ROADS

NSW looks to remove temporary speed limits outside of construction hours

NSW looks to remove temporary speed limits outside of construction hours

The NSW government has introduced legislation to remove worksite speed limits outside construction work hours in NSW.

The Transport Legislation Amendment Bill 2025, introduced to Parliament in September, requires all road authorities to install, maintain and remove roadwork speed limit signs in line with a new Standard to be issued by Transport for NSW.

“This is an important commonsense reform to the way we manage our road worksites,”

NSW Minister for Roads Jenny Aitchison says.

“Protecting workers and road users around worksites is critical and we will never weaken rules around safety. However, leaving

speed restrictions in place outside construction hours often needlessly slows down traffic movement.”

As it stands, construction speed limits often stay in place even outside active work hours, with drivers frequently forced to slow down on clear, unobstructed roads where no work is occurring.

“This measure strikes the right balance in ensuring speed limits are appropriate and respected,” Aitchison says.

Similar arrangements are in place in Victoria and South Australia. Further changes include:

Trimble has released its B2W Estimate software application for contractors in Australia and New Zealand.

Contractors use the application’s centralised cost data and its specialised templates and cost structures to develop bids quickly. Extensive bid analysis and

management reporting capabilities provide insight to further improve estimating accuracy and strategy.

BuildingPoint, a Trimble distribution partner in Australia and New Zealand, now provides implementation, training and technical support for B2W Estimate

NSW is removing construction site speed limits outside of work hours. Image: Olha/stock.adobe.com

• t urning on seatbelt enforcement by the existing mobile phone camera detection network

• removing a loophole to force all motorists driving on a foreign licence to convert to a NSW licence within six months.

The new standard is expected to be finalised by year’s end following stakeholder consultation, with implementation scheduled for next year.

as well as for other Trimble hardware and software solutions.

“Profitability in heavy construction begins with the bid,” Trimble VP and category general manager of construction management solutions Jon Fingland says.

“For the past 30 years, leading contractors in North America have relied on B2W Estimate to bid faster and more accurately to help win the right jobs.

“Adding and adapting these capabilities for contractors in Australia and New Zealand, backed by the localised expertise and resources of BuildingPoint, presents new opportunities to improve estimating workflows and integrate them within connected construction technology ecosystems.”

,

Q&R Industrial Hoses

Metso announces acquisition of Aus hosing business

Metso has signed an agreement to acquire Q&R Industrial Hoses, a privately owned Australian company specialising in the manufacture of pinch valve sleeves, rubber hoses, and other rubber products and linings.

This acquisition will expand Metso’s end-to-end slurry handling solutions and services offering for its customers.

“We have had a long relationship with Q&R, which has served Metso as a critical rubber parts manufacturing partner,” Metso director of valves and hoses Chrisian Trulsson says.

“Slurry hoses and pinch valve sleeves manufacturing are now being brought in-house, which will improve both our product range and customer service capability throughout the value chain. We can offer even more robust and reliable slurry handling solutions tailored to the needs of the mining and minerals sectors. We warmly welcome our new colleagues to Metso.”

Established in 1976, Q&R Industrial Hoses is a privately owned manufacturer of rubber products and Australia’s longest-standing locally owned hose supplier, delivering custom rubber hoses, expansion joints, and pinch valves worldwide. The company has a manufacturing facility in Sydney, Australia, with 22 employees.

Komatsu Australia reaches automated haul truck milestone

Komatsu Australia’s 500th automated haulage system (AHS) truck is now operating in Australia, having recently commenced work in Western Australia.

Autonomous haulage has become a key part of modern mining, removing operators from dangerous conditions to greatly lower the risk of accidents and injuries, while their ability to run continuously drives significant gains in site productivity.

Since introducing its AHS trucks to Australia in 2008, Komatsu has steadily expanded the use of them across major sites.

What began as small-scale trials has developed into one of the largest autonomous mining fleets in the world, a shift that Komatsu Mining Automation general manager Garry Povah says shows how quickly the industry has adapted to change.

“Having 500 AHS truck in operation across Australia is a proud achievement for Komatsu and a reflection of how strongly the industry has embraced autonomous haulage,” Povah says.

“This milestone not only demonstrates what autonomy has already achieved, but also signals the role it will play in building safer, more sustainable mining operations into the future.”

Central to this achievement is Komatsu’s FrontRunner system, the

technology that serves as the ‘brain’ of its driverless trucks.

FrontRunner coordinates entire fleets, managing truck navigation, speed, loading and dumping cycles to keep operations safe, efficient and predictable – all without an operator in the cab.

“Komatsu’s FrontRunner platform is no longer a pilot project but a mature, proven system with hundreds of trucks working at sites across Australia,” Povah says.

“Collectively, these trucks contribute to billions of tonnes hauled worldwide each year, demonstrating the efficiency gains and reliability of autonomous mining.

“Autonomy is also becoming a pathway to decarbonisation.

Komatsu is investing in batteryelectric haul truck technology, with Australian sites expected to play a leading role in trials of zeroemission fleets.

“The integration of electrification with autonomy promises not only safer and more productive operations, but also a significant step toward meeting the mining sector’s long-term sustainability goals.”

With a new branch recently opened in Toowoomba, Australian International Equipment Group is continuing its growth as a trusted supplier of new and low-hour used earthmoving machinery

There’s a new addition to Carrington Road in Toowoomba, with Australian International Equipment Group (AIEG) bringing a yard full of new and used earthmoving machinery to the local area.

Opening in March, AIEG’s new Queensland facility offers a full suite of earthmoving machinery and attachments, including new and lowhour used machinery from overseas.

With locations in the Hunter Valley and Freemantle, Australian International Equipment Group director and general manager Blake Burgess says this is an exciting expansion for AIEG as it looks to grow its footprint across Australia.

“Carrington Road is the machinery equipment hub of Queensland,” he says.

“It’s great that we’re there with a big front yard full of excavators. We also currently have a scraper in there, some dozers, a wheel loader, and a

big range of attachments as well.

“We’ve got our offices there which handles all of our administration work for Australia and worldwide, and it’s where our Queensland

sales guys are based. We also have our attachment distribution shed there too. It’s a well serviced workshop and shed in a central hub that has a large selection of attachments for excavators and wheel loaders, servicing Brisbane and rural Queensland.”

Offering earthmoving machinery from three tonnes all the way up to 95 tonnes, Burgess says AIEG services a wide range of earthmoving, mining, forestry and agricultural clients.

“At the moment our most popular model is the 13-tonne excavator,” he says.

“We stock a wide range of excavator brands, from Caterpillar to Kobelco, Kubota and Komatsu, as well as scrapers, dozers and wheel loaders.

“We’re currently quoting some Tier One operators to supply their whole fleet of equipment from this yard, and we also cover commercial farming and civil operators such as plumbers

and builders for the smaller stuff, even landscapers and arborists.

“At the other end we’ve got a scraper there, which can go into a mining operation for feeding gravel onto roads, or it can go to a farmer who wants to build a massive dam. We’ve got stick rakes and root rakes for the agriculture space and HD rock buckets for quarries and other abrasive environments. We then have grabs and so on, so we cover all industries.”

Burgess explains that AIEG is a partnership between himself and John Wells that grew from an alignment of similar values, focused around being an Australian brand that offers honest advice, high quality machinery and attachments, and a can-do attitude.

“I worked as a diesel mechanic from 2006 to about 2017 and then managed a hire company until about 2020, before starting up AIEG with John,” Burgess says.

“We bring in machinery from overseas and offer new machinery from multiple brands in the earthmoving space.

“We have very strong relationships with our suppliers in various countries all over the world. John and I visit our suppliers quite often and we’re very selective. We get to go and see the machinery that we want to purchase and feel it and touch it before we bring something to Australia.

“We are ISO accredited and every year we get audited on our systems and processes, not only around the procurement of machines, but also our customer service, our invoicing, our quoting, and the delivery of the machines.

“In house we provide a quote within 24 hours. There are no ifs, buts or maybes – if someone wants a quote, they get a quote straight away. It’s one of the big differentiators for us in the industry.”

With access to international machines, AIEG has the capacity to supply a wider range of models than are imported by OEMs, and in a more timely fashion.

“Some of the machines that we bring into Australia, if you went directly to the OEM you wouldn’t be able to have that delivered for 18 months,” Burgess says.

“We partner with Credit One to ensure our clients have the best machine finance options available from the start. Michael, the owner, and Jordan, the general manager, and their team work closely with our clients to assist with repayments and financial needs.

“They genuinely understand the products we sell, which means their advice is accurate and relevant. On top of that, their service and responsiveness are exceptional.”

In addition to new and used machinery, AIEG also has partnerships with Roo Attachments

AIEG has a long-running relationship with Roo Attachments

and FAE, allowing it to offer a wide range of attachments and customise its machinery to a customer’s needs.

AIEG has been supplying Roo Attachments products since it started, with Burgess saying that Roo’s range provides his customers with high quality, durable attachments for a great price.

“Four or five years ago, when we started to land excavators in Australia, I looked at the market and tried to find the best value for money bucket supplier. I met the owners Tim [Moss] and James [Fishburn] and they’re great guys who do a fantastic product.

“In terms of value for money and the support they provide, it’s the best. I would say it’s one of the most recognised brands on the Australian market right now, and their range is only expanding.

“We’ve had great success through having this partnership. For example, we have a customer in the Northern Territory who does a lot of council work and state government work on the roads, picking up rocks and placing them under bridges and in culverts.

“He burnt through hydraulic

grabs and was very reluctant to buy a grab off me. I explained that with Roo Attachments’ grab the structure is made from BIS 400 steel, the cylinders are protected, etc.

Eventually I said that if it failed, I’d replace it. That was four years ago – it’s still going strong.

“A more recent partnership is with the FAE Group, distributing and servicing their mulching heads in Queensland. They’re amazing products.

“They’ve thought of everything when it comes to these mulchers. They’re simple to use, very versatile. They don’t require a huge investment in your machine to run them. If you’re in the business of deleting trees quickly, that’s something that you want on the end of your excavator.”

Burgess explains that AIEG positions itself as being a solutionsbased company that doesn’t just offer machinery, but can modify it as needed so a customer gets precisely what they are looking for.

“We’ve customised wheel loaders with rippers and stick rakes, excavators with tilt hitches and secondary hydraulic lines –basically whatever you can think of,” Burgess says.

“I always like to say that all things

are possible. We’re here to get the right solution, rather than just going: here’s an excavator, deal with it.”

If you head to AIEG’s socials you’ll see that it isn’t all just machinery and moving dirt – the business also likes to use its platform to support the work of the Westpac Rescue Helicopter Service.

AIEG supplies a wide range of brands and machinery types

In June, AIEG donated $10,000 to the charity and raises funds throughout the year through selling footballs and other merch at trade shows and events.

“We’re a big supporter,” Burgess says of the charity.

“I personally like to get on my dirt bike from time to time and I’ve definitely been at a few places where Westpac Rescue had to come in and provide support, so that’s definitely one that we are prepared to get behind.”

With a new site and equipment ready to go, Burgess says that anybody in or around Toowoomba should drop in and see what’s available at the new facility.

“Even if you don’t want an excavator, come and have a coffee and introduce yourself,” he says.

“Some of the best relationships we’ve got in business started with guys that just dropped in to say G’day, and down the line they end up getting a digger or a bucket. We just love meeting people, so come have a look through our range or feel free to give us a call.”

For more information on AIEG, head to: www.aiegroup.com.au or call 1800 826 015.

A 2005 JCB 531-70 Agri telehandler has clocked up more than 110,000 hours over its 20 years of

The reliability of JCB’s telehandlers has been integral to a national cable reel management business, with one of its models still thriving after more than 20 years and over 110,000 hours of operation

Any heavy machine that is still operating after more than 20 years is a testament to ongoing maintenance performed to keep it running at an optimal level.

However, when a machine reaches more than 100,000 operating hours and is still thriving, credit must go to the reliability and durability of an OEM’s build.

For family business Reelmen Australia, that credit goes to JCB for building a telehandler that has stood the test of time, clocking up over 110,000 hours since it was purchased two decades ago.

Reelmen Australia is a cable reel

management business, which has been operating for 40 years and today boasts four locations across Victoria, New South Wales, Queensland, and Western Australia.

Cable reels, also known as cable drums, are used for the transport and installation of cable.

However, once the cable is used, many reels are disposed of as waste in landfills – which is not only detrimental to the environment but also an expense for many businesses.

Reelmen aims to solve this problem by purchasing used cable reels, repairing them and then reselling to cable manufacturers as

a recycled product to hold new cable.

These reusable products therefore eliminate the need to buy new cable reels, delivering cost savings and reducing environmental harm.

“We primarily buy cable reels from electricians and construction sites,” Reelmen Australia general manager Joe Lewis says.

“In recent times, we’ve had customers interested in using second hand cable reels in various other ways, such as tables and stools, however, this is a very small part of our business.”

A pair of JCB telehandlers – procured from national distributor JCB CEA –are integral to Reelmen’s operation, with the high reach capabilities assisting general loading and unloading of cable reels from trucks.

They are also used to transport cable reels that need to be repaired or refurbished around Reelmen’s yard.

“If there are any broken parts on the cable reels, such as timber, we need to replace it,” Lewis says.

“We will modify it, if need be, or even paint the reel if it’s required. The telehandlers help us get them back on the trucks to deliver once they’re ready.”

In the early days of the business, loading and unloading of cable reels was done both with backhoes

and often manual labour, before Reelmen procured a brand new JCB 531-70 Agri telehandler in 2005 to streamline the process.

This model has been a staple of Reelmen’s Londonderry, Sydney branch ever since, clocking up over 110,000 hours – a feat which even JCB CEA says is “unheard of for a telehandler”.

What’s even more impressive about this model’s longevity is the fact that it is still operating with the original running gear and has never had an overhaul on the powertrain, which can be attributed Reelmen’s ongoing care for the machine.

“We do a lot of the servicing ourselves and it’s been a really good unit,” Lewis says.

“It’s used every day, so we certainly have used it and abused it, but it’s still reliable and we haven’t done anything to the engine.”

Stacking cable reels on Reelmen’s trucks is just one job the JCB telehandler has thrived in, thanks in large part to its 7m maximum lift height and 3.7m maximum reach.

“We can stack cable reels up a couple of levels, so the telehandler helps to place them on top of each other,” Lewis says.

“It is a bit of a game of Tetris to make the different sized reels fit.”

Reelmen has also had a JCB 525-60 telehandler at its Melbourne branch for several years, which has performed similar jobs.

“We also have a JCB 540-14 in NSW

but it’s probably a little bit too big for our yard, so we’re looking to get something smaller,” Lewis says.

With the longevity shown by JCB, there was no question of going to another brand for a replacement.

“The 531-70 model we’ve used in Sydney has been so good for us, so we’re hoping to get another one in that size,” Lewis says.

“It’s been easy to use, has great vision and the joystick controller works really well for us. The manoeuvrability has been great, and it has been really reliable.”

For more information on JCB CEA’s telehandler range, visit jcbcea.com.au

As customer expectations evolve and the push towards a more sustainable future intensifies, the industry finds itself balancing the demands of productivity while aligning with environmental goals.

With the growing demand for cleaner solutions, renewable diesel – also known as hydrotreated vegetable oil (HVO) – presents a promising alternative to diesel, and we can expect to see more highquality environmentally acceptable lubricants (EALs) being introduced to the market.

Viva Energy Australia can help its customers by bringing renewable diesel within reach.

Robert Cavicchiolo, carbon solutions manager at Viva Energy, describes it as a ‘game-changer’ for the construction industry.

“Renewable diesel offers performance comparable to conventional diesel but with lower emissions,” Cavicchiolo says.

“It’s a simple, drop-in solution that allows companies to continue operations while reducing their carbon footprint.”

The key advantage of renewable diesel is its seamless compatibility with existing diesel engines and infrastructure due to its similar hydrocarbon composition to traditional diesel. This removes the need for costly modifications and approvals from OEMs.

Viva Energy Australia offers a suite of sustainable options including biodegradable lubricants.

As the world’s need for mobility and construction projects grow, so does the shared responsibility to meet this rising demand while reducing the environmental impact

of lubricants. The correct choice of lubricants is vital. Shell PANOLIN lubricants present an easy choice, allowing for reduced environmental impacts in an event of a leak, or accidental spillage when compared to conventional mineral oils.

Available through Viva Energy, the Shell PANOLIN portfolio includes a broad choice of readily biodegradable and low-ecotoxicity lubricants for hydraulics, gears, engines (HDEO) and greasing for machine lubrication, including leading OEM-approved products.

“Shell PANOLIN S4 HLP Synth 32, 46, 68 were the first Bosch Rexroth-approved biodegradable hydraulic oils, designed for uninterrupted equipment operation,” Viva Energy technical specialist Silvana Farrugia says.

“The Shell PANOLIN portfolio is technically well-balanced with high biodegradability and is designed for long life, with high performance and protection contributing to equipment longevity.”

Moreover, Shell PANOLIN provides uncompromising performance.

Viva Energy can help you take a step towards sustainability with renewable diesel and biodegradable lubricants

Its high viscosity index ensures performance across all temperature ranges, providing shear stability, wear protection and robust loadbearing capabilities.

“Shell PANOLIN S4 hydraulic range is a great example of this, as its good cold flow behaviour allows for the reducing risk of metal-on-metal wear,” Farrugia says.

Biodegradable lubricants are not new to the construction industry.

“In fact, Shell PANOLIN products have been trusted by customers in other industries for more than 40 years,” Farrugia says.

“This is largely being achieved through the reformulation of more balanced lubricants with higher tier synthetic ester base stocks and the development of better additives,” Farrugia says.

As the construction industry navigates the dual pressures of increasing productivity and reducing environmental impact, solutions like renewable diesel and biodegradable lubricants are essential.

With proven performance, OEM approvals, and a strong track record across industries, Shell PANOLIN and Viva Energy’s renewable diesel offerings empower businesses to take meaningful steps toward sustainability without compromising on efficiency or reliability.

For more information speak to the experts at Viva Energy Australia (Shell Lubricants Macro Distributor). Call 1300 134 205 or Email technicalhelpdesk@ vivaenergy.com.au / carbonsolutions@ vivaenergy.com.au

Proudly backed nationally by Toyota Material Handling, Takeuchi mini excavators are rugged, dependable, and productive. They provide exceptional value and outstanding performance, measured by their longevity in the field.

And right now there’s never been a better time to buy a Takeuchi, with our super low 1.69% finance rate for up to 48 months available on new Takeuchi TB210R, TB217R, TB216, TB225 and TB325R models.To dig out a great deal contact Toyota Material Handling today.

*1.69% finance offer is based on a chattel mortgage on 12, 24, 36 or 48 month term no balloon, minimum upfront deposit equivalent to 10% of the purchase price including GST on new Takeuchi TB210R, TB217R, TB216, TB225 and TB325R models. Standard hitch and buckets included. Other interest rates may apply depending on loan structure, accessories and or attachments financed. Credit provided by MKP Finance ABN 56 611 706 784 to approved Australian business applicants only (GST registered). Offer valid on orders from 01/09/2025 while stock lasts. Finance must be settled with equipment delivered to customers before 28/02/2026.Toyota Material Handling Australia Pty Limited and, or MKP Finance reserves the right to change, extend or withdraw any offer at any time. Terms, conditions, fees and charges apply. Offers subject to change without notice and whilst stocks last. Images used for illustration purposes only and not indicative of Takeuchi models available. For more information contact your Toyota Material Handling branch.

Sage Civil is promoting the opportunities available to women in the industry, with a fleet of custom-painted pink Cat® machinery

For Sage Civil founder and managing director Asha Russell, building and maintaining long-lasting relationships is of the upmost importance to her business, and there’s no greater example of this than the one formed with Caterpillar and local dealer WesTrac.

The seeds for this relationship

were planted as a young girl, with Asha growing up around Cat equipment, since her father was a diesel mechanic and owned his own earthmoving business.

Asha can remember travelling back and forth with her father to pick up spare parts from WesTrac, which she says was the catalyst for

her love of the Caterpillar brand.

Key relationships were built over many years with WesTrac, so when she was ready to start her own business in 2013, Asha knew Cat equipment would form the backbone of her fleet.

“I started Sage Civil with the shell of a Cat D6 dozer,” Asha says.

“It was all I could afford at the time, and I worked really hard for about 12 months to build the dozer into a workable state.

“I got my first job and it took off from there. As I saw opportunities, I kept on growing with the business.”

Providing various earthmoving and civil work solutions Australia-wide, Sage Civil has grown tremendously since its humble beginnings.

Today, Asha has ran up to a fleet of around 50 Cat machines – including excavators, dozers, skid steer, dump trucks, compactors, rollers, water carts and graders.

As a female leader in a traditionally-male dominated field, Asha is committed to attracting attention to the opportunities available to women in the industry and supporting them to forge a long and successful career.

To help carry out this mission, Sage Civil has custom-painted a variety of its Cat machines in bright

pink since 2017, aiming to promote women working in the industry.

Some of the brightly coloured machines in the fleet include a pink Cat D10 dozer, pink Cat 730C and 740B dump trucks, and a Cat 320 next-gen excavator with a pink boom.

Other machines that are custom painted include Cat 315, 335, 336 and 349 excavators, a 12M grader and skid steers.

Sage Civil also employs young women with little experience in the industry, providing a safe haven for those stepping up to a new challenge with comprehensive training or apprenticeships.

“By the time they’ve finished training, they might know how to operate three or four machines, so they’re ready to spread their wings and fly,” Asha says.

“Watching these young people come through and watching their lives change is what thrills me the most.”

Asha has already seen a significant

increase of women working in earthmoving and civil construction roles as a result of this mission.

“Back in 2017, there was around 2.7 per cent of women working in nontraditional roles in the civil space –New South Wales-wide,” she says.

“Fast forward to 2025 and it’s 10.5 per cent in the civil space, so it’s really happening.

“For me, just being a part of a legacy that you can look back at and know that you were a big part of for women is just amazing.”

Looking to help other women working in the industry, Asha adds her own inspiration to start Sage Civil was driven by Gina Rinehart, the executive chairwoman of Australian private mining company Hancock Prospecting.

“I read her biography and there were so many similarities within our childhood and dynamics within our family unit,” Asha says.

“It gave me the strength to go off and register my own company, so I

want to give her a big shout out for inspiring me, and I really hope to meet her one day – she is my queen.”

Sage Civil’s highly recognisable pink fleet of Cat machinery has been seen working on the Heatherbrae bypass of Seymour Whyte’s M1 Pacific Motorway extension project in the Hunter region.

The five-kilometre northern Heatherbrae bypass section from Tomago to Raymond Terrace will improve travel times and conditions for those travelling between Sydney and Brisbane.

Sage Civil’s Cat 320 next-gen excavator with the pink boom was procured specifically for this project. Brand-new at the time, the machine came straight out of WesTrac’s Tomago branch to the site, alongside several other Cat machines owned by Sage Civil.

“We had about 10 Cat machines up there running around for about 18 months,” Asha says.

“Rocking up onsite with pink Cat

equipment, it’s a flex, especially for the girls. The new excavator was flawless, and we got a lot of advertisement because it was on a freeway.”

The pink machines have also branched out to the mining space in the Hunter Valley region, working on tailings dams and rehabilitation works with BHP and Ashton Coal.

Asha describes herself as an extremely loyal person, and given her long-lasting relationship with Caterpillar and WesTrac, she says she “doesn’t wish to procure equipment from another brand.”

The relationship goes beyond familiarity however, with Cat equipment being chosen for Sage Civil’s fleet due to its well-earned reputation over the past century for quality, reliability and exceptional aftersales support.

“Caterpillar is like the Ferrari of the machinery world,” Asha says.

“You know what you’re buying –Cat equipment is structurally sound and safe, the re-sale value of the

machines is high and the brand has been running for 100 years.

“I think everyone in the industry knows that Cat equipment is the best. Whether it’s civil construction, mining or forestry, Caterpillar conquers all the different machine brands.”

Asha adds the ‘faultless’ serviceability and care-factor provided by WesTrac has ensured minimal downtime and maximum machine efficiency, which has been integral to Sage Civil’s productivity.

“I couldn’t ask for a better or stronger relationship and that’s why I stick with them,” she says.

Key to the success of many Sage Civil projects has been the Cat Grade technology, which combines automated machine control and advanced guidance to help operators accurately hit grading targets quicker and in fewer passes.

Available on a range of Cat excavators, dozers, graders and paving equipment, this technology has been integrated into many of Sage Civil’s machine prior to purchase – eliminating the need for

third-party machine control partners.

With spare parts being crucial in an industry where machinery uptime is essential, Sage Civil relies on the accuracy, availability and easiness of the online Cat Parts Store.

Sage Civil’s head mechanic orders most of the parts, and Asha says the process couldn’t be more streamlined for him.

“It’s easy, he doesn’t have to talk to anyone, it’s all there and he knows how to use it,” she says.

“You can see exactly where the part is and how long it’s going to take. You tend to get the parts 24 to 48 hours after ordering Australia-wide.”

With more than 30 years of experience in the industry and now more than a decade running Sage Civil, Asha is diversifying the business with new services to keep pace in an ever-evolving market.

The business has recently started offering quarry products and is looking at opportunities for projects in new sectors. By doing so, Asha says Sage Civil will be able to grow further,

securing the future of the business.

“I’m being a bit more diverse with what we do so I can learn new skills that might launch Sage Civil into something else,” she says.

“I love what I do, and I think the most important part of what I do is building relationships, having integrity and values.”

While Sage Civil is set for new opportunities, Asha’s personal mission continues to be at the forefront of the business through the fleet of pink machines.

“My passion is to help women get where they want to go and gain a new skillset that they’ll have for life – that’s really important to me,” she says.

“That’s what keeps me in the game, and I’m committed to helping drive women into this industry.” For more information, visit sagecivil.com.au or westrac.com.au © 2025 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow”, the “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

Shell PANOLIN offers a wide range of high-performance biodegradable* lubricants, delivering unrivalled protection** for your equipment and the environment you’re working in. Helping you meet your construction goals with less impact.

Volvo CE’s next generation articulated haulers – available from CJD Equipment – deliver key advancements in performance, efficiency and sustainability

Volvo Construction Equipment has recently unveiled its next generation of haulers, inspired by input from quarry operators.

The new hauler models have been completely redesigned to deliver performance, power and cutting-edge technology to quarries.

Designed to tackle some of the toughest jobs with ease, the next generation series is built to maximise uptime, reduce service costs and minimise the total cost of ownership. It does this through simplified maintenance with extended service intervals and streamlined servicing processes.

These reduce service costs and increase time spent on the job site, ensuring higher efficiency and reliability.

Equipped with predictive gear selection and an advanced all-terrain bogie system, the Volvo next generation haulers also offer superior traction, stability, and control across challenging terrains.

Volvo Dynamic Drive, featuring predictive gear selection, automatically adapts to slopes and load conditions.

This intelligent system selects the optimal gear for every situation, improving fuel efficiency and operator comfort while reducing wear on critical components.

Navigating mud, gravel, or rock is easy with Volvo’s Automatic Traction Control (ATC) and 100 per cent differential locks.

The system automatically engages and disengages drive combinations to maximise grip, minimise tyre wear and reduce fuel consumption. Operators also have manual override

options for extreme conditions, ensuring total confidence in the terrain.

At the heart of the next generation series is the all-new, full-suspension A50 model. With a 45-tonne payload, the A50 is designed for high-volume material movement.

Its reinforced axles and robust frame ensure durability under the heaviest loads, while the full-suspension allows for higher speeds and reduced cycle times.

The suspension also enhances operator comfort and boasts productivity, making it ideal for off-road tasks.

Thanks to faster cycle times, higher travel speeds, and smarter operator interfaces, the A50 can move up to 10 per cent more material per hour than its predecessor. This efficiency boost can reduce fleet size requirements

and lower overall cost per tonne.

In addition, the next generation series can include optional seats that are designed to boost operator comfort even more.

On top of heating and air conditioning, the climate control in the cab is automatically adjustable, so when an operator sits down, the seat will automatically adjust the air pressure based on their weight.

Safety is also vital for Volvo’s engineers and has been incorporated throughout the A50’s design.

A service access area is included directly at the front of the cab, letting operators check the fluids before starting their daily work shift.

The cab itself is certified for falling object protection and rollover protection as well.

While the previous generation machine and the A50 share some

Next generation haulers are equipped with predictive gear selection and an advanced all-terrain bogie system

Volvo’s Automatic Traction Control feature automatically engages and disengages drive combinations to maximise grip, minimise tyre wear, and reduce fuel consumption

similarities, the new series has undergone key improvements.

The new Volvo drivetrain and advanced transmission deliver up to 8 to 15 per cent better fuel efficiency than previous models.

Features like 6x4 mode and cruise control further optimise fuel use, especially on long or variable haul routes. These can be seen in the fuel filters, which previously used a manual priming system. This has been updated to an electronic priming system, inspired by feedback from Volvo CE customers.

With longer service intervals, simplified servicing, and robust components, owners can expect up to a five to six per cent reduction in service costs over 12,000 hours of operation. This translates to savings in both labour and parts and increased machine availability.

Volvo CE’s commitment to sustainability is woven into every aspect of the next generation haulers, from materials to manufacturing.

The electronics architecture in

the updated models is engineered for adaptability, making it ready for future hybrid or electric drivetrains. Additionally, all updated haulers are designed to meet or exceed the latest global emission standards.

Volvo’s Braås facility in Sweden –where these machines are built – has been carbon-neutral since 2014 and is certified as a Climate Efficient Site.

The Braås site is a model for circular manufacturing, utilising recycled materials and renewable energy throughout the production process.

The facility is landfill-free and seeks new ways to minimise waste and environmental impact. The updated Volvo haulers, available from CJD Equipment, are more than just a new generation of articulated haulers –it’s a leap forward in performance, efficiency and sustainability.

With industry-first full-suspension architecture, advanced off-road systems, measurable productivity gains, and a focus on lowering operating costs, the updated models are built to conquer Australia’s most demanding worksites.

Backed by Volvo’s legacy of innovation and CJD Equipment’s trusted support, the next generation haulers ensure quarry operations are ready for today’s challenges and tomorrow’s opportunities.

For more information on Volvo CE’s updated haulers, visit cjd.com.au

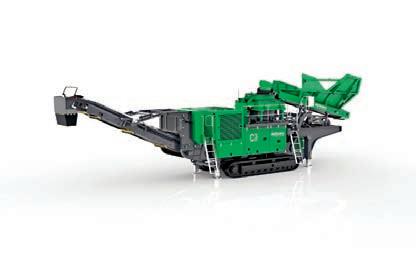

Operating in Western Australia’s gold mining sector, MACAR Group has turned to a Striker CQ400 cone crusher from Onetrak to handle a challenging project

With Western Australian crushing and screening specialist MACAR Group looking to expand its reach in the gold processing industry, and a tight timeframe to get a crusher up and running, the business turned to Striker distributor Onetrak to find a solution.

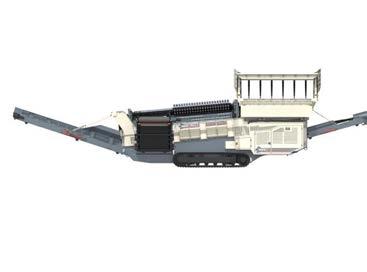

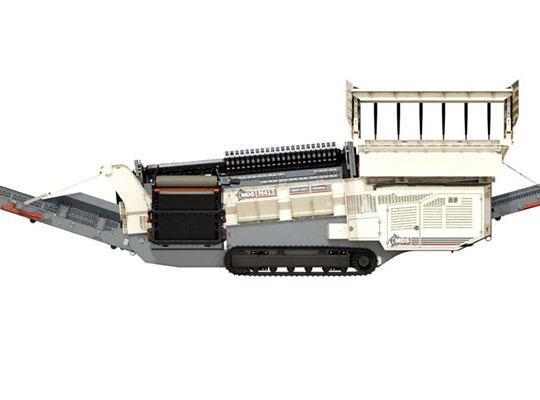

At the beginning of September, a Striker CQ400 cone crusher joined MACAR Group’s fleet and is now processing scats at a gold processing plant in Meekatharra.

The first Striker machine to join the fleet, and the first to be supplied by Onetrak, MACAR Group owner Matt Kelly says it’s a challenging application, but the CQ400 cone crusher is living up to the Striker reputation.

“This is our first purchase, but we’ve got a good relationship with Striker,” Matt says.

“With my background as a boilermaker and fitter I’m familiar with Striker machinery, and their ease of use and accessibility has always stood out.

“We were looking for a cone

crusher and Striker couldn’t supply us a machine in the timeframe we had, so they put us on to Onetrak and they’ve been fantastic.”

MACAR Group has been operating across WA since 2021, run by Matt and his wife Carrie.

Matt says his previous experience of maintaining and operating crushing equipment led them to set up their own business – initially working with Holcim Australia.

After purchasing a reclaimer screen, the next step was to expand within the Goldfields and Murchison regions of WA.

“We’ve done crushing at the Granny Smith mine for Gold Fields and we’ve just started a project for Westgold,” Matt says.

“We’re pushing hard in the gold sector at the moment.”

With a long-term plan to build a fleet of Striker machinery, Matt says the starting point is the CQ400 cone crusher. Currently it is crushing 25mm milled rock down to -8mm

“and getting through it really well”.

“At the gold plant, when they crush and then put the ore through a mill, there’s a certain size that they screen out, which in this case is 25mm,” he says.

“However, it comes out with a lot of mill balls and steel in it. So Onetrak also built us a feeder with a magnetic head drum, which is doing a great job at pulling all the steel out before we crush it.”

When asked why he chose a Striker machine, Matt says the design of the crushing chambers produces a better end product, and the ease of use means new operators can quickly be trained to run the machine.

“It’s very simple for our guys to pick up if they haven’t used the Striker machine before,” he says.

“They’re user friendly, so, if we were to dry hire this machine out, that’s a benefit. Instead of someone taking three or four days to learn the ins and outs of a machine, with this cone crusher, within a day they can have a

Matt Kelly says the ease of use of Striker machinery is a major plus for his business

pretty good handle on how it works. Plus, as a brand, Striker are reliable and proven.

“At the moment we’re crushing around 80 to 90 tonne an hour, which is slow, but it’s also very hard work. Every single rock has to be crushed to that specific size.”

Another advantage is the use of a Cat engine, which means parts are easily accessible and the majority of mechanics are already familiar with the brand. Having spent years repairing and operating crushing machinery, Matt says the design of Striker equipment stands out for its ease of maintenance.

“Striker builds machines that are very easy to work on,” he says.

“When you’re a fitter and you need

to fix something, you need to be able to get in there quickly, without having to strip half the machine to pieces.

“On a Striker, I can access 90 per cent of the stuff on there no problem.”

Matt adds that Onetrak has been highly supportive in quickly getting him the machine that he needed.

“Onetrak have just been amazing so far,” he says.

“They’ve gone out of their way to help us build and they want to see us grow. There’s a very good relationship between us, that’s for sure.”

With MACAR Group continuing to grow its presence in the Western Australian market, Matt says a major focus is safety and quality of service, with Striker machinery the brand

of choice for him as he continues to build his fleet.

“We’re focusing on the safety side and our strong maintenance background,” he says.

“By the end of this year, we’ll have our ISOs done so we can stand out a bit more. We don’t want to be the biggest, but we want to be the safest and the best.”

For more information on Onetrak’s range of Striker machinery, go to: onetrak.com.au

For any crushing and screening enquiries, contact MACAR Group on 0427212259 or matt@macargroup.com.au

IMS have added the new BP1200-48TB track electric twin power blender to its impressive collection of ed hopper each five meters long holding and controlled by a PLC control and recording system that can be operated from an iPad or phone from its own Wi-Fi system from a loader or ll fitted with invertors offering variable speed to each feed hopper conveyor. The generator can be connected to mains power and could power an

Scalping Screen with a 10 x 4 two deck screen producing three products on high rise tracks

Price $227,000 Plus GST

New IMS-MC1050-14TF

Track Conveyor with a five-meter-long feed hopper with a hydraulic remotecontrol tipping gride

Price $244,000 Plus

offered Braeside fines into roadbase to make spec or ol and CTB. The PLC control and recording system

Used 2021 & 2022 Rubble Master

Three deck screens in good condition – 18x5 & 22x5

Price $295,000 Plus GST

Jaw Crusher with a single deck screen producing two finished products. Diesel electric which is very

and only uses

LiuGong dealer Construction Distribution Australia has carried out demonstrations of the 890T wheel loader at a recycling plant in NSW

Since being released to the Australian market earlier this year, LiuGong’s T Series wheel loaders have been proving their worth in various industries, such as civil construction, quarries, batching plants, and bulk handling –generating significant sales that have already surpassed high expectations.

Another sector these loaders are thriving in is waste and recycling, evidenced by demonstrations of a waste-specification 890T model –the largest of the range – at a New South Wales recycling plant.

These local demonstrations have been carried out by LiuGong’s trusted Melbourne, Sydney & Brisbane dealer Construction Distribution Australia (CDA) –backed by the McIntosh Group – to demonstrate the loader’s capabilities in waste management applications.

CDA waste and recycling sales manager Neil Adlam says LiuGong’s T Series wheel loaders are well-suited to the ‘big players in the scrap recycling market’.

“Smaller businesses generally don’t shred, so they don’t need wheel loaders, but waste is different,” he says.

“Waste companies can have wheel loaders of all sizes throughout their facilities, varying from smaller ones to larger models like the 890T.”

In preparation for the demonstrations, the LiuGong 890T was fitted with Brawler tyres supplied by the Interfit Group, ensuring protection against punctures from sharp materials.

While the 890T loader weighs approximately 33.5-tonne as standard, Adlam says the extra

features fitted brought the overall operating weight closer to around 38-tonnes.

It is powered by a 350hp (261 kW) engine and boasts 270kN of bucket breakout force, which Adlam says was crucial for the recycling plant operation.

“If you’ve got a pile of scrap that’s been sitting in the rain, it gets rusty and sticks together, so you need a lot more breakout force than a wheel loader would normally require,” he says.

“It has great load carrying capabilities because of this.”

A potential LiuGong customer experienced several benefits using the wheel loader as part of the demonstrations at its recycling plant.

“They got an awareness of how good the quality of the LiuGong product is, how flexible the production team can be,

and the support that we can offer,” Adlam says.

“They were very pleasantly surprised by the build quality and the operator comfort.”

Many waste and recycling facilities require specific features they would like integrated onto their loaders and this was no different for this demonstration.

LiuGong’s production team proved more than flexible in satisfying the potential customer.

“Most of our waste and recycling customers want features that can range from auto-shutdown, emergency stops, battery isolators and extra guarding – to name a few,” Adlam says.

“So, we are able to provide that and in the case of the demonstration, we have included e-stops, battery isolators and the extra cabin guarding on the loader.”

These specifications are in addition to the numerous standard features, which include a multi-adjustable arm rest, joystick, and air-suspension seat, as well as 360-degree handrails and anti-slip steps for safer and easier access and exit of the cabin.

To further enhance operator safety, the 890T offers curved, panoramic glass windows and an optional rear-view camera to increase visibility.

Operators also are offered joystick and steering wheel operation on the

The loader is powered by a 350hp (261 kW) engine and boasts 270kN of bucket breakout force

machine, providing further comfort while operating the loader.

A key improvement of the T Series loaders is a liquid-driven, air-in type cooling system with intelligent fan speed adjustment, which has been rearranged to optimise the wind field and enhance heat dissipation, furthering enhancing the ability to work in extreme working conditions.

Fuel tank capacity has increased to 608L on the 890T model, while maintenance has also been made easier for operators, as they can add fuel and oil, as well as service the diesel filters all from ground level.

Oil changes are only required every 2,000 hours, helping further reduce maintenance costs.

The hydraulic system also has had an update, incorporating the conversion of a two-pump combined flow system to a single-pump unit, which has increased the working pressure of the hydraulic system.

For more information on the LiuGong 890T wheel loader, or to enquire about having a demonstration, speak to your local CDA representative or visit cdau.com.au

ITR Pacific is partnering with Miller Australia to expand nationwide availability of leading excavator attachments

ITR Pacific is proud to announce its new distributor partnership with Miller Australia – one of the world’s leading manufacturers of excavator attachments.

This partnership brings together Miller’s industry-leading quick hitches and buckets with ITR’s globally recognised expertise in earthmoving machinery parts and unrivalled nationwide distribution network, significantly increasing stock availability and service support for customers across Australia.

Established in 2013 as part of Miller UK Ltd, Miller Australia has built a strong reputation from its base in Melbourne, Victoria for producing the safest, most advanced quick hitches and buckets in the market.

With this distributor partnership, ITR Pacific will supply Miller’s quick hitches, buckets and Ready to Dig bucket bundles through its extensive branch network in Brisbane, Mackay,

Sydney, Melbourne, Adelaide, Perth and Kalgoorlie.

The partnership enables Australian operators to access Miller products faster and more reliably, supported by ITR’s large, dedicated sales team and expanding network of facilities, service capabilities and stockholding. Together, Miller’s innovation in attachment technology and ITR’s strength in global parts distribution create a natural alignment that delivers enhanced value to customers nationwide.

Alongside Miller attachments, ITR Pacific continues to offer a comprehensive portfolio of undercarriage components, rubber tracks and pads, ground engaging tools, repair parts, OTR tyres and other attachments – further strengthening its position as a onestop solution for Australian operators.

“We are delighted to launch our distributor strategy with ITR Pacific

Miller attachments will be available through ITR Pacific’s branches across Australia. Image: ITR Pacific

as part of our tactical growth plans,” Miller Australia general manager David Aldridge says.

“Combining ITR’s strong local knowledge and large distributor network with technologies that are globally proven, our equipment is ideally aligned with modern Australian practices. As such, we believe our attachment solutions, that have been tested and optimised for even the harshest of conditions, are the very best in class and ideally suited for ITR’s customer base.”

The distributor strategy with ITR further solidifies Miller’s position to be the global leader in attachments for the wide range of markets and sectors it operates in.

“There’s already a strong synergy between Miller and ITR, serving the same industries, making this partnership a natural fit and great addition to our already extensive range of products,” ITR Pacific says.

“By uniting Miller’s world-leading coupler and attachment technology with our unrivalled distribution and service network, we continue to solidify ourselves as a onestop solution for customers across Australia.

To mark the partnership, ITR Pacific will be showcasing a range of Miller’s quick hitches and buckets alongside ITR’s other core product ranges at the upcoming Diesel, Dirt & Turf Expo 2026. The event will give Australian operators the opportunity to see the combined strength of the partnership first-hand.

For more info on ITR Pacific, visit: www.itrpacific.com.au

MCCLOSKEYS2503D 2024,Usedmachinewithdemohoursonly,fullminespec, magneticheaddrum.SM337. TA1284860. $899,000+GST

MCCLOSKEYR155

R155,16'x5',Hardoxapronfeeder.SM289. TA878996. POA

MCCLOSKEYS130 14'x5'twodeck,100mmremotetippinggrid,Cat130hpInstocknow.SM248. TA908181. POA

MCCLOSKEYI3CR 2023,Delivered2024,875+/-crushinghours,magnet,side belt.KM134. TA1286065.

$750,000+GSTExsiteNorthQld

MCCLOSKEYTS4080 24mtrackedstacker,1000mmbelt,hydraulictailandtop fold.CM171. TA908173. POA

MCCLOSKEYS190SCREENER 2020,20'x5'twodeck,100mmremotetippinggrid,Cat C4.4130hp.SM242. TA1286558. $330,000+GSTExsiteNorthQld

MCCLOSKEYC3 MC300cone-directdrive,CaterpillarC13.KM109. TA1059683. POA

MCCLOSKEYS130 2020,14'x5'doubledeck,Catengine,15'hopper.SM238. TA1198773. $280,000+GSTExMSCdepot

MCCLOSKEYS190TRIPLEDECK 20'x5'tripledeckdeck,100mmremotetippinggrid,Cat C4.4130hp.SM284. TA1122980. POA

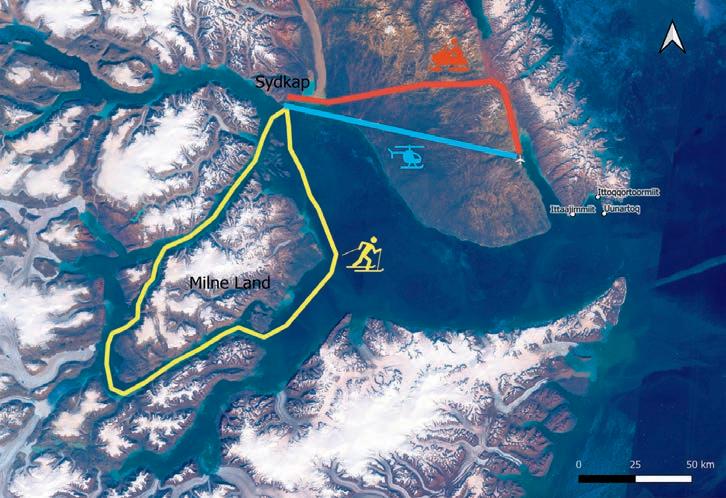

Next March, Marcus Arnold will be undertaking a 400km solo trek in Greenland in order to raise awareness of mental health in construction. Here we discuss preparing for the trip, what inspired the challenge, and the vital work being undertaken by MATES in Construction

Life can be a challenge for many reasons, but this is particularly relevant for the construction industry where workers are eight times more likely to die by suicide than a workplace accident. For younger workers, they are twice as likely as other young Australian men to take their own lives.

These are deeply sobering statistics that highlight the difficulties that men working in construction can face when managing their mental health in a culture that historically hasn’t welcomed discussions around emotions or stress.

One young man who is aiming to challenge this wall of silence and inspire more conversations around how to develop a workplace culture where mental health isn’t avoided is Marcus Arnold. An environmental engineer with Fulton Hogan, Marcus is planning to undertake an extraordinary solo trek around the third largest island in Greenland.

Earthmovers & Excavators caught up with Marcus to find out more about what inspired the expedition and how the work of MATES in Construction has been vital in helping him, and many construction workers, gain the tools they need to check in with colleagues and have the confidence to speak out on their mental health struggles.

A changing landscape

It was 2018 when Marcus first heard of MATES in Construction.

A not-for-profit charity dedicated to suicide prevention in the construction industry, MATES provides support services and workplace training focused on mental health. He says the discussion that took place was eye-opening in terms of how many people are struggling in the industry every day.

“They visited one of the projects that I was working on and delivered some of their general awareness training,” Marcus says.

“I had no idea at that point of the statistics [around suicide], particularly in our industry.

“The project that I was working on at the time was a big project with a couple of hundred people at every prestart and one of the stats that really brought it home for me was that one in 20 construction workers will have a suicide plan in any given year.

“That really brings it home when you think about how many people that actually is, and these are the people that you spend the majority of your time with. Mental health and suicide are things that we don’t acknowledge very well in this industry.”

He says that, early in his career, mental health was rarely discussed in the workplace, with the prevailing

culture being one of keeping things to yourself, managing it in silence and facing the challenges of long hours and difficult work with stoicism.

“It’s been quite astounding actually seeing the changes that have happened over the past five or six years,” he says.

“I started as a graduate engineer in 2016, and you didn’t hear the words ‘mental health’ on site at all. Now, it’s a far more prevalent theme and there’s been some fantastic work in the industry trying to get rid of some of that stigma.”

The workplace training session led by MATES helped to open up discussions around what people can often struggle to articulate, particularly in a male-dominated workplace that traditionally hasn’t welcomed such openness around emotions. Marcus says the training was a huge help not just for himself in helping him reflect on his own mental health struggles, but also the importance of looking out for your mates in the workplace and checking in to see how they are doing.

“Being able to recognise if someone is going through something is difficult because the signs can be extremely subtle,” he says.

“Being able to recognise those

subtle signs, and knowing the statistics, was enough for me to be a lot more aware of it.

If I’m working with a couple of hundred people, the statistics are telling me that quite a lot of people that I work with are going through something. So, it’s having that consistent awareness, and not just self-awareness, which has certainly fostered more of a community and provided a lot more support.”

All of this brings us to the present, with Marcus now planning a bold adventure to Greenland where he will be trekking 400km through winter conditions with no backup nearby and the threat of polar bears ever present.

It is by taking on such a huge challenge that he hopes to not only raise money for MATES in Construction but also show that there is hope. You may well be at the

very bottom and feel like there’s no way forward, but that doesn’t mean that you’re alone.

“In terms of partnering with MATES in Construction, I personally went through a hard time and was appreciative of the work that MATES do,” Marcus says.

“That was some years ago now, and I think I wanted to make this journey about something more than just a trip of mine. I saw it as a good opportunity to partner with an organisation that does some awesome work in our space but also be able to share that story and give people that are potentially going through something a bit of hope.

“If you’d asked me three years ago if I ever thought I’d be capable of doing something like this, the answer would have been ‘absolutely not’, because at that point, I was struggling to simply get through each day. I want to show that, yes, you can be in those sorts of places, and you can come through it. There is light at the end of the tunnel, and you will be able to achieve something like this.”

As to why he has chosen Milne Island in Greenland as his destination, Marcus cites his background doing research in polar regions and describes the beauty and striking geology of the landscape there as being a call to adventure.

“It’s the largest fjord system in the world,” he says.

“It’s a couple of couple of hundred kilometres long, and there are 2,000 metre cliffs either side, with glaciers cascading down into it. It’s a very, very beautiful area. I sailed the route

last year in the summer, but this time it will be winter and therefore completely frozen.”

After two months of training and preparation in Norway, Marcus will fly over to Greenland next March and pack up everything he needs for his journey from a shipping container. Once the plane leaves, he’ll be completely alone on the frozen ocean around an uninhabited island with just a husky for company.

“There’s literally nothing there,” he says.

“The airstrip is a dirt strip that was created by an oil exploration company back in the 1980s and then abandoned. I’ll have to carry all of my supplies with me

and I’ll be on my own for 30 days circumnavigating the third largest island in Greenland. I’ll be towing a sled that weighs 80 to 100kg, and the temperature will be between minus 20 and minus 35 degrees Celsius.”

The whole trek will take place on skis – which is also something that Marcus has never done before.

“I’ve never set foot on skis in my entire life!” he laughs.

“So that’s the first point of call when I do the training – learning how to cross country ski.

“I’ll go up to an ice cap in Norway, in a town called Finse, and I’ll spend three weeks there with a guide.

She’s a South Pole station leader in the summer months, and she’ll take

Marcus says the workplace training from MATES is helping to remove the stigma of discussing mental health on construction sites

me through some very targeted training. Because of the elevation, temperatures there will be similar to what I’ll experience in Greenland, so that’ll be good preparation.

“I’m trying to organise some training up in Svalbard, which is about 1,000km north of Norway, to learn how to manage polar bears.”

When asked what the main challenges will be as he treks around Milne Island, he says that the bears are his biggest concern.

“I’ve got flares, I’ve got a husky, I’ve got bang guns with blank rounds and a rifle, which is the absolute last resort,” he says.

“Every night, when I set up my tent, I need to set up a perimeter tripwire alarm system. So there are plenty of bear deterrents, but the reality is always a little bit different to the perfect plan.”

The cold and the weather will also test his endurance to its limits.

“I’ll have to manage the cold but also storms,” he says.

“There’s a something called a piteraq [‘that which attacks you’ in the local language], which happens in Greenland, where you can get winds over 300km an hour through that fjord. So that’s a very real risk for me. Hygiene is a big one. And just making sure that I’ve got enough medical supplies for anything that might happen.”

When asked why he wants to undertake this journey solo, in the face of significant risks, Marcus says it is important for him to take on a challenge of this magnitude.

“It’s about pushing myself to my

No stranger to extreme sports, Marcus will spend weeks preparing for his trek in Norway

absolute limit, and I know that I will be pushed probably beyond my limits at times,” he says.

“That’s what excites me about it. I’m not interested in doing things where everything is done for you and organised for you. I like being able to push myself and see what I’m capable of.”

Sparking conversations

This challenge may be a personal target for Marcus as he takes on the stark landscape of Greenland, but it’s also a way to bring up the subject of mental health challenges and raise some money for MATES in Construction.

“The main thing for me is that if there is one person that I know or work with that is going through a silent struggle that no one knows about, and they can see this and either ask for help, or at least feel inspired that there is a way through it, then that is a positive outcome for me,” he says.

“Doing this journey is also a platform to start conversations about mental health that might not have otherwise happened. I’d like to raise as much money as I can for MATES, because I really appreciate

Having been through challenging times with his own mental health, Marcus hopes this journey will inspire hope in others who may be struggling

the work that they do, but it’s less about the money and more about the conversations that can come from it.”

He says the influence of MATES in Construction has been significant in making it okay for construction workers to seek help if they need it, and to check in with each other.

“I think those barriers are coming down,” Marcus says.

“With MATES, the guys that do the training, they’re real people. They’ve had their own experiences.

Some people might make a remark, and they’ll say, ‘that’s a really good comment, let’s dig into that’. They actually understand as they’ve been through it themselves.

“Modern life is challenging and there’s no shame whatsoever in speaking up and saying, ‘Hey, I can’t handle this on my own right now’.”

To learn more about Marcus Arnold’s Greenland expedition and to donate, visit: greenlandalone.gofundraise.com. au/cms/home

For more information on MATES in Construction, head to: mates.org.au

If you have been affected by issues raised in this article and feel you are in immediate danger, please call the emergency services on 000.

Other services offering support include:

Lifeline Australia: Call 13 11 14 for 24-hour help or text 0477 13 11 14.

Beyond Blue: Call 1300 22 4636 or you can speak with a counsellor online at www.beyondblue.org.au

CATERPILLARD5K2XL 2019,4,500hrs, VPAT, AROwired,sweeps,screensandMS ripper. 250hrservice,workshopreport..S1201. TA1225199. $249,900plusGST

CATERPILLARD8RSERIES2 2003,11,500hrs, SUtilt,CAT4Cylinderripper,servicedwith workshopreport.S1197. TA1225194. $369,900plusGST

CATERPILLAR259D3 2021,1,850hrs,4in1 bucket,250hrservice,verygoodtracks..S1200. TA1225198. $94,900plusGST

KOMATSUD61EX 2018,5,800hrs,6wayblade, MSripper,TopConwired.S1067. TA1163362. $309,900plusGST

CATERPILLARD5K2XL 2018,2018 CATERPILLARD5K2XL233.233. TA1166133. $258,390inc.GST

CATERPILLAR12M3 2015,2015 CATERPILLAR 12M3239.239. TA1166139. $362,890inc.GST

CATERPILLAR12M3 2016,Graderwith4,950hours. 14ftblade,joysticksteering,Autoshift,Lightpackage, soldwithMSripperandpushblock.This12M3Grader willbesoldclean,detailedandservicedwithour comprehensiveworkshopreport.S1013. TA1139678.

CATERPILLARD6K2XL 2017,4,900hrs, VPAT, AROwired,sweeps,screensandMS ripper. 250hrserviceandworkshopreport..S1199. TA1225197. $269,900plusGST

KOMATSUD39EX-24 2021,1,200hrs,6wayblade, 95HP,MSripper,suitnewbuyer.ThisD39EX-24willbe soldclean,detailedandservicedwithour comprehensiveworkshopreport..S1108. TA1173489. $274,890IncludingGST

JOHNDEERE450K 1400hrs,6wayblade, sweeps,screensandMSrippertobefitted. S1063. TA1163359. $229,900plusGST

CATERPILLARD6TLGP 2017,6,590hrs,ARO wired,6wayblade,tankguarding,Conventional undercarriage,rearscreen.Soldwith250hr serviceandworkshopreport.S1165. TA1198871. $419,000plusGST

CATERPILLARD6TXL 7,150hrs,VPAT,ARO wired,nextgenMSripper,goodU/C.Soldwith 250hrserviceandworkshopreport.S1198. TA1225196. $439,900plusGST

NTEX co-founder Eileen Breen has supported the business to become a circular economy leader, driving innovation in recycling, waste recovery and sustainable construction across the Northern Territory. Having won the Industry Advocacy Award at the Women in Industry Awards this year, we speak with Eileen about how NTEX is leading resource recovery in the NT

The Northern Territory’s NTEX was once just a standard civil construction and demolition business. However, over the last decade, it has grown into a circular economy pioneer and leading provider of environmental rehabilitation, remediation and resource recovery solutions.

Based in Darwin, NTEX is committed to recycling waste from its construction and demolition projects, enabling it to repurpose and recover valuable materials, and reduce the volume of waste ending up in landfill.

At the heart of the operation is Eileen Breen and her husband Gerry, who co-founded NTEX in 2010. Having previously run a

civil, construction and demolition business in Northern Ireland, an early goal for the couple was to minimise the waste produced from NTEX’s projects.

NTEX’s Hammbreaker mobile multipurpose industrial shredder allows the business to transform waste concrete into civil construction aggregate

Eileen Breen and her husband Gerry co-founded NTEX in 2010.

Using their connections made overseas, they looked at solutions that other businesses were applying to see what could work in the NT.

“The way things were being done overseas was very different to what was happening in Australia, especially in the Northern Territory,” Eileen says.

“A lot of new equipment was being developed specifically for recycling construction and demolition waste and separating steel rebar from concrete.

“However, in the Northern Territory there wasn’t really any equipment like this, so we were pioneers in bringing this in.”

NTEX’s circular economy journey began with the purchase of a Hammbreaker mobile multi-purpose industrial shredder and crusher in 2020, which Eileen says was the first of its kind in the NT.

This German-built machine specialises in the removal of reinforced bar from concrete, enabling NTEX to repurpose waste concrete as civil construction aggregate and recycle recovered asphalt material.

“We invested in this product not knowing if anyone would be interested in this process and machine, so we didn’t know if there would be a market for it,”

Eileen says.

“It felt like a a gamble at the time, but Gerry and I were of the opinion that you can’t be what you can’t see,

so we needed to show people how it worked before they got on board.”

Traditionally, demolition waste produced on NT-based projects would be sent to landfill, but with the Hammbreaker, NTEX can crush it and use the recycled aggregate as road base in civil projects.

NTEX found this to be a much cheaper and environmentally friendly solution compared to dumping waste into landfills, with the business quite literally transforming how the local industry approached this process.

On one of NTEX’s early projects using the Hammbreaker, Eileen says

the machine helped save $130,000 for the NT government.

“Those savings aren’t even factoring in what it would cost to use products from a quarry rather than the recycled aggregates that we were able to use onsite,” she says.

“We were able to shine a lens on the opportunity for resource recovery and that was the first step in getting the NT government on board. It’s now becoming an increasingly normal consideration in demolition projects.”

As demand grew for NTEX’s concrete recycling services, the business invested in a first of its kind machine for Australia in 2022 – the Rubble Master concrete crusher recycler.

This Rubble Master unit features a magnetic separator, an inbuilt screening unit and blower to remove light plastics and organic material, making it well-suited for recycling larger quantities of concrete.

In 2024, NTEX brought another innovation to Australian shores with the Arjes Titan 900 mobile shredder.

The Australian-first piece of machinery recycles concrete, light steel, car bodies, green organic waste, and other waste materials such as tyres and rubber – which opened NTEX’s doors for new opportunities in other industries.

One of these has been the maritime industry, as rubber is often used as the main material for fenders –a protective cushion that prevents damage to a ship’s hull.

Shredding many of these rubber fenders at the end of their useful life, NTEX has found the material produced to be in demand as it can be used to create tyre-derived fuel, an alternative to fossil fuels in cement kilns and other high-temperature burning applications.

“At the moment, the Northern Territory doesn’t have an end market use for rubber tyres and fenders,” Eileen says.

“When that changes, we’ll be glad to see that circular economy opportunity onshore rather than offshore.”

NTEX has recovered and recycled a significant amount of industry waste with its approach, specifically concrete and asphalt material.

Most of this waste has been recycled for use in civil projects, helping NTEX achieve an average resource recovery rate of over 83 per cent on demolition projects, which Eileen says is significantly higher than the industry average.

On certain projects, NTEX has been able to achieve even higher resource recovery rates, with it all depending on what is deemed safe.

“We’ve been able to get up to 98 per cent resource recovery on demolition projects, but that number can go down due to contaminants found in aging infrastructure,” Eileen says.

“It’s really important to make sure what we’re recycling is safe.”

To ensure this, NTEX employs an independent hygienist that conducts a pre-demolition audit on every project. This involves a thorough analysis of obvious and potential contaminants, testing them, and then discussing the next steps with the NTEX team.

Before any demolition occurs, NTEX removes any contaminated material and disposes it at a facility that’s licensed to take that material, leaving behind only the materials

that are safe to reuse. Once this is done, there is a significant focus on waste separation to ensure cross-contamination doesn’t occur with different materials.

“We’re not just knocking everything down into a big pile, it’s really a process of deconstruction,” Eileen says.

“We may have a concrete pile, steel pile, and whatever else can be recycled. Any materials that we don’t recycle directly, we will partner with other companies.”

While this may not be your typical way of approaching a demolition project and can take longer to carry out, NTEX has made this process standard

practice to ensure resource recovery is safe and contaminant-free.

In the last few years, the business has also introduced a dedicated facility for concrete, rubber and tyre recycling and marine resource recovery – known as NTEX Code Red – which Eileen adds was a first for the NT.

Located in East Arm, Darwin, the facility has helped NTEX partner with the industry to recycle materials that can’t be processed on a project site.

“Sometimes there’s no opportunity for reusing materials on a particular project, so in the past there was

nowhere to take them,” Eileen says.

“We established the facility to accept those materials, so local businesses could bring them directly to us.”

Eileen adds the NTEX Code Red facility has proved popular with the local construction industry, as landfill costs continue to increase.

“More and more larger companies are doing mandatory climate and sustainability reporting, so they’re very keen to see where their materials go and what they end up with,” she says.

“We can give them evidence, such as weighbridge ticketing and a full chain of custody over their waste material, with evidence to back up what’s being done with it.”

Due to this large demand, NTEX is currently in the process of a developing another facility that will be more than triple the size of the existing one.

Eileen says it will have access to Darwin harbour and a barge landing,

allowing the facility to accept certain marine waste to be decommissioned on site – such as end-of-life vessels.

“That facility will be a first for the Northern Territory as well,” she says.

“The demand is such that we need more space, and we hope to be able to be moving our operations in the next 18 months, a little further down the road from where we are.”

As a result of the many initiatives NTEX has introduced to promote circular economy opportunities, Eileen was recently recognised as the winner of the Industry Advocacy Award at Prime Creative Media’s 2025 Women in Industry Awards.

While it is an individual award, Eileen says it is a recognition of NTEX’s whole team and its continuous commitment to supporting regional communities with their waste management.

“Our team feel an enormous sense

The business is in the process of a developing another facility that will be more than triple the size of the existing NTEX Code Red site

of pride – NTEX is key for a lot of the major projects that are coming to the Northern Territory, so winning the award gives us a platform to grow that awareness even further,” she says.

“Waste is a resource and viewing it in that way is a great opportunity to attract more women into the industry.

“We have a lot of challenges up here when it comes to logistics, we’ve got lots of remote communities and regional places that are far apart, so it’s really hard to connect those locations to circular economy opportunities.

“The more we can get a spotlight on that and look to support what outcomes can come for waste in those areas, it promotes the conversation, puts it in people’s consciousness, so they look for the opportunities rather than the problems.”

For more information on NTEX’s work, visit: www.ntex.com.au

Cobra

Sales have been involved with Shantui for many years and have sold and delivered bulldozers, loaders, excavators, and graders in several configurations, which have, after hours of work, proven to be both reliable and cost-effective with great fuel efficiency and work capability.

CCF Queensland and civil contractors more broadly understand and embrace the need for practical environmental stewardship.

There is nothing worse for businesses, or society, than environmental vandalism. Despite this, all too often a narrative forms that suggests we are faced with a binary choice between business and the environment. This couldn’t be further from the truth. Unfortunately, this narrative often forms the basis of environmental regulation and legislation, having the effect of significantly curtailing the ability of business to deliver efficient and practical environmental outcomes.

Per- and polyfluoroalkyl substances (PFAS) remain one of the most pressing environmental and sustainability issues facing the civil construction sector in Queensland. Often called ‘forever chemicals’ these substances have been described as an ‘emerging’ contaminant for many decades now.