KYOCERA SGS Precision Tools (KSPT) is a global ISO-certified manufacturer of industry-leading solid carbide cutting tools.

KSPT is proud to have pioneered some of the world’s most advanced cutting tool technologies, resulting from rigorous product, coating and material testing within its Global Innovation Centre.

We have manufacturing sites in the United States and United Kingdom and the KSPT European Headquarters are in Wokingham, Berkshire, UK.

Our European office specialises in bespoke and modified tooling, which means we find design tooling solutions to optimise your manufacturing performance.

In 2016, Kyocera merged with SGS Precision Tools. The merger has ultimately been a huge success between two companies sharing the same focus on client service.

In 2019, KSPTE were voted Best High-Performance Tooling Manufacturer in the SME News Enterprise Awards.

We were also finalists for the Thames Valley Chamber of Commerce Business Awards for Workplace Wellbeing.

We offer our clients unique solutions and support, helping solve difficult project challenges in their markets.

Our global network of sales representatives and industrial distributors sell into more than 60 countries and can therefore offer you a networked resource capable of solving your most difficult Medical machining challenges.

Our commitment is to our customers and to our employees. Investing in both enables us to grow and innovate together with our customers, resulting in success all-round.

Our values exist to channel us ever further towards achieving our mission.

We offer our clients unique solutions and support, helping them to solve difficult project challenges in their markets. Our sales engineers and technical team explore our customers’ goals and work with them to reduce set-up times and machining cycle times, improve quality and process reliability through the design and manufacture of specialised tools. We are a solutions provider rather than just providing high-quality tools.

It is this that sets us apart from our competitors. We do more than just produce tools; we employ a highly skilled technical sales team, who often think of completely different ways of giving the customer what they need rather than just using off-the-shelf products.

They even go as far as developing new concepts and geometries to ensure we meet our customers needs.

BE THE BEST WE CAN BE

CHALLENGE AND BE CHALLENGED

The Medical sector continues to grow as new biocompatible materials are found and the life expectancy of people in the developed world extends further. In addition, health issues such as disease, trauma, arthritis and obesity are also helping to the drive demand for Medical implants.

With this ever-increasing demand, and the challenges presented by new materials, comes a drive for more efficient, stable and cost-effective manufacturing processes.

The drive to reduce costs has never been more in focus following recent worldwide economic issues such as the Coronavirus crisis.

The CNC machining of surgical implants presents many challenges. These include small-scale machining or micromachining, because implanted devices often consist of very tiny components, and machining

difficult materials such as titanium, cobalt chrome, and stainless steel materials often used in medical devices because of their non-reactivity with the body.

Issues with the removal of coolant used in manufacturing have also led to new solutions for cooling the machining process such as C02 gas.

Working closely with medical manufacturers we have developed many new and innovative milling and drilling solutions designed specifically to overcome the challenges faced by the Medical market.

Flutes

Index

4, 6 & 8 ≠ + Ti-Namite-M Ti-Namite-X

4 & 5 ≠ + Ti-Namite-M Ti-Namite-X

2 = + + + Ti-Namite-B

5 ≠ + + + Un-Coated

7 ≠ + Ti-Namite-M Ti-Namite-X

2, 3, 4 & 6 ≠ - Ti-Namite-X

5 ≠ + Ti-Namite-M Ti-Namite-A

2 = + + Ti-Namite-M Ti-Namite-X

3 ≠ + + Ti-Namite-A

2+4 = + + Ti-Namite-M Ti-Namite-X

5 ≠ + + Ti-Namite-A

2 ≠ + Ti-Namite-X

4 ≠ + Ti-Namite-X

2 & 4 ≠ + Ti-Namite-X

Coating Key

Ti-Namite-A = AlTiN

Ti-Namite-X = AlTiN-based nanostructured

Ti-Namite-M = AlTiSiN nanocomposite

Ti-Namite-B = TiB2

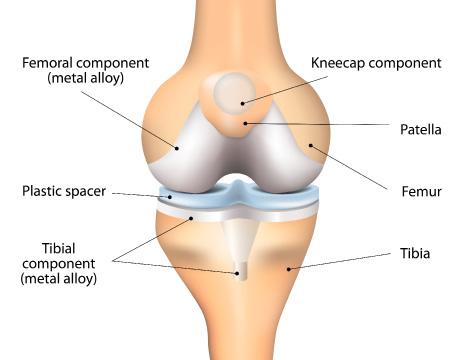

Femoral knee replacement parts mimic the natural shape of the joint and are usually made from cobalt chrome and 17-4 PH stainless steel.

Due to the tight tolerances and surface finishes required, femoral parts are usually machined on 5-axis grinding machines. However, this process can generate high temperatures that may distort the metal and lead to scrapped parts.

The drive for more efficient, stable and cost-effective manufacturing processes has in recent years seen medical manufacturers start to move towards milling solutions.

The challenge when milling is to achieve a burr-free profile with superior surface finish that minimises the need for linishing and manual polishing, and at the same time maximises productivity and tool life.

SGS has a comprehensive range of offthe-shelf high-performance tooling with geometries well suited to the machining of cobalt chrome and 17-4 PH stainless steel.

In addition, we have developed specific tooling solutions for various areas of femoral components, including taper ball end cutters for box and cam sections, and barrel cutters for the main condyle surfaces.

The condyle surfaces represent the largest portion of cycle time when machining femoral components. These surfaces have traditionally been milled with ball nose cutters using a scanning strategy.

Whilst this strategy delivers the required surface finish, the small step overs result in an unsatisfactory cycle time. The SGS range of barrel tools have achieved step overs of up to 3.0mm and a feed rate of over 800mm/min whilst still delivering surface finishes within tolerance.

Long tool life (3h recorded)

Stable process

Reduction in post milling linishing

Result: Cycle time reduction of 40% and dimensional accuracy improvement

The box section feature of femoral components present challenges when milling due to deep walls, small corners and high surface finish requirements that minimise manual polishing.

SGS’s tapered ball end tool solutions benefit from our patented vibration-reducing geometries that deliver the required component surface finishes, whilst our choice of carbide and coatings help to maximise tool life.

The bearing insert is made from polyethylene and is fitted between the femoral and tibial components to avoid metal-on-metal contact.

The component’s complex design, tight tolerances and stringy material properties can create machining challenges

SGS have developed specific ultra-sharp tooling geometries, such as those seen on our high-performance Ski-Carb range, that overcome these issues.

Ski-Carb geometries are often applied to our special tooling solutions such as t-slot and form cutters that enable the complex shapes of bearing inserts to be more easily manufactured.

General machining of polyethylene medical components can be difficult due to the stringy nature of the material.

SGS’s Ski-Carb solution has a high helix angle of 45°, whilst the ski-land with primary and secondary flute wall construction minimises chip interference by directing chips away from the secondary flute. This combination of geometry helps to eliminate burrs and produce satisfactory surface finishes.

Form tools can also be produced with the Ski-Carb geometry to the exacting tolerances demanded by this type of component. The solution shown is for machining the condyle surface of the bearing insert that the upper convex-shaped femoral component is located in. Quality of the cutting edge is key.

9 Dimensional accuracy

9 Stable, accurate process

9 Elimination of post milling de-burring

9 Tool regrind available to reduce costs

The final element of a total knee replacement is the tibial tray, which supports the upper part of the implant. Typically, tibial trays are made from titanium and cobalt chrome.

Like all medical components, the tibial tray presents challenges in terms of surface finish and productivity requirements.

SGS has a comprehensive range of off-theshelf high-performance tooling with features such as variable pitch, helix, and rake and edge preparations, making them ideal for machining difficult materials such as titanium and cobalt chrome.

SGS have developed new high-feed geometries that significantly reduce cycle times whilst at the same time minimising burrs.

SGS were the first cutting tool manufacturer to launch variable geometry tooling on to the market. Our high-performance tooling range has features such as variable pitch, helix, and patented rake and edge preparations. These features, combined with the highestquality substrates and coatings, result in tools that maximise metal removal rates, thus reducing cycle times, and and therefore improving productivity.

Our new H-Carb product range is ideally suited for high-speed roughing (profiling, trochoidal, dynamic) machining of titanium and cobalt chrome. The lower cutting forces generated by the H-Carb make them ideal for lower-powered machines and components with lower clamping / work-holding.

Application Details Cutting Data - Ø8mm

Result: Cost per part saving of 43% and increased tool life

Solution Advantages

Using the same geometries and quality substrates as in our high-performance range, SGS has developed a high feed cutter solution that combines small depths of cut with high feed rates resulting in increased metal removal when compared to conventional milling. The increased feed rates can significantly reduce cycle times when machining tibial tray components, whilst the stability of this type of tool helps to maximise surface quality and tool life.

Application Details

Operation Finishing floor of tray

Cutting Data - Ø12mm

Result: Reduction in scrap of 22% and increased feed rates

9 Stable process

9 Increased metal removal rates

9 Improved cycle times

9 Multiple regrinds available

Hip replacement is currently one of the most common orthopaedic operations and is generally conducted to relieve arthritis pain and overcome hip fractures.

Hip replacement generally consists of three parts: the acetabular cup, the femoral component and the articular interface.

Femoral hip stems are manufactured from a variety of difficult-to-machine materials such as titanium and cobalt chrome and can be single piece or modular.

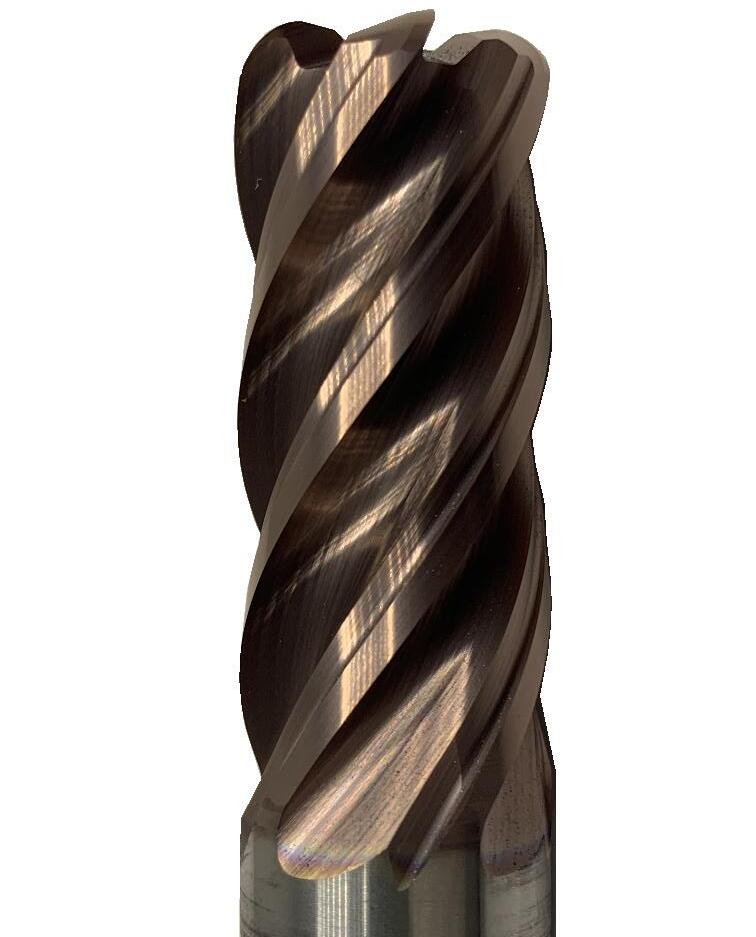

Through a combination of patented geometries, high-quality substrates, and coatings, SGS has developed market-leading tools that return tool life measured in hours as opposed to minutes when machining materials such as titanium and cobalt chrome.

SGS have a range of 3, 4, 5, 6 and 7-flute tooling solutions suitable for slotting, profiling and dynamic milling of difficult-to-machine materials such as titanium and cobalt chrome.

Each tool in the SGS high-performance tool range has specific design features such as variable pitch, helix and rake angle, all aimed at reducing resonance, vibration and chatter, the main causes of premature tool failure.

SGS’s Z5 HPR tool solution is ideal for achieving high material removal rates (MRR) and a finish of 1.8Ra or better in most materials. The specialised 5-flute design is engineered for increased productivity over 3 and 4-flute end mills, whilst its variable geometry design allows for improved chatter suppression for improved tool life. Tool life and productivity is further enhanced via a through coolant option and coatings ideally suited for machining titanium.

The Hi-PerCarb Series 135 drill features a double margin design that can remove the need for reamers, whilst other design features are engineered to maximise chip control, drill strength, penetration rates, and therefore productivity.

The ICe-Carb Series 140 drill features an internal coolant design that allows for better control of machining temperatures and chips when machining materials such as titanium. The ICe-Carb drills’ design features reduce cutting loads, increase operating parameters and enhance tool life.

SGS’s combi-drill solutions offer a reduction in the number of tools required for each hole. The drilling of stepped holes and chamfers can now be combined into one tool that delivers a stable, accurate process that reduces both cycle times and tooling costs.

The acetabulum is a cup-like socket formed by the connection of the three bones that combine to form our hip.

This component is one of the most difficult medical implants to machine due to complex features, tight tolerances, thin walls, and being produced from materials such as titanium and cobalt chrome.

Multiple tooling solutions and strategies are employed when machining these complex components.

SGS has a comprehensive range of drills and end mills suitable for machining these titanium and cobalt chrome implants. SGS’s patented Multi-tool solutions can also be used to combine the machining of some features with one tool, thus reducing cycle times.

SGS’s well-established market-leading range of high-performance tooling is well suited to the challenges presented by difficult-tomachine materials such as titanium and cobalt chrome. Working with major medical implant manufacturers SGS have adapted and refined this range of tooling to ensure that cutting data is maximised whilst simultaneously increasing tool life.

More recently we have developed geometries, edge preparations and flute polishing techniques specifically aimed at machining titanium with C02 gas or even dry.

SGS’s Series 33 solution is good for slotting and pocketing difficult medical materials and is ideal for applications where swarf evacuation is a problem. It has a 3-flute variable geometry design for vibration reduction that also gives excellent chip control. The tool has a stepped core for rigidity and is suitable for plunging applications and ramping.

Combi-tool solution

SGS’s patented one-shot combi-tool drilling and milling solutions offer a reduction in the number of tools required for each hole.

The drilling and milling of holes, counterbores and chamfers can now be combined into one tool that delivers a stable, accurate process and reduces both cycle times and tooling costs.

In addition, the combi-tool can also deliver production savings by reducing set-up and tool change times and can offer other advantages such as freeing up space in tooling carousels.

Requirement

Stable, accurate process

Additional space in tool carousel

Trauma plates come in many shapes and sizes and are manufactured from biomaterials such as titanium, various stainless steels and cobalt chrome. Plates for fractures are designed to follow the natural contours of the bone and are screwed into place holding the bone pieces together whilst they heal.

Spinal plate implants are manufactured from the same materials and are designed to decompress and stabilise the spine. SGS has a full range of high-performance end mills and drills well suited to the machining of these complex components.

The variety and complexity of design of trauma and spinal plate components dictates that multiple tooling solutions and strategies are employed when machining them.

SGS has developed comprehensive range of milling cutters and drills suitable for producing these titanium, stainless steels and cobalt chrome plates.

In addition, we have developed special tooling including high-feed tools, and our patented combi-tool solutions.

SGS have a range of 3, 4, 5, 6 and 7-flute tooling solutions suitable for slotting, profiling and dynamic milling of difficult-to-machine materials such as titanium, cobalt chrome and stainless steels.

Working with major medical implant manufacturers we have adapted and refined our high-performance range of tooling to ensure that cutting data is maximised whilst simultaneously increasing tool life.

SGS’s V-Carb solution is ideal for profiling and finishing of difficult medical materials.

Our 5-flute design also makes it suitable for trochoidal / dynamic machining strategies. As with all SGS’s high-performance tooling the V-Carb range has a variable geometry design for vibration reduction. The V-Carb range is available in stub, regular and long flute lengths, and also with a ball-end version ideal for scanning.

Drilling of titanium and cobalt chrome

SGS has a range of high-performance drilling solutions including our Hi-PerCarb and through-coolant ICe-Carb ranges. The Hi-PerCarb drill features a double margin design that can remove the need for reamers, whilst other design features are engineered to maximise chip control, drill strength, penetration rates, and therefore productivity.

The ICe-Carb Series 140 drill features an internal coolant design that allows for better control of machining temperatures and chips when machining materials such as titanium. The ICe-Carb drills design features reduce cutting loads, increase operating parameters and enhance tool life.

Hi-PerCarb drill solution

Features such as a double margin, secondary flute, and Specialized 145° notched point give the Hi-PerCarb drill the ability to maximise chip control and penetration rates. A self centering point geometry can also eliminate the need for spot drilling. The Hi-PerCarb drill range is available in 3xD and 5xD versions and in Metric, Fractional, Letter and Number sizes and in diameters Ø0.40mm to Ø16.0mm

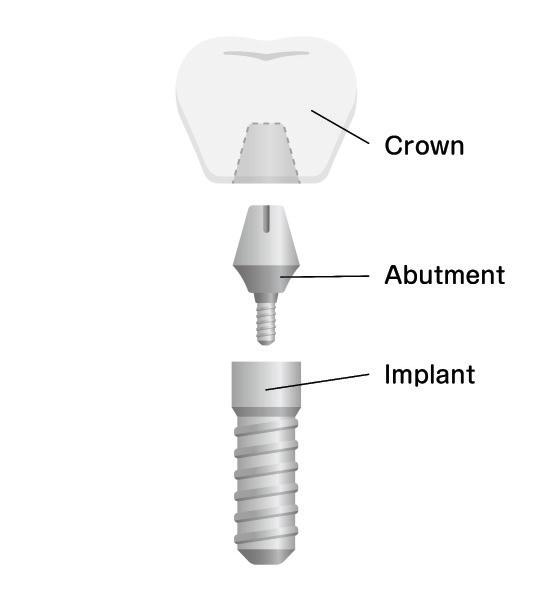

Dental implants generally consist of three parts, the implant, the abutment and the crown. Additionally, dental work may also include the fitting of bridges and bars.

The implant is a small titanium screw that is positioned into the jawbone beneath the gum and acts as an artificial root.

The implant serves as a base for fixing individual ‘teeth’ or a multi-tooth bridge.

The abutment connects the implant to the crown and can be made from several materials such as titanium and zirconia.

The crown is the replacement tooth and is the only part you see in the mouth. Screwed directly into the abutment, crowns can be made from a variety of metals and composites, including porcelain, ceramic, acrylic, or metal alloys.

Support several replacement teeth and are produced from materials such as titanium and zirconia. The components are customised to suit the individual's mouth.

By their very nature dental implants tend to be small, complex and customised to suit the individual’s mouth, and therefore require multiple small/micro tooling solutions and strategies to be employed when machining them.

SGS’s range of high-performance end mills and drills are available in sizes as small as Ø1.0mm and have the same design features as our larger tools, including variable pitch, helix and rake angle, all aimed at reducing

resonance, vibration and chatter, the main cause of premature tool failure.

In addition, SGS has developed a comprehensive range of micro end mills suitable for producing these titanium, cobalt chrome and zirconia components. Our micro tool range starts at Ø0.1mm and is available in both square and ball end solutions and in various cut lengths up to 12xD.

SGS has a comprehensive range of high-performance end mills suitable for machining these small complex components. Our range of tools start as small Ø0.1mm and has the same design features as our larger tools including variable pitch, helix and rake angle. All these design features are aimed at maximising metal removal rates, thus reducing cycle times, therefore improving productivity.

With the introduction of the patented Z-Carb range of tools back in 2000, SGS became the first cutting tool manufacturer to launch variable geometry tooling on to the market.

The launch of the Z-Carb AP range with its patented variable rake geometry further improved the tool's ability to maximise metal removal rates, thus reducing cycle times, and therefore improving productivity. In subsequent years SGS have added several variants to the Z-Carb family, creating one of our most comprehensive ranges. The Z-Carb range is available in sizes as small as Ø1.0mm and has the same variable design features as our larger tools.

76%

In recent years SGS have turned attention to the micro tool market and introduced a comprehensive range of highperformance quality tools.

During an extensive testing and development process we identified advanced geometries that extend tool life, reduce chatter, cut cycle times and improve part quality. We also identified a coating that not only gives these micro tools a 250% life increase over the competition but increases chip flow even in low RPM applications.

Our specially selected substrate is inspected at our in-house metallurgical lab prior to manufacturing to ensure only the highest-quality carbide is turned into your precision micro tool. Our micro tool range includes both metric and fractional square and ball end products and is available in diameters from Ø0.1mm to Ø3.0mm, and in various cut lengths up to 12xD.

We believe that these tools, albeit small, are a huge step forward for micro machining.

Our European office specialises in bespoke tooling designed to suit specific medical application criteria.

When developing our solutions, we consider all aspects of tool design including geometry, carbide grade, edge preparation and coating.

Working closely with medical implant manufacturers we have developed many new and innovative milling and drilling solutions designed specifically to overcome the challenges faced by the medical market.

We often develop specific special solutions on components supplied by our customers and test proposed tooling using our in-house MultiAxis CNC milling machines, whilst also utilising the latest technology in spindle monitoring and high magnification measuring equipment.

Established in 2012, Kyocera Hardcoating Technologies provides premium PVD coating solutions to a broad spectrum of industries in the UK and across Europe. We also have a facility in North America with dedicated coating scientists and a laboratory.

Through testing and development, both teams focus on the latest technical competence and coating techniques to bring a continuous stream of advancements to the market.

Here in the UK we are equipped with HiPIMS (Hi Power Impulse Magnetron Sputter) technology. This allows us to offer some of the highest performance PVD coatings, for the most demanding medical implant applications.

Hardcoating Technologies can supply MSDS sheets for all our coatings on request.

Our coatings

Increase surface hardness and heat resistance while reducing built-up edge, galling and fracture. These characteristics allow for elevated cutting data whilst at the same time delivering increased tool life.

Ti-NAMITE® and Di-NAMITE® Tool Coatings are specifically engineered for KSPT solid carbide rotary tools. The coating lineup includes proprietary processes that result in optimized tool life and increased speed and feed rates in a variety of applications.

Titanium Nitride (TiN)

Aluminum

Titanium Carbonitride (TiCN)

A general purpose coating with good adhesion and abrasion resistant properties. Suitable for a wide variety of materials.

Excellent thermal and chemical resistance allows for dry cutting and improvements in performance of carbide. The coating has a high hardness giving great protection against abrasive wear and erosion. Titanium DiBoride (TiB2)

This ceramic based coating ensures a smooth surface and a low affinity to cold welding or edge build up, which makes it optimal for Aluminum and copper applications. It has high toughness and high hardness.

A very wear resistant coating with high toughness and shock resistance. Good in interrupted cuts found in applications like milling.

The structural design of Ti-Namite-X is adapted to meet a diverse range of applications; everything from high- and low-alloy steels to hardened materials (up to 65 HRC core hardness). Ti-Namite-X is suitable for operations which require high cutting speeds, high temperatures at the cutting edge, and high metal removal rates.

This is the hardest coating available with the best abrasion resistance. It is carbon based so it is limited in application capabilities. This coating is suitable for machining highly abrasive, non-ferrous materials such as CFRP and graphite.

Features include high wear resistance, reduced friction, and excellent prevention of edge build up. This coating provides superior material removal rates and tool life when used in high performance operations with difficult to machine materials like Titanium.

View the following and more on our website:

www.kyocera-sgstool.co.uk/resources/brochures

SGS tech hubs can help get the best from our high-performance range of tooling, by applying the correct tools and optimum strategies.

Using our in-house Multi-Axis CNC milling machines we can perfect a process working in conjunction with our partners.

Whether it be machine tools, tool holding, work holding or Software suppliers of the latest CAD-CAM, we are committed to help find the best solution.

SGS R&D can develop specific tooling unique to your requirements, through extensive knowledge and creative thinking.

Using the latest technology in spindle monitoring and high magnification measuring equipment, we can develop tooling to suit your application and material specification.

Create a better way.

After Re-manufactured to original geometry.

An intuitive three-step process of selecting Material, Application and Tool allows for a seamless transition from the legacy Tool Wizard® platform.

Features include:

• Updated CAD models displaying tool application scenarios for an enhanced user experience.

• Dynamic filters that allow the user to easily find the optimal tool at the click of a button.

• Enhance shop productivity by using KSPT calculated speed and feed recommendations with the new feature allowing for the adjustment of RPM and IPM parameters.

• Save time and time drive efficiencies by referencing historical searches to access previous calculations and print results.

REGISTER TO ACCESS OVER 12,000 SGS STANDARD CATALOGUE TOOLS

KYOCERA SGS Precision Tools Europe Ltd 10 Ashville Way, Wokingham, Berkshire RG41 2PL

+44 (0) 1189 795 200 saleseu@kyocera-sgstool.com www.kyocera-sgstool.co.uk

KYOCERA SGS Precision Tools Europe Ltd KSPTE