CATALOGUE

Robotic solutions for your finishing plant

Lesta LEBOT MV A6

Lesta LEBOT I A6

Lesta LEBOT DG

Lesta LEBOT MV A5

Lesta LEBOT Picchio

Lesta LEBOT C

Control cabinet

Lesta

Lesta

WHAT WE MEAN BY

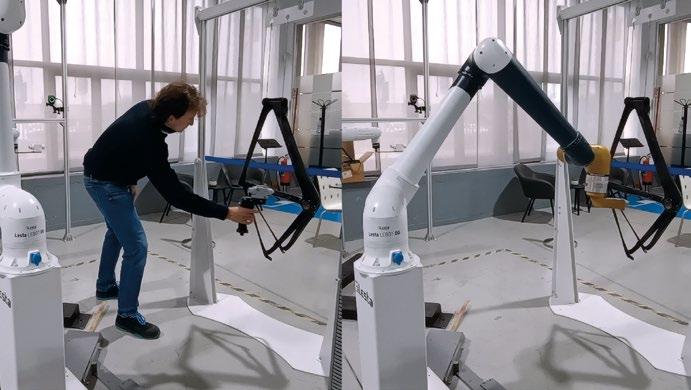

SELF-LEARNING ROBOTS

The self-learning concept is based on the “teach” function. The robot, during the learning phase records real time movements of the axes piloted by the operator. The operator uses the handle attached to the robot’s arm during the teaching phase. When the teaching phase is completed, the robot can reproduce the same movements in “auto play“ mode.

TEACHING

AUTOMATIC PLAYBACK

WHAT WE MEAN BY

INDUSTRIAL ROBOTS

BENEFITS OF A SELF-LEARNING ROBOT

PROGRAMMING TIME EQUAL TO THE TIME OF THE FIRST PAINTING

USER-FRIENDLY SOFTWARE EASY TO USE

For each use, where a robot does not have to learn the program through a “self-learning method”, Lesta integrates industrial robots into its own advanced systems. The purpose of this integration is to simplify the use of the industrial robot and the controller through Lesta’s innovative software.

Unlike Lesta’s self-learning robots, industrial robots have very heavy arms that cannot be ‘unlocked’ and moved directly by manipulating the spray gun.

BENEFITS OF A INDUSTRIAL ROBOT

LARGE ACCESSIBILITY OF THE WORKING AREA

MORE CAPACITY ON THE WRIST

MORE ACCURACY (REPEATABILTY)

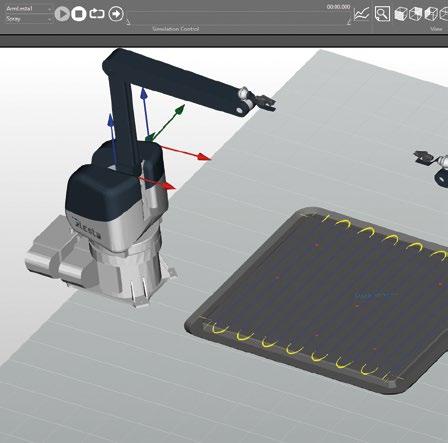

Lesta LEBOT MV A6

6-axis anthropomorphic robot for self-learning finishing

Arm material: Aluminum

Wrist payload: 4 Kg

Total weight: 380 Kg

Repeatability: ±3 mm at the wrist

Full speed: 1000 mm/s

Possible configurations: Upside down, floor, carriage, carousel

Power supply: 3x400 VAC

Programming: Self-learning, Point to point lite, offline, 2D and 3D vision systems

DATA ATEX environment compatible ATEX zona 2/22 Cat. 3G

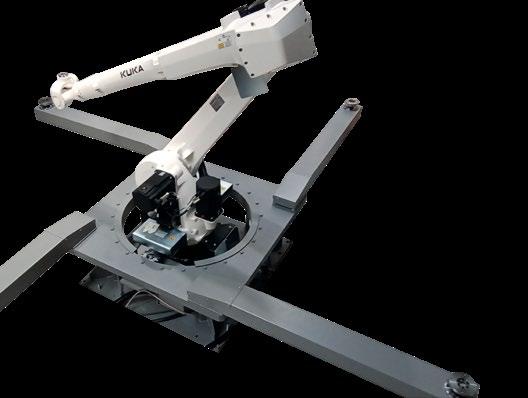

Lesta LEBOT MV A6 on chariot LIQUID APPLICATION FOR METAL

Lesta LEBOT MV A6 on carousel with E asy prog 2D LIQUID OR POWDER APPLICATION FOR SMALL PLASTIC AND METAL COMPONENTS

A system with Lesta LEBOT MV A6 on carousel with 2 variable geometry arms for painting fashion accessories.

ROBOT

VIDEO

Lesta LEBOT I A6

LEBOT I A6 on carousel with Easy prog 3D scan LIQUID APPLICATION FOR WOOD

Industrial-type 6-axes anthropomorphic robot

Protection class: IP65

Arm material: Casting of light alloys

Repeatability: ±0,05 mm at the wrist

Full speed: 1500 mm/s

Possible configurations: Upside down, floor, carriage, carousel

Power supply: 3x400 VAC

Programming: Lesta PAINT STUDIO, 2D and 3D vision systems

ROBOT

Lesta

Lesta LEBOT DG

ATEX environment compatible zona 2/22 Cat. 3G

Wrist capacity: 10 kg

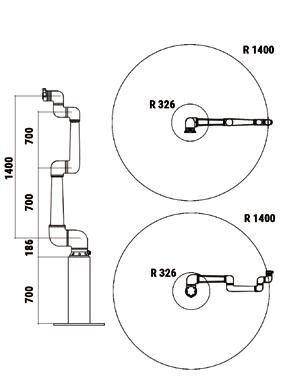

Repeatability: +0.05 mm at the wrist Working area radius: 1400 mm

6-axis anthropomorphic robot also for self-learning painting

Arm material: Aluminium

Wrist capacity: 10 kg

Total weight: 80 kg

Repeatability: >1 mm at the wrist

Power supply: 1-phase 220V

Maximum speed: 1000 mm/s

Configurations: Suspended, floor-mounted, on carriage, on carousel

Programming: Lesta GESTURE self-learning, Point to point lite, Lesta PAINT STUDIO 3.0, 2D and 3D vision systems

Wrist capacity: 20 kg

Repeatability: +0.1 mm at the wrist Working area radius: 1777 mm

L esta LEBOT DG A6-7070

L esta LEBOT DG A6-8592

ROBOT

ROBOT

Lesta LEBOT MV A5

ATEX environment compatible zona 2/22 Cat. 3G

L esta LEBOT MV A5 on a carousel LIQUID APPLICATION FOR WOODEN CHAIRS

5-axis anthropomorphic robot for self-learning finishing

Protection class: ATEX zone 2/22 Cat. 3G

Arm material: Aluminum

Wrist payload: 4 Kg

Total weight: 320 Kg

Repeatability: ±3 mm at the wrist

Full speed: 1000 mm/s

Possible configurations: Upside down, floor, carriage, carousel

Power supply: 3x400 VAC

Programming: Self-learning, Point to point lite, offline, 2D and 3D vision systems

VIDEO DATA

ROBOT

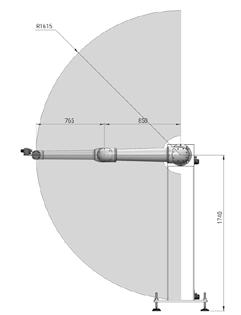

Lesta LEBOT Picchio

ATEX environment compatible zona 2/22 Cat. 3G

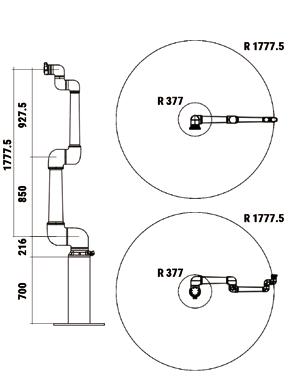

RADIUS 1238 mm

RADIUS 1615 mm

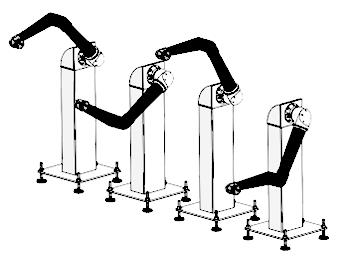

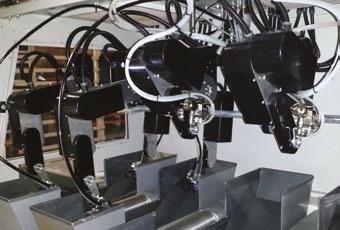

MULTI-ARM CONFIGURATION

This configuration includes up to 4 arms equipped with 3 axes each for a maximum total of 12 axes, installed in sequence and all managed by a single control unit. Each arm can move independently and perform up to 4 different applications in sequence.

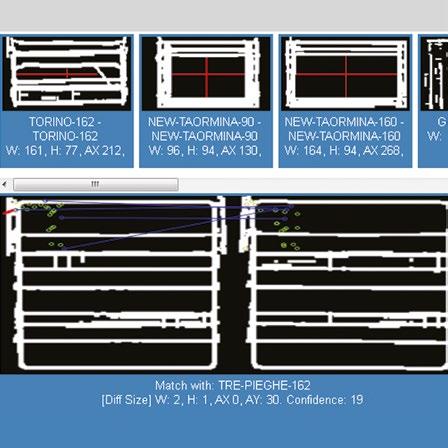

Small 3-axis robot, minimum footprint and minimum investment

Number of axles: 3

Arm material: Aluminum

Wrist payload: 10 Kg

Total weight: 94 Kg + >30Kg

Repeatability: >1 mm at the wrist

Full speed: 1000 mm/s

Possible configurations: Upside down, floor, carriage, carousel, up to 4 modules can be managed with a single controller

Power supply: 1-phase 220V

Programming: Point to point lite, Lesta PAINT STUDIO 3.0

LIQUID APPLICATION FOR PLASTIC HELMETS

MULTI-ARMS

ROBOT

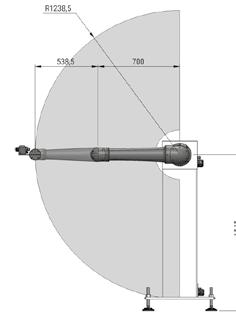

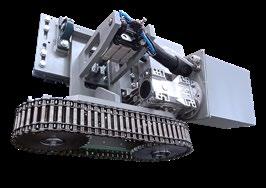

Lesta LEBOT C

ATEX environment compatible zona 2/22 Cat. 3G

Maximum window sizes and bespoke options

5-axis cartesian robot

Protection class: ATEX zona 2/22 Cat. 3G

Wrist payload: 4 Kg

Repeatability: ±3 mm at the wrist

Full speed: 700 mm/s

Power supply: 3x400 VAC

Programming: Offline, 2D and 3D vision systems

The structure, as illustrated, can paint windows up to 5 meters wide and 3 meters high

The structure also requires our technical team to adapt the system.

Lesta LEBOT C for classic windows

LIQUID APPLICATION FOR WOODEN WINDOW FRAMES

USE

Commonly for painting windows and frames

SOLIDITY

Chain is used to handle the wagon

SPEED

The wrist is applied to a linear belt guide

ADAPTABILITY

Length, height and depth of the structure can be customized

VIDEO

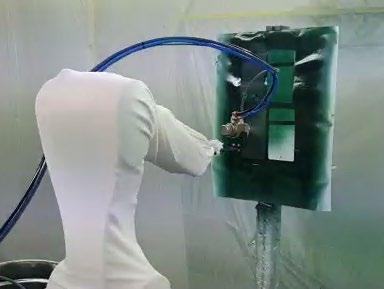

Lesta SAMPLE MAKER

LIQUID APPLICATION FOR COLOUR SAMPLES

Complete system for painting with small quantities of paint, ideal for the processing of paint samples and test objects, or for conducting tests with specific painting parameters. Once optimised, these parameters can also be applied to large-scale production.

Dimensions of the robotic island:

Standard height: 2600 mm

Standard width: 2800 mm

Standard depth: 2000 mm

These dimensions can be customised.

Includes a cleaning station for automatic cleaning of the spray gun nozzle and cup attachment

CONTROL CABINET

Lesta LECROB Robot Controller

Robot interface and control pulpit equipped with 15” touchscreen and Lesta LECROB Robot Manager management software.

CONTROL CABINET SOFTWARE

Lesta LECROB

Robot Manager

Lesta LECROB Robot Manager is the software for controlling and managing MV series robots.

It also provides the following features:

MODULAR ROBOT SPEED

With perfect reproduction, 70% to 130% of teaching speed

ARCHIVING OF PROGRAMS

On local memory, on USB key or on a network path

PICTURES AND NOTES FOR THE PROGRAMS

Each program can be associated with an image and/or a “various annotations” file

5 LEVELS OF ACCESS AND USE

Access to specific machine functions, only for authorized personnel

MAINTENANCE STATISTICS

Graphic indicators divided by activity (lubrication, greasing, routine maintenance, chain change)

ROBOT CALIBRATION

Quick and easy verification of machine zeros (encoder zeros) and with guided and intuitive encoder calibration

CUT OF DOWNTIME

The time in which the robot is not moved and the gun does not dispense paint can be eliminated through an optimization

ARCHIVING OF PRODUCTION DATA

Microsoft Excel .csv files or MySQL database

REMOTE UPDATES

Remotely upgradeable software

CONTROL CABINET

Lesta LECROB Robot Controller COMPACT

Robot interface and control console equipped with a 15” touchscreen and management software

Lesta LECROB I Manager

CONTROL CABINET SOFTWARE

Lesta LECROB I Controller

Robot interface and control console equipped with a 15” touchscreen and Lesta LECROB I Manager management software

CONTROL CABINET SOFTWARE

Lesta LECROB

I Manager

This software is designed to control the Lesta LEBOT I A6 series robots. It also provides the following features:

SIMPLIFIED INTERFACE

Interface with aggregated and simplified functions

SIMPLIFIED ACCESSORY MANAGEMENT

Each accessory has a direct interface connection with a minimum number of interaction buttons

SIMPLIFIED MAINTENANCE

Direct access to ‘special’ positions dedicated to maintenance

REMOTE UPDATES

Software can be updated remotely (via internet connection)

L esta LECROB ROBOT MANAGER

Plug-in

POINT TO POINT LITE

This plug-in optional feature allows the generation and processing of a virtual painting path by physically directing the spray gun to the desired points and confirming chosen locations with a click on the joystick. Through the plug-in interface, available with the Lesta LECROB Robot Controller, it is possible to use selected points and generate the path via software. This is done by setting different parameters such as speed, acceleration, distance from the piece, gun parameters (atomization, flow rate and fan), and more.

INTERNAL QUEUE

This plug-in optional feature allows you to define, from a list of programs, the order in which they will be executed. The operator can always step in and control programs by setting the order on the screen of the Lesta LECROB Robot Controller

This plug-in is widely used in configurations with a carousel.

FOLLOW ME

Is a systems where the robot is mounted on a carriage. When the operator has to perform movements that are larger than the usual working area of the robot, the carriage will allow the robot to reach larger spaces without the need of using the external pushbutton The robot will physically move on the cart independently following the movements of the operator. All these movements, in the “teaching” stage, will be recorded and will be repeated in the “automatic repeat” stage

POWDER PACK

Software option dedicated to powder systems:

1. SAVE PAINT

The powder is dosed only when the element reaches the operator and the registration of movements begins

2. CLEANING FROM THE OUTSIDE

It allows you to start and manage washing activities from external devices.

3. MANAGEMENT OF THE ELECTROSTATIC GUN

A special holder is installed which isolates the spray gun.

FIBERGLASS PACK

Software options dedicated to fiberglass, gelcoat, and resin systems:

1. AUTOMATIC WASHING POSITION AFTER EACH CYCLE

2. GLASS FIBER DISPENSING DOSAGE BY MANAGING THE CHOPPER

3. MANAGEMENT OF GELCOAT AND RESIN VALVES

INDUSTRY CONNECTOR

Connects the robot to factory computer systems for the exchange of production data.

VIRTUAL START CYCLE

Where systems have a conveyor, the cycle start sensor is mounted to allow the start of the painting program. When it is not possible to install the cycle sensor in the cabin due to dirt, ATEX or other reasons, it is fitted outside the cabin along the conveyor and the virtual limit switch plug-in will calculate the exact moment for the robot to start reproducing the program.

QUICK START

This plug-in allows you to record a program and, as soon as the recording is finished, to start the automatic cycle with 1 click. This plug-in is widely used on solid lines

ADVANCED EDITING

PAINTING PARAMETERS

Allows you to modify the 3 main paint dispensing parameters:

1. SCOPE

2. ATOMIZATION

3. FAN for time intervals chosen within a program after it has been created.

The gun that is mounted on the robot’s arm must be equipped with a predisposition for this function.

LIQUID PACK

Software options dedicated to liquid systems:

1. MANAGEMENT INTERFACE WITH EXTERNAL COLOR CHANGING SYSTEMS

2. AUTOMATIC CLEANING

3. MANAGEMENT OF THE ELECTROSTATIC GUN

EXTERNAL PROGRAM SELECTION

This plug-in enables the selection and launch of paint programs by an external system, e.g. a PLC controller.

The robot can receive program code via hardware signals or different fieldbuses.

SMART APP

The smart app plug-in allows you to monitor the status of Lesta robots on any device (PC, tablet, smartphone)

L esta GESTURE

Lesta Gesture is a manually guided programming solution for industrial robots that allows an experienced painter to “teach” the robot the trajectory simply by performing it manually with a spray gun (hand tool), tracing its path in real space. The robot will then automatically repeat the same trajectory using its own spray gun mounted on its wrist.

VIDEO

E asy prog PORTAL

AUTOMATIC PROGRAM GENERATION

Easy prog PORTAL is a system composed of a portal equipped with photoelectric barriers and software capable of autonomously generating the painting path. It is primarily dedicated to the recognition of windows, frames, panels, doors, as well as cylinders or similar objects. It only requires the creation of painting recipes, supply, and unloading. Specific recipes for each type of product to be painted can be created directly from the Robot Controller screen and can be recalled via barcode scanning or directly from the touchscreen.

IT MANAGES THESE TYPES OF OBJECTS

Load the piece

Laser scanning The software automatically generates the painting path

Painting

CYLINDERS SHEETS

SCANNER NOT compatible with ATEX environments. Installable outside the cabin

WINDOWS PANELS FRAMES DOORS

E asy prog 2D

LASER CENTRING OPTIONAL

Easy prog 2D can be equipped with a pair of laser pointers that can automatically compensate for any centring errors of the piece during positioning at loading.

AUTOMATIC PROGRAM GENERATION

Easy prog 2D is software capable of autonomously generating the painting path for panels, boxes, and drawers. It only requires the creation of painting recipes, supply, and unloading.

Specific recipes for each type of product to be painted can be created directly from the Robot Controller screen and can be recalled via barcode scanning or directly from the touchscreen.

The system requires the positioning of pieces according to the direction specified in the recipe.

HOW IT WORKS

Load the piece

Select a recipe via barcode scanning

The software automatically generates the painting path

E asy prog 3D S can

AUTOMATIC PROGRAM GENERATION

Easy prog 3D Scan is a software system equipped with a 3D scanner used on a carousel, capable of identifying the surface area of three-dimensional objects and autonomously generating the painting path.

Specific recipes for each type of product to be painted can be created directly from the Robot Controller screen and recalled via barcode scanning or directly from the touchscreen.

The system recognises the actual position of the objects, making it unnecessary to position the pieces in a specific direction

IT MANAGES THESE TYPES OF OBJECTS

HOW IT WORKS

Load the piece

02 04 03

Laser scanning

The software automatically generates the painting path

INTEGRATED ACCESSORIES

I mage match 2D

Image match 2D is a system composed of dedicated software and specific vision hardware capable of identifying the 2D surfaces of pieces and associating them with the corresponding painting program.

In the initial phase of the work, ‘teaching’ (painting instructions with self-learning) is carried out for each type of piece. After this, it is simply necessary to load the supply line with the pieces to be painted. Image match 2D will take care of recognising the pieces, associating them with the corresponding teachings, and painting them.

It can distinguish objects of different thicknesses

It recognises the actual position and adjusts the painting path accordingly

It can automatically generate painting paths

01 02 03 04

Record the teachings for each piece

The software applies the corresponding teachings

I mage match 3D pro

Image match 3D pro recognises the inclination and position of the pieces and automatically adjusts the painting path

Taught position

Detected position

It can distinguish objects of different thicknesses

It recognises the actual position and adjusts the painting path accordingly

It can automatically generate painting paths

Image match 3D pro is a system composed of management software and one or more 3D scanners mounted on a line, capable of recognising the dimensions of three-dimensional objects and associating them with the corresponding painting program.

In the initial phase of work, programs are created for each type of piece. After this, it is simply necessary to load the supply line with the pieces to be painted. Image match 3D pro will recognise the pieces using its 3D scanners and apply the corresponding painting program. 2D 3D

Record the teachings for each piece

Scanning

The software applies the corresponding teachings

Painting

INTEGRATED ACCESSORIES

Suction and blow-off tools

This accessory consists of a special gun capable of blowing air or suctioning water from the surface of the piece after the washing and drying tunnel.

IT PREVENTS THE FORMATION OF WATER POCKETS AFTER THE PAINT APPLICATION

IT ALLOWS FOR MAINTAINING LOWER TEMPERATURES INSIDE THE OVEN.

SUCTION BLOW-OFF

VIDEO

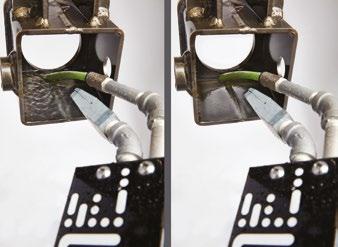

Anticollision

Three types of overload can occur:

TANGENTIAL:

Occurs if the gun collides laterally with an obstacle

AXIAL:

Occurs if the compressive force in the Z direction towards the system exceeds the overload threshold

The Lesta anti-collision system is a special pneumatic device mounted between the gun holder and the gun itself, which protects both from overloads caused by impacts.

In the event of the gun colliding with objects, a mechanical overload is generated, leading to a displacement of the sensor with the release of pressurised air. The pressure drop is detected, and the system sends a signal to the control PLC, which stops the robot.

TORSIONAL:

Occurs in the case of rotation around the Z-axis when the maximum torsional moment is exceeded

VIDEO

L esta CLEANING STATION

Lesta CLEANING STATION is a gun cleaning station that integrates into paint booths, developed for the automatic cleaning of spray nozzles.

Lesta CLEANING STATION is entirely operated by pneumatic valves

Compatible with ATEX environments

L esta CLEANING STATION RS

Lesta CLEANING STATION RS is the most advanced version of the gun cleaning station, equipped with a solvent recirculation system, developed for even more efficient automatic cleaning of spray nozzles

Compatible with ATEX environments

L esta CLEANING STATION powder

Lesta CLEANING STATION powder is the gun cleaning station that integrates into paint booths, developed for the automatic cleaning of powder guns.

Lesta CLEANING STATION powder is entirely operated by pneumatic valves

Compatible with ATEX environments

INTEGRATED

/ STAND-ALONE

ACCESSORIES

Lesta RECIPE MANAGER

Compatible with ATEX environments

The parameters that Lesta RECIPE MANAGER can manage are:

FLOW RATE

ATOMISATION

FAN PATTERN

OPENING DELAY AND ADVANCE

Lesta RECIPE MANAGER is a system for managing painting parameters, organised into recipes and easily retrievable. It interfaces with any painting system using guns or reciprocators.

The mounted gun must be equipped with a feature for this functionality.

CYCLE TIME

Lesta RECIPE MANAGER can be integrated with all Lesta robots without the need for a dedicated screen and software panel.

The user interface is integrated into the Lesta LECROB Robot Manager software.

L esta ROTATION UNIT RA

Lesta ROTATION UNIT RA is a device that allows the rotation of parts arriving from an overhead conveyor.

It can be installed with either step conveyors or continuous conveyors.

Compatible with ATEX environments

L esta ROTATION UNIT RT

Lesta ROTATION UNIT RT is a ground-based device that allows parts to be attached and rotated perpendicularly to the floor for painting.

It can be installed with either step conveyors or continuous conveyors

It can be integrated with carousel arms or a conveyor.

Compatible with ATEX environments

L esta ROTATION UNIT RHT

Lesta ROTATION UNIT RHT is a ground-based device that allows parts to be attached and rotated parallel to the floor for painting.

It can be integrated with carousel arms or a conveyor.

Compatible with ATEX environments

INTEGRATED / STAND-ALONE ACCESSORIES

Lesta PAINT STUDIO 3.0

Methods for importing parts:

IMPORTING 3D MODELS OF OBJECTS AND THE BOOTH

CAPTURING KEY POINTS USING THE ROBOT OR CREATING THEM IN THE SOFTWARE

CONSTRUCTING GEOMETRIES WITHIN THE SOFTWARE

Importing 3D models in STL format

Lesta PAINT STUDIO 3.0 is the software for programming Lesta robots and creating offline painting paths.

Every painting path created directly from the software or through selflearning can be modified.

It is also possible to adjust various parameters including:

• Speed

• Acceleration

• Distance from the piece

• Gun parameters

• Painting angle

ToolPath Editor

This newly introduced feature allows for the modification of parameters in previously auto-learned paint trajectories.

360° view of the robot’s surrounding environment even during the simulation

Automatic grid creation on surfaces to facilitate path generation

Simulation of the robot’s cycle, with verification of reachability limits and cycle times

Possibility of automatic or manual generation of connections between different paths

VIDEO

INTEGRATED

/ STAND-ALONE

ACCESSORIES

Lesta PRODUCTION MANAGER TAG WEB

Lesta PRODUCTION MANAGER is a production queue management system that allows a specific programme to be associated with a specific part or batch. It consists of a management panel (*02), tags (*05 *06), and antennas (*01 *03) capable of receiving information and transferring it to the robots.

It is generally used on inline systems when there is a need to paint a large number of different models, each associated with a different painting programme.

It has 3 possible configurations:

Lesta PRODUCTION MANAGER: programmes are transmitted to the robots by reading barcodes with a scanner gun operated by an operator. It does not require tags and antennas.

Lesta PRODUCTION MANAGER TAG: 2 antennas and a variable number of tags are installed on the hangers. The first antenna will associate a specific painting programme with each tag. The second antenna will be positioned near the painting booth and, upon the piece’s arrival, will communicate the corresponding programme to the robot.

Lesta PRODUCTION MANAGER TAG WEB: the system, already equipped with tags and antennas, can be managed remotely.

THE PROCESS CAN PROVIDE THESE PARAMETERS:

• Position of the piece in the line

• Oven temperature setting

• In the case of reciprocators, washing cycle and recipes

• Total cycle time

• Ability to catalogue all products by code, object, or macro-family

SUGGESTION SCREENS 15’’ 4:3 TOUCH SCREEN:

Optionally, the system can integrate screens, generally positioned at loading and unloading stations, that provide operators with important details about the tasks to be performed, images, or specific characteristics of the piece.

VIDEO

CERTIFICATIONS

EC declaration of conformity of the machinery

according to Annex II.1.A of Directive 2006/42 / EC

Equipment, including safety devices, once assembled/installed according to the manufacturer’s instructions can be used safely.

Ex. The robot, including safety barriers and commands related to the robot controller

The following documentation is provided:

• CE marking on the machine (plate)

• Use and maintenance manual

• EU declaration of conformity

CERTIFICATIONS

Declaration of incorporation of partly completed machinery

according to Annex II.1.B of Directive 2006/42 / EC

Equipment, in order to be used safely, must be completed or assembled with other machinery or partly completed machinery.

Ex. The robot, to be used safely, must be protected by safety barriers and by commands related to the robot controller

The following material is provided:

• Integration manual

• EU declaration of conformity

SET-UP

ATEX (EU)

If the area where the robot is to be installed is categorized as ATEX, it will be our duty to provide customers with ATEX equipment.

There are 3 characteristics that make an ATEX system:

The robot must be built in an explosion-proof version.

The robot must be delivered with all pressurized electrical parts in the machine as well as with the covers for the connections between the panel and the robot.

The pressure system is controlled by a safe PLC that stops the machine from running by cutting all voltages in cases where:

• The initial wash cycle is not completed correctly

• There is a loss of pressure in the crankcases

SET-UP

Preparation necessary for the US market. A dedicated pressure unit and specific components are implemented for the American market

LESTA SRL

L esta IN THE WORLD

LOCATIONS

ITALIA . headquarters Lesta srl Via D.Chiesa, 42 20036 Dairago (Milano) +39 0331 430817 info@Lesta.it www.Lesta.it

USA LestaUSA 27191 470th Avenue Tea, SD 57064 1-888-546-2800 robotics@Lestausa.com www.Lestausa.com

Workshop for Central/North Europe Jamnik, Slovakia 053-22

100% ITALIAN COMPANY

AZIENDA 100% ITALIANA

CERTIFICATE IT01.IT/2380.051.V

Lesta has totally European quality in both design and production.

The headquarters is spread over an industrial site of about 1600 square meters, divided into offices, laboratories, workshops, and warehouses, and is located near Milan, an area of excellence for the industry

This feature, together with the strong will of the company’s ownership to bring Italian excellence to the world, has allowed Lesta to obtain 100% Made In Italy certification (Registration No. R.N.P.I. IT01.IT/2380.051.V.

METAL WOOD PLASTIC CERAMIC