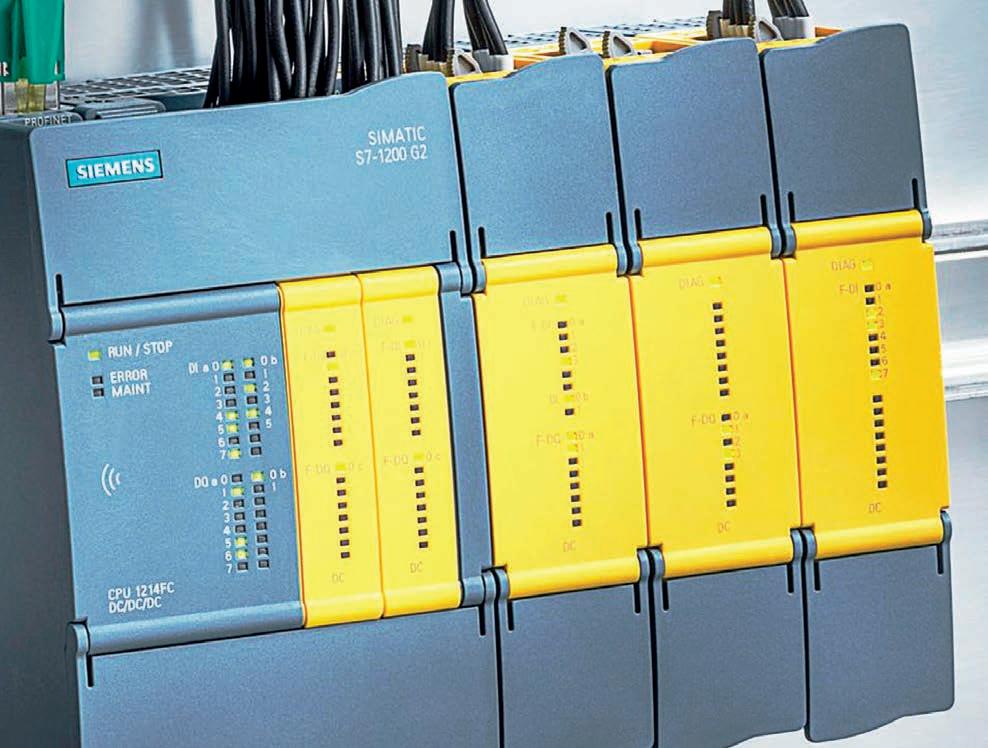

Redefining automation solutions with S7-1200 G2

Redefining automation solutions with S7-1200 G2

FLEXIBLEMACHINE SAFETY

SEAMLESS SCALABILITY

EFFICIENTMOTION CONTROL

Managing Editor: Mike Wheeler

t the heart of any food and beverage business, products, innovations and processes are driven by unique values and goals. Without a concrete “why”, a brand can struggle to stand out in a competitive market. This is clear in this issue’s selection of Meet the

Smallgoods manufacturer Borgo Salumi’s dedication to traditional methods reflects a commitment to authentic family heritage. Meanwhile, Noosa Chocolate Factory prides itself on craftsmanship that extends a family legacy for freshly handmade chocolates. Then there is Solbevi, which has brought to life a generational limoncello recipe driven by a passion for flavour and good times. Then we head up north to the Northern Territory where Humpty Doo Barramundi’s natural landbased fish farm stands as a testament to elevating sustainable Australian seafood across the globe. Finally, there is Madame Tiger, which has built its own Australian manufacturing facility from scratch to offer plant-based alternatives to almond or soy.

While a clear identity and passion are vital, they are not enough for lasting success. The manufacturers share a common focus that completes their recipe for success: efficiency. In the food and beverage sector, the word efficiency is widely used but often misunderstood.

Efficiency is not simply a process or step in manufacturing, it is fluid and evolving, shaped by the latest technological advances and consumer trends. Luckily, solutions are emerging to help companies improve efficiency.

Consider the rise of food regulations and standards. FSANZ coordinated 87 product recalls in 2023 due to contamination or undeclared

allergens, causing financial loss and reputational damage. According to sensor specialist ifm, who is also featured in this issue, artificial intelligence and predictive maintenance tools can safeguard operations through digitalisation. Another instrumentation company with expertise in the same field, Thermo Fisher Scientific, uses automation to simplify food microbiology and workflow systems.

Efficiency can also align with sustainability. With the potential ban of PFAS by the EU due to its environmental persistence, food and beverage manufacturers are under pressure to find alternatives. Treotham’s partnership with a motion plastics solutions provider focuses on finding plastic alternatives that reduce environmental footprint while maintaining quality. Then there is APS Industrials’ updated PLC that automates machinery and processes designed to reduce environmental impact.

In this issue we also look at industry bodies that are also helping businesses remain efficient in the face of sustainability challenges. A new charter for lighter wine glass bottles by the Margaret River Wine Association is helping the region’s wineries reduce carbon emissions. Packaging industry body, the AIP, is encouraging the shift in packaging designs to meet extended producer responsibility requirements.

As the world changes, evolving is essential. But the original spark that drives a business must be protected, and efficient processes across the industry will sustain it. With the right heart and the right approach, the Australian food and beverage industry can only improve moving forward.

Happy reading! F

CEO: Christine Clancy

Managing Editor: Mike Wheeler

Ph: 041 557 2106

mike.wheeler@primecreative.com.au

Journalist: Dae Hong

david.hong@primecreative.com.au

Art Director: Michelle Weston

michelle.weston@primecreative.com.au

Sales/Advertising: Joanne Davies

Ph: 0434 785 611

joanne.davies@primecreative.com.au

Client Success: Cait Pillay

Ph: (03) 9690 8766

caitlin.pillay@primecreative.com.au

Cover

Image: APS Industrials

Subscriptions AUS NZ O/S

1 year subscription99109119

2 year subscription189199 209

For subscriptions enquiries please email subscriptions@primecreative.com.au

Copyright

Food & Beverage Industry News is owned by Prime Creative Media and published by John Murphy. All material in Food & Beverage Industry News is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Food & Beverage Industry News are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2023

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Drive

Docklands VIC 3008

Ph: +61 3 9690 8766

info@primecreative.com.au www.primecreative.com.au

Sydney Office

Suite 11.01, 11th Floor 201 Miller St North Sydney, NSW 2060, Australia

Printed by: Precision Group 83-89 Freight Drive, Somerton Vic. 3062 Ph: (03) 9490 1500

6 Meet the Manufacturer: Noosa Chocolate Factory

Born in 2009, a manufacturer delivers “magical” experiences with its chocolates.

10 Meet the Manufacturer: Borgo Salumi

For nearly 60 years, smallgoods business is committed to its traditional artisan methods.

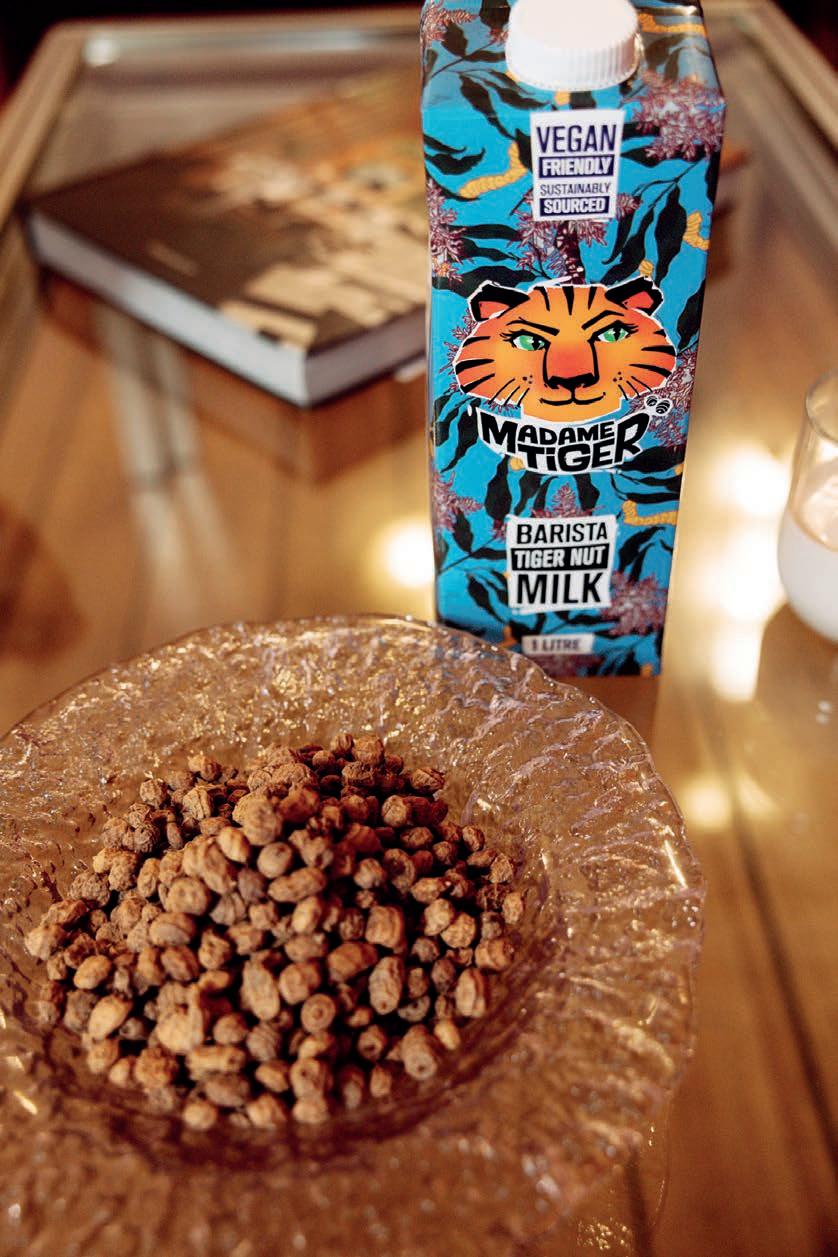

14 Meet the Manufacturer: Madame Tiger

With tiger nuts from West Africa, a milk company is lowering its water footprint.

18 Meet the Manufacturer: Humpty Doo Barramundi

A farm’s land-based natural saltwater system is the key to quality barramundi.

22 Meet the Manufacturer: Solbevi

A family cherished recipe has brought life to a limoncello spritz brand.

25 Sustainability

Are thick glass bottles good for the environment?

28 PLC

A wine association proposes lighter bottles.

APS Industrials aims to modernise food manufacturing with its new PLC.

30 Automation

Thermo Fisher is on a mission to simplify microbiology through its SureTect Automation Workflow.

33 Digitalisation

To avoid food recalls, smart process monitoring can help manufacturers.

36 Technology

Treotham is expanding its portfolio of materials for motion plastics.

38 MICE

A coffee expo explored challenges within the industry with insightful panels.

40 WorldSkills

The 2026 Team Australia Training Squad was welcomed by the prime minister at the Parliament House.

42 Methane reduction

According to an ag-tech company CEO, red seaweed can lower methane emissions.

46 Wine insights

Endeavour Group’s State of Grapes report highlights a generational shift in alcohol consumption.

48 AIP

Two winners at the Australasian PIDA Awards have re-designed packaging with the end of life in mind.

50 New products

With the

opening of its new

store on the Sunshine Coast, Noosa Chocolate Factory brings its freshly made chocolates from its factory to a discerning public.

There is a warm, nostalgic feeling associated with a chocolate factory. Romanticised by books and films as “magical”, a chocolate factory brings out the inner child for those who crave freshly made chocolates. In the heart of Noosaville, Noosa Chocolate Factory brings the art of chocolate-making back to its roots with handcrafted techniques and

With a goal to create flavourful chocolates using only fine ingredients, Noosa Chocolate Factory was born in 2009 by founders Pam and Gordon Thomson. What started in a small kitchen to create handmade batches of chocolate flourished into a large-scale factory with more than 65 dedicated team members carrying on the tradition for its specialty in panned, slab and moulded

Under the leadership of brand ambassador Andrew Thomson, the business has been revitalised and is now positioning itself for both regional expansion and international recognition. Opening its sixth store in the Sunshine Coast, Thomson explained that the shop is no ordinary outlet, but a “concept” driven one.

“We wanted to operate like a BuildA-Bear business,” said Thomson.

For an immersive and interactive

The Noosaville factory operates largely on solar power, drawing on grid energy only at night. Unlike many large-scale chocolate producers, whose products can sit in storage for a year or more before reaching consumers, Noosa Chocolate Factory operates on a much shorter cycle. It has a short stock turn period of 45 days, meaning customers are consistently purchasing fresher chocolate.

“The chocolates you have could be 12 months old by the time you purchase it. Any Noosa chocolate you eat is typically less than two months old.”

experience for customers, Thomson outlined the vision for the store to deliver customised chocolate products on the spot. The model allows customers to personalise hampers and hot chocolate drinks. They can select from jars of flavoured chocolate to create customised hot drinks and design hampers suited to their tastes or dietary preferences.

A central principle of the business is freshness. Thomson highlighted that a fresh product starts with the ingredient itself. The business sources its fruit and nuts from Australian growers where possible – strawberries from Bundaberg, macadamias from the Sunshine Coast hinterland, peanuts from Kingaroy, pecans from Boyne River, QLD, and almonds from South Australia. This close relationship with suppliers not only supports local growers but also guarantees ingredient traceability and a reduced environmental footprint.

“Everything we bring in is Australian sourced,” said Thomson. “All of our ingredients from macadamias, strawberries, raspberries and mango pieces are from Australia.”

“The chocolates you have could be 12 months old by the time you purchase it,” said Thomson. “Any Noosa chocolate you eat is typically less than two months old.”

He explained that the company’s approach to manufacturing and storage systems is what allows its chocolate to retain premium quality.

Thomson believes the disciplines of process management, precision and quality in manufacturing are universal.

“In my view, manufacturing is manufacturing,” Thomson said. “There’s not a lot of difference between manufacturing machines and chocolate.”

He emphasised the importance of Noosa Chocolate Factory’s workflows and systems. Being in the business since high school, he highlighted the company’s approach through its modern production systems, commitment to traditional craftsmanship, and its quality ingredients, which are key to its success, resulting in a high return rate from customer.

“We have 90 per cent returning customers across our business and 92 per cent in Brisbane,” Thomson added.

For each product, multiple pairs of “eyes” are involved in checking every stage, from chocolate making to packaging, labelling, and delivery. Staff involvement ensures consistent quality, safety and hygiene across operations.

What does the development process of Noosa chocolates involve?

Chocolate making is a blend of artistry and science. For Noosa Chocolate Factory’s products, having an effective tempering process is required.

“Chocolate manufacturing is all about time and temperature,” said Thomson.

Chocolate tempering is a temperature-sensitive process where consistent heating and cooling is required to achieve the “glossy” appeal and “snappy” break.

With tanks that sit at 46°C, the chocolate requires constant monitoring for temperature. Consistent monitoring is important especially when raw ingredients are added in for mixing where the temperature must be lowered. If done correctly, oils from the cocoa butter, an emulsifier, will not escape –preventing the forming of undesirable “white haze” in chocolates. After tempering, chocolates destined for

“It is a real challenge to keep humidity down to 60 per cent or below. The operational challenge for us is making sure the factory is a sealed environment, minimising people coming in and out.”

Noosa Chocolate Factory’s packaged products are coated.

A chocolate coating is the outer layer of chocolates that is hardened. While there are multiple application methods, the company utilises a panning machine for the coating process. This machine slowly rotates raw ingredients in a large dome pan. Layers of chocolate are dripped on the pan with a “dripper”, creating even coatings.

“The centrifugal force coats everything exactly the same,” added Thomson.

This method allows nuts, fruit and other inclusions to be coated evenly. Finishing touches include dustings of strawberry or decorative marbling, where hazelnut paste is drizzled over chocolate-coated nuts as they slowly rotate, creating swirled patterns for aesthetic appeal.

This year alone, Noosa Chocolate Factory has processed around 120

tonnes of products. With thousands of products moving between the factory and shops, maintaining consistent quality is not without its challenges. Thomson pointed out that the temperature and humidity in Queensland are constant operational hurdles.

“Summer is a big problem,” he said. “If you try to deliver to stores on a 40°C day, it’s a bit of a nightmare.”

With the company’s focus on freshness, the Noosaville facility is carefully sealed and fitted with heat curtains. To keep the ambient temperature of the factory at 18°C, the company works with external contractors on call to manage air conditioning and refrigeration systems. These measures are essential in an environment where excess heat or moisture can damage chocolates’ structure and appearance.

He added that no product leaves the factory from start to finish until it is ready to sell. From the factory to its retail stores, deliveries are

made three times a week using temperature-controlled vehicles, ensuring chocolate maintains its texture, flavour and quality.

“It is a real challenge to keep humidity down to 60 per cent or below,” Thomson added. “The operational challenge for us is making sure the factory is a sealed environment, minimising people coming in and out.”

Another way the company wants to manage temperature-related challenges in its operations include expansion into Sydney and Melbourne where it would likely require localised manufacturing to maintain freshness and consistency.

The business also faces broader industry challenges, particularly in the global cocoa market with 70 per cent of cocoa beans grown in West Africa, Ghana and Ivory Coast.

“A lot of plants are dying due to root rot,” said Thomson.

Root rot is a plant disease where roots deteriorate due to lack of oxygen. Cocoa plants, according to Thomson, are dying from this crop disease caused by climate change and soil conditions, increasing supply shortages and price spikes. These issues have placed pressure on chocolate manufacturers worldwide.

Despite this, Thomson remains optimistic.

“The upside is that we’re starting to see a lot of manufacturers seeking alternatives,” he said.

To stay afloat during predicaments, and to safeguard against volatility, the company has established supply contracts that guarantee volumes for

each year, supporting more accurate forecasting and stability.

Looking ahead, Noosa Chocolate Factory is planning to expand its business with new stores scheduled to open in Chermside and on the Gold Coast, with further growth mapped

across Southeast Queensland in the lead-up to the 2032 Olympics.

The company’s vision is to ensure its chocolate is accessible to every tourist visiting the region during the games. With its focus to provide more handmade and “honest” chocolate in Queensland, Thomson plans to raise awareness around the brand.

“Given the brand’s quality and loyal following, it’s really just been the case of getting the brand out there,” he said. Building its reputation on sourcing locally, manufacturing with care, and delivering chocolate at its freshest, Noosa Chocolate Factory remains committed to extend its family legacy through craftsmanship. F

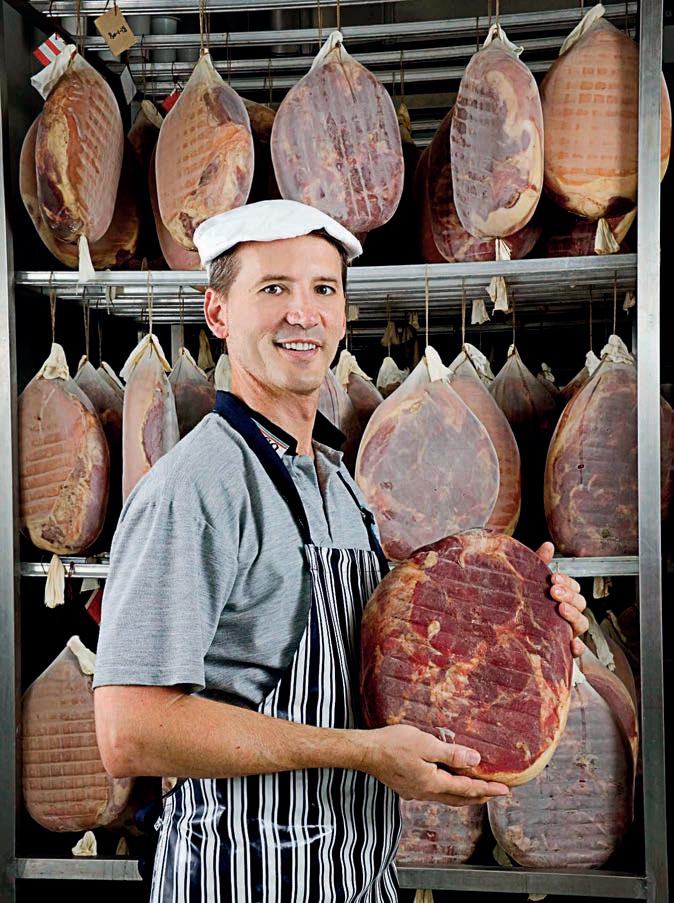

Celebrating nearly 60 years in business, Borgo Salumi continues to combine traditional artisan methods with modern innovation to produce premium smallgoods in Queensland.

Why “salumi”, not “salami”?

Joining Food and Beverage Industry News, managing director at Borgo Salumi Luigi Borgo answered a question often asked by peers. He explained that “salumi” is the Italian word for “smallgoods”.

“A salami, ham, pancetta and mortadella are examples of a salumi,” he said.

Covering a range of smallgoods products, Borgo Salumi is Queensland’s “oldest” Italian-style smallgoods manufacturer. While the company name reflects Italian roots, the company started life as Borgo Smallgoods Co.

Dating back to 1958, Borgo’s parents, Ivo and Antonietta, set up shop in Melbourne, using techniques passed down through generations and a passion to deliver authentic Italian salami. Word spread around the Melbourne streets about its high-quality salami, resulting in a partnership with Lago Butchers, to form Lago Smallgoods Company.

During a summer holiday trip to Surfers Paradise, Borgo said that his parents enjoyed the weather so much they decided they wanted to move to Queensland. They could see the European migrant population begin to spill into Brisbane and North Queensland. Ending the partnership with Lago in 1965, they decided to open an Italian-style smallgoods manufacturing plant in Queensland in 1966.

Borgo said that this move brought the business back to the start. When they left Melbourne, the business was leaving behind years of hard work with an employee count from 30 back down to two – Borgo’s parents. While this posed challenges in starting from the ground up again, the business gradually grew.

Nearly 60 years later, Borgo Salumi now employs around 30 people and manages two adjoining facilities spanning 2,000 square metres under one roof. Next year, the company will celebrate its 60th anniversary, a milestone underscoring its resilience and commitment to its craft.

There are few food businesses in Australia that can boast a family legacy spanning six decades while still retaining the craftsmanship of their earliest days. Borgo expressed a strong commitment to never

cutting corners because of his pride in delivering quality smallgoods products made with traditional Italian techniques. However, he clarifies that the business is not shy of adopting modern technologies.

So, what does the traditional method of salami-making look like?

“We cut the meat up, add salt, spices and ingredients, and fill it into natural intestine casings. We tie it by hand, hang it and then dry it,” Borgo said.

While this description simplifies the process, the amount of manual labour that goes into mincing, mixing and tying, is time consuming. Describing the business as an “SME”, Borgo said that its commitment to manufacturing by hand is its “point of difference”, to deliver premium smallgoods products compared to larger manufacturers.

For example, Borgo Salumi remains one of the few Australian manufacturers that works directly from whole carcasses rather than pre-deboned meat. Skilled butchers break down the carcasses, separating lean and fat components with precision before the meat is minced

and mixed. This approach ensures consistent ratios of fat and lean meat in each batch, something Borgo believes larger manufacturers might overlook.

The process that it follows differs, as Borgo explained that each nationality has its own way to manufacture smallgoods.

“The Italian and the French use a mincer-mixer configuration in the way they make their salami,” he said. “Germans use a bowl cutter to cut the meat up and also mix the ingredients.”

For Borgo Salumi, it prioritises the consistency with a “coarser cut”, which can be difficult to achieve with a bowl cutter. Therefore, the meat is put into a mincer where the meat will be cut up identically to the size of the plate hole of the machine.

From here, the minced meat enters the mixer to blend the lean meat and fat along with other spices and ingredients. This provides a more homogenised and evenly distributed meat mixture, crucial for consistent product delivery.

The next step is to put the meat mixture into a vacuum filler machine

to remove air, creating a denser, more uniform product. It also is an important step to evenly portion the amount of meat that goes into each casing. Once the casings are handtied, they are trolleyed into primary fermentation rooms that are temperature controlled to carefully nurture the products through this stage.

While the company’s operations are rooted in tradition to achieve the right texture, flavour and stability, it explores technology to ensure efficiency and sustainability.

In most food and beverage businesses, especially in meat manufacturing, temperature regulation is often a hurdle to maintain fresher and quality products. For Borgo Salumi, the business started its operations with single heat sources that could only be manually adjusted.

These days, process control units (PCUs) have modernised the regulation of temperature and humidity. The business still

practices daily manual checks for the fermentation process, as each batch of meat has slight variants. The variants are caused by factors such as animal diet or water content, making it essential to apply human judgement.

While larger producers often rely on preset programmes, Borgo Salumi maintains a hands-on approach to ensure consistent quality. This means that it accesses and regulates temperature and humidity settings on the spot. With modern technology, such as PCUs, the company can ensure correct climatic conditions.

Borgo’s philosophy is simple –technology is an aid, not a substitute, and human oversight remains at the heart of the craft. This philosophy extends to casings.

Previously before processing equipment and machines entered the business, clipping, tying and natural casings were all done by hand. Part of the reason for the choice of manual handling is due to the difficulty to mechanise or automate natural items unless it is uniform in its structure.

Natural casings come from intestines of animals that come in various sizes. Because of this, the diameter of each casing can vary by a few millimetres, which Borgo described as a factor that makes

automating processes difficult.

Prior to the COVID-19 pandemic, the businesses who produced these natural casings had more resources to manage the workload by hand. This shifted and many manufacturers who were producing natural casings struggled to find staff after the lockdown, which served as a hurdle in getting a hold of a supply of natural casings in Australia. While the business still aims to produce products using natural casings, Borgo highlighted that the business quickly adapted to introduce some synthetic casings to handle the amount of smallgoods they produce.

“Our point of difference is putting a human touch to every stage of the process,” said Borgo. “We use modern technology to help us regulate the processes rather than take over the whole process.”

Sustainability has become a central issue for food manufacturers, particularly in relation to packaging. For Borgo Salumi, cardboard recycling is straightforward, but plastic packaging presents greater challenges, with Borgo describing plastic as unavoidable. While there has been progress in vacuum packaging, he noted that many of the options currently available remain only partially recyclable and cannot fully preserve a product’s freshness or shelf life.

As he weighed the complications of adopting packaging that is only partially recyclable, Borgo addressed another problem – food waste.

“Adopting a partially recyclable solution may save a small amount of plastic, but it cannot be compared to the amount of food that you’re throwing away because it hasn’t maintained shelf life,” said Borgo.

He described the search for recyclable packaging as a waiting game. Borgo is hopeful of the efforts being made by the packaging industry. Until the right solution comes, Borgo Salumi continues to trial options and work closely with suppliers, while ensuring food safety and quality remain uncompromised.

When it comes to food safety audits and regulations, Borgo welcomes it, viewing it as a collaborative effort

that helps maintain trust with consumers and regulators alike. Food safety underpins every step of the company’s production process. Routine pre- and post-production swabs, product testing, and regular audits are central to operations. With a good reputation within the health department, Borgo Salumi accepts the regulations as assistance to maintain the integrity of its products.

Expanding over the years into a sizeable business with a 2,000 square metre facility, the company was recognised internationally at the 2025 IFFA competition in Germany, a smallgoods fair. Borgo Salumi achieved multiple medals including three platinum awards, which Borgo described it as a testament not only to its products but also to the dedication of its team.

Central to Borgo Salumi’s success at the event is its workplace culture. Since 2017, the company has implemented a documented set of values that emphasise care, passion, pride, integrity, respect and quality. By formalising expectations and

encouraging accountability at all levels, including Borgo himself, the business has created an environment where employees feel valued and aligned.

Celebrating its 60th anniversary next year, the company continues to balance tradition with innovation. Future plans include expanding into new product lines such as salami bites, a preservative-free, free-range snack designed to appeal to younger consumers and families seeking protein-rich lunchbox options.

The recognition at the 2025 IFFA competition was as much about the employees as the brand, reflecting the collective effort that goes into every product. Borgo Salumi focuses on maintaining product integrity and strengthening its legacy. While honouring family traditions, the company is committed to utilising modern technology to aid its processes while keeping the human touch that keeps the Italian delicacies and traditions alive.

“We’re not sales-driven, we are product-driven,” said Borgo. “Our goal is to make the best salumi we can. It is not a new goal or an old goal. It is a continuous goal.” F

Sourced from a farm in West Africa, milk manufacturer Madame Tiger is introducing Australian consumers to tiger nuts, an ingredient that only requires rainwater to grow.

With tiger-like stripe markings and wrinkled shells, tiger nuts, though the name suggests otherwise, are not actually nuts. While they resemble nuts and have similar textural “crunch”, tiger nuts are small root vegetables that are packed with fibre, natural oils and nutrients. Building its identity around this little-known ingredient, Madame Tiger was born as an idea in 2020 with the ambition to create a creamy and sustainable alternative to other plant-based milks.

Founder Laura Hindson shared that her expert knowledge of tiger nuts dates back to her father-inlaw’s staple diet growing up in Mali, West Africa. As he introduced it to the family as a healthy snack food,

Hindson decided that the Australian market needed to be introduced to tiger nuts.

Hindson quenched her curiosity around tiger nuts through a documentary about Mousso Faso, a female farming collective in West Africa that had faced setbacks from unfair corporate dealings. Determined to support a fairer and more direct supply model, Hindson got in touch with the film’s director, who connected her with the farming collective, and bought the group’s first harvest after it regained independence, importing six tonnes of tiger nuts to Australia. With a longstanding partnership, Madame Tiger has purchased the farming collectives entire tiger nut harvests from 2020 to 2025.

Madame Tiger’s journey quickly revealed challenges that many startups face. Initially, Hindson planned to work with contract manufacturers, focusing her efforts on marketing, finance and strategy. But she soon discovered that contract manufacturers had their own limitations.

“Contract manufacturers in Australia are not equipped to handle bags of tiger nuts straight from the farms in West Africa,” said Hindson. “They are more used to dealing with highly processed liquids and powders.”

This led Hindson to establish a dedicated facility in Carrum Downs, southeast Melbourne. With no prior

took three and a half years, involving investment in equipment and time to refine the recipes.

So, what does manufacturing tiger nut milk involve? On a smaller scale, all that is required is to soak it, whiz it up in a blender, and extract it using a nut milk bag. On a larger scale it’s more complicated especially given Madame Tiger is making the milk from scratch using whole tiger nuts.

As Hindson explained, there was no ready-made tiger nut milk line to purchase. Instead, the company had to adapt and combine technologies used across the plant-based sector, scaling up processes that had

“Tiger nuts behave differently to almonds as their fibre content is a lot higher, which makes it harder to break down.”

traditionally been carried out on a kitchen bench.

The tiger nuts are purchased annually and shipped to Australia, where they are stored in a dedicated warehouse. Once dried, tiger nuts remain shelf-stable without refrigeration, reducing the energy demands of storage and transportation.

The process begins with washing and soaking the tiger nuts, which helps soften and rehydrate them before grinding them in a mill. She described the milling and filtering processes as important in extracting natural fats and oils from the tiger

nuts, adding the creamy texture of the milk.

“Tiger nuts behave differently to almonds as their fibre content is a lot higher, which makes it harder to break down,” said Hindson.

Using an “intense” grinding mill, the fibrous particles are then filtered out leaving a smooth creamy milk.

The milk is then transported to Cottonwood Springs, a Tetra Pak contract manufacturer in Victoria, for blending and bottling. This model allows Madame Tiger to retain control over the unique processing stages while collaborating with a larger-scale partner for the final packaging.

As all food and beverage businesses face stringent regulations and standards, Madame Tiger meets those requirements and has already established its operations to be aligned with them. Its facility is certified under FSSC 22000, requiring annual audits, routine allergen testing and rigorous hygiene standards. As part of its food safety and quality plan, each batch undergoes microbial and sensory testing before release.

When it comes to sustainability, Hindson explained that the selection of tiger nuts is at the core of the company’s commitment to sustainable practices.

“Tiger nuts are an incredibly sustainable crop from a water

footprint perspective as it only requires rainwater to grow,” she said.

According to Water Footprint Calculator, to produce one kilogram of almonds, 16,120L of water is required. While oats and soybeans require lesser amounts of 2,500L and 2,134L respectively, tiger nuts use only 387L.

Together with the low water footprint of tiger nuts, the company also measures its climate impact through Carbon Cloud, a tool that calculates emissions across supply chains. The platform records all processes and steps from ingredients, power supplies, water usage, waste and kilometres travelled. Using these records, it provides a climate impact figure.

“Our Barista Tiger Nut Milk is 0.32kg of CO₂ equivalent per litre while the original tiger nut milk is

0.43kg of CO2e” said Hindson.

Local sourcing also plays a role in reducing the company’s environmental footprint, with the olive oil and faba bean protein produced in Australia.

Madame Tiger’s immediate goal is to broaden its domestic reach, particularly in markets such as New South Wales where the brand is less established. One of the ways the company aims to grow its business is through its participation at industry events such as Fine Food Australia. The business also plans for international expansion in the future. Hindson described the business as still being in its infancy. As a mother of six-year-old twins balancing

parenting and running a business from scratch, she admitted it is a constant juggle. While there are hardships, Hindson relies on a support network of friends and family, including her brother, who was the company’s first employee. Building a business from the ground up and educating people about tiger nut milk has been a huge task, she credited her network of family and friends who had the “business’ best interests at heart and love helping spread awareness”.

From an African farming collective

to a tiger nut milk factory in Melbourne, Hindson has cracked through the plant-based milk industry as a women-led business. With a commitment to aligning the growing demand for socially conscious food with nutritional value, she hopes to see more women in leadership roles in the food and beverage sector.

“Even though running a business with little six-year-old twins can be chaotic, I wouldn’t have it any other way,” said Hindson. “I wish to see more women performing leadership roles in the food and beverage space.” F

With its recent partnership with Sushi Izu, Humpty Doo Barramundi aims to expand the Australian seafood market with its sustainably farmed barramundi.

What is naturally low in fat, high in protein, firm in wet dishes, crispy when panfried, and loved by many Australians? The answer: barramundi.

Despite its popularity among Australian consumers, more than half of barramundi sold in the Australian market is imported. With environmental pressures, animal

welfare concerns, and operational hurdles, Australia’s wild-caught barramundi industry faces constant challenges.

The broader industry challenges such as discharges into the environment have heightened regulations and scrutiny of the products. Issues such as climate change and crop diseases affect feed

ingredients, requiring new strategies to overcome. However, a domestic barramundi farm can address these challenges through controlled monitoring and natural systems.

In Australia’s Northern Territory, halfway between Darwin and Kakadu National Park, sits one of the country’s largest barramundi production farms.

Humpty Doo Barramundi, a family-

owned company established more than three decades ago, started from producing just six kilograms of fish a week, expanding its production capacity by 20,000 times.

Chief executive officer and coowner, Dan Richards, joined Food and Beverage Industry News to share the story behind the company’s growth in the sector.

“Our mission is to responsibly produce beautiful Australian barramundi,” said Richards.

Today, it employs around 150 people and is the largest Australianowned fish producer. With an aim to demonstrate care for people, the fish, the environment, and partners, the company addresses industry challenges with incremental improvements to shape the future of sustainable aquaculture.

From hatchery to harvest

Richards said that the journey of Humpty Doo Barramundi begins at a hatchery located on an island in Darwin Harbour. Here, the team runs a breeding program in partnership with Australia’s science agency, the Commonwealth Scientific and Industrial Research Organisation

(CSIRO), selecting the best fish for both the tropical environment and flesh quality. Once the fingerlings reach 28 days old, they are transferred to the main farm where they pass through multiple nursery stages.

“We’ve got a series of nursery facilities that separate the larger aggressive barramundi from the smaller shy ones,” said Richards.

These facilities give every fish the best chance of success before moving into the saltwater grow-out ponds at around five months of age.

Land-based saltwater farm

“We’ve developed systems that are based on natural systems,” said Richards.

A key feature of the operation is its large-scale saltwater wetland system.

The farm provides the fish with a stable, high-quality marine habitat to grow in while minimising waste to the environment.

“Less than one percent of the nutrients that the barramundi produce is discharged off site,” said Richards.

He described that apart from occasionally releasing some water due to rain, the company has addressed many environmental issues that flow through cage-based farming systems through the innovation of its natural wetland system. This innovation dates to 2002 when Richards’ father, Bob Richards, was awarded the Churchill Fellowship, a prestigious research grant.

For Humpty Doo Barramundi, a healthy farm means healthy fish. The farm allows this by enabling

consistent production year-round. Its wetland recycling system creates a regenerative ecosystem where nutrients from the fish sustain natural cycles. The wetland system uses natural grasses to clean the water for recirculation through the farm. Richards emphasised that the farm is designed to produce quality fish.

“We have saltwater ponds and saltwater selects for marine algaes that give you beautiful marine flavours to the fish,” he said.

By recirculating water to encourage the growth of marine algae, the farm ensures the quality of saltwater products and minimal waste release. Alongside a fish harvesting facility, the farm also has a chilling and processing facility. Its “unique” chilling process further ensures faster production and longer shelf life.

Humpty Doo Barramundi’s wetland system is an advantageous choice that reduces workload and biosecurity risk. An example is the reduced need to bring and take away water from

Technology plays an important role in maintaining quality and efficiency at the farm. The company uses harvesting pumps and is currently working with a Norwegian supplier to trial world-first stunning techniques for barramundi at harvest.

Richards said that the company partners with a lot of local and international suppliers across packaging, construction materials and agents for international technology. This includes the likes of Technolab, a water quality management solutions provider, and OxyGuard, a Danish oxygen monitoring company.

“We often work with domestic technical providers while also receiving technology coming from Europe,” he said.

With innovation and growth at its core, the company has also taken steps in sustainable packaging.

According to Richards, the company is the first Australian aquaculture farm to incorporate Australian-made compostable pallet wrap into its operations. Working with Great Wrap, a certified material science company that manufactures compostable stretch wrap, the company uses biodegradable material for packaging that is free from microplastics and leaves no toxic residues.

“It’s been a great solution to reducing environmental footprint of all packaging and shipping,” said Richards.

From October 2025, the company will also replace polystyrene boxes with UNICOR boxes as part of a commitment to reduce footprint. These boxes are made from 60 to 70 per cent natural earth elements such as calcium carbonate. They are nontoxic, recyclable, and part of a closedloop system supported by collection centres in fish markets and cities. The change will reduce microplastic pollution, support circular economy initiatives, and lower the company’s environmental footprint.

“This initiative is part of our commitment to improving environmental sustainability and reducing our ecological footprint,” he added.

As consumers are becoming well-informed, demand for locally made products is higher than ever. Richards welcomed this and expressed his excitement to reach more Australian consumers.

“As a business producing around half of the barramundi grown in Australia, getting our product out to more Australians would be wonderful,” said Richards.

To expand its market, the company is branching into new product formats for the fish due to its versatility.

An example is its recent collaboration with Sushi Izu, introducing barramundi into the sushi market for the first time at a national scale. With discussions about introducing locally grown sustainable alternatives to sushi offerings, both companies had a common goal.

and innovation, making the collaboration a natural fit,” Richards said.

What began with a trial in Sydney quickly expanded to Queensland and then rolled out across 230 stores nationally.

“We’re really proud to provide sustainable sushi options that support Australian farmers and regional communities,” he said.

Barramundi is also broadening its reach internationally. Its products are being showcased at the World Expo in Osaka. With its barramundi on the menu in the Australian Pavilion, the event will provide a platform to highlight Australian seafood. Participation in trade delegations and collaboration with leading chefs overseas demonstrates the company’s

ambition to bring the fish to new audiences.

For Richards, the business is more than just about fish.

“My kids are fifth generation Territorians,” he said. “We see the exciting opportunity to use our business as a force for good within our community over time.”

The company is committed to positioning Humpty Doo Barramundi as a sustainable aquaculture brand through operational innovation. F

Translated into English as “sun drink”, Solbevi, a beverage company, brings Italian limoncello to life with a cherished traditional family recipe.

Many business ideas are rooted in tradition. But how do these ideas come to life in the fast-paced, innovation-packed industry? For Solbevi, it began with a relaxing afternoon with friends on a sunlit balcony in 2020. Sipping on a homemade limoncello, they realised no one had ever created a ready-todrink limoncello spritz.

Growing up in an Italian household, 28-year-old founder Stefan Di Benedetto explained that the family cherished limoncello recipe was passed down through generations and central to every gathering. To bring this feeling to life, Solbevi was born.

even the name reflects Italian roots. Solbevi is derived from sun, and

into a unique brand name that could be trademarked internationally.

Now two years on, Solbevi has positioned itself as an innovative young beverage company in Australia.

According to Di Benedetto, Solbevi is behind the world’s first limoncello spritz in a can and is stocked in retailers such as Dan Murphy’s, Liquorland and Super Liquor across Australia and New Zealand, with international expansion well underway.

This global mindset has been part of the company’s DNA since day one.

Before entering the drinks sector, Di Benedetto worked in commercial construction and consultancy. With no background or technical experience in beverage production, he began experimenting at home using a soda stream. What started as a kitchen project soon developed into a commercially viable idea.

One of the brand’s most distinctive features is its approach to product development. For example, unlike many ready-to-drink spritzes,

since the company’s early days. Di Benedetto explained that limoncello was simple to produce and could be made using a large vessel or an intermediate bulk container (IBC).

Although the process was simple, he faced challenges with scaling operations. Using a 300-litre distiller for ethanol, the company relied on a small manual bottling machine, which only bottled five bottles at a time.

“We’re talking pretty low volumes at this rate,” he said.

As demand grew, this method quickly proved unsustainable. To navigate through this challenge, the company had to seek other business models.

debate the absence of sparkling wine,

“While we were making the liqueur ourselves, we outgrew the ability to bottle the products ourselves,” admitted Di Benedetto.

As most start-ups discover, a hands-on approach during the product development stage is unavoidable. Juggling between manufacturing limoncello and growing the brand, Di Benedetto had to shift Solbevi to a new model.

The contract manufacturing model allowed the company to scale flexibly, access highquality equipment without the burden of owning it, and maintain consistency across different markets.

“With the cost required to produce everything ourselves, we moved into a contract manufacturing model instead,” he said.

The contract manufacturing model allowed the company to scale flexibly, access high-quality equipment without the burden of owning it, and maintain consistency across different markets.

“It’s a great model,” Di Benedetto said. “Once you organise all the ingredients and place an order, the completed product will be sitting there for you.”

Solbevi works with separate manufacturers for bottling and canning. After sourcing and providing the right packaging and ingredients,

the manufacturers blend and bottle. Recipes and ingredients are designed to be easily replicated with safety and precision.

The model also supports Solbevi’s international strategy, as recipes have been developed to be produced anywhere in the world. For instance, when entering the US market, the company plans to manufacture locally to reduce freight costs and simplify logistics.

By keeping the supply chain adaptable, Solbevi aims to grow in regions where volume and accessibility are key to profitability.

The export market is now a focus for Solbevi. Southeast Asia has been identified as a prime region for growth, given its large populations, warm climate, and strong appetite for premium beverages. Launched in Malaysia and Singapore, the company plans further expansions in Thailand and Philippines. Di Benedetto highlighted the importance of improving operational efficiency.

“If we can boost the number of cans we make at a time, we can lower our cost per unit and increase our margins,” he said.

Stricter labelling laws are set to come into force in 2027. To prepare, Solbevi retains tight control over product formulation and compliance. The company partners with external consultants to meet requirements and ensure products are safe and regulated.

“We work with food scientists to make sure our products are compliant through stability and corrosivity testings,” said Di Benedetto.

Additionally, the company has received help from consultants providing advice on labelling and regulatory requirements. Packaging is sourced locally wherever possible, with all labelling and most materials produced in Australia to maintain quality standards and avoid risks associated with cheaper overseas options.

Alongside expansion in Asia, the company continues to strengthen its domestic presence. Solbevi recently secured national ranging across Australian and New Zealand retailers, supported by placements in hospitality settings including Formula One events and Qantas

and Scoot Airlines flights.

“We have a big vision, and that’s to have our products sit next to brands such as Aperol and Campari in every venue around the world,” said Di Benedetto.

In the immediate future, the company plans to consolidate its position nationally, maximising its recent retail wins and building stronger recognition. In the longer term, the

“We have a big vision, and that’s to have our products sit next to brands such as Aperol and Campari in every venue around the world.”

The US represents the ultimate market opportunity for the company.

The Margaret River Wine Association is on a mission to lower carbon emissions in the wine industry with its new initiative for lightweight glass bottles.

Before glass bottles, wine was stored in clay vessels and transported in barrels. With technological advancements that led to stronger glass through high-temperature furnaces, wine bottles became the popular way to store and transport the beverage. Since then, thick glass bottles have been the standard in the industry for centuries.

However, are glass bottles good for the environment?

“The highest proportion of carbon comes from packaging followed by transport,” she said.

According to industry body Wine Australia, wine packaging accounts for 44 per cent of emissions associated with wine production, from grape to end-of-life packaging. Transport, particularly across vast distances within Australia and to international markets, makes up the second largest share.

Whiteland talked of an industry

glass bottles on the environment. International retailers have increased pressure on suppliers to reduce packaging emissions. Many UK retailers, for instance, have signed agreements requiring lighter bottles.

As the name suggests, lightweight glass bottles reduce the average weight of wine bottles in Australia, which is approximately 560g. Defined internationally as those weighing under 420g, wineries that adopt lightweight glass bottles can help

one of the easiest ways to reduce carbon footprint and it also reduces transport emissions,” said Whiteland.

The shift to lighter bottles has been made possible through collaboration with glass manufacturers in South Australia, who are themselves investing in sustainable technologies.

“The glass suppliers in South Australia are increasingly using higher percentages of recycled glass,” she said.

While including higher proportions

per cent and total furnace energy up to 30 per cent. By working closely with suppliers, the association is assisting Margaret River wineries have access to environmentally improved packaging solutions without compromising presentation or functionality.

Although environmental considerations are central, there are also practical benefits to the initiative. Due to the absence of local glass manufacturers in Western Australia, producers face greater impacts as bottles must be transported from South Australia. With reduced weight, lighter bottles minimise strain on logistics, lowering freight costs and making handling easier in warehouses and retail environments.

For staff moving cases of wine, reduced weight translates to a safer and more manageable workplace, cutting the risk of injuries from heavy lifting. Every reduction in weight cuts costs and emissions during both the inbound journey of empty bottles and the outbound journey of finished wine. Although the cost savings are not the primary motivation, they

provide an additional incentive for wineries and distributors to transition, further strengthening the business case for sustainability.

While the shift to lightweight glass bottles is attractive due to environmental factors and lower costs, stigmas surrounding the adoption of lightweight bottles still pose a barrier.

One of the few barriers to widespread adoption has been the perceived perception that heavier bottles suggest higher quality wine.

“Some businesses are nervous to put their premium wines into a lightweight bottle due to fear of losing consumers,” said Whiteland.

While this belief persists in some markets, Whiteland noted that studies in Europe show that bottle weight has little to no effect on consumer purchasing decisions.

Several Margaret River wineries have already used lightweight bottles for their premium wines for over a decade without experiencing any

negative impact on sales.

“We’re confident that lightweight glass bottles will become a feelgood purchase for environmentally conscious customers,” she added.

The technical difference lies in thinner glass walls and a reduced punt at the base of the bottle, which does not affect the wine itself.

As more wineries transition, the expectation is that any potential stigma will disappear. To help with this transition, the MRWA is at the forefront of the movement to reduce carbon footprint by launching its new lightweight glass packaging charter, a nation-first initiative for glass packaging.

The MRWA’s initiative, launched as a formal charter, reflects the association’s broader mission to align fine wine with ecological responsibility and set a benchmark for the Australian wine industry. With 175 wineries reporting production from local grapes last year, the association is central to both the region’s identity and its international reputation.

Although Margaret River accounts for only two per cent of Australia’s wine grapes, the region’s wineries produce approximately 30 million bottles of wine per year. By catalysing the shift to lightweight glass bottles across the region, the MRWA estimates saving 3,000 tonnes of glass annually.

Whiteland explained that Margaret River is recognised as one of two biodiversity hotspots in Australia and one of 25 globally. Many producers in the region are certified through Sustainable Winegrowing Australia, while others pursue organic or biodynamic certification.

“There’s a lot of people in the region trying to have a lighter footprint in their wine production,” she said.

These practices are rooted in an understanding that the region’s future prosperity depends on maintaining its natural assets.

The lightweight glass initiative therefore fits alongside the MRWA’s commitment to reducing emissions.

Currently, seven Margaret River wineries have formally signed the

charter, including Pierro Wines, Evans & Tate, and La Kooki. An additional 10 have provided a statement of intent to become full signatories by the end of the 2025-2026 financial year. Although still early, the initiative has sparked discussion across the membership, with more wineries considering the shift.

“We are trying to talk to as many people as possible to amplify the voice around why the shift is the right thing to do,” said Whiteland.

Looking ahead, the vision is for lightweight glass to become the default option across Margaret River and eventually across Australia. Wine Australia identified reducing glass weight as one of three key strategies in its 2023 Emissions Reduction Roadmap. It outlined a projected 42 per cent reduction in carbon emissions by 2030, with lightweight glass playing a central role in achieving that goal.

With mounting pressure from international retailers and global sustainability standards, the case for change is strong. Whiteland said that if every winery was to adopt bottles

“Reducing the glass weight is one of the easiest ways to reduce carbon footprint and it also reduces transport emissions.”

small-scale producers such as Jilyara, can successfully adopt lightweight bottles. The goal is to make the transition as accessible as possible and to normalise lightweight packaging across the region.

Although the initiative began at a regional level, the association hopes it will inspire change across the

Australian wine industry. Lightweight bottles represent one of the simplest yet most impactful ways of cutting emissions, and their adoption requires no adjustment in winemaking practices.

“It’s the right thing to be doing,” said Whiteland. “And we’re trying to help everyone as much as we can on that journey.” F

With its new Siemens SIMATIC S7-1200 G2, APS Industrials is modernising automation for the food and beverage sector.

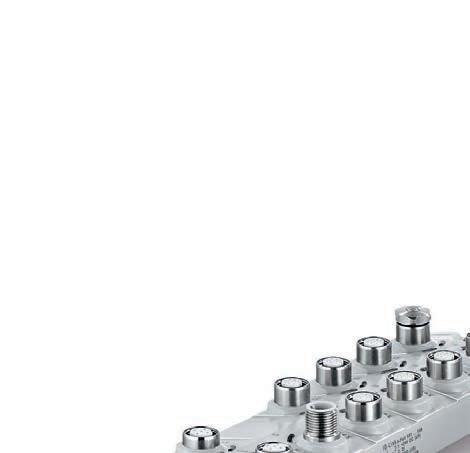

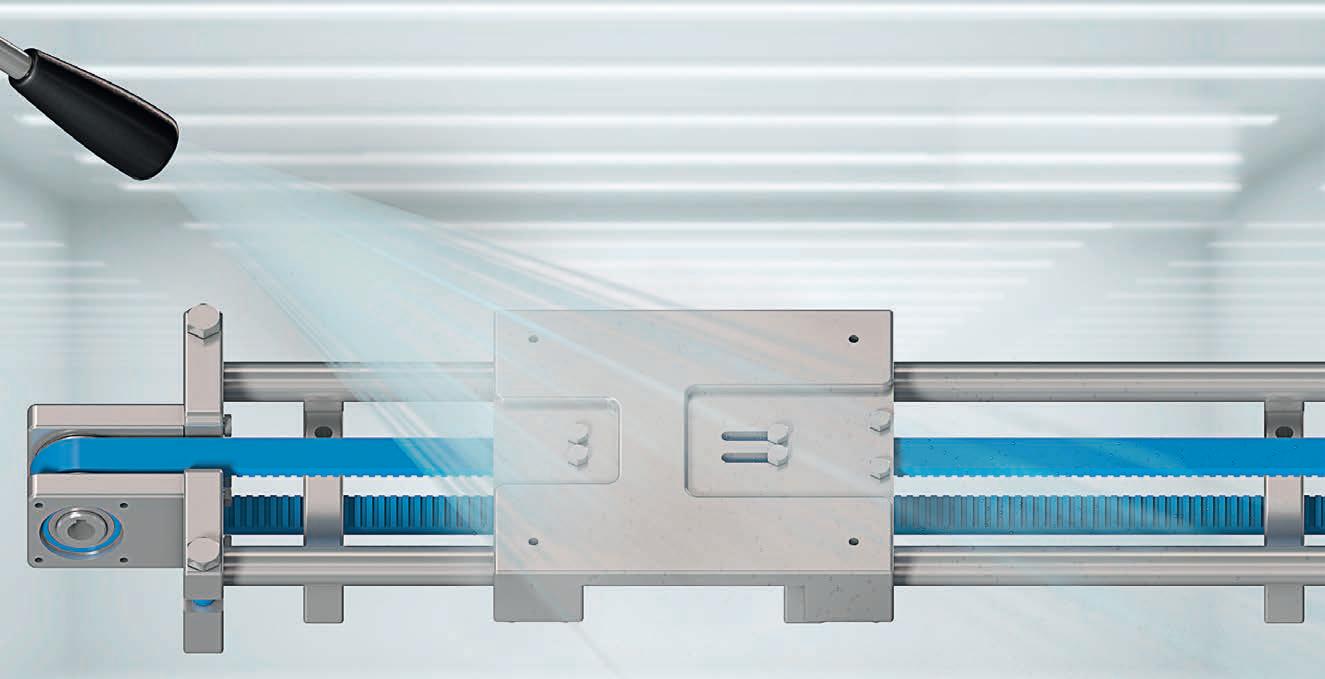

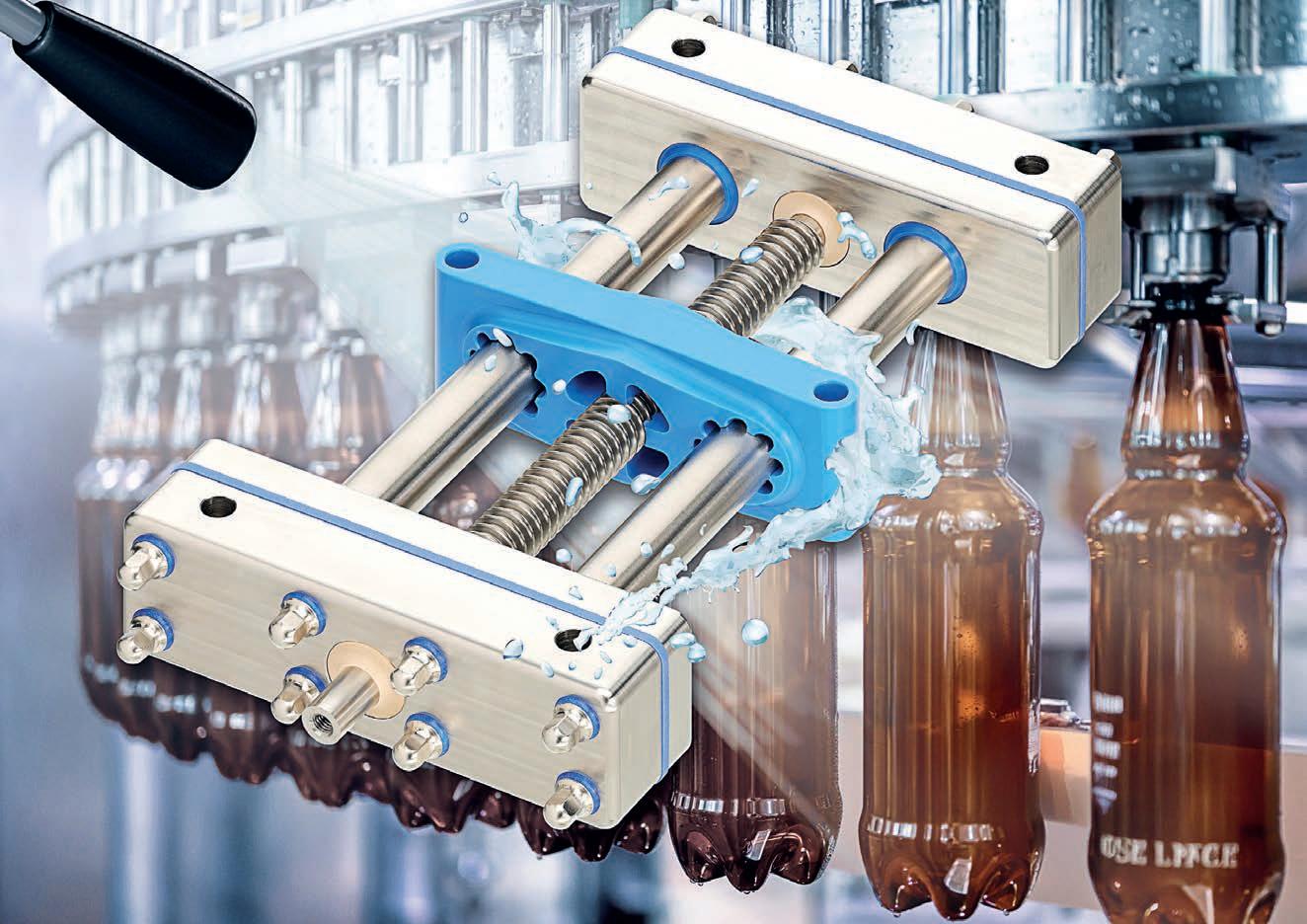

With the launch of the next-generation SIMATIC S7-1200 G2, the partnership between APS Industrial and Siemens is being strengthened to meet the rising demand for efficient control systems in Australia’s food and beverage sector. The S7-1200 G2 is a programmable logic controller (PLC), building on more than a decade of success with the original S7-1200 PLC. The PLC automates machinery and processes by receiving inputs, executing logic-based instructions, and controlling outputs. Compared to the original, the S7-1200 G2 includes new enhancements and now achieves an overall footprint reduction of 25 per cent. The updated platform is suited to industries including food and beverage production,

pharmaceuticals, packaging, and material handling where space, precision, and safety are key.

According to Automation and Drives business manager at APS Industrial, Steven Sischy, the S7-1200 G2 brings additional value with enhanced communications and efficient motion control. It also comes with pre-set function libraries that customers can download for faster operation. He explained that the S7-1200 G2 will focus on industries that rely on conveyors, packaging lines or filling capabilities.

PLC update

Manufacturers who possess earlier models and are considering an upgrade can benefit from the overhaul of Siemens’ PLC

architecture. As well as speed, connectivity and space efficiency, the S7-1200 G2 also offers features in system integration and is programmed with TIA Portal.

“We’re moving from seven different CPUs to just four – two standard CPUs and two safety versions – which makes stocking and customer support much simpler,” said Sischy.

He said that it has the capacity to handle more PROFINET I/O due to the increased expandability. Additionally, cybersecurity is native to the system, he said. APS Industrial has introduced Near Field Communication (NFC) for the first time, which allows instant fault diagnosis with an iPhone or Android with the right credentials, which maximises efficiency.

The unit’s smaller footprint is a targeted approach to increase performance and scalability. The system is aligned with the four pillars: performance scalability, flexible machine safety, efficient motion, and increased data transparency.

“This means a reduced footprint,

allowing us to address up to 31 PROFINET devices across the network, compared to just 16 previously,” said Sischy.

Flexible safety features have also received a boost. The G2 has doubled its support for system boards and now includes dual PROFINET channels – separating machine communication from IoT or cloud connections. This helps support a clearer division between IT and OT systems.

With flexible machine safety, Siemens has gone from supporting one system board to two, providing more options to the customer. According to Sischy, communications have improved where the previous generation only supported one PROFINET channel. Now, a customer can connect to IoT or cloud-based systems, while the other links directly to devices on the machine. Customers also do not need to pay for additional software licenses if they have a fail-safe CPU. This change is now included as standard in the base software package.

The PLC’s motion control is one of the key enhancements compared to original models. Where the earlier

generation had limitations to its integrated motion capabilities, the new system brings this functionality directly into the CPU, improving real-time control and synchronisation.

Sischy said that there has been a power dissipation reduction of 20 per cent for CPU 1212 and 30 per cent for CPU 1214, compared to predecessor products. Product performance increased by more than 100 per cent with a comparable weight (avg. increase <15 per cent) for all variants of CPU 1212 and CPU 1214 compared to its predecessor.

The new system also improves data visibility. With integrated NFC, operators can instantly access diagnostics wirelessly, reducing downtime and allowing quicker maintenance interventions.

APS Industrial and Siemens have committed to helping food and beverage manufacturers with a smooth transition to automate their processes. Alongside the introduction of the S7-1200 G2, their commitment includes the offering of standard functions,

motion control libraries and detailed application notes.

From beginning to end, the two companies provide tools to help customers get started, connect, configure, and even program the system. This whole process, as Sischy described, is to ensure that the S7-1200 G2 is more user-friendly and that the transition is fluid.

While the technology is newly launched, APS Industrial has already seen early adoption in food and beverage applications and is working on a water industry Remote Terminal Unit project. Sischy said that alongside these cases, the new system represents a journey into uncharted waters for APS Industrial and Siemens.

“Our key focus going forward remains on market segments where we haven’t been strong before – particularly OEM liquid filling applications. We now have the capability to pursue those opportunities,” said Sischy.

With the S7-1200 G2, both companies aim to empower manufacturers with a smarter, faster, and more transparent automation platform. F

Thermo Fisher Scientific’s SureTect Automation Workflow makes food microbiology simple for laboratories.

Food and beverage manufacturing goes beyond robust machinery and efficiency. At the end of the day, the product being delivered must be safe to consume. At the heart of every product is a rigorous research and development process, with food microbiology being a field of study to analyse the quality of food products.

Polymerase chain reaction (PCR) in food microbiology is a technique utilised to detect foodborne pathogens by amplifying DNA to detectable levels in a short time frame. The multiplication from one to several million copies to get it to a detectable level can be achieved within a few hours and what once required five to seven days to complete can now be done within two.

PCR provides manufacturers with a pathway to release products quickly while complying with high food regulatory standards. The technology is capable of detecting very low levels of microbial DNA, providing food producers with assurance that their products are free of pathogens such as Salmonella, Listeria and pathogenic E. coli, safeguarding

consumers and protecting brand integrity.

Understanding the fast-paced nature of the food and beverage industry, Thermo Fisher Scientific, is a company dedicated to science and making the world healthier, cleaner and safer by providing laboratories with the tools they need for transformative developments, particularly in PCR technologies.

As the company’s technical applications specialist Stephen Dixon said, traditional PCR processes require highly specific skilled scientists and are labour intensive. This can hinder overall performance in time-sensitive environments. To address this, Thermo Fisher

Scientific’s SureTect Automation Workflow, powered by the CyBio FeliX Instrument, provides a streamlined platform that simplifies the PCR process.

SureTect Automation Workflow

Traditional workflows required multiple stages of DNA extraction, preparation and amplification, all of which demanded a high level of technical expertise. This complexity limited its accessibility for many food and beverage laboratories, where staff often carry out a wide variety of roles and may not specialise in molecular biology.

For many food businesses, most tests return negative results, meaning

pathogens are not detected. Dixon said that under traditional methods, every sample required multiple days of culture and confirmation steps, even when the outcome was negative.

“What we’ve done with SureTect Automation Workflow is to simplify the PCR process by eliminating the extraction process so that you can proceed straight to the lysis,” said Dixon.

In PCR, lysis is the step of opening cells to release the target DNA by breaking down the cell membrane. This then serves as the template for amplification. Lysis makes the DNA accessible to the PCR reaction components, such as DNA polymerase, primers and nucleotides.

“What we’ve done with SureTect Automation Workflow is to simplify the PCR process by eliminating the extraction process so that you can proceed straight to the lysis.”

Without this release, the PCR process cannot begin. Instead of laborious DNA extraction and multiple reagent preparations, the system uses a lysis step followed by direct transfer into a ready-to-use PCR tablet.

The SureTect System keeps PCR processes simple, especially for those who are not experienced in molecular biology. The process can be

performed manually or automated, offering flexibility for laboratories of different sizes.

“With SureTect Automation Workflow, laboratories will not run the risk of errors caused by manual processes,” said Dixon.

The automation option is particularly good at minimising human intervention. The automated lysis and PCR setup reduces the risk of operator error, lowers the labour burden and allows staff to focus on other tasks while the system runs.

By integrating into existing laboratory routines without the need for infrastructure changes, the automated workflow allows handson time reduction while reproducing accurate results. According to Dixon, laboratories would no longer need to use multiple rooms for the PCR process and can be set up on a single bench.

In 2023, Coca-Cola Europacific Partners (CCEP) worked with Thermo Fisher Scientific to develop a PCR assessment for the detection of spoilage contamination in the production environment. In the past, the company relied on highly specialised equipment and expertise for microbial testing,

often concentrating testing within a small number of specialist centres. Some methods required extended enrichment periods of up to six days before analysis on expensive equipment such as high-performance liquid chromatography (HPLC). By implementing automation into its workflow with SureTect, CCEP has been able to go beyond laborious manual protocol, enabling

SureTect allows the PCR process to be performed manually or automated.

routine laboratories across multiple countries to perform testing without needing extensive molecular biology expertise.

According to Raul Mesa, Quality and Food Safety Manager at CCEP, routine manual analysis became challenging when the number of samples increased during contamination events. With the instrument using a robotic head and dual platform to perform the role of a lab technician to prepare the samples, the samples are then placed in the thermocycler for PCR. The new approach saves both time and cost while maintaining confidence in the accuracy of results. The automation function allows laboratory staff to set up tests, load the system and return later for results, making it easier to integrate PCR into busy laboratory schedules. One of the challenging steps when implementing new technology into a workplace is getting workers or

technicians on board with the project.

Dixon explained that Thermo Fisher Scientific does not simply provide equipment and leave customers to operate it independently.

“We offer training while looking after the diagnostic side of the

implemented technology. This was followed by weekly calls and refresher training sessions by specialised staff. Dixon said that technical support “lowers the barrier” for companies to adopt advanced molecular methods.

“We offer training while looking after the diagnostic side of the business and troubleshooting problems, Additionally, we provide ongoing support services to ensure our customers can effectively utilise the technology.”

business and troubleshooting problems, Additionally, we provide ongoing support services to ensure our customers can effectively utilise the technology,” he said.

With CCEP, the company provided an initial training session to ensure the laboratory was confident with the newly

With the food and beverage sector facing stricter regulations alongside growing consumer expectations around safety and sustainability, traditional microbiological testing, while effective, often struggles to keep pace with the demand for rapid

product turnaround and traceability.

With PCR, a laboratory’s approach to pathogen detection is transforming, offering speed and accuracy that align with modern manufacturing needs. Simplified systems such as SureTect Automation Workflow are part of Thermo Fisher Scientific’s long-term goal to make food microbiology more user-friendly in the food and beverage industry. By partnering with businesses such as CCEP, Thermo Fisher Scientific demonstrates how advanced molecular technologies can be integrated into routine food testing.

“What Thermo Fisher Scientific wants to do is to make life easy for laboratories,” said Dixon. “If you are looking to make a change, don’t be afraid to ask for help because that’s what we’re here for.” F

For more information please reach out to ANZinfo@thermofisher.com

Manufacturers risk discarding large volumes of food without accurate records and monitoring.

A single recall can lead to food waste, financial losses, and reputational harm. Digitalisation and smart process monitoring can ease the burden for manufacturers.

Food and beverage production has always carried strict requirements around hygiene and safety, yet the risks and costs of failures remain high. In 2023, Food Standards Australia New Zealand (FSANZ) coordinated 87 product recalls, many caused by contamination or undeclared allergens. Take for example a berry recall that happened in 2015. This publicised recall saw $3.8 million worth of product destroyed and an additional $9.4 million lost in recall costs and revenue.

One of the issues lies in outdated systems. Manual checks, paper records and unreliable sensors continue to be common across facilities. National product sales manager at ifm, Akmal Yang, provided an example with faulty temperature sensors. A faulty temperature sensor in a freezer or storage unit

leaves uncertainty over product integrity. Without accurate records or alternative monitoring, manufacturers may have no choice but to discard large volumes of food.

“This means a lot of wastage and possibly delaying your production schedules, which can itself risk reputational damage,” said Yang.

“There are environmental concerns, as well as you’re throwing food literally down the drain.”

At the same time, regulatory requirements are becoming stricter. Calibration of thermometers must now be accurate to within one degree Celsius, with checks every six months.

Since February 2024, allergen labelling had to follow a defined Plain English criterion. These rules reflect consumer expectations for transparency, placing more responsibility on producers to adopt technologies that maintain compliance.

According to Australia’s national science agency, CSIRO, many facilities still rely on manual observations and paper-based checks despite growing complexity in compliance. For example, paper chart recorders with pens remain in use, creating gaps in data caused by human error.

Temperature readings may be noted once or twice daily, making realtime correction difficult. Such tools offer only delayed insights, leaving manufacturers unable to act quickly when conditions drift out of range.

The limitations of traditional approaches that depend on human judgement lacks precision. Although there is a factor of reluctance to adopt new technology and tools, another problem lies in expensive costs of replacing old equipment to the modern equivalent. However,

these minor errors can lead to contamination, especially in stages such as mixing and filling. While modern conductivity sensors can differentiate between product and cleaning fluids more effectively than manual checks, Yang highlighted that manual processes still dominate in the industry.

Undetected equipment wear runs the risk of jeopardising food safety and can be combatted with predictive maintenance.

One of the foundations for food safety and compliance is digitalisation. Smart sensors provide constant monitoring of pressure, temperature, flow and vibration, generating accurate, realtime data. This allows abnormal trends to be identified at an early stage before they lead to

spoilage or contamination.

While worn seals or bearings that shed particles into the product stream do not immediately cause operational shutdown, they affect product quality by introducing potential contamination. Predictive maintenance, enabled by digital systems like modern sensors, addresses these risks by providing alerts before failure occurs.

Artificial intelligence (AI) strengthens this approach by analysing historical performance of

a sensor or system. Through this, it can understand normal patterns and detects irregularity, predicting future failures. AI can identify when a component is likely to wear out, giving maintenance teams time to plan interventions without disrupting production. By helping preserve equipment and product consistency, predictive maintenance also helps manufacturers reduce waste and meet sustainability goals.

water and energy.

In the past, producers would overcompensate by cleaning longer or at higher temperatures to ensure compliance. With accurate monitoring, cleaning cycles can be optimised, reducing power and water use.

“A well-functioning digitalised sensor system means you don’t have to do more than necessary,” said Yang.

Safety and sustainability go handin-hand. Research by the World Economic Forum showed that smart process monitoring not only improves safety but aids in reducing food loss and resource consumption. IoT-based temperature control can cut food waste by up to 40 per cent while smart clean-in-progress (CIP) monitoring minimises excessive cleaning practices that use additional

Despite these advantages, many businesses hesitate to adopt digital solutions due to perceived cost or complexity. However, Yang explained that unlocking value often comes down to integrating systems into already existing hardware in facilities. By making better use of available data, off-the-shelf solutions can simplify this transition and reduce the need for custom-built systems.

To support food and beverage manufacturers in food safety, ifm’s

ifm’s range of tools are designed to simplify safety and reduce downtime.

range of tools such as LW Radar, a non-contact level measurement, or IO-Link, a digital communication standard that enable detailed diagnostics, are designed to simplify safety and reduce downtime. Offering training to educate customers through its ‘lunch-and-learn’ programs and hands-on sessions, ifm aims to help customers adopt manual habits and modern digital practices.

Food manufacturing often faces high staff turnover, making it essential that systems are easy to learn. Modern platforms are designed to be intuitive, and with proper training and support, adoption can be smooth. Manufacturers that provide education alongside technology can bridge the gap between longstanding manual habits and modern digital practices.

With regulators, consumers and international markets demanding higher levels of assurance, the pressures on Australian food and beverage businesses will continue to grow. Outdated manual systems that are prone to errors cannot provide the visibility or responsiveness required.

Food safety, sustainability and operational efficiency are part of a single approach. To tie these priorities into one, digitalisation, smart sensors, and predictive maintenance are becoming essential tools. By embracing smarter systems, manufacturers can reduce waste, protect consumers, and safeguard brand reputation. F

Treotham Automation is helping companies navigate environmental regulations by providing alternatives to PTFE and PFAS while maintaining performance in demanding applications.

The evolving technological advancements in Australia’s food and beverage manufacturing sector are nothing new. Every day, challenges are addressed with solutions that improve processes, from sourcing and production to packaging and delivery. One company trying to streamline processes is Treotham Automation, which has offered a range of automation solutions for more than three decades.

Established in 1992, Treotham began as a small enterprise supplying industrial automation products. Today, it has grown into a national distributor of energy chains, chainflex cables, polymer bearings and flexible conduit systems. The company has long-standing partnerships with international manufacturers such as igus and PMA and manages distribution through a network of warehouses across Australia, stocking

more than 10,000 products.

In the food and beverage industry, where hygiene, safety and sustainability are paramount, Treotham Automation supplies products designed to meet the strict demands of the sector. With its national footprint across Sydney, Brisbane, Melbourne and Perth, the company highlights the role of “motion plastics” in ensuring highquality, efficient and sustainable manufacturing.

Treotham Automation’s focus on automation control and systems tailored to different industries is closely tied to motion, which always carries the risk of wear. Maintenance is one of the biggest challenges in food and beverage manufacturing, particularly due to labour costs and downtime. Resistance to corrosive

cleaning agents and the ability to withstand extreme temperatures are equally important in food processing. When faults slip through in manufacturing, the result can be wasted production time or even irreparable damage. Treotham’s partnership with igus helps address these issues by ensuring hygiene in food and beverage manufacturing.

German-based igus specialises in motion control components and polymerbased bearing solutions for multiple industries, with many of its products approved for food applications. Its motion plastics are designed for low maintenance and long service life while reducing the need for external lubrication. With the help of low-wear polymers, components for industrial movement

including energy chains, cables and linear guide systems, improve both durability and efficiency.

For example, igus’ iglidur coating powder can be applied to metallic surfaces to protect stressed

areas from wear. The tribologically optimised polymer powder, which is tested according to DIN EN ISO 9227 with salt spray, demonstrated corrosion protection quality after 480 hours of testing.