techniques are tackling the rising costs of AI’s energy demands

Chris Weber, VP and MD of HPE South Pacific

As enterprises accelerate their AI investments, the energy demand of AI’s power-hungry systems is worrying both the organisations footing the power bills as well as those tasked with supplying reliable electricity. From large language models to digital twins crunching massive datasets to run accurate simulations on complex city systems, AI workloads require a tremendous amount of processing power.

Of course, at the heart of this demand are data centres, which are evolving at breakneck speed to support AI’s growing potential. The International Energy Agency’s AI and Energy Special Report recently predicted that data centre electricity consumption will double by 2030, identifying AI as the most significant driver of this increase.1

The IT leaders examining these staggering predictions are rightly zeroing in on improving the efficiency of these powerful systems. However, the lack of expertise in navigating these intricate systems, combined with the rapidity of innovative developments, is causing

heads to spin. Although savvy organisations are baking efficiency considerations into IT projects at the outset, and are looking across the entire AI life cycle for opportunities to minimise impact, many don’t know where to start or are leaving efficiency gains on the table. Most are underutilising the multiple IT efficiency levers that could be pulled to reduce the environmental footprint of their IT, such as using energy-efficient software languages and optimising data use to ensure maximum data efficiency of AI workloads. Among the infrastructure innovations, one of the most exciting advancements we are seeing in data centres is direct liquid cooling (DLC). Because the systems that are running AI workloads are producing more heat, traditional air cooling simply is not enough to keep up with the demands of the superchips in the latest systems.

DLC technology pumps liquid coolants through tubes in direct contact with the processors to dissipate heat and has been proven to keep high-powered AI systems running safely. Switching to DLC has had measurable and transformative impact across multiple en-

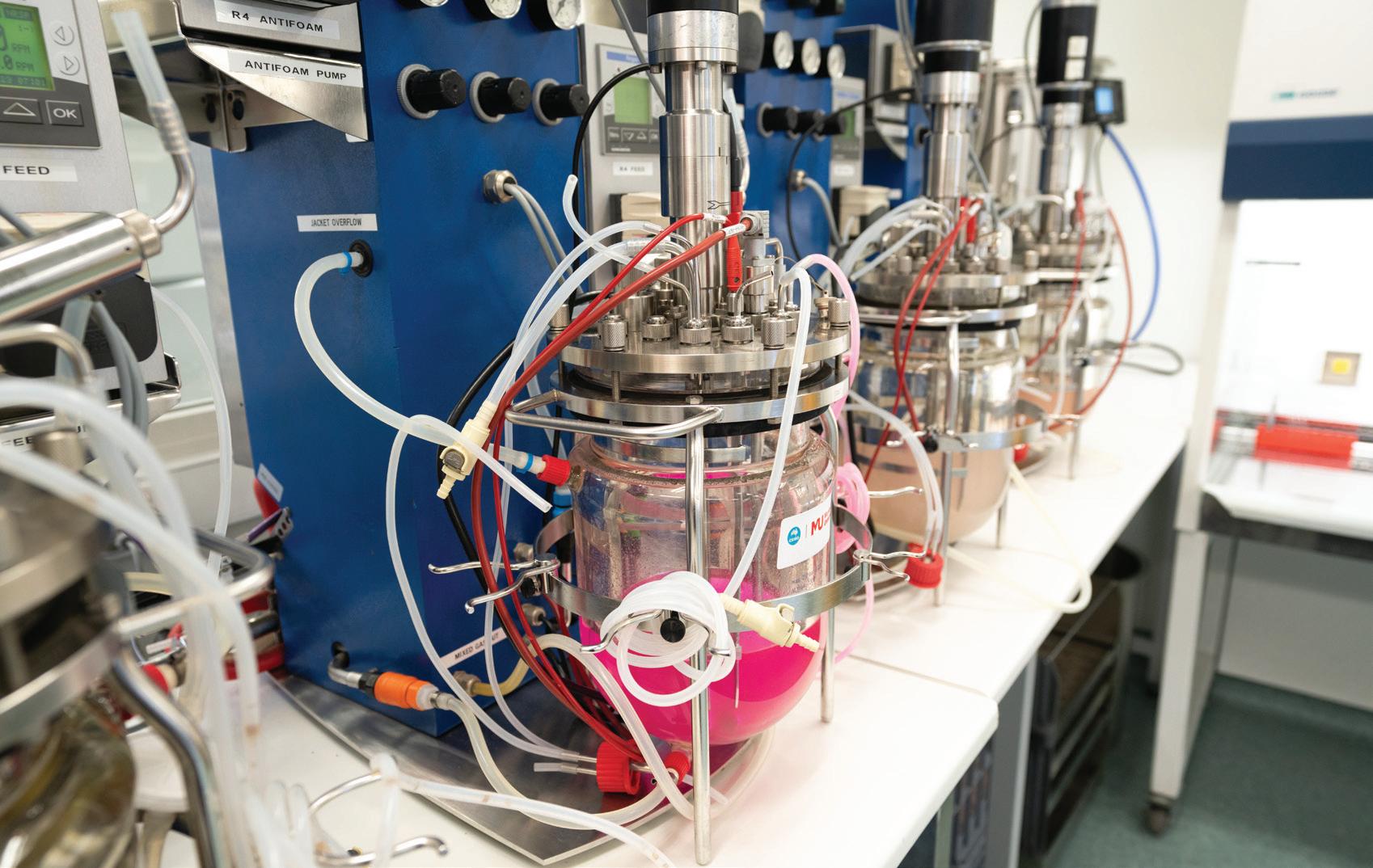

Bredel hose pumps, part of Watson-Marlow Fluid Technology Solutions, has engineered the new Bredel Heavy Duty pump with advanced safety and reliability features specifically for the mining and construction sectors. For mining companies that prioritise protecting their employees and the local environment, while ensuring reliable operations in the toughest conditions, Bredel has designed the Heavy Duty pump for an enhanced level of safety and durability.

The Heavy Duty pump is a perfect peristaltic pump solution for handling abrasive high-solid content slurries, thick sludge and corrosive fluids due to its enhanced features:

• Heavy duty frame that enables safer pump transportation using a forklift truck

• Heavy duty bearings that provide an extended lifetime when pumping high-solid content slurries

• Window guard that offers extra protection

• Robust flange bracket that reduces the risk of lubricant leakage and simplifies maintenance

• C4H paint coating that brings superior resistance in highly corrosive environments and protects against acids, bases

Jose Longo, Head of Process Industries, APAC, WMFTS, gave his input: “By handling the unique challenges mining companies face around the world, the Heavy Duty pump enhances productivity, making it a safer, more efficient, reliable and sustainable solution for the toughest conditions.”

Bredel hose pumps has recently switched its painting process during manufacturing from solvent-based paints to waterborne paints, resulting in a 90% reduction in volatile organic compounds (VOCs) emissions. Grace Madden, Bredel Product Manager, said: “The Bredel Heavy Duty pump offers exceptional safety and durability for mining and construction companies, significantly reducing downtime and increasing efficiency. Its advanced features ensure reliable performance in harsh environments, preventing costly downtime.”

The Heavy Duty pump can be used for: slurry transfer with minimal wear and tear; precise chemical dosing to enhance operational efficiency; dewatering to avoid the risk of flooding and environmental damage, and for safely transporting tailings to ensure compliance with regulations. In a nutshell, Bredel Heavy Duty Pump not only meets the tough demands of the mining and construction industry, but the pump also contributes to sustainability by reducing environmental risks and leaks, lowering energy and resource use, and supporting safe, circular and efficient industrial processes.

Our reliable and efficient peristaltic pump technology for mining procedures can achieve water savings of 71% compared to typical centrifugal pumps. Clog-free, robust and reliable Bredel hose pumps can handle undiluted tailings and thickener underflow with up to 80% solids. As Bredel hose pumps do not have seals, they eliminate the need for water flushing, so reduce the treatment of process wastewater and the need for pump service water.

Watson-Marlow Australia team will be showcasing Bredel Heavy Duty Pump at Booth D25 at the International Mining and Resources Expo, 21–23 Oct at ICC Sydney, Australia. For further enquiries please contact the team at info.au@wmfts.com or +61287871400.

Bredel is the market leader in hose pump technology for transferring viscous and abrasive fluids and solids. Bredel users enjoy sustainable, low maintenance performance through an advanced, robust pump design which includes a precision manufactured hose. Bredel peristaltic pumps and hoses are used for a wide range of applications in the mining, industrial, water and wastewater and food and beverage industries.

Bredel is part of Watson-Marlow Fluid Technology Solutions (WMFTS), a Spirax Group company. WMFTS is a world leader in manufacturing peristaltic pumps and associated fl uid path technologies for the life sciences and process industries. Further information can be found at www.wmfts.com.

Watson-Marlow

Richard Roberts, Beacon Events

Shifting end-of-life tyres into advanced recovery pathways could unlock tens of millions in added resource value each year.

Vast tailings dams, gianttyre burial grounds and leaky water stewardship will all be regulated out of mining’s future. Tyre Stewardship Australia’s Lina Goodman thinks one part of that future could be just around the corner.

The TSA CEO described the recently released National Project on Options for End-of-Life Tyres as a significant piece of research into how Australia managed used tyres, including more than 100,000 tonnes of tyres buried at mine sites each year.

The Western Australian Government-led project reported that a national industry-led Tyre Product Stewardship Scheme was gen-

erating benefits but fell short in key areas. The scheme was set up to boost resource recovery and recycling and to minimise environmental, health and safety impacts of used tyres. But to achieve more a regulated framework was vital, according to the TSA.

“As with all voluntary schemes it faces inherent limitations including free riders, the ongoing cost burden on communities and missed opportunities for advanced manufacturing,” the body said.

“For the first time, governments now have a substantial evidence base to inform next steps. TSA calls on federal and state environment ministers to progress to a comprehensive cost-benefit analysis of a regulated product stewardship scheme for tyres.

“This is a pivotal moment to secure better environmental, economic and industry outcomes.”

Australia is a major global market for ultra-class surface mining trucks and the industry’s biggest underground vehicles. It has been one of the world’s largest markets for off-the-road (OTR) tyres, which can cost US$40,000 each, for 50 years.

The International Council on Mining and Metals (ICMM) said earlier this year improving circularity in mining was critical to achieving a “net-zero, nature-positive future” underpinned by responsibly sourced materials.

The council, whose members include a number of the world’s largest mining companies, referenced a 2023 TSA report that indicated the industry accounted for 80% of an estimated 245,000 tonnes of OTR tyre, conveyor belt and vehicle track waste generated annually.

“Yet less than 5% of OTR tyres used in mining are recovered,” the ICMM said. “Mine sites are reliant on a range of resources and produce a number of different waste streams. A key waste stream is tyres, essential components of haul trucks and other vehicles used to transport ore and other materials.

“Circularity can be an important approach to meeting the [minerals and metals] demand required for the energy transition while limiting waste production and its impacts on the environment. Through the development of new and innovative approaches, tyre waste and associated environmental impacts can be reduced and new value unlocked.

“But close collaboration between industry, local communities and stakeholders is key for circular strategies to succeed.”

TSA’s 2023 report said Australia’s OTR tyre market was forecast to grow at more than 6% a year from 2022–2027. Its latest

annual review again highlighted a “tale of two sectors”, with about two-thirds of the 537,000 t of end-of-life tyres generated in the country in 2023–24 recovered through reuse, recycling or energy recovery. An estimated recovery rate of 87% was achieved for passenger, truck and bus tyres, but only 13% for mining and agriculture OTR tyres. For mining alone the recovery rate was put at less than 5%, with most waste buried onsite.

Goodman said available data shows mining presents a “complex picture of excellence and failure”. When mining companies recover tyres they demonstrate a commitment to circular outcomes by prioritising repair and high-value recycling. However, recovery rates are miniscule. “The mining industry does the right thing when they recover tyres … but they shouldn't get a free pass to bury 109,000 t annually onsite while every other industry faces strict waste disposal requirements. That’s not sustainable and it’s not fair,” she said.

She said Australia’s high on-road tyre recovery rate also masks “an underlying failure to create genuine circular economy outcomes” since more than half of Australia’s recovered tyres were used in fuel and other energy applications, much of them offshore, and not recycled into products with continuous lifecycles. Recycling capacity is a barrier, but wider changes are needed to accelerate change.

“Australia's accredited tyre recyclers should be commended for their pursuit of end-of-life tyre recovery in the passenger, truck and bus sectors,” Goodman said.

“They’ve built collection networks and processing infrastructure that works, and proven that high recovery rates are achievable when there’s commitment to proper stewardship.

“The challenge is extending this success to the mining sector, which generates the heaviest tyres but has the lowest recovery rates.

“Each sector has half the solution.

“The passenger, truck and bus tyre value chain has mastered recovery logistics but needs to focus on circular value.

“Mining knows how to create better circular economy outcomes but lacks recovery infrastructure.

“Although the overall recovery rate of mining tyres is low we’re seeing encouraging signs that mining companies are demanding — of themselves and their downstream partners — greater circular outcomes for the valuable resources contained in tyres.

“If this current trajectory continues, the mining industry will drive significant improvement in the reuse and recycling of tyres in Australia.

“We believe it’s now time to give TSAaccredited recyclers the reins to support the OTR sector and show the world that Australia can set the pace in transforming how we manage these giant tyres.”

Intelligent public policy and regulated product stewardship can speed this process, TSA believes.

It said the WA Government-led tyre management project report “identifies a critical opportunity for governments to expand recovery systems and stimulate higher-value markets”.

“Shifting end-of-life tyres into advanced recovery pathways could unlock tens of millions — and potentially more than A$100 million — in added resource value each year.”

Goodman said, “Nothing will change unless government steps in with proper regulatory measures.

“Every tyre we export for tyre-derived fuel is a missed opportunity for resource recovery, local jobs and investment. We have the collection systems, we’re building the end markets and we have companies committed to doing the right thing: we just lack the regulatory backbone to make it happen.

“Now is the time to unlock the full potential of this industry and show that Australia can lead the world in tyre circularity — not just recovery rates, but genuine circular value creation.”

‘The challenges of making circularity business as usual’, an important panel discussion at this year’s International Mining and Resources Conference + Expo (IMARC) in Sydney, will feature Goodman; Vale’s general manager, future use, Gustavo Roque; Viva Energy Australia’s head of future fuels and decarbonisation, Vanessa Lenihan; and Katherine Courtney, principal adviser, strategy and growth, at consulting firm Xenith.

The Off-the-Road Mining Tyre & Belt Forum, hosted by TSA, will also be held during IMARC, which runs from 21–23 October at ICC Sydney.

For more information and to register, please visit https://imarcglobal.com/events/tyre-stewardshipaustralia-off-the-road-mining-tyreand-belt-forum

igus is converting the range of its standard energy chain series E2.1 to the recycled material known as igumid CG LW. The E2.1 energy chain series now consists of post-consumer recyclate, such as old fishing nets and discarded energy chains, which are recycled and processed into recyclate as part of the in-house ‘Chainge’ program.

Not only do the energy chains have mechanical specifications that are comparable to those of standard chains, they are also available at the same price as the previous E2.1 series. Even in terms of wear behaviour, stability and continuous flexing cycles, the updated chains provide the same quality.

Compared to the standard material, the recycled material has an 80% lower CO2 footprint. The series is also characterised by a long service life, particularly quiet operation, and easy filling and installation.

An online platform was added back in 2022 to the recycling initiative, through which customers can also recycle other components made of technical plastics while purchasing processed material in the form of regrind and regranulate. In addition to taking back old energy chains, igus also takes back old material as part of assembly orders.

Treotham Automation Pty Ltd www.treotham.com.au

The Dimetix D-Series Laser Distance Sensors are designed to measure long distances with precision and speed, even in difficult situations. The series can measure on dark surfaces — even in exterior applications with solar irradiation.

Designed for industrial applications, the series provides a measurement rate up to 250 Hz; 1 kHz update rate for real-time data acquisition; extended temperature range up to 60°C; and industrial Ethernet compatibility, supporting PROFINET, EtherNet/ IP and EtherCAT.

Now available in a modern design, the series measures distances of up to 500 m, with an accuracy of ±1 mm. It can used in a variety of industries, such as metal, wood, hydro tech, railways, paper, mining, glass, process, transport, automotive and cranes.

AMS Instrumentation & Calibration Pty Ltd www.ams-ic.com.au

The NH6000sc is Hach’s latest innovation in online ammonia analysis, delivering reliable, reagentoptimised performance for wastewater applications.

Built on advanced gas sensing electrode (GSE) technology, the NH6000sc helps ensure accurate and continuous ammonia monitoring, enabling operators to stabilise nitrification processes even under fluctuating influent conditions.

Engineered for minimal intervention, the analyser features automatic calibration, validation and cleaning, reducing routine maintenance to just twice a year.

Its verification grab sample is designed to ensure consistency with lab data, while predictive diagnostics and guided workflows support long-term operational uptime.

With lightweight, durable filtration options, the system supports robust sample handling and remote monitoring.

Designed for ease of use, the NH6000sc offers a user-friendly interface and simplified maintenance, making it suitable for municipal and industrial wastewater treatment plants aiming to improve efficiency and compliance.

Hach Pacific Pty Ltd www.au.hach.com

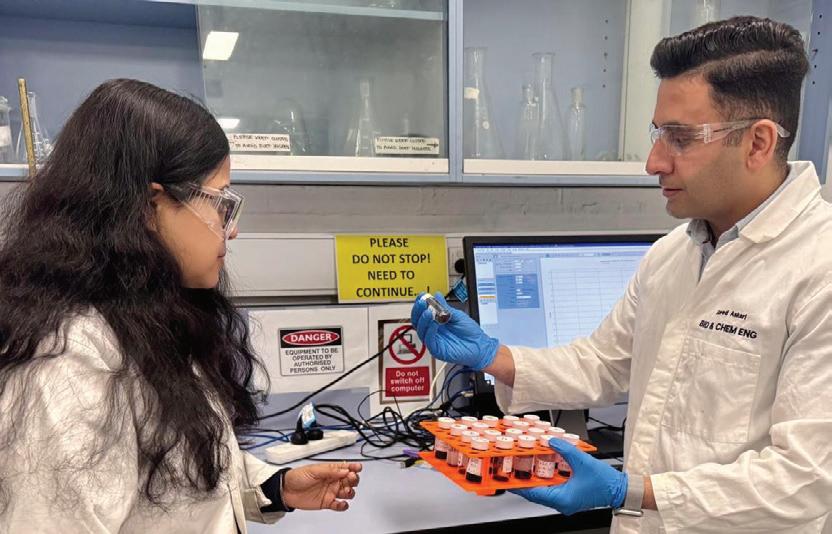

Monash University engineers have discovered a catalyst that could provide more power, longer life and lower costs for nextgeneration batteries.

While zinc–air batteries are currently used in small devices like hearing aids, this opens the door to rechargeable, high-power applications, moving the technology closer to real-world, grid-scale and transport uses.

Using a heat treatment, researchers have turned a 3D material into ultra-thin carbon sheets and added individual cobalt and iron atoms, creating a catalyst that makes the battery’s oxygen reactions much faster and more efficient.

Lead authors Saeed Askari and Dr Parama Banerjee, from the Department of Chemical and Biological Engineering, said it outperformed standard commercial catalysts made from expensive metals like platinum and ruthenium.

“By engineering cobalt and iron as individual atoms on a carbon framework, we achieved record-breaking performance in zinc–air batteries, showing what is possible when catalysts are designed with atomic precision,” Askari said.

“Our advanced simulations revealed that the cobalt–iron atom pairs, combined with nitrogen dopants, enhance charge transfer and optimise reaction kinetics, solving one of the biggest bottlenecks for rechargeable zinc–air batteries.”

Banerjee said the principles behind this design could also be applied to other clean energy technologies including fuel cells, water splitting and CO2 conversion.

“Running a rechargeable zinc–air battery continuously for more than two months is a milestone for the field. It demonstrates that this technology is ready to move beyond the laboratory and into practical applications,” Banerjee said.

“These catalysts not only solve a key bottleneck for zinc–air batteries, but their design principles can be applied across the energy landscape — from fuel cells to water splitting — offering broad impact for clean energy.”

Monash University www.monash.edu

Les Williamson, Regional Director Australia and New Zealand, Check Point Software Technologies

Security operations teams must increasingly do their bit to help their employers achieve environmental targets, which may require some system and strategic changes.

For several years now, annual sustainability reports by listed Australian companies have provided a window into cybersecurity strategies employed at these companies. But in spite of the report name, there is often no link between security and sustainability in the information presented.

As these reports cover environmental, social and governance (ESG) practices, addressing cyber risks comes under the governance piece. Yet, the security team — through its choices of hardware, software and services — has a contribution to make on the sustainability front as well.

It is commonly acknowledged that IT infrastructure and data centres are large

energy users. Teams in these spaces have worked to become more efficient: rightsizing infrastructure provisioning to fit workloads, utilising more renewable energy sources, hosting equipment in data centres that are rated to be efficient with power and water consumption and the like.

That same level of investment and effort is yet to be brought to bear on the work of the security team and their technology stack. One reason for this is likely to be the intense pressure that security teams are under to protect ever-increasing attack surfaces and ward off a constantly evolving spectrum of cyber threats.

But this is likely to change.

Security teams need to be prepared to contribute to more than the governance aspect of ESG — they need to contribute to the environmental goals of the organisation as well.

This is starting to be seen in several initiatives. These include the adoption and im-

plementation of more energy-efficient security systems, together with a greater emphasis on proactive and preventative security.

As with other types of information technology, it continues to be the case that the efficiency of security systems is improving over time with each iteration or update.

A key performance indicator is the energy consumption per gigabit of data throughput for a piece of equipment. Next-generation security gateways are a security-specific example of hardware that continues to get more efficient with each new generation of the technology.

As a case in point, a recent Check Point ESG report showed that a current-generation security gateway uses 73% less power consumption per throughput (Gbps) compared to the previous model. This reduction comes alongside a 112% improvement in threat prevention capabilities, meaning the newer

version is more efficient than its predecessor in multiple contexts, not just in energy usage concerns. And, to be clear, this kind of improvement is seen consistently between versions of systems.

This illustrates that next-generation security technologies can simultaneously enhance protection and energy efficiency. By aligning to this cadence of technology upgrades, organisations can consistently reduce their environmental footprint while maintaining effective security controls.

Proactive detection and remediation

Another beneficial strategy when seeking to run security operations more efficiently is to focus more on preventative and proactive forms of security.

The logic here is that reactively dealing with security incidents is an intensive exercise. It is taxing on the individuals that have

to perform this work, but also in financial terms. We know that the financial implications of a breach continue to increase over time.

One aspect of financial implication is the energy-intensive processes such as restoring backups, along with rebooting, restoring and/ or rebuilding entire systems.

Clearly, energy efficiency is not the primary goal of incident response. But from a broader ESG perspective, there is interest in organisations having strong cyber risk and security controls together with layered protections in place to mitigate against the risk of an attack, and/or to detect and isolate any infected infrastructure early on, such that any financial, productivity and bottomline costs can be avoided. As energy is a considerable financial input to IT costs, it makes sense not to add to these costs due to a cyber incident taking place.

Preventative measures are also required because some existing and emerging types

of attacks can run up big energy bills if they go undetected. Cryptomining malware, for example, remains a persistent threat despite its peak in 2018 when it affected 40% of analysed organisations. Even recently, malware such as XMRig has been detected targeting gaming engines. The collective energy consumption of cryptomining is estimated at a staggering 125 terawatt-hours annually — highlighting the need to quickly detect this kind of malicious payload before it can be used to run up a big bill.

Data poisoning in AI systems represents another emerging concern. These attacks compromise machine learning models, often requiring complete retraining to remediate — an extremely energy-intensive process. As organisations increasingly rely on AI-powered tools for decision-making, protecting these systems also means avoiding redundant and costly training cycles that consume substantial computational resources.

Cybersecurity is more than a governance play — it also has a growing role in helping meet the environmental aspects of an organisation’s ESG strategy. By considering the energy implications of security operations, maintaining infrastructure that is both secure and sustainable, and prioritising a proactive security approach, organisations can protect both their business interests and environmental resources.

Holding Redlich Partner Dhanushka Jayawardena, Associate Alice Wu and Undergraduate Giselle Croker

Recent tax initiatives are driving momentum in Australia’s renewable energy sector, with a raft of measures being introduced to help operators, developers and investors maximise tax efficiencies across existing and future clean energy projects.

The Future Made in Australia initiative, announced as part of the 2024–25 federal Budget, encourages investment in renewable hydrogen, green metals, low-carbon fuels, critical minerals and clean energy manufacturing. Central to this initiative are two tax measures: the Hydrogen Production Tax Incentive and the Critical Minerals Production Tax Incentive. Both incentives were introduced in the Future Made in Australia (Production Tax Credits and Other Measures) Bill 2024 passed in February 2025.

Another development is the proposed extension of the Clean Building Managed Investment Trust withholding tax concession to include data centres and warehouses. While initially proposed to commence from 1 July 2025, the 2025–26 federal Budget deferred the start date to the first 1 January, 1 April, 1 July or 1 October following Royal Assent of the relevant bill. At the time of writing, no draft legislation has been released.

The Hydrogen Production Tax Incentive (HPTI) is a refundable tax offset of $2 per kilogram of renewable hydrogen for eligible producers. It applies to income years commencing on or after 1 July 2027 but ending before 1 July 2040, subject to a maximum of 10 years. Jointly administered by the Australian Taxation Office (ATO) and the Clean Energy Regulator (CER), the incentive targets medium- to large-scale production of renewable hydrogen in Australia.

This program is separate from the Hydrogen Headstart Program, administered by the Australian Renewable Energy Agency (ARENA),

which supports large-scale renewable hydrogen projects through competitive hydrogen production contracts. Companies eligible for both programs will see reduced payments from the Hydrogen Headstart Program to reflect any refundable tax offset received under the HPTI, ensuring the two schemes work in parallel without duplicating benefits.

To be eligible, a producer must be a constitutional corporation subject to Australian tax and hold a production profile that allows for the issuance of a production guarantee of origin (PGO) certificate for the hydrogen produced. They must also comply with community benefit principles set by the Treasurer, including commitments to local communities, skills development, job security and tax transparency.

An eligible producer may only claim the tax offset in an income year if the hydrogen is produced in Australia between 1 July 2027 and 30 June 2040. The hydrogen must be produced within the facility’s 10-year offset period and at a single site in Australia with a production capacity equivalent to at least a 10 MW electrolyser. A registered PGO certificate is also required for each kilogram of hydrogen claimed, verifying that emissions intensity does not exceed 0.6 kilograms of carbon dioxide per kilogram of hydrogen, and that grid electricity, if used, meets grid matching requirements. The certificate must not be subject to correction by the CER.

The Critical Minerals Production Tax Incentive (CMPTI) provides a refundable tax offset equal to 10% of eligible expenditure for income years starting on or after 1 July 2027 and ending before 1 July 2040. This limited period applies regardless of how long a specific processing activity has been registered. There are currently 31 critical minerals eligible for the offset.

For income years commencing on or after 1 July 2012, a reduced 10% withholding tax rate applies to fund payments by Clean Building Managed Investment Trusts (MITs) to foreign investors from information exchange countries. To qualify, a building must be a commercial office, hotel or shopping centre with construction commencing on or after 1 July 2012. It must also meet and maintain either a 5 Star Green Star rating from the Green Building Council of Australia or a 5.5star energy rating from the National Australian Built Environment Rating System.

Investors, developers and operators across the clean energy sector are encouraged to obtain structuring advice early to ensure eligibility and to minimise the risk of losing access to the available tax incentives.

renewable energy, we reduce operational emissions and enhance energy efficiency.

A leading example of this is VicX Tower in North Sydney. It represents the future of commercial buildings by adopting a fully electric operating model. This ensures the base building is powered by 100% renewable energy, eliminating reliance on fossil fuels and reducing associated emissions.

We’re also advancing plans to upgrade existing building infrastructure by assessing technical feasibility and prioritising assets across our portfolio for all-electric retrofits, in alignment with our Mission Zero targets.

Grid stability and resilience is critical to keep pace with electrification. Building a grid that can adapt relies on balancing supply and demand, optimising energy storage through wind and solar and regulating response times to grid disturbances. Through upgrading our existing infrastructure and collaboration with suppliers, we are primed to support the broader energy transition.

One Melbourne Quarter has taken a significant step towards cleaner energy use with

the installation of a 200 kW rooftop solar PV system. The system supplies around 17% of the base building’s annual electricity needs, directly contributing to its market-leading 6-Star NABERS Energy rating. By generating renewable energy on-site, the building reduces its carbon footprint, showcasing our unwavering commitment to decarbonising operations through practical, scalable solutions.

But it’s not just about energy. It’s about nature. Tree canopy and vegetation can help mitigate urban heat effect, manage stormwater, promote carbon sequestration and support biodiversity. The vegetation lowers surface temperatures and boosts solar efficiency, a perfect harmony of technology and nature.

Public spaces are fundamental to these changes. At Melbourne Quarter, over 50% of the precinct is dedicated to green and open areas. At its heart is Sky Park — Melbourne’s first elevated park, boasting 75 m of urban greenery in the centre of the city.

Decarbonising construction practices and materials is also critical. We are moving towards our goal of fossil-fuel free con-

struction, prioritising electric construction machinery and equipment and using biofuels such as biodiesel and renewable diesel where electric options are not available. At Melbourne Quarter West residential, we are using renewable diesel to power a stationary concrete pump. As of March this year, using renewable diesel in place of mineral diesel has saved 30 tonnes of CO2, which is equivalent to 420 Sydney–Melbourne flights.

Decarbonising supply chains is one of the biggest challenges we face. Reducing embodied carbon in common construction materials like steel, cement, glass and aluminium requires the focus and investment of the whole value chain. We continue to specify, procure and trial lower carbon materials and develop tools to measure impact. Our inhouse Lendlease Embodied Carbon Advisor (LECA) tool is aimed at helping project teams set and deliver project-specific embodied carbon targets.

Decarbonising our cities is a complex but urgent undertaking. Not only an environmental imperative, but a shared responsibility that demands a system-wide shift, reliant on government policy, industry innovation and community engagement moving in lockstep. At Lendlease, we’re committed to driving this change by embedding sustainability into every stage of development. By electrifying our buildings, investing in greener infrastructure, adopting circular practices and reimagining our public spaces, we’re proving that progress is possible. The solutions exist; what we need now is the collective will to accelerate them.

The Bioplastics Innovation Hub (BIH), a joint venture between Murdoch University and CSIRO, is responding to the plastic waste crisis with the development of a bioplastic alternative that vanishes over time — leaving no trace on land or in water.

The BIH brought together microbiology, molecular genetics, synthetic biology and biochemical engineering experts with advanced manufacturing to develop bioplastics alternatives.

BIH director Professor Daniel Murphy said creating “completely compostable products” for the food industry was a priority, and working with industry partners would lead to a more seamless transition from the lab to the shelves.

“A key product that industry is asking for is a compostable lining for recycled paper or cardboard-based food packaging,” Murphy said. “In market currently, for example, there are some packaging products made from waste materials that are compostable. However, they can only be used for foods with outer layers such as eggs and fruit.

“Foods without a natural protective layer require packaging to have a plastic lining to be ‘food safe’. If this lining was made from bioplastic, it would meet industry requirements, be welcomed by consumers looking for greener alternatives, and leave no lasting legacy in the environment.”

Murphy said some of the Hub’s most promising research uses microorganisms native to WA, which could help to create a robust circular economy.

“Synthetic plastics break down into microplastics — and those microplastics can move through the water, they can move through the food chain, they even move through the atmosphere through clouds,” Murphy said.

“We’re looking at plastics that are biodegradable and environmentally benign as in they’re not having any impact on the

environment. And that’s really important because otherwise we’ll continue to have a build-up of plastic in terrestrial environments on land and in the oceans — which is obviously not what we want for future generations.”

And the answer to the green alternative may come from within WA’s unique environment, with WA scientists using microbes found in local environments to make these bioplastics. BIH researcher and PhD candidate Harrison O’Sullivan is among those working with these naturally occurring microbes.

“At the moment, we’re working with some pretty cool bacteria we’ve pulled out of the environment ... Australia-made as you might say,” O’Sullivan said.

“A lot of these microbes are living in a wild state. They don’t often know where their next food is going to come from — so, in circumstances where they have a lot of extra food, what they’ll do is begin storing organic molecules within the cell, and then we recover these molecules to make the bioplastic material.”

In the WA Government’s 10-Year Science and Technology Plan 2025–2035, a research priority and focus area is “recycling for a circular economy”. BIH environmental microbiologist Dr Sakshi Tiwari said the Hub’s goals were just as ambitious for industry, and the community.

“We are hoping to reach a level where bioplastics and biopolymers reach every household. I believe it’s a longer-term plan, but will be our end goal,” she said.

The Murdoch University Bright Lights story, ‘Solving the plastic waste crisis’, can be viewed in the video below. Murdoch University www.murdoch.edu.au