets. This technical competence becomes particularly relevant in a context where consumers and specifiers increasingly demand detailed information about the lifecycle of the materials they use.

The carbon footprint assumes a particularly relevant role given its direct relationship with current climate change. In the case of natural stone, these emissions are distributed throughout various moments of the product's lifecycle, beginning in the extraction phase and extending to its end of life. The "Environmental Footprint of the Natural Stone Sector" Project not only allows these emissions to be calculated with a high degree of detail but also identifies the main polluting sources, which include electricity consumption, the use of fossil fuels, industrial processes themselves, and transport.

In-depth technical knowledge about environmental footprint enables the sector to demonstrate with scientific data a reality that is often unknown: natural stone presents, in many cases, a significantly lower environmental footprint than alternative materials such as ceramics, concrete, or synthetic materials. This competitive advantage becomes evident when considering the complete lifecycle of products, including the exceptional durability of natural stone, its capacity for reuse and recycling, and the fact that it is a material that does not require energy-intensive manufacturing processes.

The ability to present rigorous comparative studies, based on internationally recognised methodologies, confers upon the Portuguese sector a technical credibility that translates into concrete commercial advantages. When a company can demonstrate that its natural stone products have a carbon footprint 30% lower than that of a competing material, or that its production process consumes 50% less water than industrial alternatives, it is creating a competitive differential based on solid scientific evidence.

Knowledge about the sector's footprint represents a decisive step towards aligning the sector with international commitments to decarbonisation and adoption of the best and most efficient practices in their production systems. Among the main strategies are the transition to renewable energy sources, improvement of energy efficiency, and rationalisation of logistics. These efforts are not limited to mere regulatory compliance - they are also an opportunity for companies to improve their reputation, attract new investors, and conquer demanding markets where sustainability is already a selection criterion.

Just as with atmospheric gas emissions, water also emerges as a central resource whose use must be reconsidered and rationalised. The water footprint, in this context, allows measurement of the total volume of fresh water consumed during production, which acquires particular importance in a sector where water is widely necessary - from extraction to polishing of pieces. In regions of Portugal with significant water restrictions, this management becomes even more critical.

The project contemplates the assessment of three dimensions of water: blue (captured from rivers or aquifers), green (from precipitation), and grey (necessary to dilute pollutants). With this data in hand, it is possible to detect inefficiencies and advance with solutions such as recirculation and treatment of used water - or, furthermore, the adoption of technologies that reduce consumption. This is, once again, an approach that not only protects the environment but generates tangible economic benefits. Additionally, it allows companies to reinforce their socioeconomic commitment to operate and demonstrate capacity to respond to the growing demands of the market and society.

For this transition to be successful, it is essential that the sector adopts a continuous commitment to monitoring and controlling its environmental parameters. The use of meters and sensors, for example, already allows real-time monitoring of energy and water consumption, identification of usage patterns, detection of failures, and swift action. Well-structured control also involves clear definition of environmental targets, standardisation of procedures, and continuous training of teams.

The integration of new technologies - such as digital platforms for environmental management - constitutes decisive support here. The DIGITALbuilt project exemplifies this approach, offering technological solutions that enable companies to integrate environmental monitoring into their operational management systems. These solutions provide updated and real-time data, conferring greater precision and speed to decision-making, whilst facilitating the implementation of continuous improvement strategies based on scientific evidence.

The combination of rigorous technical knowledge of environmental footprint and advanced digital tools creates ideal conditions for the natural stone sector to position itself as a leader in the transition to a more sustainable economy. This leadership is not based merely on declarations of intent, but on concrete data, scientific methodologies, and innovative technologies that allow unequivocal demonstration of the intrinsic sustainability of natural stone.

In summary, sustainability in the natural stone sector should be understood as a permanent journey of improvement - a process supported by rigorous measurements, informed decisions, and a proactive attitude. It is not merely about protecting the environment: it is about building long-term resilience and competitiveness, equipping the Portuguese sector with the technical and technological tools necessary to demonstrate to the world that natural stone is, and always has been, a sustainable and responsible choice.

Cláudia Paiva Silva MINERAL - Collaborative Platform

What is luxury? How can we describe the word without falling into the trap and deception of the superficial, unnecessary spending, or ostentation? Is luxury confined only to material goods, or does it go beyond that, being involved in a brand, a tradition, the passing down of oral and written word, manual activity, or even in the identity and culture of a region, of a country?

Luxury, in current times, transcends this superficiality, focusing on quality, exclusivity and sustainability. It is the search for authentic, personalized and memorable experiences, reflecting values of well-being and social responsibility. Luxury is having time, having comfort, and having the pleasure of enjoying products and services that respect ethics and the environment.

It may represent a lifestyle that privileges excellence and attention to detail, but as long as it promotes conscious and balanced consumption. In essence, modern luxury is the harmonious integration between pleasure, ethics and authenticity, valuing what really matters. And when associated with brands that characterize the cultural identity of a country, it gains a rich and meaningful dimension.

In Portugal, for example, the use of natural stone, such as Alentejo marble, or schist and granite, further north, represents a luxury rooted in tradition, history and artisanal excellence. These stones, worldwide recognized for their quality and beauty, transcend mere aesthetic and material value, symbolizing cultural heritage and skill transmitted through generations. In this context, we are not only referring to possessing a high-quality product, but mainly we can connect with the history and cultural identity of the country.

Companies that work with natural stone in Portugal stand out for their respect for sustainable practices and commitment to preserving traditional techniques, while incorporating innovation and contemporary design. This balance between tradition and modernity offers a unique and authentic experience to consumers, valuing origin and the creation process.

Thus, the luxury of natural stone in Portugal reflects authenticity, exclusivity and durability. It rises as a symbol of national identity, where each piece tells a story and carries the essence of a rich and diversified culture. Luxury, therefore, is the celebration of cultural authenticity through products and practices that honor tradition while looking to the future. And we have several examples, besides marble, schist or granite, the lioz limestone, of unique and unquestionable beauty, has been used in great national works, historical and secular, as well as in the most modern buildings, inside and outside our borders.

The Museum of Art, Architecture and Technology (MAAT) in Lisbon, presents a facade covered with white limestone tiles, and the Leixões Cruise Terminal, in Porto, which uses local granite, demonstrating the harmonious integration between tradition and innovation.

National natural stone companies combine traditional quarrying and processing techniques with advanced technologies, producing materials that are exported for premium luxury projects around the world. From the Grand Mosque in Abu Dhabi or the Perelman Performing Arts Center at Ground Zero in New York that apply Portuguese marble, to the application of limestone from the central region in various international projects, true pieces of art and engineering, there are countless examples of works around the world with our stone that make us very proud.

However, the combination of sophistication, status, luxury, craftsmanship and tradition can be united in a single name. BROOT – Dialogues from Within, a project by ASSIMAGRA, curated by OLIVAH, was born from the desire to combine stone work with Portugal's secular and ancestral traditions. Mixing different types of stone, it goes to each region of the country, seeking the best that is made in local industry. Various raw materials that, together with stone, give rise to unique works of art, from drawings, ideas and manual work that crosses generations. A proposal for interior and intrinsic dialogue of people and knowledge, allowing the real luxury that is our home, our inspiration and our country.

ASSIMAGRA - Portuguese Association of the Mineral Resources Ind ustry

More than a project that promotes dialogue between different Portuguese materials, Broot is a tribute to the delicacy and fertility of what emerges from the earth. With a contemporary perspective on an ancestral tradition, this singular initiative celebrates the millenary heritage of Portuguese natural stone, transforming it into a laboratory of innovation and creativity.

The BROOT project, promoted and coordinated by ASSIMAGRA and supported by the Green Agenda Sustainable StonebyPORTUGAL, is born from a profound vision of Portuguese identity. In its purest state, Broot is an ode to the natural raw materials that sprout from the earth to become works of art through the strength and talent of hands that work to change the world.

This philosophy echoes the ancestral traditions that mark the Portuguese way of being and making, where stone becomes a metaphor for permanence and transformation, fundamental elements of our cultural identity.

Funded by the Portuguese Recovery and Resilience Plan, BROOT functions as an experimental laboratory that places Portuguese natural stone in dialogue with other traditional materials of the country. The initiative aims to diversify the export potential of the sector and project the national industry, creating a bridge between ancestral wisdom and contemporary innovation.

The first collection, entitled "Dialogues", emerges from the encounter between five design studios, each exploring a specific dialogue between stone and other traditional Portuguese materials. With curation and production by OLIVAH, the collection presents an experimental approach that celebrates the territorial diversity of the country.

Studio Olivah investigates the symbiosis between two materials deeply rooted in Portuguese territory: granite from the Center-North region and burel, an ancestral fabric from Serra da Estrela. This fusion between the timeless solidity of rock and the resilient softness of wool mirrors the duality of the mountain landscape, marked by forms sculpted by the glacial era — U-shaped valleys, erratic blocks and escarpments carved by ice. The resulting pieces evoke this contrasting relief, where granite emerges in severe lines while burel insinuates itself like dense fog, molding the hardness of the terrain with gestures of shelter. In a design exercise that unites matter, time and territory, Studio Olivah reinterprets, with contemporary sensitivity, the geological and cultural memory of Serra da Estrela.

JMM Design Studio orchestrates an inspiring collection where mysticism and seduction take shape in pieces that evoke the monumentality of ancient megaliths and the organic delicacy of cork oak silhouettes. In this singular composition, Estremoz marble — noble, dense, marked by time — finds in cork a light, porous and renewable counterpart, extracted from the living skin of the montado. This encounter between stone and plant matter gives body to a dialogue

between permanence and transformation, between the ancestral past and a sustainable future. The collection thus rises as a poetic manifesto of the Alentejo landscape, revealing its mineral and natural identity, and suggesting new ways of inhabiting, interpreting and projecting the territory.

Vítor Reis Cerâmica, in Caldas da Rainha, investigates the dialogue between limestone from the Center region and red clay, in a combination that recovers and reinvents the secular traditions of Portuguese ceramics. In this telluric fusion, the fossil weight of limestone meets the warm plasticity of clay, evoking an ancestral choreography where matter and gesture intertwine. The resulting pieces become tangible testimonies of the relationship between territory and humanity — forms that, molded by fire and time, echo the history of human evolution through the art of pottery. More than objects, they are living fragments of knowledge that crosses generations, sedimenting the memory of the earth in each contour.

Studio Anansi draws inspiration from the landscapes of Vale do Côa to reinterpret, through design, the first artistic manifestations in Portuguese territory. Their creations establish a dialogue between

schist — stratified and silent stone, characteristic of the region — and acacia wood, organic and living matter, in a fusion that echoes the ancestral relationship between human beings and nature. The sinuous forms of the pieces evoke the figures of deer, horses and cattle engraved in rock, symbols of survival, mobility and reverence

for life. In this evocation of an ancestral bestiary, Studio Anansi transforms raw matter into symbolic gesture, merging art, territory and memory in a design that looks to the past with contemporary intention.

Estúdio Eneida Lombe Tavares captures the essence of Pico Island through the dialogue between basalt and wicker, materials that translate the brute force of volcanic rocks and the flexibility of vineyards that shape the landscape. Basalt, the result of ancestral eruptions, represents the solidity and resistance of the territory, while wick-

er, woven with delicacy, refers to cultivated life and the agricultural tradition of vines in stone corrals. This combination symbolizes the harmony between the natural environment and human intervention, reflecting the uniqueness of the Azorean archipelago and inspiring pieces that celebrate the identity, history and memory of Pico Island.

The BROOT project celebrates the geological and cultural diversity of Portugal by representing five distinct regions through their emblematic materials and the hands of artists committed to the artisanal and identity legacy of each territory. The "Dialogues" collection brings together a total of 25 original pieces created by five studios, each exploring the singular relationship between a pair of materials characteristic of their region:

Center-North Region: Studio Olivah (Gisella Tortoriello and Paula Sica) works with granite and burel from Serra da Estrela, symbolizing the fusion between mineral hardness and textile softness of this glacial landscape.

Alentejo: JMM Design Studio (João Marcos Moreira) explores the dialogue between Estremoz marble and cork, materializing the history and modernity of cork oak silhouettes.

Center Region: Vítor Reis Cerâmica (Vítor Reis), in Caldas da Rainha, combines limestone from the Aire and Candeeiros Mountains with red clay, evoking the secular traditions of Portuguese pottery.

North: Studio Anansi (Evan Jerry) fuses schist from Vila Nova de Foz Côa with acacia wood, drawing inspiration from the rock engravings that witness the country's first artistic expressions.

Islands: Estúdio Eneida Lombe Tavares (Eneida Lombe Tavares) incorporates basalt and wicker from Pico Island, translating the volcanic force and delicacy of vineyards that define the Azorean landscape.

Each material carries millenary stories and artisanal techniques preserved throughout generations, conferring deep cultural and technical significance to the pieces. The studios developed objects that transition between functional and decorative, offering a collection that is, in itself, a true manifesto of Portuguese identity in dialogue with the present.

The BROOT project has led Portugal to stand out at the most important international fairs of art, design and architecture, placing the country's traditions and innovation at the center of global debate. Since its debut at INDEX Saudi Arabia 2024, in Riyadh, where it conquered attention through attention to detail and the stories that involve each piece, to its presence at Maison & Objet Paris, where it was recognized as a striking example of "New Era" design, BROOT has been establishing itself as an ambassador of Portuguese culture.

At Milan Design Week, the largest and most influential design event in the world, BROOT presented itself alongside the biggest and most

prestigious global luxury brands, confirming the capacity of Portuguese design to dialogue with the most recognized names in the sector. This participation reinforced the project as a contemporary reference that combines heritage and modernity.

The presence at events like NYCxDesign underlines BROOT's commitment to promoting not only contemporary design, but also the rich Portuguese artisanal legacy, which confers depth and meaning to each creation. In Osaka, at the Portugal Pavilion of Expo 2025, the project had the honor of exhibiting five selected pieces, which represent the geological, cultural and artistic diversity of the country, evidencing the importance of bringing to the world a representative sample of the best of Portuguese design and craftsmanship.

In an era when globalization tends to homogenize cultures, the BROOT project emerges as a creative resistance — a true manifesto of Portuguese singularity. In 2025, BROOT will bring to the world more than Portuguese natural stone: it will bring with it stories, ancestral techniques and the soul of a people who have always known how to transform the richness of the earth into art.

Committed to responsible practices and conscious design, the project invests in the reuse of raw stone blocks and already extracted pieces, especially those less commercially valued. This sustainable approach not only minimizes environmental impact, but also reveals new tonalities, textures and movements of stone, giving them new life and meaning.

BROOT is much more than a design project: it is a celebration of Portuguese territory, of the hands that shape it and of the creativity that transforms it. It is proof that when ancestral traditions meet contemporary innovation, something unique, authentic and universally inspiring sprouts — a true dialogue between past and future, local and global, matter and spirit, that defines the best of Portuguese making.

ASSIMAGRA - Portuguese Association of the Mineral Resources Ind ustry

This Technical Manual edited by ASSIMAGRA represents a groundbreaking initiative by the Portuguese Association of the Mineral Resources Industry, providing the natural stone sector with its first comprehensive scientific guide covering design, dimensioning, processing, application, maintenance, and lifecycle management of natural stone products in construction. This innovative publication emerges at a critical time when Portugal stands as the seventh largest global producer of natural stone, with exports reaching €470 million in 2024, demonstrating the strategic importance of this industry to the national economy.

The manual serves as both a technical reference and a strategic tool for industry transformation, systematizing specialized knowledge that has been accumulated over decades while integrating international best practices. Its comprehensive approach addresses the growing market demand for advanced technical solutions that combine the inherent beauty of natural stone with increasingly stringent performance requirements in modern construction.

Portugal's position as the seventh largest global natural stone producer underscores the critical importance of technical excellence and innovation in maintaining competitive advantage. The industry's substantial contribution of €470 million in exports in 2024, combined with its role as a significant employer of thousands of workers, positions natural stone as a cornerstone of the Portuguese economy.

This publication emerges as a direct response to the industry's need for technical sophistication and standardization. As global markets become increasingly competitive and quality requirements more stringent, the manual provides Portuguese producers with the scientific foundation necessary to maintain and expand their market leadership.

The manual's approach to sustainability and digitalization reflects the industry's recognition that future competitiveness depends not only on product quality but also on environmental responsibility and technological advancement. This forward-looking perspective ensures that Portuguese natural stone products remain relevant in markets where sustainability credentials are increasingly important.

The manual's comprehensive treatment of natural stone facade engineering represents one of its most significant contributions to industry knowledge. The section dedicated to facade applications addresses the complex interplay between aesthetic requirements and technical performance, providing detailed guidance on dimensioning, composite laminate solutions, and adherence to relevant codes and standards.

The facade engineering section responds directly to market demands for increasingly sophisticated building envelope solutions. Modern construction projects require natural stone facades that not only provide visual appeal but also meet stringent performance criteria for thermal efficiency, structural integrity, and long-term durability. The manual's systematic approach to these challenges provides designers and contractors with the tools necessary to deliver solutions that meet both aesthetic and functional requirements.

The integration of composite laminate solutions within the manual reflects the industry's evolution toward hybrid technologies that combine natural stone's inherent properties with advanced engineering materials. These solutions offer enhanced performance characteristics while maintaining the visual and tactile qualities that make natural stone desirable in high-end construction applications.

The manual's dedicated chapter on structural applications of natural stone addresses a growing area of interest within the construction industry. Natural stone's exceptional compressive strength and durability properties make it an attractive option for structural applications, particularly in projects where longevity and reduced maintenance requirements are prioritized.

The section provides detailed coverage of structural engineering concepts specific to natural stone construction, including comprehensive analysis of forces and force paths, relationship between form and structural behavior, and specialized techniques such as pre-stressing. This technical depth ensures that structural engineers have access to the specialized knowledge required for successful natural stone structural applications.

Understanding the unique characteristics of natural stone in structural applications requires specialized knowledge of how forces are transmitted through stone elements and how various constraint conditions affect structural behavior. The manual's treatment of these topics provides engineers with the technical foundation necessary for safe and efficient structural design using natural stone materials.

Chapter IV of the manual addresses standardization, quality, and certification processes that are fundamental to ensuring the international competitiveness of Portuguese natural stone products. The comprehensive coverage of international standardization frameworks, including European and national standards, provides industry participants with clear guidance on meeting global market requirements.

The section's detailed treatment of CE marking requirements and European Assessment Documents (EADs) ensures that Portuguese producers understand and can comply with the regulatory requirements necessary for accessing European markets. This compliance framework is essential for maintaining market access in an increasingly regulated global marketplace.

The manual's approach to certification processes reflects understanding that quality assurance extends beyond product characteristics to encompass entire production and supply chain processes. This comprehensive view of quality management ensures that Portuguese natural stone products can compete effectively in markets where customers demand not only high-quality products but also documented proof of quality management systems.

This publication represents more than a technical document; it constitutes a strategic tool for industry transformation and development. By providing systematic access to specialized technical knowledge, the manual enables Portuguese natural stone companies to enhance their technical capabilities and market competitiveness.

Blending international best practices with the extensive experience of the Portuguese natural stone sector, the manual serves as a unique resource that bridges global innovation with local know-how. This synergy enables companies to harness cutting-edge advancements while capitalizing on their own heritage and strengths to deliver market-leading solutions.

The manual's comprehensive scope, covering everything from basic material selection through advanced lifecycle management concepts, positions it as a foundational resource for industry development. As the natural stone sector continues to evolve in response to changing market demands and technological opportunities, the manual provides a stable technical foundation upon which further innovations can be built.

With the release of this technical manual, ASSIMAGRA sets a new benchmark for the Portuguese natural stone industry. It is the first comprehensive publication to systematize decades of accumulated

knowledge while integrating advanced international best practices. Its strategic relevance extends beyond technical application, reinforcing the long-term global competitiveness of Portuguese natural stone products.

By addressing critical areas including facade engineering, structural applications, quality assurance, and sustainability considerations, the manual provides industry participants with the tools necessary to meet evolving market demands while maintaining the aesthetic and performance qualities that distinguish natural stone as a premium construction material.

The manual's role as both a technical reference and a strategic development tool ensures its continued relevance as the industry evolves. As Portuguese natural stone companies face increasing global competition and rising performance requirements, the manual provides the technical foundation necessary for maintaining market leadership while pursuing new opportunities for growth and innovation.

Through its comprehensive approach and integration of scientific rigor with practical application guidance, this publication establishes a new standard for technical excellence in the natural stone sector, reinforcing Portugal's position as a global leader in this strategically important industry.

Ana Sofia Amaral

CTCV – Innovation and Technological Centre

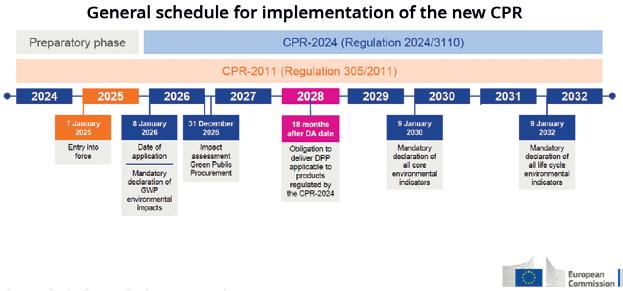

The new Construction Products Regulation (CPR) - Regulation (EU) 2024/3110 was published in the Official Journal of the European Union on 18th December 2024. It partially came into force on 7th January 2025, and the new Regulation will be in force from 8th January 2026. However, given the changes it introduces, the period of coexistence with Regulation 305/2011 could be extended, at most, until 2032.

The review of the previous Regulation (EU) 305/2011 revealed significant limitations, such as poor performance in standardisation, inconsistencies with other EU legislation, ineffective enforcement actions and a lack of robust product safety criteria. Regulation (EU) 2024/3110 thus aims to modernise the legal framework for the construction sector, promoting sustainability, digitalisation and strengthening supervision and compliance.

The natural stone products sector is one of the most important geological-based industrial activities in Portugal, with a strong economic weight and significant impact on exports. With more than 2,000 active companies, spread across the extraction and processing sectors, employing around 15,000 workers, this sector is characterised by a combination of tradition and innovation. Portuguese natural stone products — such as Estremoz marble, Lioz limestone, and Vila Real granite — are widely recognised internationally, with some having been classified as ‘Heritage Stones’ due to their heritage importance. Although the sector has the technical expertise and product quality to ensure competitiveness in international markets, it faces growing challenges in the current context. Environmental requirements, production traceability, process digitisation and technical compliance with EU regulations require management and control systems to be updated. In this sense, the publication of the new Regulation (EU) 2024/3110 emerges as a regulatory milestone with a major impact, with direct implications for the information (characterisation of functional and environmental performance) accompanying the product in the marketing of natural stone on European market.

CPR 2024/3110 introduces mandatory assessment of the environmental performance of construction products based on their life cycle. This approach is part of a circular economy logic and focuses on the need to reduce the environmental impact of products, to promote the efficient use of natural resources, encouraging the reuse and recycling of materials.

One of the new features of the new Construction Products Regulation is the introduction of a new assessment and verification system, the System 3+, Notified body’s control of environmental sustainability assessment, dedicated to monitoring environmental sustainability assessments. The manufacturer shall be responsible for collecting data, assumptions and modelling in order to issue a report that will subsequently be validated by the notified body after analysis.

The System 3+ will be applied across the board to all products, regardless of their function in the construction project. Construction products, in accordance with the requirements for their use in the project, already had an evaluation and verification system in place: Systems 1, 1+, 2+,3 e 4, which will now exist in parallel with System 3+ for assessing environmental performance/sustainability.

The harmonised standards for natural stone products define, in Annex ZA, the applicability of System 4, which only requires the manufacturer's intervention.

To ensure compliance with harmonised standards, natural stone products must undergo a series of initial type tests (laboratory tests carried out on a representative sample of the product to verify that it complies with the essential requirements set out in the applicable harmonised standards), that assess the technical and physical performance of the material.

Harmonised specifications for natural stone CE marking:

Standard Product

EN 1341

Slabs of natural stone for external paving - Requirements and test methods

EN 1342 Setts of natural stone for external paving - Requirements and test methods

EN 1343 Kerbs of natural stone for external paving - Requirements and test method

EN 1469 Natural stone products - Slabs for cladding – Requirements

EN 12057 Natural stone products - Modular tiles – Requirements

EN 12058 Natural stone products - Slabs for floors and stairs – Requirement

EN 771-6

EN 12326-1

Specification for masonry units - Part 6: Natural stone masonry units

State and stone products for discontinuous roofing and external cladding.

Part 1 – Specifications for slate and carbonate slate

EN 15285 Agglomerated stone - Modular tiles for flooring and stairs (internal and external)

EN 15286 Agglomerated stone – Slabs and tiles for wall finishes (internal and external)

These tests are necessary for the issuance of the Declaration of Performance and Conformity, which must contain the essential characteristics defined in Annex ZA of the specification standard.

Some Initial Type Tests for natural stone products:

Essay

Flexural strength

Compressive strength

Resistance to abrasion wear

Slip resistance

Apparent density and open porosity

Water absorption at atmospheric pressure

Resistance to freezing and thawing

Petrographic description

Thermal shock resistance

Objective

Assess mechanical resistance to tensile/flexural stresses, especially in slabs or panels

Quantify compressive load-bearing capacity (structural elements)

Determine friction and wear resistance on pavements

Assess slip resistance performance on indoor and outdoor flooring

Determine the relationship between mass and volume occupied and the porosity of the material.

Measuring porosity and moisture behaviour

Simulate extreme climate variations and assess dimensional and physical changes

Characterise the mineral composition and internal structure of natural stone

Assess resistance to sudden temperature changes

In addition, in order to affix the CE marking, the manufacturer must implement Factory Production Control, a system that should consist of internal production control procedures, results of the tests carried out during FPC and must demonstrate that products placed on the market comply with the specification standards and the values declared by the manufacturer. Companies in the natural stone sector must implement robust Factory Production Control systems that ensure the inspection and control of raw materials, products in the manufacturing process and final products, and the traceability of materials through systematic production records. Companies must prepare themselves to integrate new digital methodologies that incorporate digitised documentation and interoperable systems, which provide operational and technical support for the sector's evolution towards digitisation.

The Declaration of Performance (introduced by Regulation 305/2011) evolves, with the new Regulation, into a Declaration of Performance and Conformity, with a standard model defined in Annex V of the document. In addition to the technical aspects and information previously covered, the Declaration of Performance and Conformity will include data on the product's life cycle and environmental performance, in the form of declared indicators, which will be introduced in stages, with targets in 2026, 2030 and 2032, depending on the updating and publication of harmonised standards.

Annex II of the new Regulation defines the essential environmental characteristics related to product life cycle analysis, in line with the guidelines of standard EN 15804+A2, used for the preparation of Environmental Product Declarations (EPDs):

(a) climate change effects – total; (b) climate change effects – fossil fuels; (c) climate change effects – biogenic; (d) climate change effects – land use and land use change; (e) ozone depletion; (f) acidification potential; (g) eutrophication aquatic freshwater; (h) eutrophication aquatic marine; (i) eutrophication terrestrial; (j) photochemical ozone; (k) abiotic depletion – minerals, metals; (l) abiotic depletion – fossil fuels; (m) water use; (n) particulate matter; (o) ionising radiation, human health; (p) eco-toxicity, freshwater; (q) human toxicity, cancer; (r) human toxicity, non-cancer; (s) land use related impacts.

These indicators will enable the impact of a given natural stone product to be assessed throughout its life cycle, ensuring transparency and enabling comparability between suppliers.

When providing the Declaration of Performance and Conformity, the manufacturer assumes responsibility for the product's conformity with the declared performance.

If necessary, the Declaration of Performance and Conformity must contain information about the presence of hazardous substances in

the construction product, namely those identified in Regulation (EC) No. 1907/2006 concerning the registration, evaluation, authorisation and restriction of chemicals (REACH).

To ensure technical and regulatory consistency, a programme to review harmonised standards is underway, led by groups of experts designated as Acquis Groups. The revision of harmonised standards aims to introduce environmental characteristics (consistent with EN 15804 – Environmental Product Declarations and cPCR – complementary Product Category Rules), updates in line with technological advances and greater adaptability to market needs. Given the extensive list of harmonised standards, it was decided to prioritise the products on the list of product families set out in Annex VII to the Regulation.

Ten priority product families have been defined, for which the revision of harmonised standards is already underway and will be published at a later date. The standards relating to the remaining 26 families will be reviewed at a later date. Natural stone products can be included in code family 21 – Interior and exterior finishes for walls and ceilings, whose harmonised standards will be reviewed after the priority products.

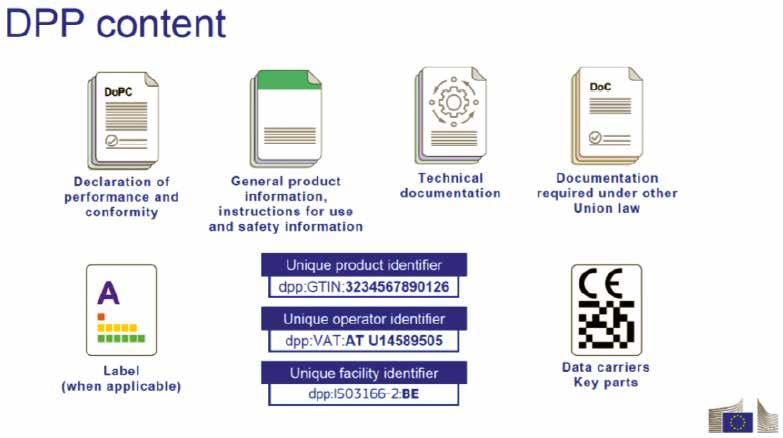

The digital transition is one of the strategic pillars of the new Regulation. In this context, the introduction of the Digital Product Passport (DPP) stands out as a mandatory tool for identification, documentation and digital sharing of information about each product.

A delegated act with detailed information on the DPP is expected to

be published in mid-2026. Meanwhile, it is considered that the content of the DPP should include the Declaration of Performance and Conformity, and information about the origin of materials and components, health and safety requirements, instructions for use and environmental impacts according to the defined categories, among others.

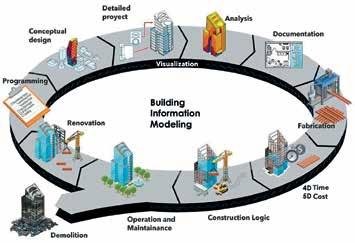

The DPP, provided for in Article 76 of the Regulation, shall be mandatory 18 months after the publication of the corresponding delegated act. It will be a key tool in building interoperable databases that can be integrated with tools such as BIM (Building Information Modelling) which are essential for strengthening product traceability and value chain transparency.

Article 83 of the new CPR establishes binding conditions for Member States in the adoption of mandatory environmental criteria in public procurement procedures, whose selection criteria must incorporate minimum environmental sustainability criteria applicable to technical specifications, supplier selection criteria and tender award rules.

This obligation can represent a competitive advantage for natural stone companies that adopt rigorous environmental practices and provide the required technical and environmental documentation, enabling them to participate in sustainable and environmentally friendly public works projects.

CPR 2024/3110 reinforces the European market surveillance framework, in conjunction with Regulation (EU) 2019/1020, by strength-

ening the powers of the competent authorities, harmonisation of complaint and sanction mechanisms, improved inter-institutional coordination and enforcement practices, the creation of portals for consumers and professionals and increased control over the circulation of non-compliant products.

Manufacturers, importers and distributors now have additional obligations with regard to verifying the conformity of their products, correct product identification and information provided in the Declaration of Performance and Conformity.

Regulation (EU) 2024/3110 is a new European benchmark for construction products, responding to the current priorities of the European Union: promotion of sustainable practices, circular economy, digital innovation and consumer protection. The natural stone sector, due to its tradition, aesthetic value and potential for durability, can take advantage of these changes, viewing them as a step towards innovation and differentiation within the sector. To do so, it must ensure compliance with new environmental requirements, adopt effective digital tools, and strengthen its internal quality management/ production control systems in the factory. Modernisation is therefore not only a regulatory requirement, but also a lever for strengthening the sector's competitiveness in European and global markets.

REGULATION (EU) 2024/3110 of the EUROPEAN PARLIAMENT and of the COUNCIL of 27 November 2024 – Construction Products Regulation.

Chapter I – General Provisions (Article 10º)

Chapter II – Procedures, Declarations and Markings (Article 15º)

Chapter III – Obligations and Rights of Economic Operators (Article 22º)

Chapter VIII – Market Surveillance and Safeguard Procedures (Articles 63º a 68º)

Chapter X – Digital Product Passport (Articles 75º a 80º)

Chapter XII – Incentives and Public Procurement (Article 63º) Annexs II, III, V, VII and IX.

REGULATION (EU) 2024/1781 of the EUROPEAN PARLIAMENT and of the COUNCIL of 13 June 2024 - Regulation on the Eco-design of Sustainable Products.

EN 15804:2012+A2:2019+AC - Sustainability of construction worksEnvironmental product declarations - Core rules for the product category of construction products.

Pedro Oliveira CTCV – Innovation and Technological Centre

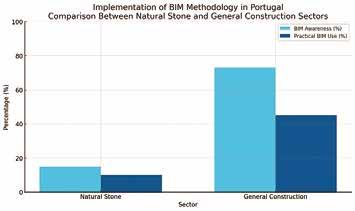

The Architecture, Engineering and Construction (AEC) industry is undergoing a significant paradigm shift, leading to profound changes in its methods of organisation and execution. This transformation is driven by increasing digitalisation, stricter environmental and sustainability requirements and a rapidly evolving global economic landscape. As a result, the AEC sector is reinventing itself, incorporating concepts and methodologies that prioritise efficiency, transparency and technological innovation. In this context, Building Information Modelling (BIM) has emerged as a key player, revolutionising the way projects are conceived, planned, executed and maintained. The natural stone sector in Portugal, with its strong historical roots and traditional skills, has built up an international reputation for excellence, particularly for its high-quality marble, limestone and granite from various regions of the country. Traditionally dependent on conventional methods of extraction, processing and export, the sector is now facing unprecedented challenges, both at home and abroad. On the one hand, growing international competition, especially from Asian markets, along with constant fluctuations in energy and logistics costs, is leading to a strategic re-evaluation. On the other hand, the pressure to innovate processes and products, coupled with the demand for personalised and aesthetically unique solutions, requires a change in traditional practices. Thus, the strategic adoption of the BIM methodology is not just a modern trend; it is an essential and irreversible path towards guaranteeing a sustainable, efficient and globally competitive future for the Portuguese natural stone sector.

Portugal has been consolidating its position as a world power in the production and export of natural stone. With a range of geological resources of excellence, namely marble from the Alentejo, granite from the North and Centre and limestone from the Central Region, the country reached an annual export volume of over 488 million euros in 2023 (source: Assimagra), making it one of the world's top seven exporters. In recent decades, Portuguese companies have conquered diversified markets that value the authenticity and uniqueness of the Portuguese product - be it for the beauty of the material, its physical resistance or its prestige in architecture and global design.

However, the sector is facing a strategic crossroads. Externally, there are clear threats from global oversupply, with aggressive pricing policies from emerging countries altering established commercial dynamics. Internally, sustainability challenges are growing: legal requirements regarding carbon emissions, energy consumption and efficient resource management are increasingly decisive in order to obtain essential certifications for export and acceptance in international reference projects.