Introduction Using this Guide Applications

This section includes product recommendations for typical applications, always verify product suitability based on your specific requirements and key selection criteria.

Key Selection Criteria

Utilize material and strength charts to help select the Panduit products required to deliver superior performance in your application.

Select the appropriate tools to speed installation time, and take advantage of our lowest installed cost solutions.

Consider Panduit permanent identification solutions to help provide legibility in harsh environments; the complete system includes marker plates, tags and ties and is available for use with On-site Custom Marking Tools or through our Factory Custom Marking Service.

Selection Guides

Organized by part number, use each chart to assist with your product selection.

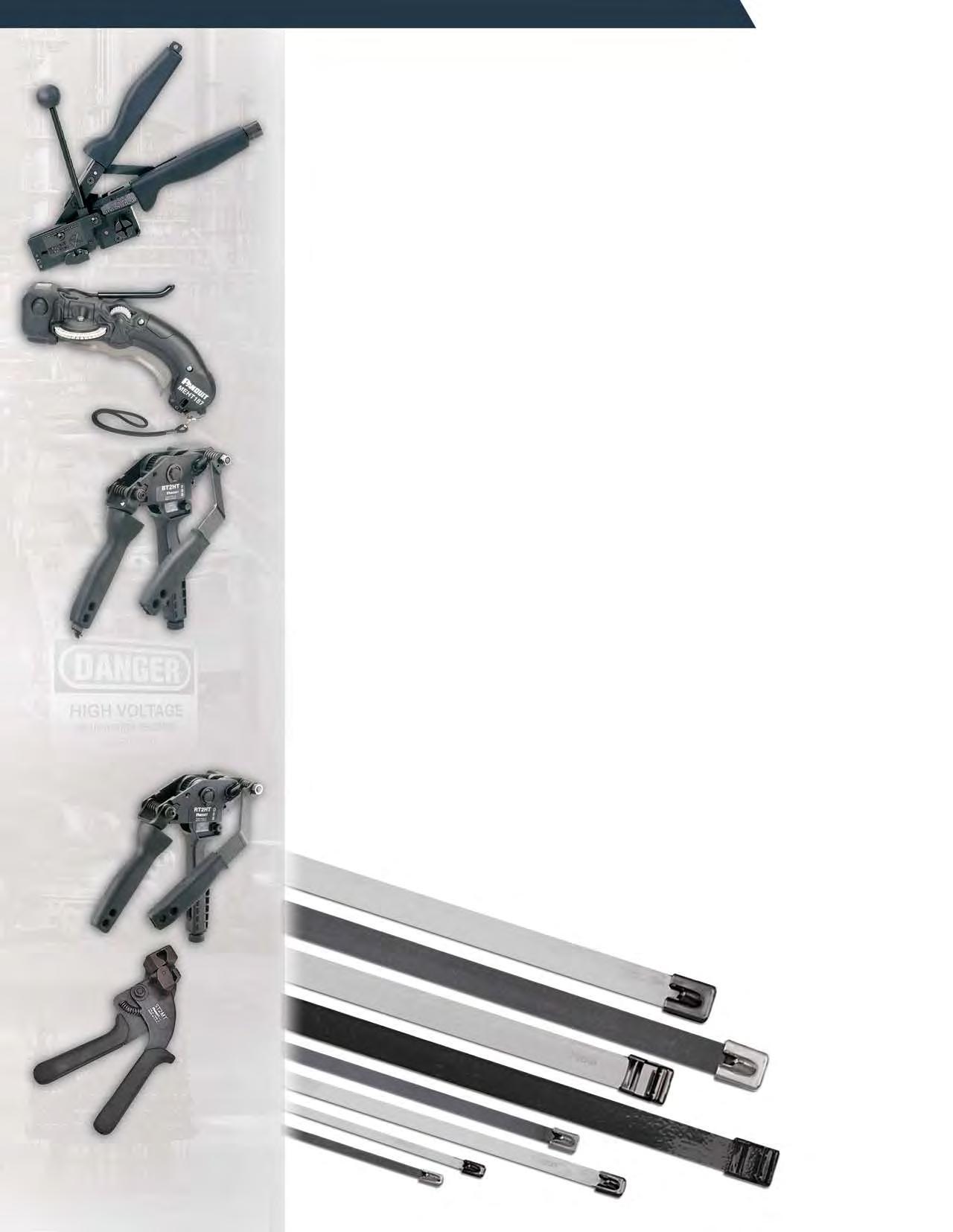

Pan-Steel® System

Reliable system performance:

Delivers strength, long life and resistance to chemicals, vibration, radiation, weathering, and extreme temperatures.

Increased job site safety:

Features rounded edges to prevent installer injury and damage to cable bundles or finished product.

Lowest installed cost:

Includes reliable, ergonomic tooling and an innovative cable tie design to provide fast and reliable installation.

Effectively identified workplace:

Offers the most comprehensive selection of on-site and factory custom marking products in the industry.

Standards compliance:

Meets and exceeds the most stringent industry standards.

Stainless Steel Cable Ties

This section includes product recommendations for typical applications, always verify product suitability based on your specific requirements and key selection criteria

Retained Tension Ties

Panduit retained tension ties deliver a durable, secure fastening solution for mechanical applications. The system delivers the highest retained tension in the industry, providing tight fastening of rigid materials in high vibration and harsh environments.

Stainless Steel Strapping

Panduit coated and uncoated stainless steel strapping is the ultimate solution for large mechanical applications. The buckle design and installation tools offer a quick and safe installation.

Aluminum Cable Ties

Panduit aluminum cable ties are used to bundle and identify cabling or secure aluminum marker plates and tags to cabling and devices. Aluminum cable ties are a lightweight, flexible bundling, and permanent identification solution.

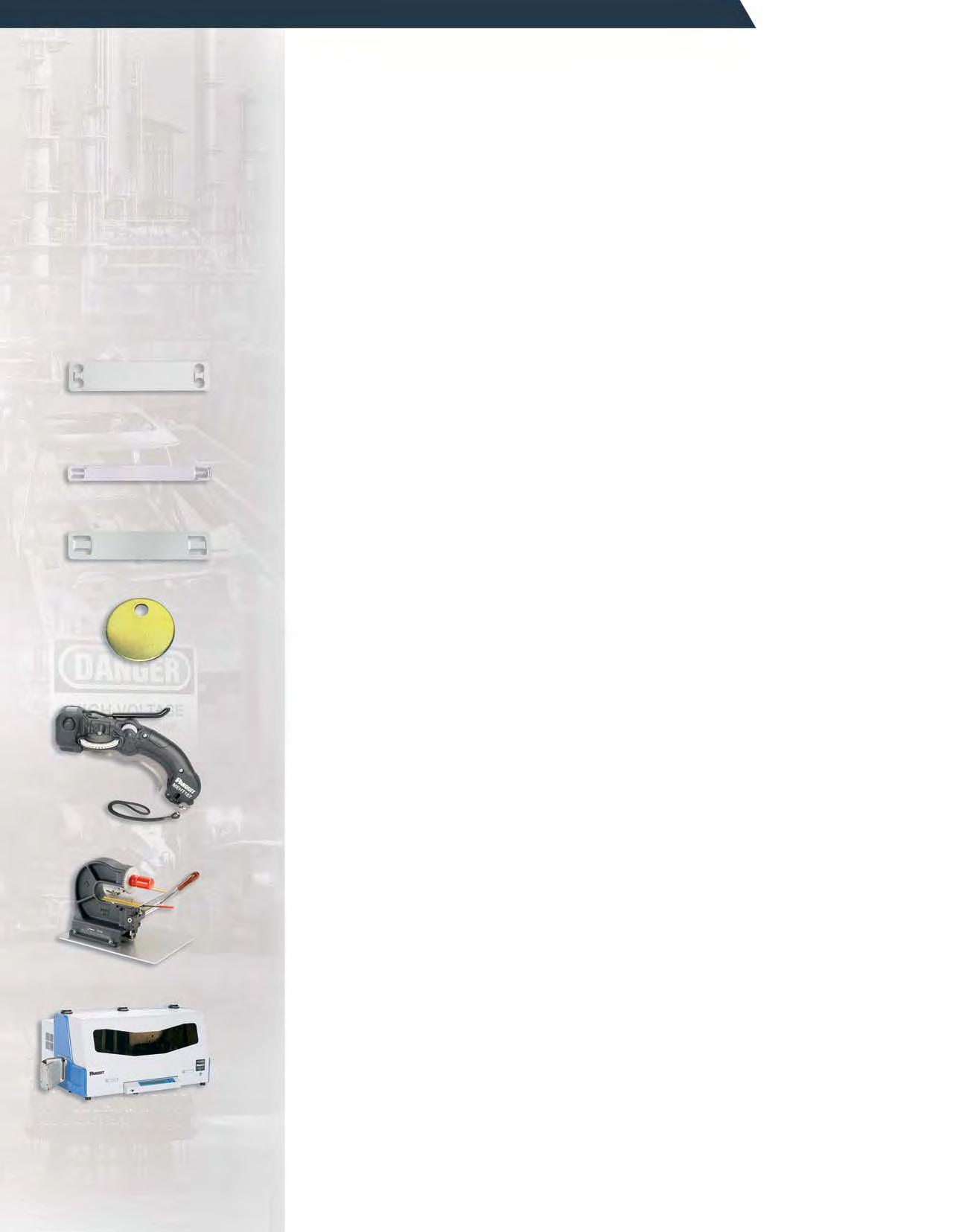

Permanent Identification

The widest range of permanent identification solutions available includes stainless steel and aluminum cable ties, marker plates and tags in a variety of shapes and sizes. Factory custom marking service delivers embossed or laser etched identification. On-site marking tools are excellent for quick and easy identification in the field.

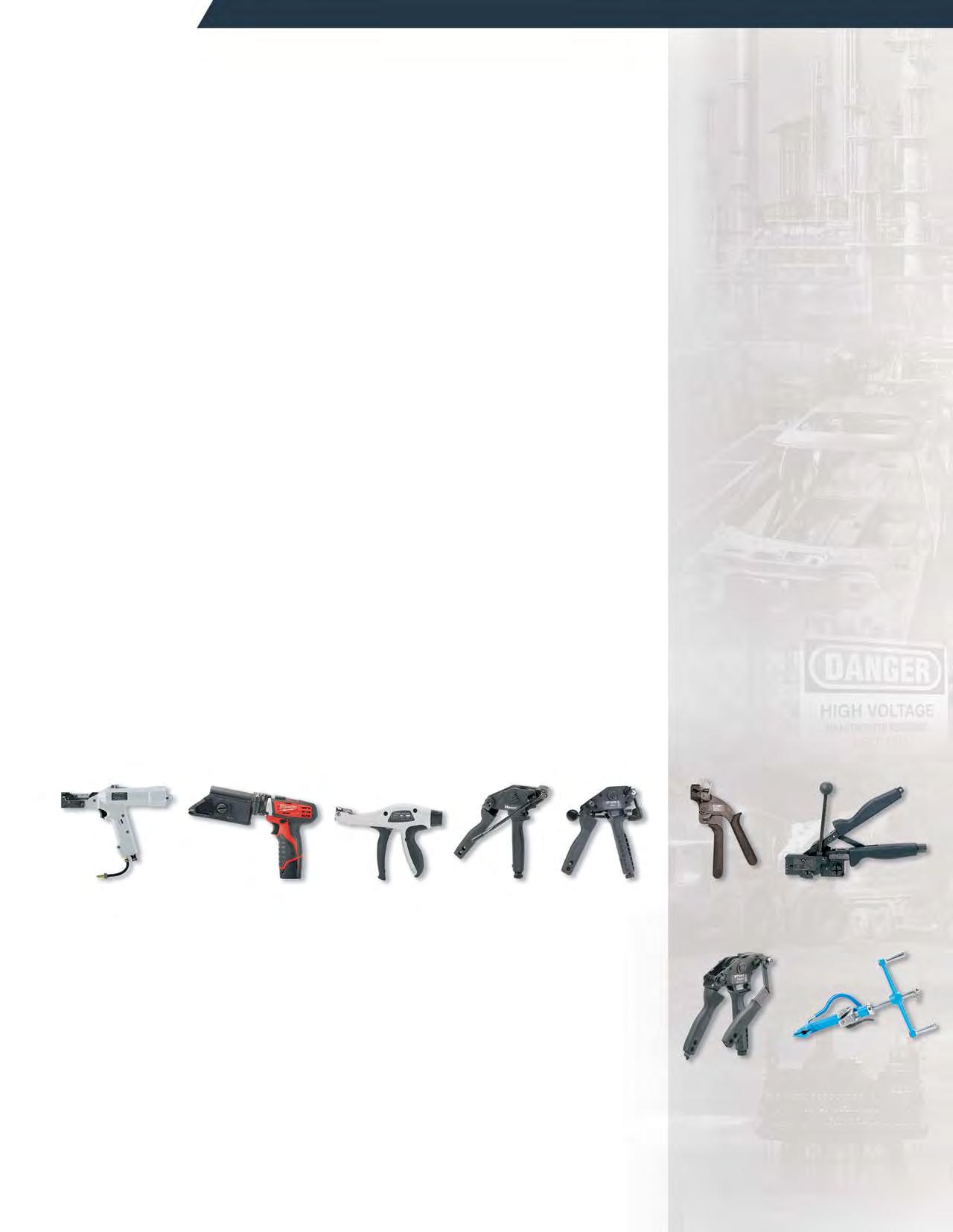

Installation Tools

Panduit cable ties and industry leading installation tools work together to provide repeatable high performance at the lowest installed cost. Ergonomic tools are available for low, medium, and high volume applications. Reliability is designed into every tool.

Strong, safe, and reliable solutions for long service life and lowest installed cost in harsh environments

Panduit stainless steel cable ties and permanent identification solutions can deliver a useable life greater than 30 years. The combined value of material cost, labor savings, and improved safety results in the lowest total installed cost.

Panduit Self-Locking Cable Ties

Applications

Panduit offers a wide variety of metal cable bundling, mechanical fastening, and permanent identification solutions to meet your specific application requirements. Common applications include:

Cable Tray, Outdoor

Oil Rigs, Refineries

Description: Electrical or Communication Cabling secured to cable tray in harsh environment.

Selection Criteria: Resistance to extreme temperatures, chemicals, salt-water spray, ultra-violet light.

Product Recommendations:

• For Horizontal, Stainless Steel Cable Tray –Use Uncoated Heavy 316 Stainless Steel Metal Locking Tie

• For Vertical, Stainless Steel Cable Tray –Use Uncoated Extra-Heavy 316 Stainless Steel Metal Locking Tie

• For Horizontal, Aluminum Cable Tray –Use Coated Heavy 316 Stainless Steel Metal Locking Tie

• For Short Circuit – up to 112kA –Use Metal Locking Ties or MS75 Metal Strapping

Cable Tray, Indoor

Ships, Submarines, Chemical Plants, Industrial Facilities

Description: Electrical or Communication Cabling secured to cable tray in harsh environment.

Selection Criteria: Resistance to extreme temperatures, chemicals, vibration, and shock.

Product Recommendations:

• For Horizontal, Stainless Steel Cable Tray –Use Uncoated Heavy 316 Stainless Steel Metal Locking Tie

• For Vertical, Stainless Steel Cable Tray –Use Uncoated Extra-Heavy 316 Stainless Steel Metal Locking Tie

• For Horizontal, Aluminum Cable Tray –Use Coated Heavy 316 Stainless Steel Metal Locking Tie

• For Short circuit – up to 71.5kA –Use Super-Heavy Double Loop 316 Stainless Steel Metal Locking Tie

• Cushion Sleeving available for military applications

• For Short Circuit – up to 112kA –Use Metal Locking Ties or MS75 Metal Strapping

Instrument Tubing Oil Rigs, Refineries, Chemical Plants, Industrial Facilities

Description: Instrument tubing secured to pipe or rail inharsh environment.

Selection Criteria: Retained tension, resistance to extreme temperatures, chemicals, salt-water spray, ultra-violet light.

Product Recommendations:

• Coated 1/2" Wide (12.7mm) 316 Stainless Steel Custom Length Strapping

Pipe Insulation

Chemical Plants, Refineries,Industrial Facilities

Description: Secure metal shield over pipe insulation.

Selection Criteria: Resistance to extreme temperatures, chemicals, ultra-violet light.

Product Recommendations:

• Uncoated Extra-Heavy 15, 304 Stainless Steel Metal Locking Tie

Rubber Steering Rack Boot

Trucks, Autos

Description: Securing CV boots or steering rack boots on vehicles.

Selection Criteria: Resistance to high temperatures, salt spray and chemicals, retained tension, liquid tight seal.

Product Recommendations:

• Standard or Light-Heavy 360° Radial Seal 304 Stainless Steel Retained Tension Tie

Heat Shields

Motorcycles, Trucks, Autos, Aircraft

Description: Secure heat shields on engines.

Selection Criteria: Retained tension, resistance to extreme temperatures, thermal expansion, salt spray, chemicals.

Product Recommendations:

• Standard, Light-Heavy, or Heavy 304 Stainless Steel Retained Tension Tie

Aerial Support

Railway, Power, and Communication Lines

Description: Electrical or Communication Cabling secured to support structure.

Selection Criteria: Resistance to extreme temperatures, chemicals, ultra-violet light.

Product Recommendations:

• Uncoated Heavy or Extra-Heavy 304 Stainless Steel Metal Locking Tie

• Stackable spacers available

Cable Identification

Cell Towers, Oil Rigs, Ships, Submarines, Industrial Facilities, Mining

Description: Electrical or Communication Cabling secured to support structure and identification.

Selection Criteria: Resistance to extreme temperatures, ultra-violet light.

Product Recommendations:

• 304 Stainless Steel Marker Plate (Embossed)

• Aluminum Marker Plate (Embossed)

• Uncoated Heavy 304 Stainless Steel Metal Locking Tie

• Aluminum Metal Locking Tie

Pipe Identification

Water Treatment Facilities, Refineries, Chemical Plants, Industrial Facilities

Description: Securing stainless steel or aluminum tags onto valve, conduit, pipe, cable.

Selection Criteria: Resistance to chemicals, extreme temperatures, ultra-violet light.

Product Recommendations:

• 304 Stainless Steel Marker Plate

• Standard, Light-Heavy, or Heavy 304 Stainless Steel Metal Locking Tie

Valve Identification

Industrial Facilities

Description: Securing stainless steel or brass tags to valve.

Selection Criteria: Resistance to extreme temperatures, ultra-violet light.

Product Recommendations:

• Brass Marker Tag

• Standard 304 Stainless Steel Metal Locking Tie

General Mechanical Sign and Signal Mounting

Description: Securing signs to outdoor poles.

Selection Criteria: High strength and secure installation.

Product Recommendations:

• MS75 Strapping System

Telecommunications Backbone

Commercial Building

Description: Bundling Fiber Optic Cabling to aluminum cable tray.

Selection Criteria: Strength, cable protection and corrosion resistance.

Product Recommendations:

• Coated Heavy 316 Stainless Steel Metal Locking Tie (apply at lowest tension setting)

Panduit stainless steel cable ties perform exceptionally well in temperature, chemical, and environmental extremes.

Key Selection Criteria

Variables such as exposure to extreme temperatures, salt spray, and weather have differing effects on the performance of stainless steel and aluminum. Each of these factors contributes to the useful life of a cable tie, marker plate, or tag. Use the following sections as a guide to select the optimum Pan-Steel® Solution for your application.

• Performance in harsh environments

• Strength for application

• Workplace safety and abrasion protection

• Lowest installed cost

• Effective identification

• Compliance with industry standards

Performance in Harsh Environments

Materials

Stainless steel: Recommended for harsh environment and general purpose applications where strength and/or resistance to severe conditions are required.

Aluminum: Recommended in applications where light weight and flexibility are required. It is also well suited for use with aluminum cable tray to avoid corrosion from dissimilar metals.

Material Selection for Temperature Resistance

The following are recommended operating temperature ranges for stainless steel and aluminum. The operating temperature for uncoated and coated stainless steel is -112°F (-80°C) to 1,000°F (538°C) (Uncoated), -76°F (-60°C) – 572°F (300°C) (Nylon) and -40°F (-40°C) to 302°F (150°C) (Polyester). The operating temperature for Aluminum is -112°F (-80°C) to 212°F (100°C).

Material Selection for Salt Spray Resistance

Panduit cable ties were subjected to salt spray testing for 2,000 hours at 95°F (35°C). Both materials showed no signs of corrosion. The 316 Stainless Steel had trace surface staining and is recommended for mission critical applications. The 304 Stainless Steel had moderate surface staining and is recommended for general applications.

Material Selection for Weather Exposure

Panduit cable ties were exposed to weather for prolonged lengths of time outside our manufacturing facility in Illinois, USA, without loss of performance or signs of corrosion. Loop tensile strength increased from year one to year four and remained stable over time.

Weather Conditioning

Effective Identification

Panduit offers the broadest range of permanent identification solutions in the industry to withstand and provide legibility in harsh environments. Safe, quick, and easy to install, permanent identification solutions include stainless steel and aluminum marker plates, tags, marking tools, and ties to deliver improved productivity and workplace safety.

On-site Custom Marking Tools provide portability for permanent identification and demand. Panduit also offers a Factory Custom Marking Service for embossed or laser etched marker plates, tags, and ties to speed installation time and reduce labor costs. This global custom marking service provides rapid response and quick product availability to keep projects on schedule and within budget.

(35°C)

Split Mandrel

The split mandrel test fixture is used to measure loop tensile strength and retained tension of an installed cable tie.

Strength for Application

Cable tie design, material selection, and installation tooling determine the resulting strength of a system. Use the following table as a guide to determine the strength of various Panduit stainless steel cable ties and strapping for your applications.

Loop Tensile Strength: Rated load based on statistical analysis with additional margin. Tested mean based on sum of loop tensile strength over sample size.

Ties and Strapping

Panduit Retained Tension Tie (Heavy)

Metal Locking Tie

Band Clamp

Pinch Ear Clamp

Retained Tension:

Measured in pounds of residual force remaining on object after tie is installed.

*Representative

Rotational torque:

Measured in pounds of force required to cause deflection of the tie or strapping when applied to a non-resistant object.

Vibration and Shock:

Electrical cables were secured to cable tray using Panduit stainless steel cable ties. The cable assemblies were subjected to multiple levels of severe vibration and shock loading. No damage occurred to the cable ties or cable insulation jacket, which prevented short circuits from occurring.

Lowest Installed Cost

Factors that influence installation time include assembly time, thread force, and reliability of tooling. Panduit tools and ties combine to speed installation time and deliver the lowest installed cost. Use the following tables as a guide to select Pan-Steel® solutions and tooling.

Reliability

The following is an example of Life Cycle Comparison Data demonstrating the superiority of Panduit tooling, with a very low failure rate, versus a leading competitor. Life Cycle Performance may vary depending on environment and use.

Thread Force

Thread force is the measurement of force required to insert the end of a cable tie into the head. Panduit cable ties feature low thread force for extremely fast installation, improved productivity, and worker safety.

Assembly Time

Panduit ties, strap, and banding are fast to assemble and install versus standard banding.

Workplace Safety and Abrasion Protection

Panduit stainless steel solutions feature fully rounded edges and a flush cutoff to protect the bundle from abrasion during and after installation. Both of these features are also critical to ensuring worker safety.

On the job injuries due to laceration caused by a sharp edge or poor cut-off have several associated costs. The Occupational Health and Safety Organization (OSHA) reports that dollars spent on direct injuries are a fraction of the total costs of a lost time incident, other costs incudes:

• Productive time lost by an injured employee and impacted supervisors

• Cost of continuing all or part of the employee’s wages

• Increased workers’ compensation insurance rates

• Time to hire or to retrain other individuals to replace the injured worker

• Time and cost for repair or replacement of any damaged equipment or materials

• Clean up and start up of operations interrupted by the accident

The costs associated with these factors can approach $10,000 per laceration.

Cross sectional view of Panduit tie body versus

ramp Assures locking in any position Extended retaining tab Increases overall tie strength