By Brenda Ruggiero CEG CORRESPONDENT

On Sept. 26, 2025, an expanded Howard Street Tunnel reopened in Baltimore, Md.

CSX noted that this historic and transformative more than $450 million infrastructure project will modernize freight rail transportation along the East Coast. The project marks a major milestone in the decades of effort by state, federal and private partners to deliver a long-sought boost to Maryland’s economy and the nation’s supply chain.

“The completion of the Howard Street Tunnel reflects the dedication of our people — a once-in-a-generation achievement that will drive commerce, jobs and growth across Maryland and the East Coast for decades,” said Joe Hinrichs, president and CEO of CSX. “This project reinforces CSX’s position as a high-performing, customer-focused railroad investing for profitable growth.”

The Howard Street Tunnel (HST) stands as a testament to 19th-century engineering and continues to serve as a vital piece of modern infrastructure. Built in 1895 and extended in the 1980s, the brick-lined passage serves as CSX’s

main North-South rail line along the East Coast. As one of the last remaining single-track segments on the CSX network, it represents a unique challenge and infrastructure opportunity on one of America’s busiest freight routes.

By Lucy Perry CEG CORRESPONDENT

In July, the White House announced its action plan for winning the global AI race. Innovation, infrastructure and international diplomacy are named pillars of the administration’s plan to push

are

are

and

The AI Age is good news for civil contractors who specialize in site prep and pre-construction. Under its pillar to accelerate AI innovation, the Trump administration calls for reduced red tape and

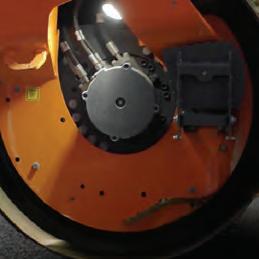

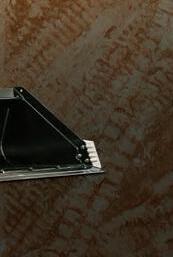

The gantry crane sets the precast inverts after the floor has been excavated to increase the tunnel’s clearance.

see TUNNEL page 44

Outback

The Virginia Department of Transportation (VDOT) has a select team of experts who operate under the banner of “Improve 81.” The team decided to bundle multiple projects together in the Wytheville area.

Tracey Road Equipment held its annual “all day” open house Oct. 2, 2025, at its Syracuse, N.Y., headquarters at 6803 Manlius Center Road. This year’s event featured a full-day celebration.

Founded in December 1956, Industrial Tractor Parts (ITP) can trace its roots to Cesar Mevorah, who emigrated from Bulgaria to the United States in the 1940s. In Europe, Cesar had developed expertise in tractor parts.

The Utility Expo shattered attendance records as more than 22,600 utility construction and infrastructure professionals from all 50 states and 59 countries gathered at the Kentucky Exposition Center, Oct. 7-9, 2025.

What once was a 6,500-sq.-ft. facility storing fertilizer on a local family farm housed in Bellefonte, Pa., now boasts an immaculate heavy equipment service shop now known as Nittany Tractor & Equipment.

28

The American Road & Transportation Builders Association (ARTBA) recognized transportation design and construction industry leaders Sept. 29, 2025, with division awards during the association’s national convention in Irving, Texas.

Fifteen years ago today, AEM launched the I Make America campaign with one simple goal: to give the 2.3 million men and women of the industry a powerful, united voice for pro-manufacturing policies.

34

The Pennsylvania Turnpike (PA Turnpike) has officially deployed new maintenance equipment that will improve safety, increase efficiency and better support access to tunnels and other hard-to-access locations.

ConExpo-Con/AGG announced it will debut the Ground Breakers Stage, a new keynote platform showcasing autonomous tech, sustainable solutions and workforce innovations from global construction leaders.

37 ARTBA ELECTS CAT GROUP PRESIDENT ANTHONY FASSINO ITS NEW CHAIR

Anthony (Tony) D. Fassino, group president, construction industries, Caterpillar Inc., was elected 2025-2026 chair of ARTBA. The announcement was made during ARTBA’s national convention, held Sept. 28-Oct. 1 in Dallas, Texas.

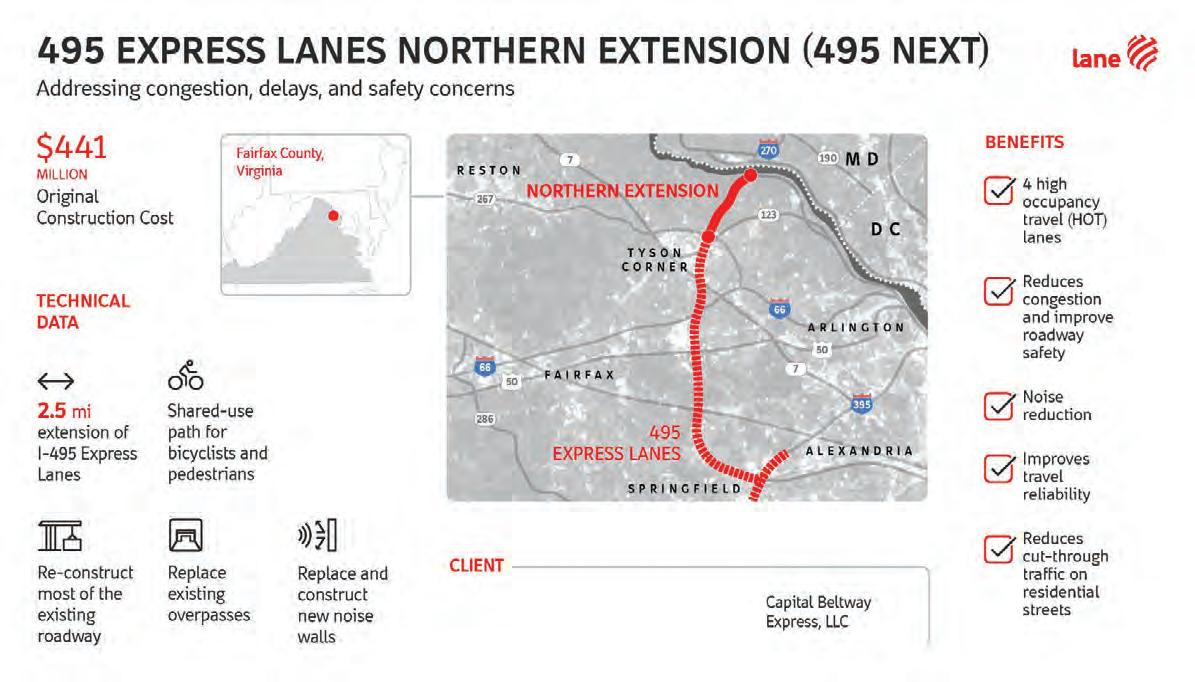

The Virginia Department of Transportation (VDOT) and its I-495 Express Lanes Northern Extension (495 NEXT) project partner, Transurban, have launched a driver safety campaign.

59 SAKAI PRODUCES 1,000TH SV544 SOIL COMPACTOR IN GEORGIA

Sakai America Inc. announced a milestone with the production of its 1,000th SV544 soil compactor at its Adairsville, Ga., factory. The specific machine is heading to Power Motive, a dealer in the western United States.

77 DON’T GET BURIED: USE THIS PRE-SEASON SNOW PREP CHECKLIST

Snow removal contractors know winter doesn’t give second chances. When the first storm hits, there’s no time to scramble for parts, tackle maintenance issues or hurry operator training.

90 NEW STADIUM IN WASHINGTON APPROVED FOR COMMANDERS

The District of Columbia City Council voted in favor of constructing a new stadium complex on the site of the old RFK Stadium, clearing the way for the NFL’s Washington Commanders to leave their current home in Landover, Md.

105 MESSICK’S ACQUIRES READING TRACTOR AND EQUIPMENT

Messick Farm Equipment announced the acquisition of Reading Tractor and Equipment, strengthening its ability to serve farmers, contractors and property owners across eastern Pennsylvania.

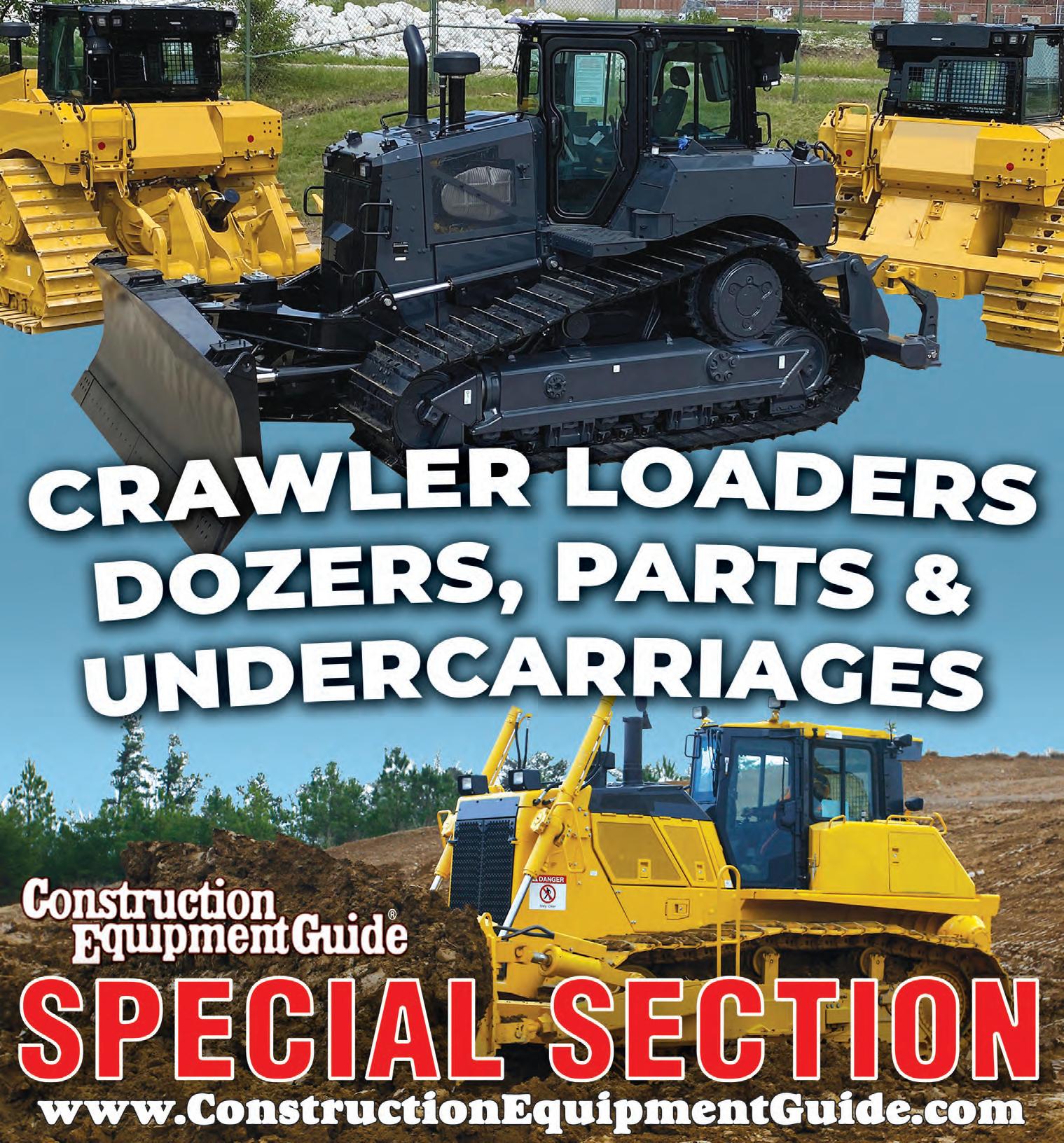

50 CEG’S CRAWLER LOADER, DOZERS COMPARISON CHARTS

DEERE EXPANDS LINEUP WITH X-TIER, P-TIER ENHANCEMENTS

NEXT GENERATION CAT D8 DOZER PROVIDES NEXT-LEVEL TECH

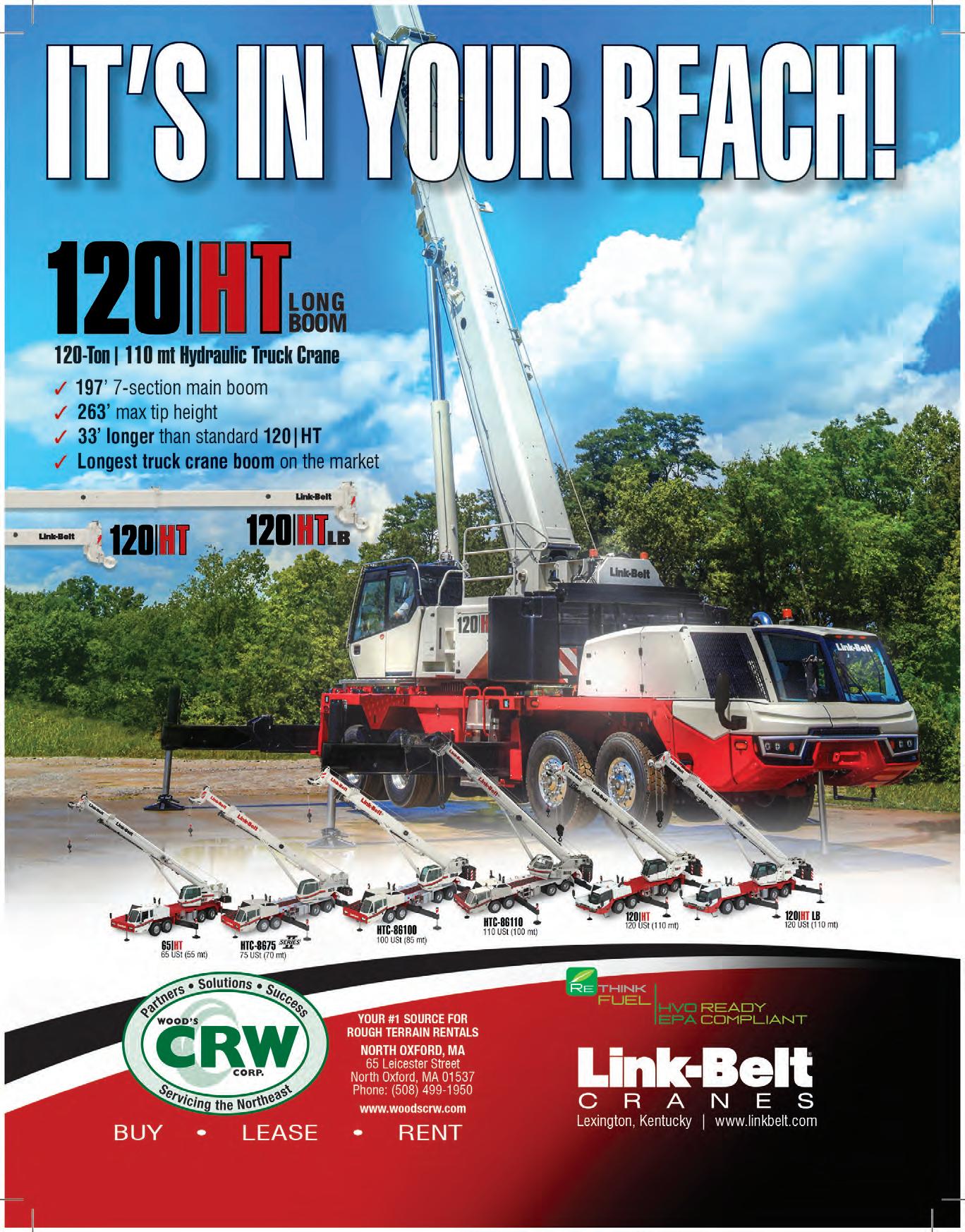

A large percentage of the I-81/I-77 Interchange Safety Improvements project’s excavation quantity (89,000 cu. yds.) is large rock in the median, where the new road alignment is planned to go.

By Chuck MacDonald CEG CORRESPONDENT

Interstate 81 cuts a 325-mi. swath across Virginia from the northwest part of the state, connecting motorists heading for Maryland and Pennsylvania, to the North; it connects drivers traveling southwest to Tennessee. Near Wytheville, this important corridor intersects with Interstate 77 where drivers travel north into West Virginia and south into North Carolina.

The Virginia Department of Transportation (VDOT) has a select team of experts who operate under the banner of “Improve 81.” With an eye on enhancing

safety, reducing congestion and unlocking the region for further economic growth, the team decided to bundle multiple projects together in the Wytheville area.

The Wytheville bundles began in 2024 and are scheduled for completion in 2027.

• Orders Construction has been tasked with replacing three bridges on I-81 in addition to improving traffic flow by extending the acceleration lane at exit 41 (Peppers Ferry Road) to the deceleration lane for the exit to I-81 southbound. The design-build contract is worth $54 million.

• A team from Branch Civil will reconfigure I-77 exit 41 (Peppers Ferry Road) and add an auxiliary lane between southbound I-

Excavation work continues on I-77 where work is under way to improve the exit 41 on and off ramps in Wythe County.

81 exit 73 (Route 11) and exit 72 (I-77 interchange). The Progress Parkway Connector Road also is included in this bundle for a $53.5 million contract.

Robert Baker, VDOT Bristol district’s construction engineer, pointed out an advantage of bundling projects.

“Bundling projects saves money through economies of scale,” he said. “For example, the Progress Park project will remove a large quantity of material, and the project where the contractor is working near exit 41 will have a deficit of material. By bundling projects, the contractor will be able to move the excess material to where it will be valuable on the other project.”

The construction teams on the entire bundle of projects will move some 633,000 cu. yds. of dirt and rock. Later in the projects, paving teams will lay down some 107,000 tons of asphalt using pavers and rollers. The work on the bridges will require more than 414,000 lbs. of steel.

Safety is always a high priority for VDOT projects. However, the contractors faced a difficult safety concern with a large rock formation in the median of the I-81/I-77 part of the project. The rock needed to be removed because it is the site of the new road alignment.

see BUNDLES page 80

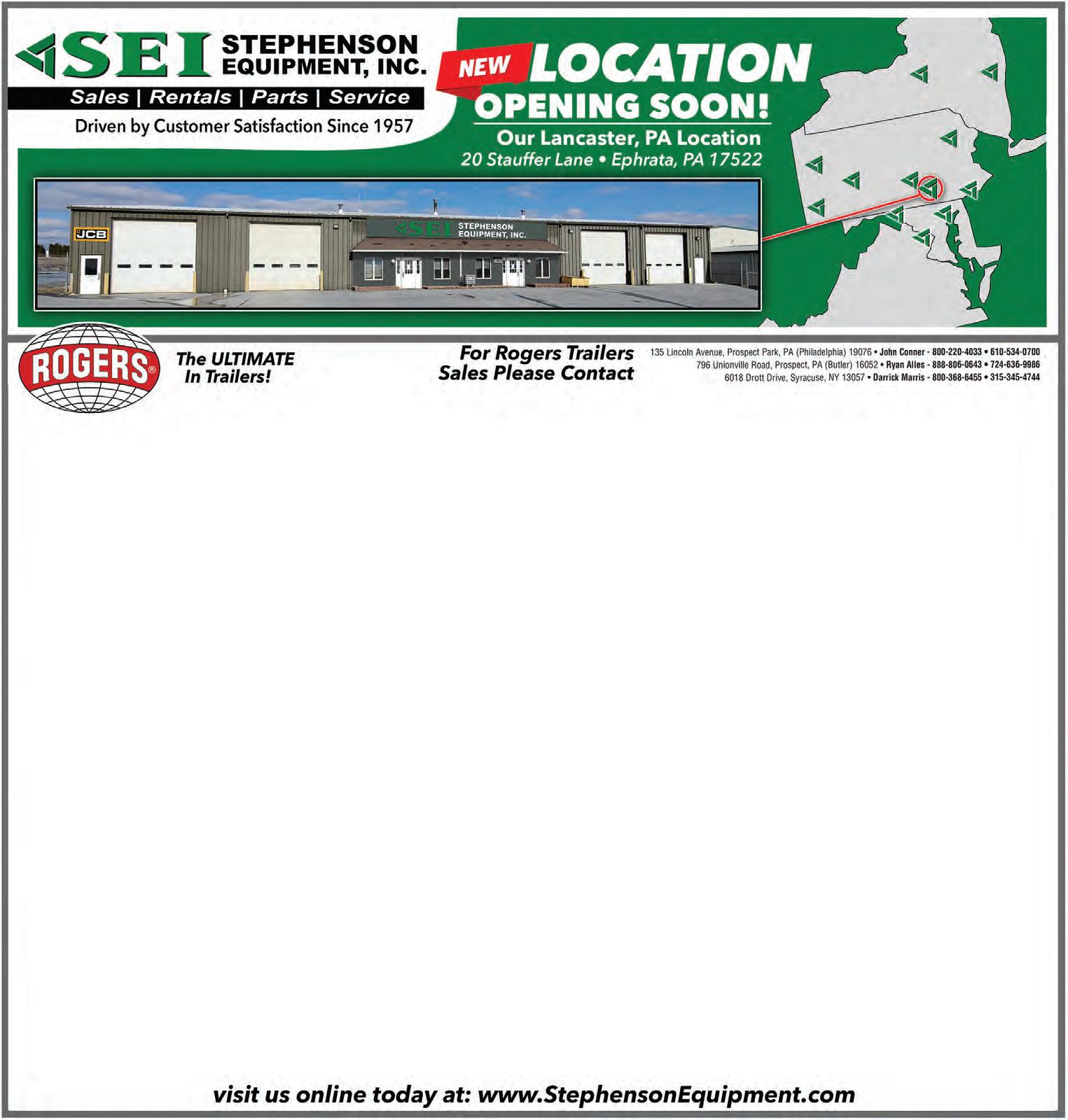

New Model TAG25, 24’ or 26' deck with 6' Tail, Safety Lighting Pkg., Bucket Pocket' in Deck & Tail, Black Paint In Stock!

Rogers 40 ton Tandem, No-Foot Neck, 24' deck, adjustable width ramps, bucket pocket, 275's, aluminum outers, night lights, work lights, strobes. Rogers Black............ IN STOCK!

New Rogers TAG25's, 24' or 26' deck. Wood or Ladderbar Style 6' Tail. Wood or Ladderbar Style 8' Air Ramps Full floor or Custom Bucket Pocket in the deck. Safety Lighting Package........ In Stock and In Production!

New Rogers 35 ton CR35GR Gentle Risers In Stock, No-Foot Neck w/ tool box, Gooseneck work lights, 24' deck, 16* slope, adj. width bi-fold ramps, side reinforcing full length, chain boxes, outriggers, 275's on alum. outers, Air Ride, Air Dump, Aux. Night Light Battery, Extra Markers & Turns, Rear Strobes. Side Strobes Viper Red and Black................In Stock!

Rogers 55 Ton CobraNeck, Severe Service Design. 2-position pin, ratchet ride height, adjustable width bi-fold steel ramps, 26' clear deck, deep well pocket, chain bins, tool boxes, 275's, alum. outers, side reinforcing, extra lights, strobes, night light pkg. Air Lift 3rd Air Lift 4th axle, Black Paint..........IN STOCK!

Rogers TAG21XL, 22’ + 6’ Tail & TAG21XXL, 24’ + 6’ tail, 235's on Aluminum, Air Ramps, Safety Lighting Pkg. with Strobes. Black Paint.. IN STOCK!

Rogers TAG21XXL, 24' deck, 6' tail, 235's on aluminum outers, 8' Air Ramps. Safety Lighting Package. Red Paint.. IN STOCK!

New Rogers 55 ton, CobraNeck, 2-position pin, Ratchet Ride Height, 26' deck, 18" ride height, deep well pocket, 275's on aluminum outers, air lift 3rd,& 4th. Night Light Pkg., Strobes, 3 or 4 Axles............ IN STOCK!

Rogers TAG25XXL, 25 Ton Capacity, Premium Specs, Superior Quality, 235’s Aluminum, 7-Year Warranty, Black Paint, 24’ deck + 6’ tail, 8’ Air Ramps IN STOCK!

Rogers TAG25-32, 26' deck, 6' tail, 8' air ramps, dual gear, side steps, broom/ shovel chutes, Safety Lighting package, 235's on aluminum outers, Viper Red Paint........IN STOCK

BACKHOES:

2019 NEW HOLLAND B110SPC, 747 HRS, CAB HVAC, QUICK TACH FRONT BKT, EXTENDAHOE, FRONT HYDRAULICS..$88,995

2021 NEW HOLLAND B95C TLB, 139 HRS, CAB, HVAC, 4 IN 1, EXT HOE............................................................................$99,995

CHIPPERS:

SCREENERS:

2021 VIBROSCREEN SCM40

2021 VIBROSCREEN SCM27

$79,995

$62,995

NEW VIBROSCREEN SCM75C BOX SCREEN W/CONVEYOR, TIER 3 ENGINE......................................................................SOLD

NEW VIBROSCREEN SCM115T TROMMEL, NO DPF, NO DEF

DOZER:

20212 CASE 850M, 850 HRS, WIDE TRACK, CAB, HVAC, COLD WEATHER START KIT, DRAW BAR, 24” TRACKS, 112”DOZER BLADE, HYD PUMP W/PTO..............................................$159,995

MISCELLANEOUS:

$179,995

$41,995

2017 BANDIT 250XP 12” CHIPPER, CAT 120HP DIESEL ENGINE, 2305 HRS, AUTO FEED, WINCH........................................

2022 BANDIT 250XP CHIPPER, 400 HRS, WINCH, 12" CAPACITY, CAT 120 HP........................................................................$64,995

EXCAVATORS:

2017 HITACHI ZX135-6, 3900 HRS, HYD THUMB, FRONT BLADE, COUPLER, PATTERN CHANGER......................................$105,000

SKID STEER LOADERS:

AFE ROTARY FORESTRY HEAD, SKID STEER MOUNT $17,995

HLA 96” SNOW BUCKET, SKID STEER MOUNT, 47.3 CU. FT.

HEAPED..................................................................................$3000

$49,995

2016 KUBOTA SVL95-2 TRACK SKID STEER, 936 HRS, CAB HVAC, HIGH FLOW, RADIO............................................................

2012 KUBOTA SVL90-2 TRACK SKID STEER, 1446 HRS, CAB HVAC, HIGH FLOW, LEXAN DOOR, COMES W/BKT, FORKS........

KUBOTA KX080 EXCAVATOR TO SKID STEER COUPLER ADAPTOR $3,199 48” REVERSE LUG GRADING BUCKET, FITS KUBOTA 57&55, NEW

$45,000

$149,995

2023 KOBELCO SK130LC-11, 516 HRS, CAB, HVAC, HYD THUMB, COUPLER..........................................................................

2022 KOBELCO SK170LC-11, 256 HRS, CAB, HVAC, HYD THUMB

$169,995

2023 KOBELCO SK350LC-11, 397 HRS, CAB, HVAC, 54” BUCKET, PLUMBED........................................................................

$295,000

2019 KUBOTA KX033-4, 2421 HRS, CAB, HVAC, 3 BUCKETS, HYD THUMB, COUPLER................................................................SOLD

2021 NEW HOLLAND L320, 360 HRS, CAB, HVAC, 2 SPEED, PILOT CONTROLS, BLOCK HEATER..............................................

$32,995

2018 NEW HOLLAND L234, 540 HRS, CAB, HVAC, 2 SPEED, PILOT CONTROLS........................................................................$36,995

2013 NEW HOLLAND L230, 2303 HRS, CAB, HVAC, 2 SPEED, PILOT CONTROLS, BLOCK HEATER..................................$26,500

HYD COUPLER, FITS HITACHI ZW140/ZW150-6 ISO

ROKBAK MODEL RA30 OFF ROAD TRUCK: 30 TON CAPACITY WITH TAIL GATE, 276HP SCANIA ENGINE. AVAILABLE FOR SALE OR RENT! +N5027..........AVAILABLE FOR RENT OR PURCHASE

NEW ASV RS75 WHEEL SKID STEER: OPEN ROPS, SUSPENSION SEAT, 74" BUCKET, 21.3 GPM, ELECTRIC PLUG ON BOOM FOR ATTACHMENTS, MAX CAB, UNIT# N4200......CALL FOR PRICE

ANACONDA DF410 SCALPING SCREEN: 2 DECK TRACKED SCREENING PLANT WITH LOW HOURS, UNIT# AG1381........................................................................................CALL FOR PRICE

ANACONDA TR75 TRACKED CONVEYOR: 42” X 75’ CONVEYOR, IT ALLOWS FOR STOCKPILING OR FEEDING OF A RANGE OF APPLICATIONS. THE TR75 HAS A VARIABLE SPEED CONVEYOR IN ORDER TO FACILITATE FOR DIFFERENT APPLICATIONS SUCH AS SAND, GRAVEL, AGGREGATES, COMPOST, COAL AND WOOD CHIP. WE STOCK A FULL RANGE OF SPARE PARTS AS A DISPLAY OF OUR COMMITMENT TO PROVIDE A DEDICATED AND RESPONSIVE SERVICE TO ALL OUR CUSTOMERS, 6 UNITS IN STOCK........................................................CALL FOR PRICE

ANACONDA FTR150 UNIT AG1353: MID SIZE FEED LOADER RANGE. FULLY EQUIPPED WITH 50' STOCKPILING CONVEYORALLOWS DFOR STOCKPILING OR FEEDINGA WIDE RANGE OF APPLICATIONS. INCLUDES OPTIONAL 2 DECK VIBRATING GRID......................CALL FOR PRICE

ASV MODEL RT50: ALL WEATHER CAB WITH HEAT AND AC, SUSPENSION SEAT, 15” RUBBER TRACKS, 60” BUCKET WITH BOLT ON EDGE, UNIVERSAL SKID STEER COUPLER, YANMAR TURBO DIESEL ENGINE, BLOCK HEATER, ATTACHMENT CONTROL KIT, REAR VIEW CAMERA, APPROXIMATELY 300 HRS, UNIT# 4310............................................................CALL FOR PRICE

SIMEX PLC-24 24" WIDE COLD PLANER WITH REVERSIBLE DISCHARGE CONVEYOR: CUTTS UP TO 7" DEEP, 16 DEGREE TILT, 27-40GPM DISSCHARGE CONVEYOR HELPS LEAVE A CLEANER CUT, WINDROWS MATERIAL BEYOND THE CARRIER FOR EASIER CLEAN UP, UNIT# AT4540...... $25,400

2020 BOBCAT T740: WITH CAB, HEAT & AIR EXCELLENT CONDITION, 1600 HOURS, HYDRAULIC COUPLER, 2 SPEED, UNIT# U5863................................................................$39,000

KOBELCO SK350LC-10, APPPROXIMATELY 2400 HOURS, 31.5” TRACK SHOES, 10’10” ARM, 2 WAY AUXILLIARY HYDRAULICS, HAND CONTROL PATTERN CHANGER, HEATED AIR RIDE SEAT, VERY GOOD CONDITION, UNIT# N3651................................................................$183,000

AG1359, ANACONDA J12 JAW CRUSHER: IS AN AGGRESSIVE & POWERFUL MOBILE JAW CRUSHER. WITH THE PROVEN ABILITY OF THE UNIVERSAL CRUSHERS JAW CHAMBER 28" X 44" WITHIN AN INNOVATIVE ANACONDA TRACKED SOLUTION........................CALL FOR PRICE

30”X50’ ELECTRIC RADIAL STACKERS: 5 IN STOCK..........................................CALL FOR PRICE

2020 KOBELCO SK210LC-10: 2 WAY AUX HYDRAULICS, 31.5” SHOES, PATTERN CHANGER, 850 HOURS, 1 OPERATOR. UNIT# U5865............................................................CALL FOR PRICE

MCLANAHAN 44” X 33’ FINE MATERIALS WASHER: IN STOCK & READY FOR IMMEDIATE DELIVERY, UNIT# AG1402....................................................................$94,500

BOMAG BW120SL-5: FOLDING ROPS, 47.2” WIDE DRUMS, 5511LBS. OPERATING WEIGHT, KUBOTA

24.8HP DIESEL, FRONT & REAR VIBRATORY, 4320 VPM, .020 IN AMPLITUDE, UNIT# N4538..$45,995

2023 ANACONDA TR100 TRACK CONVEYOR: 42”X100’ TRACK MOUNTED CONVEYOR, LESS THAN 500 HOURS, INCLUDES A WEIGHT SHARK BELT SCALE................................$CALL FOR PRICE

Sakai compaction equipment from Tracey Road Equipment can be seen at work on paving projects all across New York State and northeastern Pennsylvania. (L-R) are Brad Belvin, sales and marketing manager; Daniel Margrave, product training and marketing manager; and Toshikazu Hayashi, vice president, sales and marketing.

Tracey Road Equipment held its annual “all day” open house Oct. 2, 2025, at its Syracuse, N.Y., headquarters at 6803 Manlius Center Road.

This year’s event featured a full-day celebration that pulled community, innovation and fun all under one roof. More than 2,000 attendees enjoyed live music, delicious food from a large lineup of local food trucks, equipment demonstrations and fantastic giveaways.

Tracey Road Equipment team members and factory representatives were on hand throughout the day ready to answer questions, highlight new technology and connect customers with everything they need.

Tracey Road Equipment represents a wide

Tracey Road Equipment considers relationships with its customers and their families to be extremely important to its success. (L-R) are John Lyons of Lan-Co Companies; Jerry Tracey, president of Tracey Road Equipment; and his grandson, Nate Julka.

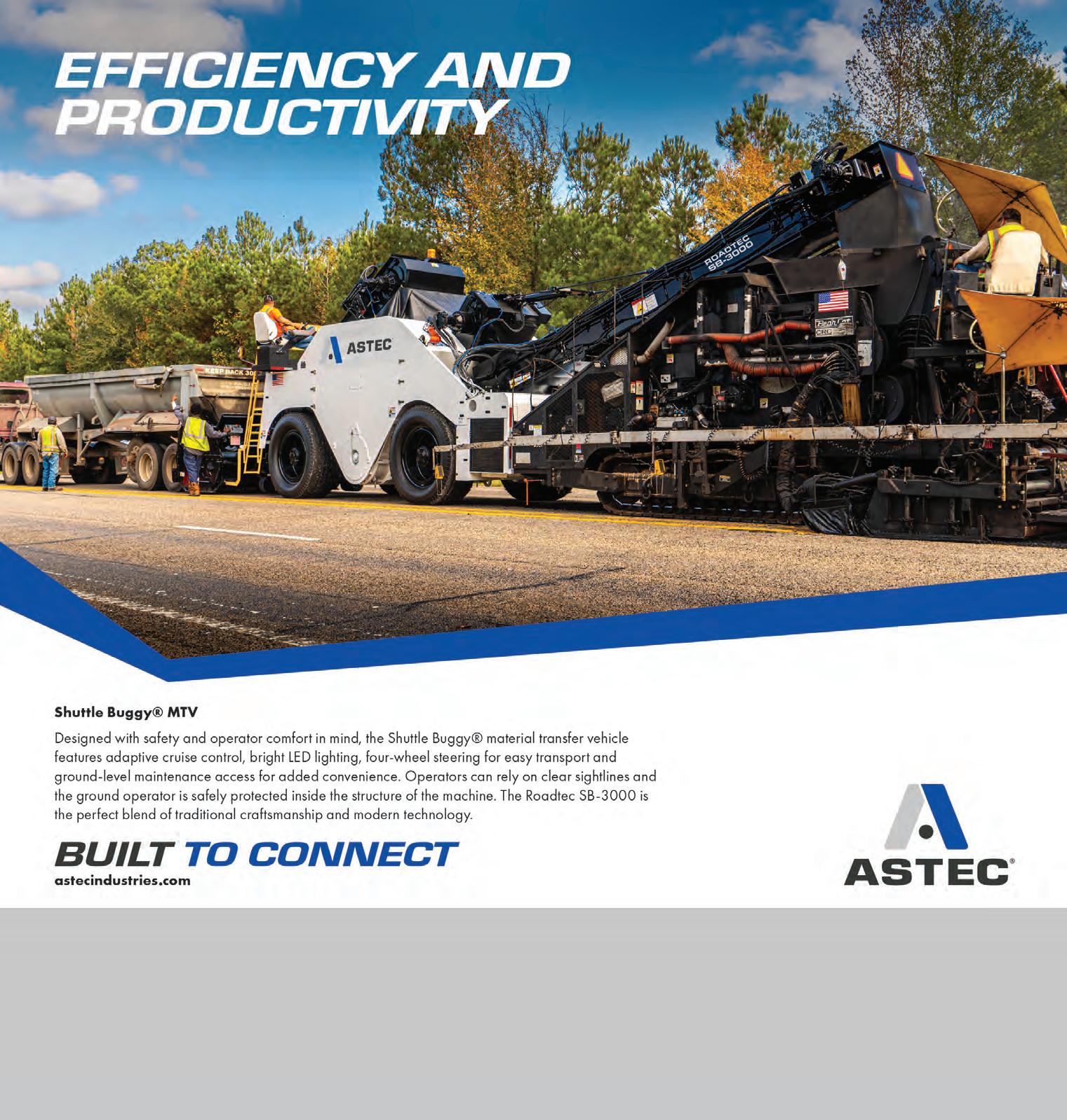

variety of equipment for a host of industries including earthmoving, road building, municipalities, aggregate production and recycling, just to name a few. Tracey Road Equipment expressed gratitude to the manufacturers that it represents who chipped in to sponsor the refreshments and entertainment. Some of Tracey Road Equipment’s key suppliers include Astec, Hitachi, Liebherr, Hyundai, Freightliner, Kobelco, Bell Trucks, Mauldin, The Alamo Group, Felling Trailers, Morbark, Sakai, Etnyre, Rockland, Werk-Brau and more. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

see TRE page 88

Liebherr equipment is world renowned for its advanced technology in earthmoving and excavating machines. (L-R) are Scott Barton, district service rep; Jason Brady, general manager of dealer development; and Kai Friedrich, president Liebherr, United States

Road Equipment

in a relatively short period of time.

are

Founded in December 1956, Industrial Tractor Parts (ITP) can trace its roots to Cesar Mevorah, who emigrated from Bulgaria to the United States in the 1940s. In Europe, Cesar had developed expertise in tractor parts during an era when mechanized farming and tracked machines were becoming more common. Forced to flee Eastern Europe during World War II, he arrived in New York City with little more than knowledge of the trade and the determination to start anew.

To support his family, Cesar initially imported a wide range of goods — including Bulgaria’s famed roses and fragrances — until he could bring his wife and daughter to America. The family eventually spent time in Fargo, N.D., where Cesar established his first warehouse and began importing tractor parts in earnest. Later, he returned to Queens, N.Y., where in December 1956, Industrial Tractor Parts was formally founded.

The business began with a small New York office and a Brooklyn warehouse.

Industrial Tractor Parts has welcomed Larry Gindville as the new general manager of its Illinois branch. Gindville, a seasoned equipment industry professional, brings more than two decades of dealer-side leadership experience to the company.

Gindville’s career began in the contracting world before he transitioned to dealerships in 2001. He has held key leadership roles, including vice president and general manager with both Volvo and Komatsu dealer groups, overseeing multiple locations across Wisconsin and the Upper Peninsula.

Gindville said his focus will be on “expanding growth” by strengthening customer relationships, improving inventory and expanding the territory this branch can serve.

“We’re a stocking distributor, which sets us apart from competitors who act as middlemen,” he said.

Gindville emphasized that his goal is to continue branding Industrial Tractor Parts in the market as a trusted source for undercarriage and parts, highlighting its nearly 70-year history and long-standing role as a Berco stocking distributor. With his addition — and a growing team in Illinois — Gindville sees significant potential to serve customers across Illinois and surrounding states.

Cesar focused on importing quality tractor and crawler parts and distributing them across the region, laying the foundation for a company that would span generations.

Following Cesar’s passing, the next generation — his son-in-law — took the reins. In the 1960s, he forged what would become a defining partnership. Traveling to Italy, he met with Berco, already a wellregarded name in the undercarriage industry. With little money in hand and his Italian routes, he asked Berco’s leadership to extend credit and trust. Berco agreed, providing containers of parts on consignment — an extraordinary show of faith at the time.

That trust paid off. With Berco’s product line behind it, Industrial Tractor Parts quickly established itself as a premier aftermarket supplier. By the mid-1960s, shipments were coming into New York and a second branch in New Orleans, fueling rapid growth.

For decades since, Berco has remained central to ITP’s business, with its signs displayed proudly at every ITP warehouse.

Nearly three years ago, the company welcomed its fourth generation of family leadership with the arrival of Jack Sitzer. Bringing a fresh perspective and forward-looking mindset, Jack has quickly made an imprint on the organization while continuing to learn from the third generation, his two uncles, whose decades of experience provide both guidance and continuity. Jack’s leadership has not only carried forward ITP’s long-standing tradition of quality and service, but also accelerated its modernization and expansion efforts.

One of his first major initiatives was the implementation of a new ERP system, creating efficiencies across operations and strengthening the company’s ability to scale. Alongside this, he has overseen the recruitment of several new hires, building a stronger team equipped to support growth and innovation. Jack is also spearheading a complete redesign of the company’s website, with integrated e-commerce capabilities currently in development and slated to

ITP page 58

The Utility Expo shattered attendance records as more than 22,600 utility construction and infrastructure professionals from all 50 states and 59 countries gathered at the Kentucky Exposition Center, Oct. 7-9, 2025.

Spanning 1.5 million sq. ft. of hands-on equipment demos, job site simulations and interactive product displays, the biennial event reaffirmed its place as North America’s largest trade show for utility and infrastructure professionals seeking the latest technologies, equipment and safety solutions. The show unveiled the latest breakthroughs in underground utility, electric transmission, telecom and water/wastewater technologies shaping the future of the industry.

“This year’s Utility Expo set a new benchmark for innovation and handson learning in our industry,” said Brianne Somers. “The remarkable turnout demonstrates the industry’s drive to adopt smarter, safer and more sustainable solutions for utility construction.”

Twenty manufacturers used The Utility Expo 2025 as their launchpad to showcase new utility construction equipment and technology. Highlights included:

• Hyundai Construction Equipment debuted its HT38 compact track loader in North America. The HT38 CTL can lift a .8-cu. yds. standard bucket to a pin height of 10 ft. 9 in.

• Diamond Mowers unveiled four mulching attachments: two drumheads for open and depth control models, a belt drive disc design, and a 50-in.

model for excavators.

• Vermeer showcased the ML180 mini loader which features advanced electricover-hydraulic controls, a suspended undercarriage and air-ride suspension technology.

The ML180 helps address persistent operator fatigue and productivity challenges in traditional stand-on mini loaders.

• John Deere introduced two redesigned compact excavator models: the 17 P-Tier and the 26 P-Tier. Built to John Deere specifications and shaped by extensive customer

feedback and testing, both models feature enhancements that improve versatility and ease of operation.

Attendees took advantage of live demonstrations and test drives, making the show a premier destination for discovering fieldready solutions.

New for 2025, The Quick Pitch Showcase introduced 30 small, mid-sized and new-toshow companies that shared product information and innovations directly with attending media during a special pre-show break-

fast. This early access gave journalists a first look at emerging technologies and products before the show floor opened.

“As a first-time exhibitor at The Utility Expo, the Quick Pitch Showcase was an incredible opportunity for us to introduce our company and products to the media,” said Steve Wojtaszek of 3S Craftings LLC. “It was a welcoming environment that truly set the tone for a successful first show.”

see EXPO page 76

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR .

$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR . .$195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires

$15,500

(4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready

From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote

$4,000 to $10,000 (8) Sheepsfoot, 48" and 60", double drum & single drum, tow type

$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready

$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites

$87,500

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs .

$21,500

Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean

185’s, JD diesels

CALL

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready

$162,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites

$89,000

$224,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday

$179,000

$122,500

$72,500

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR

$82,000

$49,500

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition

CALL

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice CALL

CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR

$142,500

100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call For Your Needs FORKS (8) IT28F/G Forks, Balderson qc, 48"-60" pallet style, excellent

$229,500

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR

What once was a 6,500-sq.-ft. facility storing fertilizer on a local family farm housed in Bellefonte, Pa., now boasts an immaculate heavy equipment service shop — showcasing four service bays, parts and a dedicated hydraulic hose area — now known as Nittany Tractor & Equipment.

Located directly off of PA-64 S and just moments from PA-26, Nittany Tractor & Equipment now serves the Bellefonte and surrounding areas with many services, including full preventive maintenance, troubleshooting and diagnostics, component repairs and rebuilds, hydraulic hose production, resident technicians, line boring and more. With nearly two decades of experience brought by each of the company’s factory-trained technicians, coupled with 24/7 service and the latest technology and software to service any heavy equipment make or model, Nittany Tractor & Equipment fills a much-needed gap within the agricultural and construction industries.

“We founded this business not just to sell equipment or provide services, but to fill real gaps in the local market and deliver value where it’s most needed,” said co-owner, Lance Bucha. “That includes bringing essential offerings to the region that were previously unavailable, such as line boring, hydraulic hose production and resident technician opportunities. These services are more than just business operations; they’re about keeping local industries running smoothly and efficiently, minimizing downtime and ensuring that our customers can depend on us when it matters most.”

Within a short 10 weeks, owners Samantha White and Lance Bucha conceived, built and launched Nittany Tractor & Equipment. Together, the two share more than 30 years of industry experience and are wellknown in the area for their knowledge and expertise.

White, who specializes in customer and employee satisfaction, brings years of human resources experience to the table as she manages the office side of the business, including benefits, internal and external communications as well as employee and customer relations.

“My career has always been rooted in a deep passion for people — ensuring that every team member feels valued, supported and empowered,” White said. “From the very beginning, I’ve believed that when you take care of your employ-

Nittany Tractor & Equipment, located in Bellefonte, Pa., is now officially open to the public and offers extensive heavy equipment services and parts.

ees, they, in turn, take care of your customers. This belief has guided every step of my journey and continues to serve as the foundation for everything we do at Nittany Tractor & Equipment.”

White also actively works within the community at a local college by hosting “Nittany Tractor Days,” a training and learning opportunity to students and upcoming technicians interested in the heavy equipment and agricultural fields.

Nittany Tractor & Equipment also works closely with the school to hire interns, so students can obtain real-life professional experiences and true mentorship.

Meanwhile, Bucha manages the operational side of things, by providing first-class service to the company’s customers in every manner — from investing thousands into the best equipment, software and tooling, to making every customer feel valued.

The 6,500-sq.-ft. facility, located in Bellefonte, Pa., offers four service bays.

“We have invested and done a lot to take care of our customers,” he said. “We want to make sure the customers get a family feeling instead of feeling like a number and make sure they are always up and running. We are not trying to be a big corporation; we want to get back to taking care of customers and treating them correctly.” Bucha and White have received immense support from the surrounding community, which made the startup of this organization, in such a short window of time, possible. As a thank you to the community and promotion of their newly established company, Nittany Tractor & Equipment hosted a grand opening event.

Nittany Tractor & Equipment hosted a grand opening Oct. 3, 2025, at its facility in Bellefonte, Pa. Bucha and White unveiled their new facility, top-of-the line service trucks, including three Ford 550s and an International service truck, and offered food, drinks and even corn hole to the employees, customers, family and friends that gathered.

White spoke to the success of the event as well as the future of the company.

“As we look to the future, I’m filled with gratitude and pride — not only for what we’ve accomplished but for the family we’ve built together at Nittany Tractor & Equipment,” she said. “This journey has never been just about business; it’s about people, relationships and the shared commitment to excellence that unites us all.

“Working alongside Lance [Bucha] has been one of the greatest privileges of my career,” she added. “We balance and complement each other’s strengths — his unwavering commitment to doing ‘the right thing’ and his passion for ensuring that the customer always comes first continually inspire me. Together, we’ve built a company culture grounded in respect, honesty and hard work — values that mirror the spirit of our community and the heart of our family.”

With family front and center, even the smallest staff member of Nittany Tractor & Equipment, eight-year-old and daughter of White and Bucha, Charlee, attended the grand opening event and looks forward to the future ahead.

“I get to take pictures for Nittany Tractor & Equipment — I’m the marketing helper,” she said. “I can’t wait until I can work at NTE.” CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide, except where noted. All Rights Reserved.)

What once was a 6,500-sq.-ft. facility storing fertilizer on a local family farm housed in Bellefonte, Pa., now boasts an immaculate heavy equipment service shop.

The American Road & Transportation Builders Association (ARTBA) recognized transportation design and construction industry leaders Sept. 29, 2025, with division awards during the association’s national convention in Irving, Texas.

The honorees were in announced in four categories:

Nello L. Teer, Jr. Award:

tor, Parsons

John Hay, former senior vice president, government relations, CRH (retired)

The award honors a contractor member who has made outstanding contributions to the association’s contractors division and the transportation construction industry.

Paul F. Phelan Memorial Award:

John Hay, former senior vice president, government relations, CRH (retired)

Established in 1971, this award is given annually in recognition of outstanding contributions to the ARTBA materials and services division and the transportation construction industry as a whole.

Guy Kelcey Award:

Ozzy Bravo, business development direc-

This award, which honors Guy Kelcey, one of the panning and design (P&D) division’s organizers, is given each year to an ARTBA member who has exhibited a high degree of service to the association’s P&D division.

John “Jake” Landen Memorial Highway Safety Awards:

(Private Sector) Jim Crowley, vice president of new product development, sales and marketing, Valtir, LLC

(Public Sector) Bill Lambert, state safety engineer, highway design, New Hampshire Department of Transportation

Established in 1989 in memory of Traffic Safety Industry Division leader and Past ARTBA Chair (1976) J.C. Landen, this annual award recognizes outstanding contributions to highway safety.

For more information, visit artbafoundation.org.

Fifteen years ago today, AEM launched the I Make America campaign with one simple goal: to give the 2.3 million men and women of the industry a powerful, united voice for pro-manufacturing policies.

Since then, the campaign has grown into a nationwide grassroots effort with tens of thousands of supporters urging policymakers to help equipment manufacturers do what they do best: invest in their communities, grow their businesses and create more family-sustaining jobs in America.

Launched on a Sept. 29, 2010, in Washington, D.C., with support from television host and manufacturing advocate Mike Rowe, the I Make America campaign began as a rallying cry for the policies needed to fuel the industry and support the 2.3 million men and women who make the equipment that builds, powers and feeds our world.

home. Both initiatives continue to this day, with the latest installment of Through the Lens recently featured in Washington, D.C.’s iconic Union Station.

The campaign’s most ambitious initiative came in 2024 with the launch of the AEM Manufacturing Express: a nationwide, 80stop bus tour that brought I Make America to communities across the country. Featuring interactive exhibits, policy discussion, law-

The campaign has grown into a nationwide grassroots effort with tens of thousands of supporters.

Within just a few years, the I Make America campaign had grown to a community of 30,000 supporters who rallied behind the idea that when the equipment manufacturing industry is strong, America also is strong.

By 2014, the I Make America campaign was in full swing and headed to Las Vegas, Nev., for ConExpo-Con/AGG. AEM staff, along with member company volunteers, manned the I Make America booth and fanned out across the trade show to engage, educate and energize new supporters…and give away a custom-painted 2014 HarleyDavidson Road King to one lucky winner.

Two years later the campaign hit the road with the I Make America Game, an interactive experience designed to educate voters about the manufacturing issues at stake during the presidential election in a fun and engaging way.

In what was to become the inspiration for a much larger initiative, the campaign traveled across the Midwest with a custombuilt I Make America trailer where participants would compete in several construction- and agriculture-themed challenges to gauge their knowledge about the industry.

In 2019 the campaign’s increasing focus on telling the stories of the men and women who make America got a boost with the launch of the Through the Lens photo series and the Behind Every Product documentary series, which features equipment manufacturing workers across America.

These two initiatives have been deployed ever since to tell the amazing stories of the men and women who make America and the small town and communities that they call

maker engagement and the Manufacturing Challenge, the tour added thousands of new supporters during its first year. In 2025, the bus tour rolled on — highlighting the industry’s innovation, workforce and economic impact at the Celebration of Construction on the National Mall in Washington, D.C,. and continuing to Texas for another 22 stops at equipment manufacturers.

“During the past 15 years the I Make America campaign has made a long-lasting impact on everyone who cares about the future of equipment manufacturing in America,” said Kip Eideberg, AEM senior vice president of government and industry relations. “Together with our supporters, we have engaged and educated hundreds of thousands of Americans who will help us change hearts and minds about importance of manufacturing; and we have told the stories of the 2.3 million men and women who make our industry strong and America exceptional. As we look ahead to the next 15 years, the campaign has never been more important to the future of our industry and our country.”

Looking ahead, I Make America is showing no signs of slowing down. The AEM Manufacturing Express will be heading to Louisville, Ky., for The Utility Expo and will spend the rest of the fall continuing to tell the stories of the people that make America ahead of next year’s elections. But with every anniversary that passes, the goal of the campaign remains the same: to give the 2.3 million men and women of the industry a powerful, united voice for pro-manufacturing policies.

For more information, visit aem.org/.

The Pennsylvania Turnpike (PA Turnpike) has officially deployed new maintenance equipment that will improve safety, increase efficiency and better support access to tunnels and other hard-to-access locations.

Through a partnership with two United States based companies, Lift-a-Loft and SwapLoader, the PA Turnpike added two hook lift-mounted platforms to its fleet, each that can be elevated up to 22 ft. high.

“We are proud to keep raising the bar when it comes to transportation innovation and this industry-first piece of equipment is no different,” said Craig Shuey, chief operating officer of the PA Turnpike. “That success is possible thanks to a workforce eager to find and implement new ways of addressing everyday challenges. This maintenance-initiated project underscores our commitment to being responsible stewards of our customers’ toll dollars, while remaining dedicated to safety and efficiency.”

Workers can raise or lower the platform directly to the height they need and slide the platform outside of the footprint of the vehicle. The larger platform provides more capacity for additional workers, tools or materials, providing more collaboration and fewer trips or adjustments compared to the equipment that was previously used for these tasks.

While other transportation organizations have similar lifts permanently affixed to their trucks, the PA Turnpike’s two new units represent a first-of-their-kind evolution, allowing them to be swapped among existing fleet trucks. Beyond the increase fleet flexibility, swapping lifts has saved approximately $300,000 so far, eliminating the need to buy two new truck cabs and chassis. The equipment also can be effortlessly swapped for deployment across various job sites.

Through a partnership with two United States based companies, Lift-a-Loft and SwapLoader, the PA Turnpike added two hook lift-mounted platforms to its fleet, each that can be elevated up to 22 ft. high.

ConExpo-Con/AGG, North America’s largest construction trade show, announced it will debut the Ground Breakers Stage, a new keynote platform showcasing autonomous tech, sustainable solutions and workforce innovations from global construction leaders.

Keynotes and presentations on the Ground Breakers Stage will be features of the show, occurring in Las Vegas March 3-7, 2026, complementing robust educational programming and more than 2,000 exhibitors across the 2.9 million sq. ft. of exhibit space. Speakers will range from the CEOs of Fortune 100 companies to successful entrepreneurs.

Most importantly, the lift improves workplace safety due to the equipment’s push-out deck extensions, providing a leveled space for PA Turnpike employees to perform elevated work without reaching or twisting, reducing potential injuries or fall risks. Beyond providing better positioning, the new platform features include mounted work lighting, a selfclosing gate, emergency stop system and transmission neutral interlock to prevent drive capabilities at elevation.

The PA Turnpike has five tunnels, most of which were built for the unfinished south Pennsylvania Railroad, along its roadway. They require ongoing maintenance and infrastructure investments, with each supported by its own dedicated employee team.

PA Turnpike Maintenance Fleet Supervisor Von McGee and his team have been working on finding a more efficient method of reaching tunnel ceilings.

“It’s a part of my job that I really enjoy. I’m a fabricator and a mechanic, so these types of projects are really up my alley,” McGee said. “Beyond tunnel work, this new platform can serve multiple functions that maximize its value and provide smarter, cost-effective tools for our maintenance operations.”

McGee envisions the platform enhancing work with light fixtures, bridge work and on tolling equipment under Open Road Tolling. Open Road Tolling is a cashless, free-flowing mode of collecting tolls without traditional toll plazas or toll booths, using tolling equipment mounted on overhead structures — called gantries — located between interchanges. Open Road Tolling launched in January east of Reading and on the Northeast Extension; it goes live across the system in

Employees were trained on the new lift over the summer and are now incorporating it into their work. Since August, crews have been performing annual maintenance work and inspection in tunnels along the Turnpike. Beyond addressing daily issues, tunnel teams perform scheduled maintenance such as cleaning and replacing tunnel system components, drains, grates, lighting, reflective tape and barrier skins, plus testing all fire hydrants and extinguishers. The Lift-a-Loft will be incorporated into some of this work.

For example, it was recently used to replace indication lights at Tuscarora Tunnel.

“It’s the perfect piece of equipment for working on stationary projects that require us to get directly underneath, like some of the lighting in the tunnels,” said Chuck Zeis, an electrician for the Turnpike. “It adds another level of safety.”

This customized platform is the latest innovative solution deployed by the PA Turnpike to advance safety and mobility within its operations. It joins other field solutions, including:

• LaneBlade, created by J-Tech, a custom-made debris removal tool;

• in-house welding to create hard-to-get parts for snowplows, rear bumper equipment, access gate key boxes and vent cap covers;

• portable solar-powered generators with a propane backup;

• a snowplow simulator to support employees’ familiarity and confidence with equipment;

• piloting a rear-facing air horn system to alert distracted motorists if they are approaching a Truck-Mounted Attenuator (TMA) too quickly; and

• Fotokites, tethered drones, to provide live streaming for incident management and traffic studies.

The PA Turnpike’s Maintenance Department is the Commission’s largest, with more than 720 employees and nearly 30 facilities. It operates around-the-clock, 365 days a year, to provide efficient and safe operations of the PA Turnpike system.

“Autonomous and sustainable technologies are redefining how we build, hire and innovate and ConExpo-Con/AGG is where the industry tests those technologies at scale,” said Dana Wuesthoff, show director at ConExpo-Con/AGG. “The Ground Breakers Stage gives attendees a front-row seat to the ideas and investments shaping construction’s global future.”

Every three years, nearly 140,000 construction leaders gather in Las Vegas to discuss innovation, technological advances, challenges and opportunities impacting the more than $2 trillion United States construction industry. The innovative leaders who will be featured on the Ground Breakers Stage will be announced in the months leading up to ConExpo-Con/AGG 2026.

For more information, visit conexpoconagg.com.

ONE TON, 4 DOOR, 4 WHEEL DRIVE, 6.6 DIESEL ENGINE, 53,500 MILE, COMES WITH 5 YR/ 150,000 MILE EXTENDED WARRANTY, WESTERN COMMERCIAL GRADE SNOWPLOW INCLUDED - GOES FROM 8'6" TO 11' WIDE

ONE TON TOP OF THE LINE PICKUP, 6.6 GAS ENGINE, AUTOMATIC TRANS, 4 X4, 4 DOOR APP, 86,000 MILES, 5 YR/ 150,000 MILE EXTENDED WARRANTY WITH ONE YEAR REMAINIG, ALL SERVICE DONE AT DEALER. INCLUDES TOP OF THE LINE WESTERN COMMERCIAL GRADE SNOWPLOW GOES FROM 8'6" TO 11' WIDE, PURCHASED AND INSTALLED FROM GM DEALER

Visit Us @ www.besttractor.com For More Available Equipment Contact Murf

Appraisals - Consignments - Consulting - Equipment Brokerage "Have Iron Will Travel" Phone: 315-952-2828

P.O. Box 727 * Central Square, NY 13036 Murf@BestTractor.com

2018 Cat CB24B

#165-05069, 3,176 hours, ROPS folding Rollbar, hydrostatic, 47in double drum vibratory, lights, water system $21,500

2019 SUPERIOR BROOM SM74C

#175-18038, 2,952 hours, Cab, air, 74hp Cat diesel engine, 2 speed, 8ft front mounted broom, 45degree angle, water system, ST225/75R15 tires, (1) spare tires $37,800

2017 CATERPILLAR 725C2

#140-12010, 6,418 hours, 6x6, Cab, air, 25-ton capacity dump body, mechanical tailgate, 23.5R25 tires $162,500

Farmington (Rochester), New York Fax: 585-924-7624 Email: tdelany@americanequipmentllc.com

585-924-5480 ext. 520 www.americanequipmentllc.com

Anthony (Tony) D. Fassino, group president, construction industries, Caterpillar Inc., was elected 20252026 chair of the American Road & Transportation Builders Association (ARTBA). The announcement was made during ARTBA’s national convention, held Sept. 28-Oct. 1 in Dallas, Texas.

Fassino, a 30-year company veteran, has extensive expertise in engineering, sales, product development and operations across North America and Asia. Today, he is responsible for a global business that includes earthmoving, excavation, building construction products, global construction and infrastructure, construction industries services and Cat rental and used divisions, along with the segment’s supply management group.

His roster of ARTBA volunteer leadership roles includes serving as senior vice chair (2025), first vice chair (2024) and vice chair-at-large (2021-23). Fassino co-chaired the association’s reauthorization task

force, a 27-member group that developed the industry’s policy proposals for the next federal surface transportation bill due by Oct. 1, 2026. “Moving America Forward: A Blueprint for Strategic Highway & Public Investment” was unanimously approved by ARTBA’s board in May 2025.

At an Oct. 1 ARTBA board meeting, Fassino outlined key issues driving the transportation construction industry’s agenda for the year ahead. He noted these items were consistent with the association’s five-year strategic plan.

Among them:

• Securing robust and timely surface transportation program reauthorization that increases federal highway and public transportation investment to recapture the lost purchasing power from unforeseen inflation surge from 2021 to 2023.

• Pursuing a regulatory structure that supports expanded infrastructure improvements. Fassino said this means pushing for thoughtful solu-

tions on regulations like Buy America expansion and the Occupational Safety & Health Administration’s proposed heat rule to ensure they do not impose unnecessary requirements, along with ARTBA’s ongoing legal advocacy efforts to stop federal overreach on issues like the Waters of the United States rule.

• Broadening the infrastructure coalition by partnering with the general business community to articulate how strong federal leadership facilitates a national transportation infrastructure network that promotes economic competitiveness, security and prosperity for all Americans.

• Developing a safety and mobility campaign that highlights the ability of infrastructure improvements to enhance daily life for all Americans and ensures that both roadway workers and motorists — with added emphasis on teen drivers — get home safely at the end of each day.

For more information, visit artba.org.

onerous regulation, among many other changes in policy.

With the federal government’s seal of approval, centers continue to be designed and built across the country.

That drive to lead the AI infrastructure race creates many opportunities not only for building contractors but for contractors whose focus is earthwork and site prep. Depending on the scale of the facility, this pre-construction phase can be a considerable undertaking, according to construction software provider Autodesk.

“The site is levelled and cleared to prepare it for construction, then excavations for footings, utility and infrastructure placement begin,” it said.

“Construction begins on sub-floors, and electrical grounding grids are laid to protect equipment,” added Autodesk in a blog post.

The size of the digital facility determines the intensity and detail of the pre-construction phase. A chosen site is leveled and cleared for footings, utility and infrastructure placement.

Site development contractor Muller said the demand for reliable data storage and processing has skyrocketed in recent years. Businesses, government agencies and institutions all rely on data centers to power their operations, the company noted.

As the foundation of the digital economy, data centers require meticulous planning and construction to ensure longterm reliability and performance, it said.

“Building a data center is a complex endeavor that involves multiple considerations.”

That includes every phase, “from site selection to utility installation, and from erosion control to regulatory compliance.”

The North American “hyperscale” data center market is set to grow from $9 billion in 2022 to more than $20 billion in 2025, according to Sunbelt Rentals.

A provider of equipment to contractors who specialize in site prep work, Sunbelt wrote in a blog post that new data centers are more than just big buildings.

“They have redundant HVAC systems designed to keep everything cool and dry and backup generators to keep things running in case of a power failure.”

Companies have to factor the effects of climate change into the design and location of new AI centers, Sunbelt continued.

Can it be cooled if average temperatures rise? Must the structure be hardened against extreme weather? Is there reliable, long-term water and power?

“These are questions that affect every phase of construction from design to commissioning,” wrote Sunbelt in a walk though of data center construction phases.

The company suggests that planning helps in ensuring stakeholders have what they need to keep the project on schedule and within budget.

“The first step in any successful data center project is clearly defining the data center design and construction objectives,” said Muller. “This involves understanding the scope of the project, the expected future capacity, and the necessary compliance and security standards.”

Whether the project is for a co-location, cloud or enterprise data center, defining the type and purpose of the facility early on is essential, said the contractor.

“Is it meant to serve a local region, a specific company or a global network? Will it need to expand in the future to accommodate growing storage demands?”

The ideal data center should meet both current and future requirements, said Muller. A critical part of this process involves determining the scalability needs.

This process also should ensure that the design can

As AI expansive data centers become more visible in communities across the country, contractors are staying busy.

In Louisiana, the Richland Parish Data Center project is taking shape with the help of drones outfitted with innovative scanning technology.

Mortenson Construction addressed the issue of underground hazards, including high-pressure gas lines and abandoned wells with the technology. The MagArrow Scan technology uses drones equipped with advanced sensors to detect abnormalities in the earth’s magnetic field.

“This bold, new approach allowed the team to locate metal objects deep underground, such as gas lines and old wells,” said Mortenson. These structures might not be documented or easily found through traditional locating methods, the construction company explained.

“The accuracy of the scan was a lot more

detailed than I thought it was going to be,” said Brian Nelson, senior superintendent II.

According to Mortenson, the scan not only uncovered this hidden gas line but also validated the locations of old irrigation and gas wells.

The irrigation and gas wells were previously inaccurately mapped, so the precision of the scan significantly narrowed down these locations.

Mortenson said it acts as a vital safety check, preventing accidents that could seriously endanger team members and disrupt projects.

“In addition to the scan, the project also employed innovative solutions,” said the construction contractor.

Bridges were installed to allow large equipment to safely traverse over gas lines without applying pressure directly over the gas line.

The pressure could have caused disruptions to the gas lines, resulting in leaks or more cata-

strophic events.

Mortenson said the scan gave the team the precise location to place the bridges.

Jopy Willis, Mortenson general superintendent, described the bridges as multifaceted.

“We’re using them not only to navigate over gas lines but also to cross wetlands, ensuring that our logistics remain efficient and safe.”

The drone scanner’s ability to detect these hazards is not just about safety; it's about efficiency and accuracy, added Mortenson.

“By identifying these underground features, construction teams can plan their projects with greater confidence.”

That’s because these teams know they won't inadvertently hit something dangerous underground.

“This proactive approach to safety and planning is a testament to our team’s commitment to innovation and the well-being of its workers.”

accommodate growth without disrupting the data center’s operations, it said.

“Additionally, compliance with standards for security, energy efficiency and environmental impact is essential, particularly for government and military projects.”

Budgeting is a crucial part of any construction project, but data centers require special attention due to their scale and complexity, said the company.

“Balancing the budget with the long-term operational needs of the data center facilities is essential to ensuring that the project remains sustainable and efficient over time.”

Choosing the right location for a data center is one of the most critical factors for long-term business success, said Muller.

The site, it said, must meet specific requirements to ensure the data center’s smooth operation and ability to handle expansions.

“A data center requires more than just a large plot of land,” said Muller. “You need to evaluate the proximity to power sources and fiber networks.”

During the site survey and engineering phase, reference points and markers will be staked to guide the construction of everything on the data center site.

“The work starts with existing conditions, including the terrain, structures ad above- and below-ground infrastructure,” said Sunbelt.

The local climate also is a factor, said the site developer, Muller. Zoning laws, permits and environmental regulations also can impact site selection.

Once a site has been selected, proper site development is critical to ensuring a strong foundation for the data center.

In the excavation, grading and erosion control phase, these crews will remove, add, shape and compact soil and prepare it for the foundation.

“That could require a perfectly level base or one with a set slope,” noted the Sunbelt blog post. “Once complete, the general contractor brings in … onsite power and gets ready for pipe and utility line installation.”

Erosion control is a vital consideration for any construction project, but for data centers site stability and regulatory compliance are key concerns, said Muller.

“Without proper erosion control, stormwater runoff can wash away soil, destabilize the foundation, and introduce contaminants into the local ecosystem.”

This can threaten both the integrity of the data center facility and the surrounding environment, said the firm.

“Effective erosion and sediment control measures can prevent costly damage and ensure compliance with environmental regulations.”

Further, data centers depend on access to a robust network of utilities, including power, water and high-speed data connections.

“Utility installation is one of the most critical steps in the pre-construction phase,” said the company.”

Data centers require large amounts of electricity to power both servers and cooling systems. Water may be needed for the cooling system, and reliable fiber networks are essential for data transmission. That’s why both wet and dry utility installations are necessary to support the operations of a data center, said Muller.

Utility installation affects power, gas and water lines as well as underground cables and sewage pipelines.

Data centers require large amounts of electricity to power both servers and cooling systems and water also may be needed for the cooling system. So, both wet and dry utility installations must support operations.

A site utility contractor can determine the exact location, depth and layout of any existing infrastructure.

“They keep the worksite safe while overseeing electrical and plumbing contractors, who install additional underground utilities,” said Sunbelt. “The grading contractor ensures surfaces are level in preparation for pouring the foundation.”

The type of structure to be supported, the soil it will lay on, bedrock depth and environmental risks become critical factors in foundation design.

“Ultimately, a combination of concrete and steel below keeps the structure above stable,” said Sunbelt.

clearance, while also improving drainage. This work was performed as part of the overall HST project, a key CSX capital improvement initiative. It will eliminate clearance restrictions for double-stack trains along its vital I-95 rail corridor between Baltimore and Philadelphia, as well as from the Port of Baltimore’s Seagirt Marine Terminal Intermodal Container Transfer Facility to consumer markets in the Midwest.

“Not only will this project improve a vital CSX rail corridor, but it will create a ripple effect that will strengthen the Port of Baltimore’s ability to compete with other East Coast ports,” said Ray Hagen, Fay’s deputy project manager. “Its forward-looking improvements are expected to significantly boost productivity at the port and expand freight rail capacity throughout CSX’s rail network.”

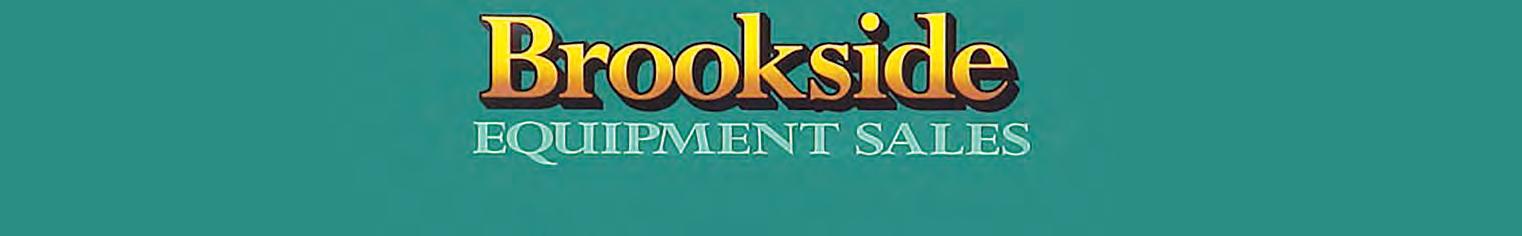

Fay noted that HST is an 8,700-ft.-long brick and stone arch tunnel. It had a clearance of approximately 19 ft., which the JV increased to 21 ft. Due to its status as a historic landmark, the structure could not be removed and rebuilt. Instead, the JV excavated the tunnel’s floor to lower the track and installed enormous new pre-cast concrete invert slabs, which will improve the drainage and support the weight of the trains.

Because of space constraints, the JV needed to come up with a customized crane design capable of carrying multiple 20,000-lb. precast concrete invert slabs to be laid along the length of the tunnel bed. The group came up with the initial idea of attaching a gantry crane atop a flatbed railcar, which would allow workers to safely move and efficiently position the slabs on the newly lowered tunnel floor. The final design and machine were the result of the JV’s combined ideas and engineering in collaboration with Kelley Engineered Equipment and Wolf Hills Fabricators.

“The idea was to place a gantry crane on a railcar to create a machine that could lift and carry the enormous weight of the pre-cast sections into the tunnel,” said Thomas Costabile, Skanska’s onsite Construction Manager. “We needed to precast, rather than allowing them to cure inside the tunnel because of CSX’s tight construction timeline. Necessity really is the mother of invention.”

First, the JV envisioned a single-beam gantry crane built on a train car, but due to the cross slopes inside the tunnel, the side load on the beam would not have been able to handle the loading.

“We ended up going with a double-beam system to allow for horizontal curves,” said Ed Chaney, a Fay senior superintendent also involved in the project.

The design allows the crane to extend approximately 30 ft. past the base of the gantry, which makes it possible to set the inverts while also bearing their load.

Powered by electricity from the local grid, he noted that the gantry system is agile and quiet. It also illuminates the tunnel and eliminates the need for diesel generators and trucks transporting loads of equipment and workers in and out of the tunnel. Crews worked around the clock, installing an average of six of approximately 1,190 total segments each day.

The process of placing the concrete invert segments was completed in the following order: all the materials and equipment arrived by rail through the tunnel’s eastern portal. Crews started by excavating the floor of the tunnel, removing the original invert and excavating to the desired depth. To do so, the JV used specialized Mecalac excavators, which

• More than 450,000 man hours worked to date, peaking at 175 field craft, 20 subcontractors and peak salaried supervision staff of 40 engaged in the expansion.

• 233 consecutive days of 24/7 work in the tunnel (Feb. 5 through Sept. 25).

• 1,128 dewatering wellpoints installed.

• 1,188 PCIS (precast invert slabs) placed, weighing in at nearly 10 tons each.

• 14,276 linear ft. of wall drain installed.

• More than 4,000 cu. yds. of concrete placed.

• More than 24,000 cu. ft. of grout placed (mixed by hand).

• More than 25,000 cu. yds. of excavated invert material removed from within tunnel.

• More than 78,000 linear ft. of temporary electrical cable installed.

they chose to work within the confined space.

“The excavators each have a unique two-piece boom with a low profile,” said Chaney. “They’re designed to swing in a nine-foot, seven-inch radius.”

All excavated material was then hauled out in crawler carriers on a rotating chassis to eliminate backing trucks through the tunnel. Once outside the tunnel, the material was transferred into 40-cu.-yd. side-dump gondola cars for the trip to the excavated material placement area, roughly three miles from the tunnel.

While nearly double the length of the average rail car at approximately 120 ft. long, the gantry’s structure was com-

pact enough to navigate the curves in the tunnel. The precast slabs were delivered beneath the back end of the crane, which lifted the concrete invert slabs and carried them through the crane to the front, past the base of the gantry. Then, the crane set three slabs, one at a time, in the excavated area. Workers then grouted each section through grout ports to ensure a sound foundation and installed rebar on the sides to cast concrete wing structures. Once those cured, the track was bolted in place, the crane advanced forward, and the whole process was repeated.

see TUNNEL page 58

Realistic Scale Models of Construction Equipment, ideal gifts for

Mack Granite Standard Mixer, 2008 World of Concrete, 1:34 scale - $150

Granite Material Handler w/ Concrete forms, 2007 World of Concrete, 1:34 scale - $160

Offering outstanding grading performance and 3 levels of Operator Assistance Systems, you can complete your job with cutting edge p cision and costeffective operation. www.liebherr.com

MAKE YOUR MOVE

Push

... more material with the new Hyundai HD100 crawler dozer's best-inclass power-to-weight ratio.

See

...more than ever with the unobstructed view to the blade.

Engage

...more accurately and more productively with standard 2D or optional 3D machine guidance.

Doze

...with confidence, knowing your new 115 hp Hyundai crawler dozer delivers the quality and value you expect from Hyundai, with the peace of mind that comes with our industry-leading warranty.

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, na.hd-hyundaice.com.

650M LGP 68 (50.6) 16,936 (7,682) FPT F5C F5HFL463D*G003

650M LT 68 (50.6) 15,931 (7,226) FPT F5C F5HFL463D*G003

650M

68 (50.6) 16,457 (7,464) FPT F5C F5HFL463D*G003

750M LGP 92 (69) 21,005 (9,527) FPT F5HFL413J*A002

750M WT 92 (69) 20,756 (9,414) FPT F5HFL413J*A002

750M LT 92 (69) 20,168 (9,148) FPT F5HFL413J*A002

850M LGP 112 (84) 23,430 (10,627) FPT F4HFE413P*A008

850M WT 112 (84) 22,855 (10,366) FPT F4HFE413P*A008

850M LT 112 (84) 22,319 (10,124) FPT F4HFE413P*A008

1150M LGP 127.4 (95) 33,346 (15,125) FPT F4HFE613F*A002

1150M

Komatsu SAA6D114E-6

(24,199) Komatsu

D71PX-24

D71PXi-24

D85EX-18

D85PXi-18

(177 )

(23,100) Komatsu SAA6D114E-6

(177 ) 51,147 (23,200) Komatsu SAA6D114E-6

D85EX-18 WH 264 (197)

D85PX-18

D155PX-8

(32,077) Komatsu SAA6D125E-7

(31,688) Komatsu SAA6D125E-7

(40,500) Komatsu SAA6D140E-7

John Deere announced the launch of the new 850 X-Tier dozer and significant upgrades to the 700, 750 and 850 P-Tier dozers.

These advancements enhance power, precision and efficiency, helping operators maximize productivity while minimizing downtime, according to John Deere.

Building on its legacy of E-Drive, the 850 X-Tier dozer sets impressive standards in power, efficiency and precision to dozer applications, according to John Deere. The 850 X-Tier uses dual path electric drive technology for added simplicity over traditional drivetrains and optimizes torque delivery and reduces machine complexity. To enhance customer confidence, John Deere now offers the 850 X-Tier dozer electric drive component assurance, providing 84 months/15,000 hours of coverage on key E-Drive components for qualified machines purchased between March 1, 2025, and Dec. 31, 2026.

Building off the L-Series cab, the 850 XTier enhances operator comfort and visibility, featuring 14 percent more glass area, ergonomic controls and an Advanced Vision System (AVS) for improved jobsite awareness. Designed for minimal downtime, the dozer also features a tilting cab,

John Deere photo

John

allowing quick access to E-Drive components for easy diagnostics and maintenance, according to John Deere.

“The 850 X-Tier dozer is a powerhouse machine designed to be fuel efficient and productive in challenging job sites,” said Matt Costello, product marketing manager, John Deere. “From enhanced operator

comfort to advanced SmartGrade technology, this machine helps the operator move dirt fast with precision.”

John Deere enhances the 700, 750 and 850 P-Tier dozers with next-generation technology, to maximize jobsite productivity. SmartGrade capabilities include EZGrade, SmartGrade ready with 2D

grade control and 3D SmartGrade, providing operators with precise grading control and enhanced situational awareness, according to the company.

The SmartGrade platform provides plug and play capabilities for laser and total station control allowing customers access to more job sites. Larger touchscreen displays simplify navigation and setup for machine operation, ensuring a more intuitive experience, according to John Deere.

Operator-focused features, included in the P-Tier and X-Tier models, include heated and ventilated seat options, expanded storage and enhanced climate control, delivering greater comfort in all working conditions. Auto-load and carry automatically adjusts blade settings based on ground conditions, reducing the need for manual adjustments, according to John Deere.

“With advanced SmartGrade capabilities and enhanced operator features, our latest P-Tier dozers are engineered for greater efficiency and control,” said Costello. “These updates deliver the reliability and performance operators need to tackle even the most challenging projects.”

For more information, visit JohnDeere.com

Caterpillar Inc.’s new Cat D8 dozer with advanced technology is designed to provide faster more accurate results.

The next generation design makes it easier for operators to transition to different machine sizes. The bulldozer’s elevated sprocket offers better ride and balance than low-drive undercarriages, and its long undercarriage delivers the D8’s renowned performance of high penetration forces and superior dozing performance.

The Cat C15 engine offers an increase in horsepower over the previous build to take on a wide range of dozing, ripping and grading tasks.

The D8 dozer’s next generation cab offers more space than the previous design complete with a wide air suspension seat with multiple adjustment options. Featuring an integrated rollover protective structure (ROPS), the next generation cab provides 17 percent improved visibility than the previous design. (Visibility improvements based on virtual visibility analysis. Comparisons made from a D8 (21B) model to the Next Generation D8 (22A) model.) It can be removed in approximately 30 minutes to facilitate machine servicing.

The 10-in. touchscreen main display has built-in key features assistance to give operators an overview of the machine, technologies and helpful tips. When the machine is in reverse, the standard high-definition rearview camera feed shows prominently in the display.

Distributed air from the heating, ventilation and air conditioning (HVAC) system effectively circulates around the operator and helps reduce window fogging and frosting.

Assist technology features minimize operator input, boosting productivity for less experienced operators and decreasing effort and fatigue for everyone, while delivering quicker and more precise outcomes. Cat Assist with Attachment Reader Option (ARO) standard features include:

• Stable Blade to work seamlessly with operator inputs to help produce a smoother surface when operating manually

• Traction Control automatically reduces track slip to save time, fuel and track wear (Feature not operational indoors or in areas where a GNSS/GPS signal is not available.)

• Steer Assist reduces steering inputs by automating track and blade tilt steering

• Blade Load Monitor leverages GPS and provides realtime feedback on current load versus optimal blade load, based on ground conditions, and actively monitors machine load and track slip2

• AutoRip automates ripper raise/lower and shank in/out positioning to maximize ripping productivity

• Attachment Ready Option (ARO) provides wiring and mounting for faster installation of dealer-installed options like Cat Grade with 3D, AccuGrade, Universal Total Station (UTS) or other grade control systems

• AutoCarry uses a GPS signal to automate blade lift, helping to maintain consistent blade load and reduce track slip2

• Cat Grade with Slope Assist automatically maintains pre-established blade position without a GNSS/GPS signal

• Slope Indicate is included in the main machine displace and shows side slope and uphill/downhill grades to help operators with slope work

Featuring an external connector for efficient dealer installation of a plug-and-play, roof-mounted remotecontrol unit, the new D8 dozer ships from the factory remote control ready. Cat Command for Dozing removes the operator from the cab by enabling remote dozer operation when working in hazardous environments.

With no on-site network requirements, the portable and lightweight Command console provides quick and efficient line-of-sight remote control from up to 1,312 ft. for optimum operator visibility. The Command station delivers comfortable, non-line-of-sight operation either on-site or from miles away. The station features a comfortable seat, familiar controls and allows the use of Grade, Payload, Assist and other technologies using the included touchscreen.

The next generation D8 dozer design enables a wider range of machine connectivity than prior models. Streamlining service efficiency, Remote Troubleshoot saves time and money by allowing the Cat dealer to perform dozer diagnostic testing remotely. Remote Flash enables on-board software updates without a technician at a convenient time that does not disrupt the production schedule.

Customizable dashboards streamline fleet management efficiency by providing critical machine operating information like dozer hours, miles, location with mapping, idle time, CO2 emissions, asset status and operation, and fuel utilization.

The D8 dozer leverages VisionLink to provide actionable data insights, accessed anywhere a connection is available through Cat Product Link, for all connected assets, regardless of fleet size or manufacturer.

The next generation Cat D8 waste handler is designed and built from the frame up to withstand challenging landfill operating environments. Specialized guarding, striker bars and seals help protect the machine and undercarriage from impact, material wrapping and airborne debris.

Impact-resistant polycarbonate cab doors eliminate the need for door screens, while lights are mounted high on the dozer, away from the debris for protection, to illuminate the work area. The configuration features a high debris cooling system with automatic reversing fan, cooling system swing out cleaning access, laminated thermal shields and insulated clean emissions module. Its waste undercarriage with centerhole track shoes and landfill-specific blade designs help to optimize performance.

For more information, visit cat.com.

(Caterpillar photo)

Five Star Equipment, Inc. www.fivestarequipment.com

60 Paul Rd., Rochester, NY 585-235-3011

1653 NY Route 11, Kirkwood, NY 607-775-2006

284 Ellicott Rd., Orchard Park, NY 716-662-2191

5835 East Taft Road, North Syracuse, NY 315-452-4560

1300 East Dunham Dr., Dunmore, PA 570-346-1701

46 Route 97, Waterford, PA 814-796-2663

2585 Lycoming Creek Rd, Williamsport, PA 570-494-4030

Groff Tractor & Equipment

www.grofftractor.com

6779 Carlisle Pike, Mechanicsburg, PA 717-766-7671

2550 E. Cumberland St., Lebanon, PA 717-273-2616

800-225-4001

3215 State Rd., Sellersville, PA 215-258-5700

800-523-2209

400 Stoke Park Rd., Bethlehem, PA 610-867-4657

800-587-9790

640 Lowther Rd., Lewisberry, PA 717-938-6568

866-787-0001

179 Perry Hwy, Harmony, PA 724-776-3636

963 South Center Ave., New Stanton, PA 724-755-0124

www.lec1.com

Beaver, WV

304-255-1525

Cowen, WV

304-226-3299

Cross Lanes, WV

304-204-1818

Pleasant Valley, WV

304-534-5454

Norton, WV