Key features:

• 100% Waterproof

• Key reflective areas

• Composite toe cap

• Comfortable, cushioned and removable PU footbed

• Robust functional heel kick

• Energy absorbing heel

• Available in sizes: Men’s UK 6-13 and Women’s: UK 4-8 EN ISO 20345:2022+A:2024

• Certified to Ankle Protection (AN)

• Outsole certified and tested to new maximum Slip Resistance (SR)

• Fuel and oil-resistant outsole

• Performance ladder grip tested to New Ladder Grip Standard (LG)

• Outsole heat resistant to 300°C

• Certified to Cold Insulation (CI) at -17°C

• Certified to Heat Insulation (HI) at 150°C

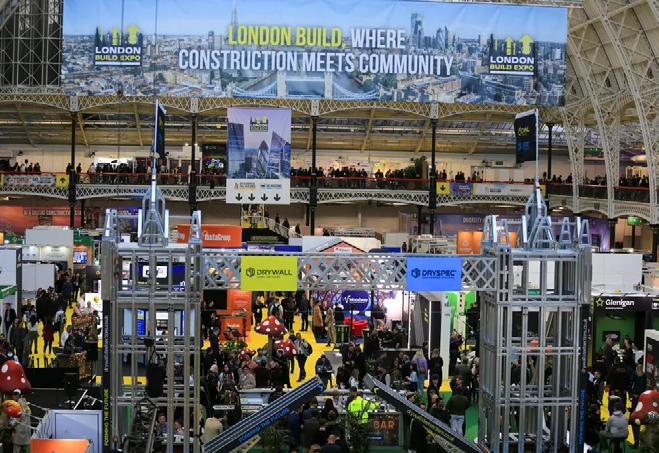

Quelfire Returns to London Build Expo 2025

London Build Expo Marks 10 Years with Its Biggest Edition Yet

Interview with James Rowell, founder of Capture Expense

Modern excavators & digitisation

- By Bart Vingerhoets

The New Cyber Risks Facing Property Managers

On The Tools Awards 2025 Finalists Announced

Free pitched roofing courses to address skills shortage

The Fight for Façades –Incorporating Building Services Effectively

Casey Group Applauded for Leading the Way

Does the construction industry have an Integrity problem

Tel: 01843 808 106

Editor Maria Lapthorn editor@constructionmaguk.co.uk

Editorial Assistant Sophie Weir editorial@constructionmaguk.co.uk

Sales Manager Hannah Marshall hannah@constructionmaguk.co.uk

Admin Assistant Jade Still jade@constructionmaguk.co.uk

Production/Design Laura Whitehead laura@constructionmaguk.co.uk

Accounts Richard Lapthorn accounts@lapthornmedia.co.uk

Circulation Manager Leo Phillips subs@constructionmaguk.co.uk

Website: constructionmaguk.co.uk

Twitter: @constructionukm

LinkedIn: @constructionmaguk

Every

London based real estate investment firm Castleforge recently celebrated the topping out of One Golden Lane, its 120,000+ sq ft Grade A office development adjacent to the iconic Barbican Centre in the City of London.

The ceremony, attended by senior City of London Corporation officials including Gwyn Richards, Planning and Development Director, marked the structural completion of the building’s 12th storey, set for completion in Q2 2026.

Pictured Left: Matthew Reid, Head of Development and Asset Management at Castleforge (centre), and Castleforge team

Located four minutes from the Elizabeth Line at Farringdon, One Golden Lane forms part of Castleforge’s broader pipeline, which will deliver over 1,000,000 sq ft of Grade A space in the next 24 months, including a landmark redevelopment at 75 London Wall, 55 Mark Lane and Cannon Bridge House.

The milestone comes at a critical time for Central London’s increasingly supplyconstrained office market, where Grade A vacancy rates have fallen to historic lows of just 2.1% in prime City locations.

The Grade II listed development, originally designed by Tate Britain architect Sidney Smith, retains its heritage features including the 1896 façade while its newly completed 12th storey offers commanding views across the Barbican—demonstrating how historic buildings can be transformed into best-inclass modern workspaces.

Additionally, One Golden Lane pioneers sustainability in construction, retaining 95% of the existing building and becoming the first London scheme to reuse over 5 tonnes of reclaimed steel from the same site.

The development is targeting Net Zero Whole Life Carbon and BREEAM ‘Outstanding’ certification, with integrated urban greening throughout and 100% renewable energy powering operations.

Wrexham AFC have appointed McLaren Construction Midlands and North under a PCSA for the redevelopment of the iconic Kop Stand at the STōK Cae Ras.

The project will restore the stadium to a full four-sided structure, increase capacity to over 18,000, and deliver modern facilities to achieve UEFA Category 4 compliance.

McLaren will finalise designs, subcontractor packages, and construction timelines, with early works beginning this month.

Completion is scheduled for the 2026/27 season.

Part of the wider Wrexham Gateway Partnership, the redevelopment will enhance both the stadium and the city’s infrastructure.

CBRE Investment Management’s (CBRE IM) ambitious sustainability approach has been fulfilled, with the final BREEAM certification for 30 Semple Street being awarded at the top “Outstanding” level.

With a final score of 93.2%, this marks a number of significant achievements for the project as it becomes Scotland’s first BREEAM Outstanding-certified office building, Scotland’s highestrated BREEAM building across all

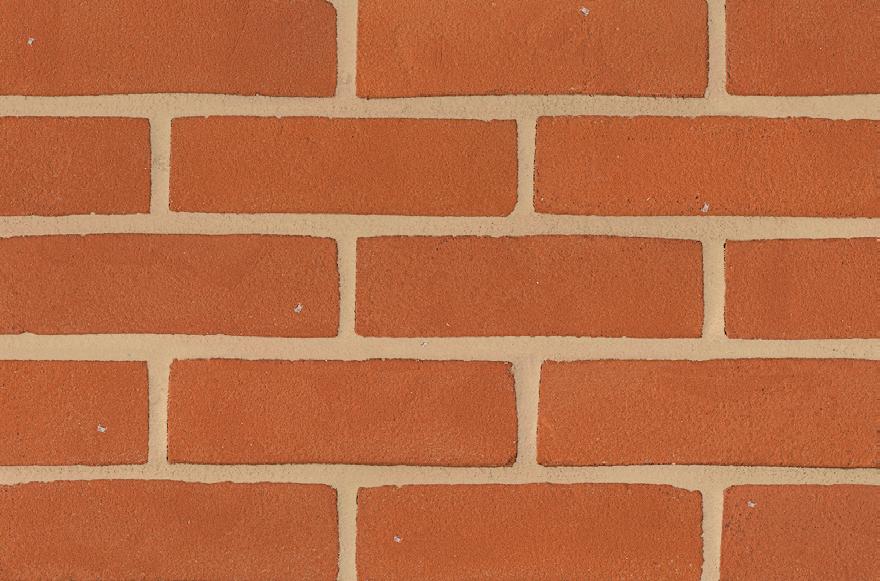

VIVID has completed its redevelopment of the historic Brickworks Museum site in Bursledon, with 12 new affordable homes now ready for customers.

Working in partnership with Imperial Homes, the 2- and 3-bedroom houses are built using traditional Flemish bond brickwork — a nod to the cottage-style homes once lived in by brickworks employees. The homes offer a blend of heritage and modern living, designed to meet local housing needs through a mix of social rent and shared ownership.

The land was purchased from The Brickworks Museum, allowing the renovation and preservation of two

Grade II listed Victorian brick drying sheds. Built in 1897, these historic structures were once part of a bustling site that produced over 20 million bricks a year.

This development brings everything full circle—breathing new life into the very place where the bricks that built our homes were once made.

asset classes, and the second highest-scoring completed building refurbishment in the world, according to published BRE records.

In addition to such other accreditations as NABERS 5*, “Platinum” scores for Air-Rated and Active Score, and an EPC “A”, the building is designed to achieve net zero carbon operation status in accordance with the UK Green Building Council’s framework definition.

Designed by MLA Architects, the redevelopment of 30 Semple Street comprised the strip-back to bare frame of the former office building on the site, the addition of two new floors, as well as a stunning 360-degree contemporary façade. The building has flexible floorplates up to 8,040 sq. ft. and an abundance of natural light and opening windows.

The design team also included mechanical and electrical engineering consultancy K J Tait, project management and cost consultancy Axiom Services Limited, structural and civil engineering consultancy Blyth & Blyth, and Atelier Ten as fire engineering consultants. Ogilvie Construction was the main contractor.

Cuthbert White and Knight Frank are marketing the remaining 25,000 sq. ft. of space in the property.

Bradford College marked a significant milestone as governors and special guests gathered at the £19.3 million Junction Mills development for a commemorative topping-out ceremony.

The college event celebrated the highest point of the building’s structure being put in place, signalling the next phase of work to create a cutting-edge training facility for automotive, digital, and engineering skills.

Set to open its doors to students in 2026, the four-storey building has been made possible thanks to £17.8 million from the Department for Education Further Education Capital Transformation Fund (FECTF) and a £1.5 million College contribution. Morgan Sindall Construction is building the new facility.

Attendees included Bradford College governors, project delivery staff, and a group of current Level 2 Motor Vehicle students who will move to the new building on completion. After donning their safety gear, the group listened to a project briefing by Morgan Sindall’s Project Manager, Dan Marsh.

The group then toured the Thornton Road construction site, discussing internal spaces and their intended uses, construction methodology and logistics, and information about project-specific challenges. At the top of Junction Mills, the group signed the structural steel frame before the ‘topping out’ of the

building, with Vice Principal Chris Malish assisting with the laying of a roof ballast.

Once completed, the Bradford College Automotive and Digital Engineering Department will relocate from Bowling Back Lane to the premises, with as many as 650 students potentially enrolling at the Centre. Junction Mills will offer skills in new technologies, such as modern automotive and digital engineering, electric/hybrid vehicles and advanced manufacturing. The Centre will be vital in supporting the growth of technology and lowcarbon skills capability within West Yorkshire.

The project has already been awarded a Morgan Sindall platinum standard for carbon savingsthe first in the Yorkshire region. Currently, a total of 182 tonnes of carbon has been saved, which is equivalent to heating 67 UK homes annually.

The next phase of the project will include further watertightness works, window installation, completion of the Steel Framing System (SFS) and Cement Particle Boarding, and the continuation of super-structure brickwork.

The first new homes as part of City of Wolverhampton Council’s transformation of New Park Village estate are emerging from the ground.

Chosen construction partner, Keon Homes, is currently constructing seven new wheelchair accessible council bungalows on Longford Road, which are expected to be completed in spring 2026.

It is part of a major redevelopment of council housing in the area that will also see 205 outdated 1960s maisonettes, within eight linked deck-access blocks, flattened and replaced with 188 new energy-efficient homes over two phases.

Phase one demolition has been completed by DSM Demolition, and the site has been handed over to Keon Homes, who are undertaking intensive underground surveys and liaising with utility companies to work through the complex water, gas, electricity and telecommunications layouts. Enabling works are expected to start later this year, with construction beginning in spring 2026.

The regeneration will provide new two, three and four-bedroom council homes for rent, as well as increased car parking and improved public open space at the heart of the estate, which will include a children’s play area, green gym and seating.

Pictured L-R: Sarah Stone, Secretary of New Park Village Committee and Resident Steering Group Member, Steve Spencer, Member of New Park Village Committee and Resident Steering Group Member, Matt Beckley, Partnerships Director at Keon Homes, Cllr Steve Evans, City of Wolverhampton Council Deputy Leader and Cabinet Member for City Housing, Esther Gogo-Hassan, Vice Chair of New Park Village Committee and Resident Steering Group Member, and Cameron Aziz, New Park Village TMC Housing Services Manager

We’re huge stockists of fire and safety glass, offering fast delivery from local branches. Our team provides technical help and specification support, with options for supply-only or supply-and-fit to suit your project and budget needs.

Introducing the REHAU Artevo System—our newly launched fenestration solution engineered for high performance and design flexibility. This advanced hybrid system combines glass fibre-reinforced PVC with an optional aluminium exterior, supporting glass panes up to 72mm thick. It delivers outstanding sound insulation up to 48dB and achieves U-values as low as 0.6 W/m²K, offering superior thermal efficiency, slim sightlines, and substantial savings compared to conventional aluminium systems.

Speak to one of our experts to find out more: Call: 01933 227 233

Email: spd@astraseal.com

Visit: www.spdbyastraseal.co.uk

Astraseal are specialist fabricators of premium uPVC and aluminium glazing systems. Operating from three manufacturing sites, totalling 110,000 square feet, our comprehensive, premium-quality selection of products allows us to meet the fenestration needs of any project.

SPD is a dedicated department within Astraseal, providing revolutionary new glazing fenestration solutions for large-scale, multi-room, high-rise building projects, with an experienced team of knowledgeable CAD technicians, architects, structural engineers, façade specialists, and fully qualified site managers.

Experts in Advanced Glazing Systems

We specialise in high-performance glazing for both commercial and high-rise buildings, offering cuttingedge solutions for aesthetic and energy-efficient façades.

Tailored glazing designs that meet specific project needs, from structural glazing to curtain wall systems, ensuring the perfect fit for any building style.

Offer soundproof glazing options to minimize exterior noise pollution, ideal for urban locations or buildings near transportation hubs.

Integrate creative design elements like glass fins, balustrades, pressings, and decorative panelling features to add a modern, visually striking aspect to building façades.

Professional Installation & Project Management

Full-service installation with an experienced team, ensuring efficient project execution from design to completion, on time and within budget.

Modern Technology & Tools

State-of-the-art manufacturing facilities, with full production control across our three premises in Northamptonshire.

In-House Architect & Design Service

Dedicated department including certified architects, CAD technicians, and façade specialists.

Partnerships formed with structural engineers, acoustic consultants, and relevant industry test houses, providing involvement to suit project requirements.

By Paul Fitzgerald (right), Managing Director, HKC and Pip Courcoux (below), Technical and Product Director, Abloy UK.

The convergence of technologies in the built environment has accelerated in recent years. As security threats have become more sophisticated and expectations around safety, compliance and operational efficiency have grown, there has been a greater demand for integration.

One area seeing a rapid shift is the integration between access control and intruder alarm systems. Research shows having an access control system that can be integrated into a comprehensive security solution is of key importance to industry professionals.

In fact, 93% of respondents stated open architecture and interoperability was either very or somewhat important when specifying an access control system. A different study also found 27% of the existing access control hardware market was already integrated into either a building management system or physical security information management platform.

This evolution is not only enhancing security provisions but also delivering measurable benefits for commercial

premises and critical infrastructure sites alike.

Traditionally, access control and intruder alarms have been treated as separate entities - installed, managed and maintained independently. But this fragmented approach can lead to inefficiencies, higher operational costs, and critical gaps in security coverage.

In contrast, integration enables these systems to communicate in real time, providing a holistic overview of a site’s status and enabling faster, smarter responses to potential security threats or breaches.

For example, an access control system can instantly disable a user’s credentials if an intruder alarm is triggered or restrict access to specific doors or areas during a lockdown event. This level of interaction not only enhances safety but also ensures that protocols are automatically enforced, reducing reliance on human intervention.

For commercial buildings, the benefits are clear. Integrated systems support streamlined building management, helping facilities teams monitor occupancy, track movements, and ensure compliance with fire safety protocols, all from a single interface. They also support efficient staff workflows and reduce downtime in the event of a security incident, since alerts and access restrictions are deployed automatically.

In critical infrastructure environment, where uninterrupted operations and stringent regulatory compliance are paramount, the stakes are even higher. Here, integrated solutions can offer layered protection, ensuring that only authorised personnel gain access, and that any breach triggers an immediate and proportionate response. Importantly, these systems can also deliver comprehensive audit trails, which are essential for both internal governance and external inspections.

The shift toward integration is being driven not just by technology providers, but by end users demanding more intuitive, intelligent systems.

Security teams want to move beyond reactive alerts and into a realm of proactive management, where data is centralised, risks are identified early, and the system supports rather than hinders day-to-day operations.

HKC Security and Abloy UK have seen this change firsthand. HKC’s SecureWave 10270 panel has been designed with tools to help the professional installer deliver integrated solutions to the customer, allowing seamless connectivity with certain access control and fogging systems.

Meanwhile, Abloy’s SMARTair access control solution offers a flexible, scalable way to control movement throughout a building, and can be linked with alarm systems to enhance situational awareness.

As integration becomes the new standard, it’s clear that collaboration - both between technologies and between suppliers - is key to delivering more secure, efficient and future-ready environments. Whether it’s a highrise office building or a high-security utilities site, the message is the same: integrated security isn’t just better, it’s essential.

Accredited courses, expert trainers, and handson learning.

Quelfire is a leading UK manufacturer of firestopping solutions for service penetrations in buildings. With a rigorous testing programme, awardwinning customer support, and over 600 tested details, the company helps customers find accurate, compliant solutions for even the most unique scenarios.

The company’s main mission is to educate the construction industry, which is why Quelfire’s team offers free training sessions, including early engagement consultations, product overviews, and its CPD titled, “Effective Passive Fire Protection for Service Penetrations in Buildings.”

The safest choice should always be the easiest choice. To support this, Quelfire makes its resources – including product documentation and its wide range of tested details – readily available for download at any time on its website. Additionally, Quelfire provides a library of YouTube videos that can be accessed 24/7 with a single click of a button.

Since the Grenfell tragedy, knowledge sharing has become more important than ever to bridge the gap between key stakeholders and ensure buildings are designed with the safety of the end user in mind.

Exhibitions like London Build support this mission and help the industry communicate in ways that everyday activities can’t match.

Team Orange is once again set to join the conversation at London Build 2025, where they’ll be on hand to support visitors and answer any questions.

As part of the ongoing “Because It’s Your Job to Know” campaign, this year’s stand will showcase Quelfire’s products before and after fire exposure, giving visitors a real-world look at how they perform and ‘what good looks like’.

As usual, the team will have product examples prepared for discussion, and the technical team will be available to help with any complex questions.

Quelfire provides a library of YouTube videos that can be accessed 24/7 with a single click of a button.

On the second day of the show, November 20th at 2 pm, Craig Wells, Quelfire’s Sales Director, will lead a panel discussion titled, “Gateway 2 Submissions: What We Know Now.” He will be joined by other industry professionals to share their experiences and insights.

Quelfire’s presence at London Build aims to stress the importance of collaboration and early engagement in construction projects, and to highlight the benefits, such as reduced risks, lower costs, and minimised rework.

To learn more about early engagement, visit Quelfire on stand N35 at Olympia London on November 19th and 20th, 2025. Because It’s Your Job to Know!

19 and 20 November 2025 | Olympia London | Stand N35 th th

WE TEST…

Because evidence matters.

Because it enables us to respond more quickly.

Because offering transparency helps educate our customers.

Because it’s our job to inform best practice.

Because it’s our job to offer guidance.

Because firestopping is complex.

Because results are worth sharing. Because people matter.

WE SHARE… BECAUSE IT’S YOUR JOB TO KNOW.

Download our White Paper, ‘Early Engagement in Firestopping’ at quelfire.co.uk/campaign

The sooner, the better.

Scan here

London Build 2025 returns to Olympia’s Grand and National Halls on November 19th and 20th to celebrate 10 years of connecting the construction industry. To mark the milestone, this year’s event will offer more networking innovation, and community building than ever before.

As the UK’s largest and most prestigious construction event, London Build is where the entire built environment comes together. With 38,000+ attendees, 750+ inspiring speakers, 450+ leading exhibitors, and 12 CPD stages, it’s your chance to connect with decision-makers shaping the future of the industry.

London Build attracts senior professionals across every sector of the industry, including contractors, architects, developers, housebuilders, civil engineers, government representatives, and major suppliers. Attendees include leading names such as:

• Architects:

Allford Hall Monaghan Morris, BDP, David Chipperfield Architects, Foster + Partners, Grimshaw Architects, Hawkins\Brown, HOK, Rogers Stirk Harbour + Partners, Sheppard Robson, WilkinsonEyre, Zaha Hadid Architects.

• Developers & House Builders: Barratt Developments, Bellway Homes, Berkeley Group, Countryside Properties, Crest Nicholson, L&Q Group, Legal & General Homes, McCarthy & Stone,

Notting Hill Genesis, Persimmon Homes, Redrow, Taylor Wimpey.

• Civil Engineers:

AECOM UK, Arup Group, AtkinsRealis, BDP Engineering, Buro Happold, Cundall, Faithful+Gould, Jacobs UK, Mott MacDonald, Pell Frischmann, Ramboll UK, Stantec UK, Sweco UK, Tony Gee and Partners, Waterman Group, WSP UK.

• Government:

Greater London Authority, Homes England, Transport for London, Network Rail, Department for Levelling Up, Housing & Communities, City of London Corporation, National Highways, HS2, London Boroughs including Westminster and Southwark.

As the UK’s largest and most prestigious construction event, London Build is where the entire built environment comes together.

• Exhibiting Companies include:

Acrow Bridge, Chelsea FC, Chevron, Hempel, Houzz Pro, Howdens, HSS Hire, Laing O’Rourke, Peel Ports Group, Saint-Gobain Group, Sherwin-Williams, Skanska, Southern Renewals Enterprise/ VolkerFitzpatrick, Technal, Toyota, Volker Wessels, Wates Group.

• Discover the latest products, solutions, and technologies driving the industry forward.

• Earn CPD points while learning from top architects, contractors, developers, and thought leaders.

• Network face-to-face with thousands of senior decision-makers, potential partners, and new clients.

• Celebrate 10 years of London Build with special anniversary events, competitions, and unique experiences across the show.

Event Details:

Dates: 19th November (9:30 am –4:30 pm) & 20th November (9:30 am – 5:00 pm)

Venue: Olympia (Grand & National Halls), Hammersmith Rd, London W14 8UX

Register: Visit www.londonbuildexpo.com to receive your free attendee pass and explore the full event programme.

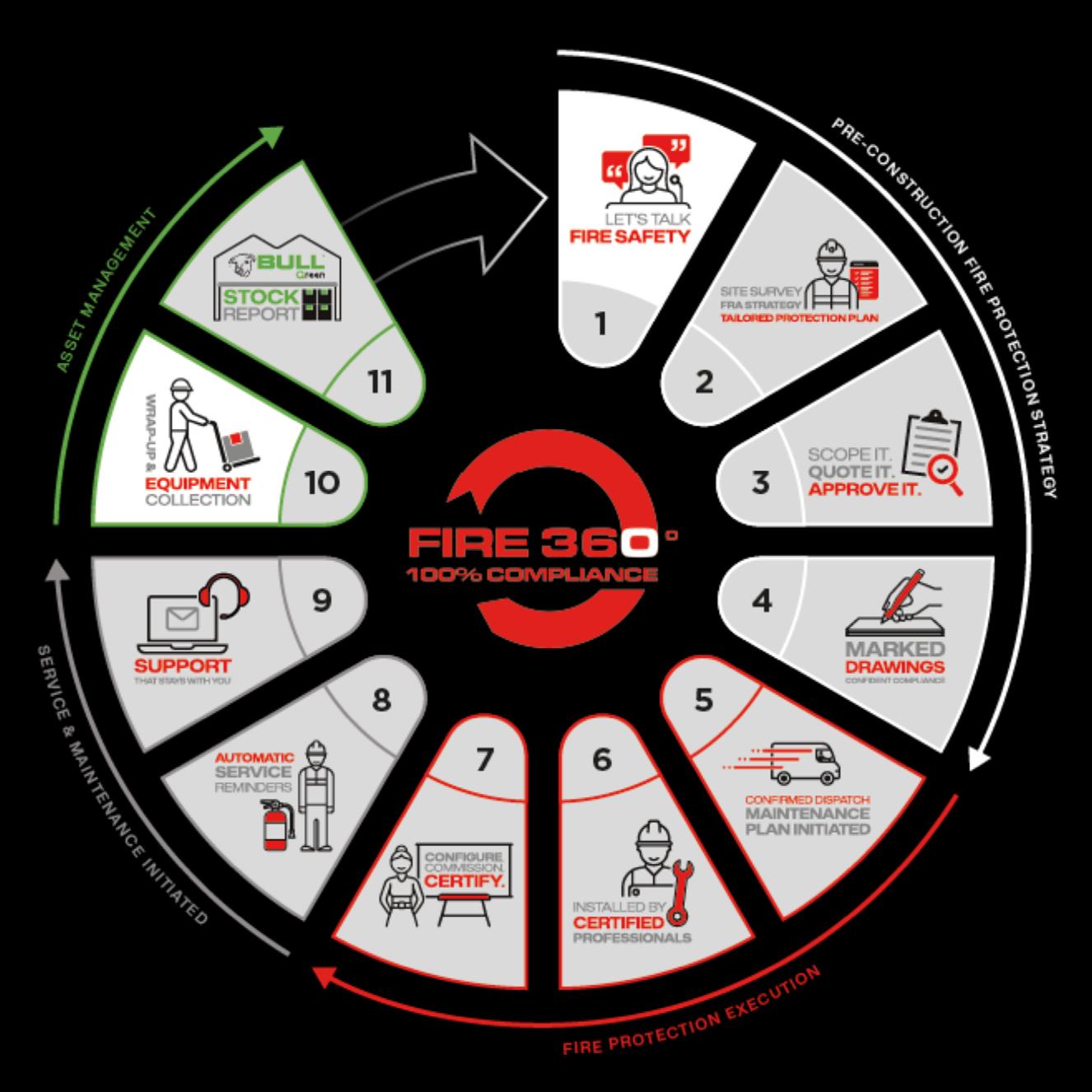

Bull Products will be exhibiting at London Build on 19–20 November on stand M50, where the company’s industry-leading Fire 360° service will take centre stage as a cornerstone of its commitment to construction site safety and compliance. This end-to-end fire protection solution has been developed to deliver systems and services that meet and exceed statutory requirements, with a focus on 100% compliance, reliability, and seamless support.

Fire 360° streamlines fire safety on construction sites across the length and breadth of mainland UK with an allencompassing fire safety solution. Fire 360° guides projects seamlessly through every major phase: from pre-construction fire protection strategy, through fire protection execution, to service and maintenance, and ongoing asset management. This approach ensures robust protection and 100% compliance at every stage, offering peace of mind from project inception to completion and beyond.

Bull Products’ fire detection and alarm range includes SITENET, a fully EN 54-certified solution developed in accordance with best practices outlined by HSE (HSG 168), JCoP, and UKTFA. As a BAFE-registered organisation, Bull

Products ensures that every customer benefits from expert support, with a dedicated team, including sales and service coordinators and CSCS-certified engineers, providing guidance and hands-on assistance throughout the process. Fire 360° delivers more than just equipment, from project start to end it offers 100% compliance, peace of mind, and support for sustainability goals by helping to reduce carbon footprint and operational costs.

As part of the event, Bull Products will be hosting a panel talk, ‘Fire 360° in Practice: Compliance, Regulation, and Sustainable Safety in Construction’, at the Building Security Stage, 10:00 -10:50 on 19th November. Attendees will gain valuable real-world insights into how Fire 360° streamlines fire safety on construction sites.

Visitors to the Bull Products stand will also learn more about the fire alarm product pyramid, featuring SITENET, SITEPROTECT, and SITEEVAC+. These systems are based on wireless mesh technology and are designed to address the diverse requirements and budgets of the construction industry. They also all bear the Made in Britain collective mark, an elemental part of Bull Products’ pledge to a more sustainable future.

On display will be SITENET, the only system on the market that is fully compliant with JCoP and HSG168. This fully EN 54 certified and wireless mesh intelligent fire detection and alarm system is built on patented self-forming, self-healing wireless mesh technology with multipath network redundancy and innovative channel hopping technology. SITENET provides a single integrated site-wide fire detection and alarm solution to meet the diverse needs of complex construction sites. Bull Products is the only provider offering a fully EN 54 certified fire detection and alarm solution for both internal and external spaces.

SITEPROTECT provides a versatile wireless mesh fire detection and alarm system that utilises EN 54-5 and EN 54-7 certified detector heads, encompassing wireless emergency fire, first aid, intruder, and lockdown alarms for complete site safety. The SITEPROTECT Lockdown alarm system, originally developed for the education sector, is also suitable for large public venues such as shopping centres, where rapid response to critical events is essential.

SITEEVAC+ is a wireless mesh fire detection and alarm system designed for cost-sensitive projects, allowing up to 50 devices across three zones. This easy-to-install and use system is ideal for housebuilders and developers, utilising EN 54-5 and EN 54-7 certified detector heads to maintain essential functionality without compromising quality.

London Build has grown beyond a trade show — it’s now a catalyst for industry change. Nowhere is this clearer than in its Women in Construction (WIC) focus, which champions equality, visibility, and lasting progress.

For 2025, London Build has pledged a 50:50 gender split across its speaker line-up — setting a new benchmark for representation. On the Diversity & Inclusion Stage, this commitment

ensures that panels reflect diverse voices, experiences, and leadership perspectives.

Beyond visibility, the event drives advocacy through its Ambassador Programme. Open to anyone passionate about equity in the built environment, it offers resources, public recognition via the “Wall of Fame,” and opportunities to shape live discussions — turning allyship into action.

This year also marks the launch of the WIC Resource Library, a practical online hub featuring guides like Breaking Barriers: Women in Construction Share Their Journeys and How to Network with Confidence. Combined with a dedicated LinkedIn group, it offers ongoing mentorship and community beyond the show.

London Build’s partnerships with NAWIC, Women in BIM, Modern Women, and WISH strengthen its reach — connecting attendees with established networks that sustain progress throughout the year.

More than ever, London Build 2025 embodies a shift from representation to inclusion. By combining resources, allyship, and real collaboration, it’s helping to build an industry where women don’t just enter construction — they thrive, lead, and inspire lasting change.

www.londonbuildexpo.com/womenin-construction

The Government’s new mantra to “build, baby, build” must be matched with a national effort to “skill, baby, skill,” the National House Building Council’s (NHBC) Chief Operating Officer David Campbell will warn at the Labour Party Conference on Sunday.

The call follows Housing Secretary Steve Reed’s vow to deliver 1.5 million new homes by bringing together developers and housebuilders to accelerate construction. But Mr Campbell will warn that without a significant expansion of the workforce, these targets will be difficult to achieve.

“We welcome ‘build, baby, build,’ but we need to ‘skill, baby, skill’ to ensure we have the workforce needed,” he will say.

£100m investment in training hubs

NHBC is investing £100m in 12 multiskill training hubs across the UK, each training 3,000 apprentices a year in

trades such as bricklaying, groundworks and site carpentry. Its first hub in Lichfield, developed with CITB and Barratt Redrow, is already open.

“More than 250,000 extra construction workers will be needed by 2028 just to meet current demand,” Mr Campbell will say.

“That’s why we must get moving now. You can’t create a skilled workforce overnight.”

Training apprentices in near-real site conditions and to NHBC standards, hubs are delivering qualified tradespeople in 14 to 18 months – nearly half the time of traditional education routes. With a 90% retention rate, most are expected to remain in the house-building sector.

NHBC also warns build quality is at risk without more skilled workers, highlighting the historic link between rising volumes and falling satisfaction. Mr Campbell will welcome government investment in skills but stress that collaboration between industry and government is essential.

“Together, we can build the homes this country needs and ensure they are built to the highest standards,” he will conclude.

By Tim Foreman, Managing Director of Land and New Homes, LRG

The appointment of a new Secretary of State for Housing offers a chance to reset the agenda. Steve Reed has wasted little time urging developers to “build, baby, build”. His ambition to accelerate delivery is welcome, but ambition alone will not shift the numbers.

Housebuilding is stalling. Planning approvals are down, completions are falling, and confidence is subdued. While government remains committed to 1.5 million homes this Parliament, we are well off track. Developers face rising costs, more regulation, slower planning and constrained demand – a system increasingly misaligned with reality.

Figures underline the challenge. The S&P Global Construction PMI shows the steepest drop in activity since the

pandemic. Housing starts have lagged completions for six quarters. The OBR forecasts just 192,000 completions in 2026 – far below the 300,000 per year target.

Demand for homes remains strong, but transactions are weak because firsttime buyers are locked out. The average property costs ten times average salary, while deposits and mortgage costs remain prohibitive. Developers cannot accelerate delivery without viable demand.

At the same time, costs are rising. Requirements for affordable housing, biodiversity net gain, new building safety standards and infrastructure contributions all add up. For land bought before these obligations, many sites no longer stack up financially.

What can government do? First, restore demand from first-time buyers. While a return of Help to Buy is unlikely, a targeted equity loan scheme could

unlock chains and boost confidence. A more ambitious mortgage guarantee scheme, backed by better promotion, would help too.

Tax reform could also support delivery. While new builds are zero-rated for VAT, many associated costs are not. Cutting these would make marginal sites viable. Investment in skills is also critical: the HBF estimates 239,000 new recruits are needed in five years, yet support for training remains limited.

Finally, planning must be faster and more predictable, with clearer timelines and more flexible application of affordable housing and environmental requirements.

The housing sector is ready to deliver. With decisive action to ease regulation, support buyers and restore confidence, government could create the conditions for success. Without it, the target of 1.5 million homes risks becoming another missed opportunity.

James Rowell is the founder of Capture Expense, a fintech platform built to simplify and modernise financial workflows in construction. With a background in digital transformation and a focus on real-time data capture, James has spent his career helping firms replace outdated, manual processes with tools that deliver speed, control, and compliance.

At a time when many SMEs still rely on spreadsheets, paper receipts, and fuel cards, James is championing fintech as a way to bring automation, visibility, and sustainability directly into site-level decision-making. From linking project spend to cost codes at the point of purchase, to enabling instant subcontractor payments with full compliance, he sees technology as a driver of efficiency and resilience in an industry facing mounting regulatory, financial, and ESG pressures.

In this interview, James shares his insights on how fintech is evolving in construction, the inefficiencies it can solve, and the role it will play in enabling sustainable practices and stronger compliance in the years ahead.

How is fintech used in construction today, and how will it evolve over the next five to ten years?

While fintech is beginning to make its mark in construction, adoption remains uneven, especially among SMEs, many of which still rely on spreadsheets, email, paper receipts, and fuel cards to manage site spending. However, larger firms are beginning to embrace more advanced tools like virtual cards, expense apps, invoice automation, and ERP integrations.

However, the real value lies in controlling site spend at the point of purchase and ensuring coded data flows directly into the job ledger without delay.

Looking ahead, the next five to ten years will bring a shift toward real-time financial workflows. Purchases will be instantly tied to specific projects, cost codes, and budgets at the moment of payment. Virtual cards will be issued per project and supplier, with approvals happening via mobile messaging apps like WhatsApp or Teams, ultimately making the process more intuitive and accessible.

AI will automate the reading and matching of delivery notes, receipts, and purchase orders, significantly reducing manual intervention, while still allowing for human oversight where needed. Even subcontractor payments will become instant, with compliance checks running seamlessly in the background.

Where are the biggest inefficiencies in traditional workflows, and how can fintech fix them?

The biggest inefficiencies stem from an over-reliance on manual processes like spreadsheets and long email chains. Site managers often make ad hoc purchases,

receipts go missing, and coding is delayed (sometimes by weeks) which causes month-end processes to drift. Approvals are manual and scattered across inboxes. Petty cash and fuel cards often sit outside the finance system, leading to VAT errors, especially with reverse charge complexities, which I’m sure is something that everyone wants to avoid.

Adopting fintech solutions can help address these issues by shifting control to the start of the process. Mobile capture at the point of spend helps to ensure data accuracy, which is a huge help for finance teams. Card controls can be linked to cost codes and budgets, and OCR technology is now reliable enough to automate much of the data entry. Approvals happen in-app with a clear audit trail, and receipts are automatically matched to transactions. Data posts directly into the ERP with correct tax treatment, resulting in faster month-end close, fewer reclassifications, and tighter budget control.

What role can fintech play in ESG and carbon tracking?

Fintech can play a pivotal role in ESG reporting by turning everyday expense and purchasing data into actionable carbon insights. Capturing merchant details, spend categories, mileage, and travel modes at the point of purchase allows for automatic conversion into emissions data. This enables firms to set carbon budgets per project, surface environmental impact during approvals, and encourage more sustainable choices, such as rail over short-haul flights.

The same dataset also supports supplier transparency and waste reduction, all without introducing new manual processes. It’s simply a matter of capturing better data at the point of spend.

How will regulatory compliance impact adoption?

Regulatory compliance is a key driver of fintech adoption in construction.

AI will automate the reading and matching of delivery notes, receipts, and purchase orders, significantly reducing manual intervention, while still allowing for human oversight where needed.

Firms are increasingly seeking providers that can handle UK VAT rules, including reverse charge, as well as CIS workflows for subcontractors, PSD2 banking standards, GDPR, and certifications like ISO 27001. Data residency and retention policies are now central to procurement decisions.

Fintech tools that ensure correct coding by default and maintain a full audit trail help reduce risk and exposure to HMRC scrutiny. These are board-level concerns, and as a result, compliant fintech solutions are becoming the safer, more strategic choice. These solutions are not only helping firms reduce audit risk and improve governance but also help them build trust with clients and regulators.

This goes a long way in protecting the business and also strengthens its competitive position in a compliancedriven market.

What advice for firms starting their fintech journey, and what should they look for in a provider?

Start with the areas that cause the most pain but require the least disruption. Site purchasing and expenses are ideal; they impact cost, control, and speed without needing to replace your ERP.

When choosing a provider, look for:

1. Native project and cost code tagging - multi-entity support, and correct UK VAT handling, including reverse charge and CIS.

2. User experience on site - the solution should work on any phone and integrate with apps like WhatsApp or Teams for offline access and simple capture.

3. Controls - per-project budgets, merchant/category rules, and approval workflows that align with your governance.

4. Integrations - proven connectors to your ERP, with clean data posting and no manual rework.

5. Security and compliance - ISO 27001, GDPR, and clear data ownership and exit terms.

6. Time to value - a good vendor should be able to launch a pilot in 4–6 weeks with measurable outcomes.

www.captureexpense.com

At first glance, most clay bricks appear similar, but beyond colour and texture lies a world of difference. Bricks are manufactured to meet distinct structural and aesthetic requirements, ensuring buildings are safe, durable and visually appropriate for their setting.

This overview introduces the most common brick types, their key characteristics and where they’re typically used.

These are the visible bricks used on external or feature walls, where appearance is as important as performance. Despite their aesthetic role, they must also demonstrate excellent compressive strength, thermal performance and long-term durability.

There are four main manufacturing methods for facing bricks, each producing distinct finishes::

• Extruded (wirecut) bricks are formed by pushing clay through a die and cutting it to size with a wire. The resulting bricks can be perforated or

solid, with perforations helping to reduce weight and fuel costs.

• Waterstruck bricks use water to stop clay sticking to the die, resulting in a rougher, more rustic texture.

• Stock bricks are moulded with a frog (a hollow depression) to make them lighter.

• Handmade bricks are created by throwing sand-coated clay into a mould, giving each brick a unique texture and colour.

At Michelmersh, facing bricks are central to our product range, from high-volume options for large housing developments to bespoke handmade bricks for specialist or heritage projects.

Less visible but vital to structural integrity, engineering bricks offer exceptional compressive strength and low water absorption. These properties make them ideal for foundations, retaining walls, tunnels and other civil works exposed to pressure, moisture and temperature changes.

Despite their name, common bricks are often used in limited applications. They’re more economical due to lower-grade materials and simpler manufacturing, resulting in a rougher texture and less consistent colour. Typically used where surfaces will be plastered or rendered, they’re common in internal walls and secondary layers.

Certain applications demand more specific designs:

• Special bricks (brick specials) are purpose-shaped to suit particular architectural requirements, such as angles or curves. They may be extruded, handmade or cut to shape after firing.

• Clay pavers are laid horizontally for pathways or courtyards. Tested for slip, frost and abrasion resistance, they perform well under foot or light vehicle traffic.

• Air bricks available in clay, plastic or metal, provide ventilation through perforations that prevent damp and decay in sub-floor spaces.

• Fire bricks are made from heatresistant materials like alumina and silica, suitable for furnaces, chimneys, barbecues and pizza ovens.

If you’re searching for more information about the best types of bricks to use on your project, we have multiple resources that can help. Our fully customisable Façade Designer tool allows you to create your own brick façade with our full range of products to visualise your perfect project. You can also learn more about clay bricks and get an accredited CPD certificate from our event ‘Right Brick, First Time’—contact us for more details and booking.

www.mbhplc.co.uk

sales@mbhplc.co.uk

0844 931 0022

By Charlie Brain, Senior Consultant, Water Hygiene Centre

Managing Legionella risk is rarely simple — and becomes even more complex when dealing with multiple, varied properties. This article explores how organisations can reduce risk effectively across a diverse estate.

All organisations must, as stated in ACoP L8:

(a) identify and assess sources of risk;

(b) prepare a written scheme for preventing or controlling the risk;

(c) implement, manage and monitor precautions;

(d) keep water safety records;

(e) appoint a competent person.

This can be straightforward in a single building, but more challenging across multiple, varied sites.

Different buildings, different management needs

Factors that can differ include:

• Size and complexity of systems

• Frequency of use

• Susceptibility of occupants

• Different management structures

• Building location

Organisations with multiple sites may centralise policies, training and contractors, but each building still requires tailored consideration.

A useful first step is a property risk screen, which categorises buildings by risk based on occupant susceptibility, exposure duration and system type. This helps prioritise risk assessments, highlight where controls are needed and identify properties requiring minimal management.

Risk assessments indicate a building’s inherent risk, ensuring control measures are proportionate and clarifying potential exposure if controls fail. Smaller, simpler systems with low-risk occupants require less oversight, while larger or more complex systems demand more resources.

Residential Accommodation vs Healthcare

The HSE offers simplified tasks for residential accommodation (HSG 274, part 2). By contrast, healthcare sites must follow stricter HTM guidance due to patient vulnerability. For mixed portfolios, resources can be focused on higher-risk healthcare sites, while applying lighter measures to offices or staff accommodation.

ACoP L8 requires a document outlining risk systems and how they will be managed. Creating individual schemes for each building may be unmanageable, so many organisations adopt a broader water safety plan supported by asset registers.

The most challenging aspect is often scheduling maintenance and keeping accurate records.

Once control measures are set, a logbook of maintenance tasks is formed, covering activities such as:

• Monthly temperature checks

• Flushing infrequently used outlets

• Shower cleaning

• TMV servicing

• Water sampling records

Traditionally, these were paper-based at each site, but auditing them across portfolios is difficult. Digital logbooks now allow central access, real-time updates by contractors, and data analysis through dashboards and reports, making management more efficient.

The more varied a property portfolio, the harder it is to manage. Total uniformity is impossible, but consistency helps: using the same risk assessor, training provider, logbook format and record-keeping system across all sites simplifies oversight. Technology can further streamline processes, but it’s a clear management framework and proportionate resource allocation that make the biggest difference.

By recognising the differences across buildings yet applying consistent standards where possible, organisations can not only meet regulatory requirements but also protect the health and safety of all building users.

A brand-new public space has opened in Reading as part of the £850 million Station Hill redevelopment — and behind its clean, modern look is a smart and efficient drainage system. Designed for high foot traffic and visual harmony, this public realm now features our slot grating system combined with the MultiV200 drainage channel.

Installed across key pedestrian zones, this solution supports both surface water management and architectural integrity — making it a perfect match for one of the UK’s most ambitious urban regeneration projects.

Slot grating is increasingly the drainage choice for public spaces, plazas, and pedestrian routes, and for good reason. At Station Hill, it provides the ideal balance between functionality and aesthetics.

Here’s what makes slot grating stand out:

• Discreet Appearance

With only a slim surface opening visible, slot drainage integrates beautifully into paved surfaces. It maintains the visual flow of the landscape — no bulky metal grates, no visual clutter.

• Safe for All Users

Designed with narrow openings, the system reduces trip hazards and accommodates all pedestrians, including those using mobility aids or pushchairs.

• High Drainage Capacity

Under the surface, the MultiV200 channel works hard to capture and direct runoff efficiently. It’s engineered for urban areas that experience large volumes of rainfall and foot traffic.

• Compliant and Durable

Fully compliant with BS EN 1433, the system is suitable for load classes up to D400 — making it tough enough for occasional vehicle access without compromising design.

MultiV200: Built for Urban Environments

At the heart of the system is the MultiV200 channel, known for its design, high hydraulic capacity, and ease of installation. Its wide internal dimensions help handle greater water volumes, while the V-shape profile increases flow velocity — reducing sediment build-up and improving self-cleaning.

For a landscape like Station Hill — with mixed gradients, planted areas, and a 4-metre level change — this kind of adaptability is essential.

A Better Urban Experience

Station Hill has transformed an underused part of central Reading into a welcoming, walkable space with green areas, seating, public art, and improved connections to the town centre. The drainage system may be invisible — but it plays a key role in keeping this space functional, safe, and looking its best in all weather conditions.

Looking to Improve Drainage in Your Public Space Project?

Our slot grating and MultiV200 system is the ideal choice for architects, engineers, and urban developers who want performance without compromising design.

Get in touch with our team to learn more or request technical specifications. Make the Right Choice for Your Drainage System

Contact ULMA today for expert guidance and reliable, high-performance drainage solutions.

Life on the coast has its perks — nice views, fresh sea air, and an abundance of ice cream parlours. However, for builders and architects, the seaside also presents some serious challenges. The salty breeze and sea spray can wreak havoc on building materials, causing rapid corrosion, especially to steel components.

Render is often used on coastal houses to protect the substrate from the elements but staining from rusty steel beading, which is used to reinforce the edges and create attractive straight finishes, can spoil the look. Thankfully, there is a solution that stands up to the harsh coastal environment: PVC render beads. These beads offer longlasting protection and performance, outperforming their steel counterparts for a finish that endures.

Why do coastal conditions cause such severe corrosion?

The main culprits behind the rapid corrosion of steel near the coast are moisture and salt. When these substances combine with metal, they speed up the rusting process significantly. Steel exposed to salty air corrodes up to ten times faster than it would in typical inland conditions with normal humidity. This makes the choice of materials for coastal construction projects crucial, as the wrong choice can lead to rapid deterioration and costly repairs.

The effects of corrosion aren’t just a cosmetic issue. While rust from steel beads can cause unattractive stains on facades, the damage goes deeper. Corrosion weakens the structural integrity of the facade, and what starts as a minor issue can evolve into a major problem, requiring significant investment to fix or replace affected materials.

Top: A UK coastal residential street with a clean rendered house exposed to the seafront

Above: Sovereign Quay, Cardiff, an example of a coastal building where Renderplas PVC render beads have been used

What counts as coastal conditions?

Determining what qualifies as a coastal environment can be tricky. The impact of saltwater and salt air depends on a range of factors, including local geography, weather patterns, and wave heights. The more exposed an area is, the more likely it is to face harsh coastal conditions.

As a rule of thumb, any location within about 5 km of the sea is considered to be exposed to coastal conditions. Buildings within 500 metres are at even greater risk.

For a nation like the UK, which is surrounded by water, this means a significant portion of land — including many large cities — can experience these effects. Builders working in these areas need to be aware of the heightened risks and choose materials accordingly.

The best materials for coastal construction

Standards such as BS EN 139141:2016 advise using corrosionresistant materials for rendering in

marine environments. While marinegrade stainless steel is one option, it is often prohibitively expensive. A more cost-effective and durable choice is PVC beads.

Renderplas PVC render beads, for example, are designed specifically for harsh environments and come with a guarantee of at least 25 years of performance, or the complete lifetime of a render.

Unlike steel, PVC does not rust, making it an ideal material for use in coastal areas. It offers the same strength and reliability without the risk of corrosion, ensuring that buildings maintain their appearance and structural integrity over time. Additionally, PVC beads are easy to install and require little maintenance, saving time and money on projects, and can be manufactured from up to 100% recycled PVC to reduce a project’s carbon footprint.

Building in coastal areas presents unique challenges, but choosing the right materials can make all the difference. While stainless steel may seem like a solid choice, the rapid corrosion it faces in salty conditions makes it less ideal. PVC render beads, such as those offered by Renderplas, provide a robust, cost-effective alternative that ensures durability and longevity. For builders looking to protect their projects from the ravages of saltwater and salty air, PVC render beads are the superior choice.

Bottom left: Renderplas PVC render beads will not rust and are guaranteed for the full servicelife of the render, or at least 25 years

Bottom right: Examples of building render where steel render beads have been used, which has led to rust leaking into the render, causing unpleasant discolouration and damage

By Bart Vingerhoets (pictured right), Senior Commercial Manager at Komatsu Smart Construction

Internet-connected hardware and artificial intelligence (AI) are becoming increasingly important in the construction and earthmoving industry, particularly site management. With advancements in technology, machinery such as excavators are becoming smarter, ultimately enhancing safety and efficiency on construction sites.

Have you found users asking for more technology on their excavator?

There has been a significant push towards digitisation by excavator operators, construction companies and governments. Technology is not only improving the efficiency of excavators but also aiding in increasing safety.

The earthmoving industry as a whole understands the benefits of technology. In Europe, some regions were initially priced out of being early adopters. However, with hardware becoming more cost-efficient, adoption rates are rising. Smart Construction has seen this firsthand, with 38% of its 3D Machine Guidance system sales taking place in East and South Europe.

Customer demands vary depending on region and client size. Many technologies initially adopted in West and North Europe are now being embraced elsewhere. In early adopter countries, the main concern is safety, along with productivity.

Digitally enabled hardware helps teams work more efficiently, make better decisions, and deliver stronger outcomes. For example, Komatsu’s Smart Construction Dashboard creates a digital version of the job site, showing live data on materials, measurements and potential issues.

What do users want the technology for?

Construction companies seek technological advancements to enhance profitability, save time, and reduce costs. Every year, businesses become more eager to improve risk

management and site safety, which digital solutions help facilitate.

Excavator operators benefit directly from incorporating digital solutions into their daily work. These tools save time for managers, enhance problem solving and improve data transfer. This allows more resources to be allocated to oversee multiple sites and communicate with suppliers and clients. Digital construction also enables virtual site inspections, reducing the need for frequent visits and cutting errors and rework.

Komatsu Smart Construction’s

Intelligent Machine Control excavators feature semi-automatic control to eliminate over-digging, avoiding costly re-work—especially crucial when working with different material layers. Teams can respond quickly, solve issues on the go, and avoid delays.

Do you anticipate users’ tech needs changing in the next five years?

The technology needs of excavator users are expected to evolve due to emerging trends. With the growth in digital twin technologies, excavators will play a key role in capturing surveygrade data. Having every bucket or blade move represented in a highly accurate model—such as Komatsu’s Intelligent Machine Control—adds productivity gains.

In 2025 and beyond, smart tech and AI adoption will continue to rise as more cost-effective options enter the market. The global AI in construction market was estimated at £1.3 billion in 2023 and is projected to reach £9.1 billion by 2030.

Digitalisation is making strides across earthmoving. Komatsu Smart Construction recently announced that its Remote solution is now standard with all Komatsu-branded guidance and control systems, promoting interoperability and ease of digital transformation.

Are users asking for additional tech solutions?

Smart Construction reported a 44% adoption increase in its software-asa-service (SaaS) tech from FY2023 to FY2024. Many users now say they couldn’t work without it. While each solution works independently, they deliver enhanced results when used together—such as Dashboard and 3D Machine Guidance.

We maintain close relationships with customers on the job, often turning their feedback into new features and products. In each country we operate, customers actively request to test new solutions based on our performance— like the latest version of Edge, launched last year.

As the industry evolves, we expect users to continue seeking additional technology that integrates with existing systems.

To find out more about digital solutions, visit: smartconstruction.io

Breath the purest air thanks to the revolutionary swiss air PAPR!

· Eliminates 99.8% of particles, including quartz dust, from the air

· No face shaving and no fit test required

· Ultra easy to use

· Compatible with all common helmets, ear defenders and goggles

MASCOT® WORKWEAR has delivered professional workwear across industries for more than 40 years. Now it has launched a new range of multiprotective clothing that combines safety, comfort and freedom of movement in one solution.

Safety and comfort go hand in hand in MASCOT® WORKWEAR’s new range of multi-protective clothing. MASCOT® ACCELERATE MULTISAFE is an innovative multi-protective range that includes hi-vis and non-hi-vis products for use in particularly hazardous environments in the oil, gas and wind industries.

A maximum level of safety when it counts

MASCOT’s many years of experience means they can deliver the highest quality workwear combined with exceptional comfort - without compromise. Employee safety is not just a priority, but a necessity. They need to be confident that their workwear will protect them optimally in any work situation.

MASCOT® ACCELERATE MULTISAFE consists of products that have both antistatic and flame-retardant properties. The majority of the products in MASCOT® ACCELERATE MULTISAFE are certified according to EN 13034 Type 6 meaning the products have protection against liquid chemicals. The products have a PFAS-free surface treatment which helps repel and resist the penetration of sulphuric acid and sodium hydroxide.

The range also provides protection against electric arc hazards according to EN 61482-2.

Try the layer-on-layer cladding method to increase overall protection. By using multiple layers of clothing, the overall protection can be higher as each layer helps to absorb and dissipate the energy from an electric arc.

Dye – Innovative dying method with environmental benefits

In the MASCOT® ACCELERATE MULTISAFE range MASCOT uses the dope dye method on several products to ensure higher colour fastness, equal distribution on dye and to ensure the colour does not wash out over time. All modacrylic in the main fabric of workwear and winter clothing (qualities 281, 284 and 292) in colour 010 – dark navy – is dyed using the dope dye method.

PROWASH® - Industrial washable products

Many products in the range have the PROWASH® label, meaning they are very durable and keep their shape and colour after repeated industrial washes. These products have been tested to ensure that they hold their fit, seam resistance, material strength and shrinkage, while also testing for colour change and smearing.

With the MASCOT® ACCELERATE MULTISAFE range, MASCOT offers workwear that is so comfortable that it becomes a natural part of everyday life while providing protecting in the event of an accident.

ULTIMATE STRETCH is MASCOT’s term for garments with four-way stretch. This means that the garments are elastic in all directions, taking freedom of movement to new heights. It’s workwear you’ll never want to be without.

A complete solution for every work situation

MASCOT offers a complete solution –workwear in the same design for every work situation. MASCOT can dress the whole company, whether the need is workwear, hi-vis work clothes or multi-protective clothing. The design line across the MASCOT®ACCELERATE, MASCOT®ACCELERATE SAFE AND MASCOT®ACCELERATE MULTISAFE ranges are similar, giving you the opportunity to create a strong, common identify across work tasks and safety requirements.

MASCOT is more than the highest quality products. In addition to the industry’s widest range and high delivery reliability, you get simple and efficient online ordering, customised logo solutions and fast delivery.

Property management, traditionally focused on tangible assets and service efficiency, now faces a growing challenge: cyber risks. These threats demand a dual focus on physical and digital risk management to ensure operational continuity, tenant safety, and financial health.

A 2025 Royal Institution of Chartered Surveyors (RICS) report revealed that 27% of UK buildings experienced cyberattacks in 2024, a 16% year-on-year increase. Cybersecurity Awareness Month highlights the need to reassess vulnerabilities and build resilience.

Cybercriminals are exploiting Artificial Intelligence (AI) to target the real estate sector. AI enables the creation of deepfakes, voice cloning, and forged documents, making it harder to distinguish genuine communications from fraudulent ones. The sector’s reliance on trust, urgency, and highvalue transactions makes it particularly vulnerable.

Property transactions involve significant financial transfers among multiple parties, creating opportunities for exploitation. Remote processes and e-signatures, while efficient, expand digital footprints and reduce in-person verification, increasing risks.

Modern properties rely on interconnected systems for access control, CCTV,

HVAC, and building management. While automation improves efficiency, it also broadens the attack surface. Cyber-attacks can disrupt essential services, leaving tenants in unsafe or uncomfortable conditions.

Financial transactions, such as rent collection and vendor payments, are prime targets for scams like Business Email Compromise (BEC). AI-driven scams have become more sophisticated, tricking property managers into redirecting funds to fraudulent accounts.

Contractors and facilities management providers often lack robust cybersecurity measures, creating potential back doors for attackers. Shared credentials and unvetted remote access tools exacerbate these risks.

Digital platforms for rent payments and service requests are increasingly targeted by cybercriminals. Fake apps, phishing emails, and spoofed alerts can lead to data breaches, eroding tenant trust and exposing sensitive information.

• Unexpected bank detail change requests.

• Outdated software without a patching schedule.

• Contractors with remote access but no cyber policy.

• Unencrypted service charge communications.

• Staff using personal emails for critical messaging.

To mitigate risks, property managers should:

• Train Staff: Educate employees on recognising phishing and social engineering attempts.

• Use Multi-Factor Authentication (MFA): Make MFA mandatory for administrative access and tenant portals.

• Enforce Vendor Protocols: Include cybersecurity clauses in contracts and conduct regular security assessments.

• Verify Payments: Use dual verification for bank detail changes and impose a 48-hour waiting period.

• Update Systems: Replace outdated software and ensure regular patch management.

• Develop Incident Response Plans: Tailor response strategies for each property.

• Report to the Board: Include digital risk in governance updates.

Stricter UK regulations and insurance requirements are reshaping how organisations handle cyber threats. Insurers now demand proof of controls like MFA and incident response plans, making cyber resilience essential for insurability.

With the average cyber-attack costing UK businesses £10,830, property managers must prioritise cybersecurity. As building systems become more connected, proactive measures are essential to protect assets, tenants, and operations from evolving threats.

For further information scan the QR code above.

Whether you're a growing contractor or a large-scale firm, Sage Intacct Construction can you help you build smarter. Take control of your construction finances—minimise risk and maximise efficiency with real-time job costing and automation.

For further information, please scan the QR code

Why choose Sage Intacct Construction?

Automate AP/AR processes and gain 20–40% in work e ciency.

Reduce average month-end close time by 25–50%.

Minimise busy work and increase time spent on analysis and strategy by 25–75%.

Track actual and committed costs in real-time across multiple projects and entities.

Discover More

The best of Britain’s construction talent has been unveiled as the finalists for the On The Tools Awards 2025, celebrating the skill, dedication, and innovation shaping the industry.

The shortlist recognises exceptional tradespeople across apprentices, bricklayers, carpenters, bathroom fitters, electricians, and more. Jewson returns as headline sponsor, supporting the awards in shining a spotlight on the people driving the UK’s construction sector forward.

From apprentices beginning their careers to highly experienced craftspeople perfecting decades of expertise, the On The Tools Awards finalists represent the pinnacle of UK construction.

Their achievements demonstrate not only technical skill, but also passion, innovation, and a commitment to raising standards across the industry.

Winners will be revealed at a prestigious awards ceremony in The Midlands later this year, celebrating those who make a tangible impact on their communities, their teams, and the industry as a whole.

The On The Tools Awards continue to champion individuals who demonstrate excellence, resilience, and innovation. By highlighting those at the top of their game, the awards inspire young people to consider careers in the trades and shine a national spotlight on the professionalism, creativity, and dedication within the sector.

The finalists have now entered the final stage of the competition, with the winners set to be revealed on 30th October 2025 at a prestigious event at the Vox, Birmingham. The winners will be chosen by a prestigious panel of judges from across the industry, and their scores will be based on their expertise, quality of work, and commitment to their trades.

Visit www.onthetools.tv/awards to find out more.

The Construction Industry Training Board (CITB) is delighted to announce the winners for the Top 100 Most Influential Women in Construction Awards 2025.

The awards ceremony, which celebrates and honours the outstanding individuals within the sector, took place on 18th September at Manchester’s Kimpton Clocktower Hotel.

The ceremony saw Katy Robinson – a Senior Project Manager with East Riding of Yorkshire Council and Campaign Leader for the National

Association of Women in Construction for Yorkshire (NAWIC) - awarded as the UK’s Most Influential Overall.

Deborah Madden, Executive Director, Nations Engagement at CITB said:

“It’s essential that we keep on paving the way for more women to join the industry.

Highlighting some of the trailblazing women already working in construction as inspiration for others is a key route to achieving this. We hope that these awards will encourage more women to consider, and forge, a career in construction. The workforce gap can only be bridged by attracting more people from more diverse

backgrounds to careers in construction – those who might not have traditionally joined the industry – and supporting their growth through training and skills development to retain their talent.”

Some of the UK’s leading contractors and consultants, including Vinci, RLB, BAM, and Pulse, were among the winners at this year’s National Project Excellence Awards, hosted by the Procure Partnerships Framework at Liverpool’s Titanic Hotel.

The event brought together over 400 contractor, consultant and client partners to celebrate the projects delivered through the framework and the people behind them. Across 15 award categories, a total of 48 projects were shortlisted, recognising excellence in project delivery, innovation, decarbonisation and social impact.

Regional highlights included GRAHAM, which won Project of the Year (North) for Trevelyan Square on behalf of Leeds Trinity University, and Volkerfitzpatrick, which picked up Project of the Year (East) for Cambridge City Council’s sustainable Operations Hub. Danaher & Walsh secured Infrastructure Project of the Year for their work at Waltham Cross, while BAM was recognised with Project of the Year (West) for the Bedworth Physical Activity Hub.

Social value and sustainability took centre stage, Vinci claimed the Social Value Excellence in Action Award for its work with Sefton Council at Bootle Strand, and Tilbury Douglas took home the Social Value Impact Award after generating an impressive £16.4m in social value add while delivering the New Custody Suite for Durham Constabulary.

GSS Architecture, RLB and Bidwells all picked up awards for Consultant of the Year in their respective region, whilst the Multi-Disciplinary Team of the Year award went to Pulse Consult, who led a multidisciplinary team on the supported living accommodation Kingston Lane, on behalf of the London Borough Richmond Upon Thames.

The night’s top honour, Construction Project of the Year, was awarded to Speller Metcalfe for the Edmond Transplant Centre, delivered on time and on budget for University Hospitals Birmingham NHS Foundation Trust. Originally facing delays and cost pressures, the project team reworked both the design and programme to meet urgent clinical needs and was described on the night as a “true showcase of collaboration, innovation and project excellence.”

The UK’s house-building sector is gearing up to address its most urgent challenges, from housing market growth and climate change to the Future Homes Standard and build quality, as the industry works to deliver the government’s target of building 1.5 million new homes this Parliament.

The National House Building Council (NHBC) will host BEYOND ’26 LIVE on 25 February 2026 at the CBS Arena, Coventry. The event will bring together over 1,200 professionals and more than 40 expert speakers and leaders. It will offer valuable content for all levels, from CEOs and technical directors to site managers, sub-contractors and apprentices. Attendees will gain fresh ideas, practical guidance and new insights from leading voices in house building.

Hosted by broadcaster and journalist Louise Minchin (pictured below), best known for her 20 years on

BBC Breakfast, the event will take on the climate crisis with sessions on sustainable construction and preparing for the UK’s 2050 net-zero commitment. It will also address future skills needs, the current housing market and what needs to be done to stimulate growth.

BEYOND ’26 LIVE will showcase best practice in modern timber frame construction, including expert guidance and a live demonstration. A Pride in the Job panel will share insights from this year’s competition and what it takes for site managers to succeed. A dedicated stage will cover roofing quality, highlighting critical external elements and how to avoid common faults, costly rework and claims.

Other topics include NHBC Standards updates, new technologies, construction products, the Building Safety Levy, social housing and water efficiency.

The event will also provide attendees with valuable Continuing Professional Development (CPD) opportunities.

With government housing targets under pressure, BEYOND ’26 LIVE promises to deliver actionable insights to help house builders overcome barriers and seize opportunities in a rapidly evolving market.

For more information and to register, visit nhbc.co.uk/beyond.

As construction sites become more connected and data-driven, the risks of cyber threats are rising fast. From digital blueprints to project management and client relationship platforms, and subcontractor details, the industry holds vast amounts of sensitive data. That’s why ISO 27001 – the global standard for Information Security Management Systems (ISMS) – plays a significant role, and the latest update to ISO 27001 marks a pivotal shift for construction firms aiming to stay secure, compliant, and competitive.

The ISO 27001:2022 revision brings a sharper, more adaptable framework to help organisations manage digital risks. The number of controls has been reduced from 114 to 93, now grouped under four themes: Organisational, People, Physical, and Technological. These categories reflect how today’s threats span both digital infrastructure and human behaviour.

Newly added controls, such as threat intelligence, physical security monitoring, and data deletion, are highly relevant to construction environments, where remote site access, mobile devices, and shared platforms are commonplace.

For companies already certified, this update requires a transition – a rather urgent one: until the 31st of October 2025 – to align with the new Annex

A controls. For those yet to certify, it offers a clearer, more modern route to managing business security holistically.

Construction is now one of the top targets for cybercriminals. Whether it’s ransomware attacks, phishing schemes, social engineering probes, or unauthorised access to cloud-based drawings, contracts and financial documents, the sector’s growing reliance on technology makes it vulnerable.

The 2022 update renders ISO 27001 more practical and accessible, enabling the industry to:

• Better manage subcontractor risks

• Strengthen security across job sites and offices

• Show clients and regulators a serious commitment to information protection

ISO 27001 as a Competitive Asset

Beyond risk mitigation, aligning with ISO 27001:2022 can support growth. How? Many public sector and infrastructure tenders now require demonstrable information security credentials. An updated ISMS provides a valuable edge in competitive bidding, particularly as clients demand greater transparency around digital safety.

Whether managing multi-site builds or single-site operations, construction companies should now:

• Accomplish transitioning to the revised standard in case of holding earlier certification to ISO 27001:2013

• Review current security processes against the new ISO 27001 version structure and start their implementation for the first time certification

• Train key staff on new control areas, especially those involving access, monitoring, and incident response

The construction industry is changing and so are the standards that protect it. Embracing the ISO 27001:2022 update isn’t just about compliance; it’s about building safer, smarter, and more resilient operations from the ground up.

Construction insurance tailored to you.

Gallagher offers the strength and positioning of a global insurance group, combined with the personalised care and attention of a local UK broker. With a rich history dating back to 1927, we believe we have the expertise and experience to meet your construction insurance needs.

CONNECT WITH A SPECIALIST

For further information, please scan the QR code.

Roofing specialist BMI is taking action to tackle the critical skills shortage in the roofing industry with the release of free pitched roofing courses for the second half of 2025. Alongside new course dates, the BMI Academy has bolstered its team with new hires to meet rising demand for hands-on, high-quality training.

The construction sector is facing a well-documented skills crisis, with roofing among the hardest hit. According to the latest National Federation of Roofing Contractors (NFRC) State of the Roofing Industry Report, 47% of roofing contractors struggle to recruit skilled workers, highlighting the urgent need for training and investment across the industry.

In response to increased demand earlier this year, BMI released additional dates for its popular pitched roofing programme. Open to apprentices, contractors, merchants, specifiers, and other roofing professionals, the free courses blend classroom teaching with hands-on practice using real BMI Redland roofing systems. They’re designed to help participants at all levels build practical skills, stay current with industry standards, and gain confidence to make an immediate impact in their day-to-day work.

Commenting on the announcement, Stuart Farndell, Lead Technical Trainer at the BMI Academy said: “Roofing isn’t a static trade. There’s always something new to learn,