CFMOTO

CFMOTO

This is a celebration of success — thanks to your hard work and our dedication to you.

Together, we’ve achieved 1 million tyres sold and shaped 1 million stories.

A million more are waiting to be written. Try Agri Star II and start creating your story now!

10 CFMOTO is rewriting the rules for farm-ready ATVs and UTVs, with a broad product portfolio suited for varying agricultural needs, backed by a local dealer network

6 Machinery and tech on show at FutureAg in Melbourne

54 New releases among the highlights from AgQuip 2025 in Gunnedah

15 Mahindra launches new OJA compact tractor range

19 Viva Energy and Shell Rimula heavy duty diesel engine oils keeping machinery running

22 M idwest harvest platforms built from inspired idea

24 JSG Industrial Systems offering tools for hassle-free machinery lubrication

26 JCB dealer Michael’s Group committed to aftersales support

Editor Lincoln Bertelli

lincoln.bertelli@primecreative.com.au

Journalist Jackson Haddad

Contributors Trevor Whittington, Gary Northover

Design Danielle Harris, Jacqueline Buckmaster

Art Director Daz Woolley

Managing Editor Eugene Duffy

Cover image Mahindra

30 NSW farmer’s McCormick tractor and Orsi mulcher working together

34 Veldonas pumps tackling water shortage issues for farmers

40 Narrow tractors help Antonio Carraro excel in horticulture setting

37 DLL finance solutions powering agribusiness GO.FARM’s growth

42 Spreyton Fresh growing with Achmea Farm Insurance partnership

46 A BARES tipping bumper year ahead for industry

47 Newest Nuffield scholars aim to transform Australian agriculture’s future

48 Survey finds farmers mostly optimistic about season ahead

48 Government puts $1 billion into farm hardship loans funding

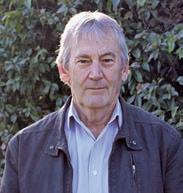

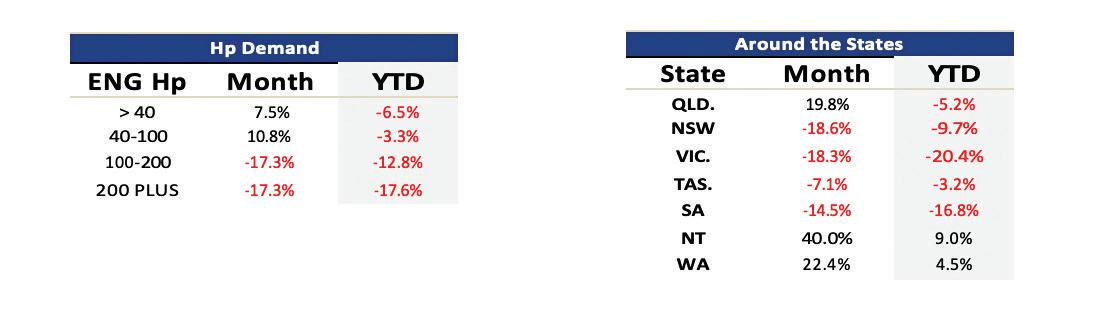

49 Smaller horsepower tractors enjoyed a sales rebound in August, date from the Tractor & Machinery Association shows

50 WAFarmers CEO Trevor Whittington says regional skills shortages are only getting worse, with overseas solutions meaning more challenges and red tape

4 Editor’s note

52 Calendar of upcoming events

74 List your item for sale!

Big Forklifts recently supplied a gantry crane for precast concrete on a major project

There is never a quiet month in Australian agriculture and this is certainly no exception.

As attention starts turning to harvest around the country, we also take a look at some recent events which have occurred.

AgQuip was another highlight, despite heavy rains during part of the event creating some muddy surfaces for exhibitors and visitors to contend with.

We take a look at an extensive array of machinery being displayed during that event, along with some of the unique products and technology which visitors could check out during the second ever FutureAg event in Melbourne.

Another event to take place was Mahindra’s launch of the OJA tractor.

Held on the Gold Coast, this follows on from the Indian manufacturer teasing its launch on last month’s cover.

Farms & Farm Machinery was at the launch to bring you everything you need to know about this new machine designed for hobby farmers.

Plenty of customer testimonials feature in this edition, including one from a New South Wales property owner who purchased a McCormick tractor after reading about it in Farms & Farm Machinery earlier this year.

Our cover story focuses on CFMOTO, which is boldly rewriting the rules for farm-ready ATVs and UTVs thanks to its broad product portfolio suited for varying agricultural needs.

JCB dealer Michaels Group is profiled, along with an extensive look at how Midwest harvest platforms have been developed and perfected, plus a snapshot at some of Antonio Carraro’s unique horticulture tractors.

It is important to look beyond the machines themselves, also considering the other vital elements which are needed to keep Australian agriculture running.

To do so, we delve into the story of an Achmea Farm Insurance customer to learn the importance of trusted insurance providers, along with the story of how DLL has powered an Australian agribusiness’ growth.

Pump supplier Veldonas talks about its water cart pump and engine sets, while Viva Energy – the Shell Lubricants Macro Distributor in Australia – shares the importance of highquality engine oils.

We also hear from JSG Industrial Systems about the need to keep both large and small farm machinery consistently lubricated during its operation.

Our industry news section includes a look at ABARES’ promising predictions for the year ahead while celebrating the latest group of Nuffield scholars.

Lincoln Bertelli Editor

After switching from May to August, there was a noticeable increase in crowds during FutureAg’s opening day.

The event, powered by leading German event Agritechnica, featured a wide range of agricultural technology from both local and overseas companies.

This technology, which includes everything from satellite navigation systems to mapping programs, aims to be a showcase of the innovations which will shape farming’s future.

It is complemented by a range of popular agricultural machinery such as tractors and telehandlers from various manufacturers, with more than 100 exhibitors inside the hall.

Here are some of the machinery highlights during the event:

The Multifarmer 44.9 was one unit which Merlo chose to display at FutureAg.

Supported by several key members of its Australian team, Merlo was there to tell customers about the unique Multifarmer features which combines the benefits of tractors and telehandlers.

This particular unit offers a 9m lift height, 4,400kg maximum lift capacity and 170hp engine, and has the greatest lift height of what Merlo offers locally within the Multifarmer range.

Comfort, efficiency, performance and safety are the four areas which Merlo says has been crucial to the machine’s development.

Lubricants provider JSG Industrial Systems displayed a range of its products, particularly those designed for smaller machinery.

This included the Automatic Electric Cartridge Pump, which takes the hassle out of lubrication by providing small amounts of grease throughout the day to machinery while it is operating.

Melbourne’s Showgrounds hosted the second FutureAg expo in August, with a trade show complemented by a conference

It is just one example of an automated system which JSG has the know-how to provide, and which can prevent major problems through undergreasing or overgreasing valuable machinery.

Other items on display were the OCL-M oil chain lubrication, and the SKF Lincoln Power Luber.

While the manufacturer may not have had a formal stand at FutureAg, New Holland’s T7.300 tractor was still on display after being introduced at last year’s event.

The T7.300 was introduced to offer a heavier and bigger framed tractor with more power but the same manoeuvrability.

This unit delivers 280hp rated power and a maximum of 300hp, with its 6.7L engine making it well equipped to handle big jobs.

It was also upgraded with New Holland’s Precision Land Management Intelligence that provides features such as IntelliSteer autosteering, IntelliTurn and ISOBUS compatibility.

An array of real-world fire suppression systems were being showcased by MusterFire.

These included compact foam systems, which can easily attach to machinery and provide an instant source of protection from issues such as overheating.

Different options are available for

everything from tractors to harvesters to slashers, with some integrated systems providing fault alerts and monitoring to prevent issues.

MusterFire also gave visitors the option of booking a free fire risk assessment for

team highlighted its fire suppression range

with

Allynav robot

Alllynav displayed its Aries300N orchard spraying robot, which is also suitable for the likes of vineyards and forestry sites.

This hybrid fuel-electric robot incorporates GNSS satellite navigation, autonomous driving and obstacle avoidance to deliver accurate and consistent spraying.

Its crawler chassis and compact design help with precise turning and comfortable operation of slopes of up to 30 degrees.

Remote control operation and real-time monitoring makes this a safe and efficient option for tricky spraying jobs.

Spread-a-Bale range

British made products were also represented thanks to Spread-a-Bale.

Designed as a new, efficient and safe way to spread straw, the machines also took centre stage during the tech demos and showed how a bale can be discharged within one minute and with minimal dust.

The company says its machines can spread all types of round and rectangular bales with up to 50 per cent straw saving and 75 per cent labour saving.

Low maintenance and running costs are highlighted as benefits, along with improved health due to minimal dust and an easy-to-operate design.

Landforce leveller

Landforce had the Sports model of its laser land leveller on display.

This was one of multiple machinery types which the Indian manufacturer showcased, along with disc harrows.

The land leveller uses a guided laser beam throughout the field to deliver even results and improve the land’s capability.

A heavy-duty frame is backed up by a host of features including a long scraping blade.

robot

The Robotti from AgroIntelli is described as an autonomous implement carrier which is designed for both horticulture and general farming.

It enables precise and accurate planting, with high capacity and efficiency enabled by the autonomous operation without a driver.

Soil, plant and operational data are also documented, giving farmers all the information they need about the machine’s performance.

It helps to reduce soil compaction, while safety features such as virtual fencing and radar obstacle detection are also included with farmers notified of any triggers.

Hangcha displayed one of its new additions – an X Series diesel telehandler.

This unit has a 4,000kg lift capacity and offers operational modes such as fourwheel crab steer, two-wheel front steer and four-wheel circle steer.

There is a maximum speed of 35kmh,

along with a full-proportional joystick, ergonomic suspension seat and 17cm display that provides real-time monitoring.

The telehandler range complements an array of forklifts with Hangcha is known for and which was also on display.

The 754-B tractor from Hanwo caught the eye for many visitors.

This 75hp unit is powered by a Quanchai diesel engine offers 4WD operation and 12 forward and reverse gears.

Front and rear counterweights boost traction and balance, while dual-speed PTO and two rear hydraulic remotes make it ideal for implement connections.

A full cabin with suspension seat and ergonomic layout makes it a comfortable tractor for users.

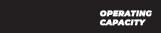

CFMOTO is rewriting the rules for farm-ready ATVs and UTVs, with a broad product portfolio suited for varying agricultural needs, backed by a local dealer network

Australia’s rural sector doesn’t reward pretenders. Machines earn their keep by starting every morning, towing without fuss, and surviving years of dust, mud and fence lines.

That’s the arena CFMOTO Australia has leaned into, and why the brand’s off-road vehicle footprint has expanded so quickly across the country’s farms and stations.

Backed by a global business founded in 1989 and headquartered in Hangzhou, China, CFMOTO brings serious scale and engineering horsepower to the paddock.

The company now employs more than 8,000 people worldwide and has built one of the fastest growing powersports portfolios on the planet.

Global revenue reached more than US$2.1 billion last year and keeps rising.

That momentum matters locally, it translates into sustained product investment, supply stability, and the

ability to tailor vehicles to Australian conditions rather than simply shipping a “global” spec and hoping for the best.

Three significant streams underpin that work – engines, electrification and intelligence.

On engines, decades of liquid-cooled development have delivered the stout, tractable torque that farm work demands.

The company has invested in electrification since 2017 to build true workhorse EVs rather than show-pony concepts, paving the way for lower running costs and zero-emission operation in sheds and tunnels.

In terms of intelligence, the CFMOTO RIDE digital platform connects owners to their vehicles and a suite of practical functions, which is part of an ongoing effort to make machines easier to live with through improved information.

Scale only counts if it reaches the farm

gate. CFMOTO’s manufacturing footprint spans five plants across China, Thailand and Mexico, with global capacity exceeding one million units annually.

For Australian buyers, that footprint underwrites a steady cadence of ATVs, UTVs, and SSVs across CFMOTO’s CFORCE, UFORCE, and ZFORCE families, as well as the ability to deliver rolling improvements quickly when local feedback identifies opportunities.

Australia is not a “weekend-toy” market. Here, off-road vehicles are tools first, recreation second.

Through distributor Mojo Motorcycles, CFMOTO has invested considerable effort in local testing, feeding valuable learnings directly back to the engineering teams.

The brief is simple – make the next unit better than the last in the ways that matter

beyond the dealership car park – cooling, gearing, sealing, towing, and ergonomics.

That farm-first mindset is reinforced on the ground by a national network of more than 100 dealers who live the realities of regional service and parts support.

CFMOTO’s product spread is deliberately broad to cover every chore.

Youth and mid-capacity CFORCE ATVs handle light property duties and stock work, while higher-displacement models bring the grunt for spraying, fencing and heavier towing.

ZFORCE side-by-sides cater to properties that need speed across distance or access to rougher terrain, while UFORCE UTVs provide payload and protection for all-weather jobs, featuring cabins designed for long days and easy-to-reach service points that simplify maintenance.

Many Australian farmers have opted

for the UFORCE UTVs, specifically the U10 Pro range, as these models feature enhanced power, advanced technology and a redefined design.

Two distinctive models make up the range, the standard U10 Pro and the U10 Pro Highland, with operator features differentiating each other.

Both models boast the same performance capabilities, however the Highland variant includes extra comfort options, such as a sealed cabin with a full heating, ventilation and air conditioning system, electric tilt glass windshield, and full doors with electric windows.

This makes it well-suited to farmers who demand the ultimate comfort and capability in any climate and weather conditions, while the standard U10 Pro is a more cost-effective option.

Electrified options are also ramping up, providing stations, councils, and

businesses with new levers to reduce emissions and cut fuel and servicing costs over the vehicle’s life.

CFMOTO recently launched its first pure-electric UTV, the UFORCE U6 EV, offering farmers a machine with no engine fumes and near-silent operation.

The lack of emissions and noise produced by this electric UTV make it ideal for sensitive environments and early morning starts, which can be particularly beneficial for farms with livestock.

Customer feedback has already been overwhelmingly positive, with one Victorian sheep farmer experiencing several benefits from the electric option.

“The key standout was the silent operation during lambing season,” the farmer says.

“It was a blessing in disguise, no longer startling mobs of sheep, easily conducting stock checks and the ability of doing all the other jobs in between.”

Capability is only half the equation; durability and simplicity complete it.

CFMOTO’s latest platforms focus on practical touches that farmers and station managers keep asking for.

This includes robust driveline components, sealed electrical connectors, drivetrain cooling suited for heavy towing at low speeds, and cabins that are designed for a dog and a toolbox as often as for a passenger.

Just as important, accessories – such as windscreens, roofs, winches, and spray rigs – are engineered as system solutions rather than afterthoughts, which makes dealer fit-out faster and ownership tidier.

Australia’s quad bike and UTV buyers

are vocal, so listening to customer is of the utmost importance for CFMOTO.

It’s why the brand shows up where its customers are, attending more than 30 agricultural field days and regional shows every year.

Those conversations, paired with back-to-back comparisons, expose weak points quickly and highlight the value farmers expect for their money.

to minimise downtime during lambing, seeding, or harvest.

It’s the kind of investment that shows respect for the work these machines do.

In addition to the range of ATVs, UTVs, and SSVs, CFMOTO is renowned for its ever-growing motorcycle range with key players in the off-road adventure market, including the popular 450MT and new 800MT-X models.

Where to from here? CFMOTO’s roadmap is clear – continue to expand the product portfolio, remain aggressive in R&D, and capitalise on electrification and intelligent features that reduce downtime and simplify fleet management.

Globally, the company is scaling manufacturing in new markets and doubling down on quality systems, while the local focus remains the same as it

CFMOTO’s UFORCE UTVs provide payload and protection for allweather jobs, featuring cabins designed for long days

Mon 1 - Thu 4 Jun e 202 6

Adel a id e Con ve n tio n Cen tre 1 - 4 J un e 202 6 Ade l aid e Conve ntio n C entre

Mahindra has officially launched its latest Australian tractor range and is excited about the impact it can have on the subcompact and compact markets

Its name comes from a Sanskrit word meaning “powerhouse of energy”, and this is an apt moniker for Mahindra’s newest tractor range.

The OJA series was officially launched to the Australian market last month, with dealers from around the country converging on the Gold Coast to see the tractors in person.

Farms & Farm Machinery was invited to attend the launch, where figures including Mahindra’s head of global product planning, head of tractor product planning, and Australian national manager spoke with passion about the new product.

The OJA series of tractors is very much aimed at hobby farmers, lifestyle properties and maintenance jobs such as mowing.

Mahindra has built its title as the world’s largest tractor manufacturer by volume sold through targeting this lower horsepower market and constantly refining its products around what users in this segment need.

After about five years without a fresh launch to the Australian market, the manufacturer has returned with a bang by offering a product which it says offers

best-in-class features in several crucial areas including power, strength, price and warranty.

The Australian range begins with the 1123 and 1126.

A 25hp engine on the 1126 compared to 23hp on the 1123 is one of the immediate differences, however many of the other specifications are the same.

These include a 420kg loader lift capacity, two-range hydrostatic transmission, 25L fuel tank capacity, 28.7L/min pump capacity, 11.7km/h maximum speed, Category 1 three-point linkage, and 735kg overall weight.

On the 2126 model, which is a larger machine, the overall weight increases to 980kg, loader lift capacity jumps to 580kg – along with an impressive 800kg lift capacity at the hitch, while there is a 42.3L/min pump capacity.

While the tractors may be in the smaller categories, they are still power packed and aim to provide the grunt needed for Australian agricultural usage.

“One feature that is important is the

power to weight ratio, because it’s a lighter tractor,” Mahindra’s head of global product planning Ravindra Shahane says.

“For places like golf courses or landscaping, you don’t want to leave a mark on the ground, so you need to have a lighter weight tractor.

“All of this range is four-wheel drive, which is important on the agricultural side where you need to work with muddy conditions and you need a lot of power available on your wheels.”

It is when looking at some of the unique selling points of the OJA range that the attention to detail Mahindra has applied to the design becomes clear.

One such feature, while in some ways simple, shows this clearly.

Start assist is a series of four lights on the dashboard that must all be green before the engine will turn on and has been added in recognition of the fact many OJA users will be first-time tractor buyers rather than lifelong farmers.

“To start a tractor, unlike a car, you need three or four things to be in neutral,” Shahane says.

“It can be very difficult for first time users to find out what’s not in place, so the smart assist is an indicator which tells you which one particular thing needs to be done before the tractor will start.”

Another small detail is a feature called ‘follow me home’, where the headlights will stay on for another minute after turning the engine off to ensure visibility remains when wrapping up a day’s work in potentially dark surrounds.

The attention to detail even extends to having colour-coded controls, with everything related to power takeoff in one colour, everything for motion in another and general applications in a different colour altogether – another simple feature which improves the userfriendliness for new operators.

Push button PTO removes the need to operate that aspect with a lever, while there are safety features to ensure it cannot be misused.

Many of these features will be particularly helpful for the first few times an operator sits on the tractor – or if a family member is sharing the load.

Shahane also highlights the operator experience as a benefit, with tests having been done to ensure farmers with large feet are still comfortable and spacious.

“The platform which the operator is using – the operating pedals and levers –is an area where we feel we have done a great job,” he says.

“The seat is extremely comfortable and there is tilt and telescopic steering like a car, which most other tractors don’t have, so that’s a unique proposition.”

Omkar Nabar, Mahindra’s head of international product planning for all markets outside India, says the OJA range is designed for “ease of operation, comfort and versatility”.

“There are features like start assist panel, the twin HST panels, the cruise control so you can run at a constant speed,” he says.

“You have colour-coded controls, you

have the push button PTOs - all that will make it easy to operate.

“You have the loader joystick too, so you can see the easily fold your armrest and put your arm on it and comfortably operate the tractor.”

Two other elements which Mahindra is keen to highlight are price and warranty.

The 1123 is available with a loader and four-in-one bucket for $23,490 – a figure the company describes as best-in-class – with the 1126 listed as $25,490 and the 2126 at $27,900, each with the loader and bucket. These are Recommended List Prices, excluding pre-delivery and freight.

Across the range, there is also a three-year comprehensive and six-year Powertrain warranty as standard.

The Mahindra team is clearly excited to have the OJA tractors in Australia, following launches in some of its other key markets around the world.

It has been in the United States for about 18 months, where feedback on the tractors

as a whole and many of their unique features have been positive.

All of this leaves Ankit Taneja, who heads up Mahindra’s agricultural business in Australia, confident that OJA will stack up well in the local market.

“On many of the features, we have the best-in-class performance parameters,” he says.

“The weight of the tractor is one of the highest in that segment, and the loader lift capacity is again way higher than the competition.

“Similarly, if you look at the lift capacity, it is one of the best in the segment.

“We are offering a great value proposition, plus a phenomenal warranty so that it brings peace of mind to farmers.

“Multiple features are best in class at a very competitive price because we really want to aim for a high market share in this highly competitive and price sensitive segment.”

The OJA range is available nationwide through Mahindra’s dealer network.

Viva Energy, the Shell Lubricants Macro Distributor in Australia, proudly supplies Shell Rimula R4 X 15W40 – a heavy-duty engine oil formulated with Shell’s innovative Dynamic Protection Technology

As globalisation reshapes agriculture and rising equipment costs tighten margins, farmers are feeling the pressure more than ever.

Yet, Shell Lubricants’ latest global research reveals that nearly half of farmers miss regular equipment maintenance and it is only when their equipment breaks down that they realise the effect on their operations.

As a result, 8 out of 10 farmers are forced to spend hard-earned income on repairing broken and unreliable machinery.

Australian farmers often operate in extreme conditions ranging from heat, cold and dust across all seasons with the pressure of maintaining food security in the agriculture sector.

This is why choosing the right lubricant is vital in maximising operational efficiency while also protecting your equipment for operations to run smoothly.

Choosing the wrong lubricant for your machinery and equipment can cause breakdowns and accrue costly repairs and maintenance, quickly putting the engines out of service and causing unnecessary downtime on the farm.

Shell is one of the most well-recognised oil and fluid brands in the world, and Viva Energy, the exclusive distributor of Shell brand lubricants in Australia, makes these

products available for your machinery and equipment needs.

Whether it’s a tractor, harvester, plough or seeder, Shell has developed a unique product range that assists operators in ensuring careful management and maintenance of their engines.

When developing a new lubricant, Shell Lubricants undergo rigorous rounds of tests, in the widest possible range of conditions to ensure products are developed for the real world.

One of the most widely used products in the Shell Lubricant range in the agriculture sector is Shell Rimula.

This lubricant not only improves engine and oil durability but also helps to lower maintenance and increase reliability in machinery and equipment.

Shell Rimula is developed with Shell’s Dynamic Protection Plus Technology to create exceptional resistance to corrosion, wear and oxidation while producing lower equipment and machinery emissions.

This technology is also versatile in a wide range of environments providing protection against acid and deposit build up to keep engines working hard and longer.

“In extreme Australian temperature conditions, lubricants with good thermal stability and oxidation resistance are

essential,” Viva Energy technical adviser Silvana Farrugia says.

High shear stability helps prevent lubricant breakdown to ensure excellent load-carrying performance.

As part of the development process for today’s Shell Rimula, based on the API CK-4 engine-oil specifications, over 160 million kilometres of road-tests were run in the USA, Europe, China, Australia and other markets.

The Shell Rimula R4 range is engineered to protect engine integrity and efficiency, helping heavy-duty machinery to perform reliably and last longer.

Formulated with Adaptive Additive Technology, it adapts to varying engine conditions to deliver dynamic protection. This helps to safeguard engines against wear and acid corrosion which can be harmful to engine life, thus lowering maintenance costs and increasing vehicle reliability.

Shell Rimula R4 range allows farmers to plan for engine maintenance cycles with confidence, with some service intervals ranging from 200 to 500 hours depending on equipment.

It is essential to note that Oil Drain Intervals (ODIs) are determined by the equipment manufacturer (OEM), not the oil supplier.

Operators must always follow the OEM-recommended service intervals as outlined in the product manual.

Any extension of ODIs should only be considered in consultation with the OEM and supported by Used Oil Analysis to ensure engine protection and optimal performance year-round.

In particular, Shell Rimula R4 X excels within the Shell Rimula R4 range.

It is designed to provide triple protection targeting key areas such as acid and corrosion, wear control and deposit

control, to help keep engines clean and critical engine components working.

Additionally, it is suitable for most low emission engines and for use with biodiesel as per OEM-recommended oil drain intervals.

Protecting the performance of exhaust emissions control systems is not only important to ensure that machinery comply with legislative requirements, but it also ensures operational efficiency.

To learn more about the Shell Rimula R4 range, reach out to Viva Energy Australia (Shell Lubricants Macro Distributor) at 1300 134 205 or technicalhelpdesk@vivaenergy.com.au

A grandfather clock might have little to do with harvesting crops, but it provided the inspiration for a successful Australian product – Midwest harvest platforms

Inspiration can often strike in the most unlikely ways.

It was the impact from a tyre blowout during harvest almost 30 years ago, combined with the concept of a grandfather clock, that has led to Midwest harvest platforms being a staple of Australian farming.

Founder and harvest platform designer Martin Schutt and his family’s determination saw the first ever Midwest platform come to life in 1998 and the company has been at the forefront of innovation since, including becoming the first to develop a 60-foot (18.3m) platform.

Martin tells the story of how the tyre blowout incident became the catalyst for him realising there needed to be a better way than what was available.

“We were at the stage where everyone was only running 30-foot (9m) platforms – that was as big as you could buy – but another thing that really magnified in my head was the fact the platform was rigid to the combine,” he says.

“We were harvesting a fairly light

crop and sitting on about 11km/h and physically blew a front tyre on the header, which was just flattened in a millisecond.

“The header just dropped down and it actually pirouetted the combine about 30 degrees from there, because you’ve got huge tyres on the front of the headers.

“When you’re running quite fast and low to the ground in a light crop, suddenly the end of the platform that the tyre blew on very severely impacts the ground and half pirouettes the header around.

“That was the catalyst for change, and one of the thoughts that kept ticking over in my mind was that we needed some way to make them freely oscillate on the combine.”

Recognising the need for change was one thing, but it took Martin’s know-how – plus applying the concept of physics – to have his ‘Eureka’ moment.

“When you start mucking around and looking at things, physics makes it simple,” he says.

“Look at the grandfather clock – it has a big pendulum and it doesn’t matter which way you land the clock, the pendulum always hangs straight down.

“That’s where the idea of the pivot ball being mounted on top of the feeder house came from, and the platform being balanced so there is equal weight on both sides.

“That way it doesn’t matter what the header does, the platform stays at the same height doing its own thing.”

This means that while the platform is feeding the combine, any movement of the header does not affect the platform and vice-versa.

Midwest platforms are built as a pendulum, Martin says, which is suspended horizontally and with springs strong enough to support them if a header or platform dips over a contour bank.

The first Midwest platform was built as an internal test for themselves, with Martin deliberately buying a new combine

harvester without a platform knowing he was going to trial a concept.

Its success led to encouragement to develop, patent and commercialise the product, while winning an award for new innovation at FarmFest in his native Queensland was another major step forward.

One of Midwest’s key points of difference, which was developed early on, was repositioning the cutter bar.

This patented design was an inspired move and has been the catalyst for an overall size increase in platforms for the industry.

“Everyone was restricted on overall width because of weight, and the Midwest design and patent allowed that weight to move back and sit on the top of the feeder house instead of hanging forward of the feeder house like everyone else,” Martin says.

“That’s what allowed us to start going to 45-foot and 50-foot platforms, and then we pushed the envelope out to 18.3m.

“We released the first 18.3m platforms in for sale in 2014 and some people told us we were crazy, but it was just based on demand.

and Durus models, both of which are available in sizes up to 18m.

The Legacy is purpose-built for John Deere X9 1000 and X9 1100 Series combines, while the Durus is compatible with a range of popular combine brands.

Both are designed for high-output harvesting and offer consistent performance; with Midwest’s innovative design and local manufacturing meaning farmers can be confident in the long-term strength no matter what Australia’s harsh conditions provide.

Nowadays, Martin is semi-retired but

concepts or innovations that Midwest is working on.

As for what is next – Martin believes a maximum width of the platforms has been reached due to the challenges it would cause with unloading combines.

“We’ve got people who are wanting to go wider than 18.3m but I think it’s reached the point where you ask how do you unload?” he says.

“We’ve worked our way around how to unload with 18.3m platforms, because some of the new combines will do that

JSG Industrial Systems has the products and know-how to take the stress out of machinery lubrication for all Australian farmers

Farmers know that any machinery downtime is costly, particularly at harvest time, but also at any point of the year.

While not every possible scenario can be planned for, ensuring machinery is correctly and adequately lubricated is one way of avoiding unnecessary and costly breakdowns.

For smaller farms, where there may only be one tractor or other type of machinery, these stoppages can sometimes mean a total shutdown of operations until the problem is fixed.

JSG Industrial Systems has the products to ensure farmers can avoid these issues, with much of its range also being automated to ensure the greasing largely takes care of itself.

One example of this is through the SKF Lincoln Automatic Electric Cartridge Pump (AECP).

Designed for smaller tractors and telehandlers, it is described as a simple and compact unit which can be placed directly on to the machine.

It automatically does what JSG describes as the most important element for farmers to consider with any lubrication system – providing small but progressive amounts of grease throughout the day to ensure ongoing lubrication.

“We’re trying to introduce is the idea that regular greasing or periodically greasing a machine is better than doing it once a day, because when the machine isn’t working it

doesn’t really need grease,” JSG lubrication sales manager Branco Zivic says.

“When the machine is working and you apply the grease, that’s when it is more effective than anything else.”

The AECP works with standard 400g grease cartridges, meaning the only regular requirement for a farmer is to replace the cartridge when it is empty.

A built-in visual, low-level sensor provides an early warning of this, while a small footprint of the actual unit makes it ideal for compact machine applications.

It operates for one minute every hour, therefore providing ongoing lubrication, and has an estimated lifespan of 5,000 machine operation hours.

Machinery lubrication can often be an area neglected by farmers amid the array of daily tasks that need to be completed.

Pushing the problem down the line or only applying some grease at the beginning of the day are both scenarios which JSG says can cause long-term issues.

Both undergreasing and overgreasing are not desirable, Zivic adds, with either of these likely to lead to difficulties.

Undergreasing can cause increased wear and tear – plus potentially complete operation failure – with a one-off greasing before a long day of machinery use often creating similar problems as the grease runs out later in the day.

Overgreasing can lead to issues where

much of the product is wasted, which also means more money has been spent than needed.

JSG also says farmers who manually grease their machinery often do so until they can see grease coming through the cavities, which is a telltale sign of overgreasing and can result in those parts of the machine overheating within a couple of hours and damaging the bearings.

Recognising the challenges around getting the right amount of grease to all necessary parts of a machine – including those which can be tricky to physically access – and also doing so without taking a considerable amount of time out of every day, JSG says the modern systems which automate the lubrication process have proven to be a winner.

The AECP is one example of an automatic system which takes the daily work out of machinery lubrication, however JSG Industrial Systems’ range extends beyond this.

Lincoln and Faicom are two well-known brands which JSG stocks, with Faicom’s offering including compact and portable grease dispensing kits.

These are available as either carry or trolley kits, where the handle is directly fixed to either the pump or to a stable trolley.

Designed to be combined with hose reels up to 15m long, the doubleeffect pumping system allows regular

distribution and greater flow, along with improved efficiency.

The Lincoln lubrication range includes the P502 system, which is a small, simple and compact pump that can handle several lubrication points while not requiring much room.

Economical operation is at the forefront with the P502, which also has progressive divider valves to distribute grease to the required areas such as bushes, pins and bearings.

Another SKF Lincoln product is the Compact Lubrication Pump (CLP), which is another automated system designed to be reliable and affordable for simple lubrication tasks.

Lincoln also offers the Quicklub system, which is an advanced and customisable offering for machinery including large combine harvesters.

One Queensland customer who installed a Quicklub system had the harvester serviced after a full year of operation, with the ongoing greasing revealing that most of its bushes and bearings were in “perfect condition” and did not need replacing.

This factor, along with the reduced time spent on lubrication every day, is why JSG recommends farmers consider automatic systems for their machinery.

Pre-assembled kits help to minimise installation time, while the wide range of temperatures which they can handle mean that even the hardest-working machine in the toughest of Australian conditions will not be compromised.

The full range of lubrication products available can be viewed at www.jsgindustrial.com

Australia’s largest JCB dealer Michael’s Group has four branches throughout Victoria and southern New South Wales, which are all deeply committed to providing the best aftersales support

With more than 60 years of history over four generations, family-business Michael’s Group has built a reputation as one of the most trusted agricultural equipment suppliers in Victoria and southern New South Wales.

The business is a specialist dealer of Simplicity Australia seeders, Bernard van Lengerich (BvL) feed mixer wagons, and parts for Boss Agriculture, but perhaps what its most known for is being a dealer of JCB machinery.

No matter how large or small its customers’ operations are, Michael’s Group has something for everyone with a full comprehensive range of JCB agricultural and construction equipment available, including telehandlers, tractors, wheel loaders, skid steers, backhoe loaders, and excavators.

This range is on offer across all four Michael’s Group branches, including its originating store in Donald, Victoria – known as Michaels of Donald – along with NSW-based Michaels Moama and Victoria’s JCB Gippsland and JCB Ballarat.

Michael’s Group technical sales representative Dan Brown says these branches have contributed to the business becoming Australia’s largest JCB dealer.

“We cover a large area throughout Victoria and southern New South Wales,” he says.

“Our Ballarat branch has recently opened a brand-new state-of-the-art depot.”

One of the most popular machines sold by Michael’s Group are the JCB telehandlers, thanks in large part to their farming-specific models.

Available in Agri, Agri Super and Agri Pro variants, customers can choose a model that suits their specific needs, with the main differences being the horsepower and features available.

“JCB is the number one selling telehandler in Australia for sales and units on-farm,” Brown says.

“That’s because there’s a model for nearly every application in the agricultural industry. From a small

and compact machine needed to fit into a chicken shed, or a large machine to move serious amounts of hay, JCB has something to suit everyone’s specific needs.”

The JCB Fastrac tractor series is another popular machine sold by Michael’s Group, which have become a household name since entering the Australian market.

As the name suggests, these tractors are renowned for their speed. The top-of-therange iCON 8330 boasts a 348hp (260kW) engine, enabling speeds of up to 70km/h – making it the fastest production tractor in the world.

This is complemented by a 10-tonne rear lift capacity, allowing the JCB tractor to make light work of even the largest implements.

By having this speed and pulling power, farmers can drive long-distances between faraway paddocks, all while getting their jobs done efficiently.

Operator comfort is second-to-none on the Fastrac tractors, with the iCON cabin offering 360-degree visibility, an

adjustable screen, seat, armrest and configurable controls, climate control, plus a heated and ventilated seat.

“We sell the most Fastracs of any JCB dealer in the country,” Brown says.

“They’re sold into all different applications, whether it’s silage contractors or broadacre cropping farmers, we’ve got them everywhere.

“I’ve seen them pulling tow-behind sprayers, spreaders and muck spreaders, butterfly mowers, you name it – the Fastracs have been doing it all.”

Michael’s Group often also sees the JCB construction machines including the wheel loader and backhoe models being

ensire the job can always get done properly.

This is evident through the business’ demonstrations, which enable its customers to get behind the wheel of a machine to test it for themselves before making a purchase.

Brown has done many of these JCB demonstrations, particularly with the Fastrac tractor models and the Agri telehandlers, often videoing them with drones and uploading the footage to his TikTok page.

“The demos are just something we offer as the norm and we can do them for any machine on the customer’s farm,” he says.

“I’ll show the customer how to use the product and then leave it with them for two or three days so they can get a proper taste of what they’re looking at.”

Once a machine is purchased after a demonstration, Brown heads back to the customer’s farm to help with the installation process and to provide serviceability training – further highlighting the Michael’s Group’s focus on aftersales support.

“I go through every single button on the machine to make sure the customer knows what each one does, so they get the most out of the machine,” he says.

“I recently showed a group of workers at a corporate farm how to do their daily and weekly checks on a machine to reduce the risk of potential breakdowns and for general maintenance and upkeep.

“We’ve also got an extensive workshop with all the special tools required from the manufacturer, along with skilled technicians that are fully equipped to service the JCB machinery range.”

Michael’s Group’s commitment to providing the very best aftersales support is reinforced by JCB itself, with the manufacturer paying close attention to customer feedback.

“The beauty of JCB is that they always listen to feedback, so if there’s something being said by customers and dealers that needs to be changed, they act on it and make that change 99 per cent of the time,” Brown says.

“That’s because the best people to test their machines are the customers that are driving them to do their job.”

JCB machinery is distributed in Australia by JCB CEA’s extensive dealer network, which includes Michael’s Group. To find your nearest outlet, visit www.jcbcea.com.au or call 1300 522 232.

Australia’s No1 locally built mulcher for the last 25 years. Available in Low Body or High Body models in various sizes. Great for clearing up paddocks and bush blocks.

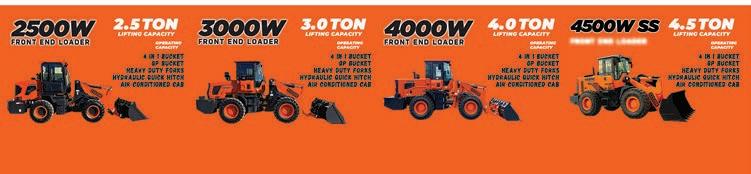

The best value for money Front End Loader mounted post hole digger on the market. Standard with Eurohitch connection with other styles available. Various augers sizes and types available

Large range of linkage and trailing disc ploughs to suit all tractors and applications.

Aerate and level your arena with this strong and versatile arena rake. Can be used for cultivation or grooming.

Australian Made slashers with 5 year gearbox warranty. Various sizes and models in single and twin rotor set-up. Great value and strength. Also available in galvanised.

10 ‘ & 12’ Trailing Grader Blades. 2000kg in weight Best value for money blade of its type

Huge range of linkage models available also.

Discovering the McCormick X4.120TM tracked tractor might have been by chance for John Gowing, but its on-farm purpose will ensure bushfire trails are not left to chance

Some agricultural machinery purchases are made after months of detailed research, talking to fellow users or upgrading from a model that has already been tried and tested.

For New South Wales property owner John Gowing, it was an article in Farms & Farm Machinery earlier this year which made him realise exactly what he needed.

McCormick’s X4.120TM crawler tractor was highlighted in the April edition after joining Clark Equipment’s stable, with

the national distributor highlighting its versatility and ability to be used with attachments such as mulchers.

While reading this, it dawned on Gowing that the X4.120TM – which he added a bulldozer blade to – was the perfect solution to a current problem while potentially also being an investment into protecting multi-million dollar assets.

Before discovering McCormick’s newest tractor, Gowing says there was a “big problem” at a farm that his wife owns.

A tornado came through last year which caused a “tremendous amount of damage” to established forest, with about 400 full height gum trees being snapped off, spun around and thrown everywhere.

While the need for a clean-up job after such an event is obvious, it became even more important as it was impacting the property’s fire trails.

The chain of events that led to the McCormick purchase began when Gowing’s wife found somebody who owned a tracked loader with a forestry mulcher on the front.

Keep your tractors, skid steers, telehandlers and small harvesters running longer with compact lubrication solutions. From portable grease guns to automatic pumps, we make it easy to save time, cut costs, and prevent downtime.

“She got him to come to our place to do some initial tidying up because we hadn’t really done much work on the fire trails for a few years, due to it probably being overlooked and the weather being not suitable,” he says.

“I thought ‘that’s a bloody good bit of gear’, then I saw the magazine and realised I don’t really need that because the tracked tractor solved the same problem and it had a little bit more versatility.”

While the tornado damage accelerated the need for this clean-up work to be undertaken, Gowing also knew it was important to maintain the property’s fire trails before any serious incidents occurred.

As Australia nears summer and bushfire season, it is also a timely reminder of the need for farmers to be thinking about preparing their properties.

“Buying the tracked tractor was really for keeping all the trails, particularly the boundary trails, in order so you can drive on them, walk on them and provide protection during serious bushfire risk seasons, which we often have,” Gowing says.

“We couldn’t get the fire brigade in last year to do some burn offs because they said the fire trails aren’t well enough maintained, so we tried to get someone in to do that, but we couldn’t, so we just couldn’t make it happen – it’s like a catch-22.

“Now we’ve got the equipment to touch up the trails with a blade and to get rid of any small regrowth.

“Even though it was a fairly expensive purchase, I think in the end it was a good investment because you can save a multimillion dollar home and fences.”

McCormick’s X4.120TM is the largest model within the manufacturer’s X4 series of tracked tractors, and the only one

which Clark Equipment currently imports into Australia.

It offers a 112hp (82kW) engine that produces 420Nm of torque, and it was this additional horsepower offering over the smaller X4 models which made Clark Equipment so keen to bring it into the country.

It offers the option of rubber or steel tracks between 400mm and 450mm wide, which help to maintain a light footprint and minimise soil compaction while also handling difficult terrain.

Clark Equipment national product manager David Knoke said earlier this year that he believed it would suit a wide range of Australian customers.

“Customers are running discs, deep rippers, post drivers, backhoes and speeders on that particular unit, so it’s about having a bit more versatility,” he said.

“It also has front linkage, so it allows for a few options on the front like mulchers, pruners or trimmers, while we can also run blades, grabs and buckets.

“It’s not a dozer or anything along those lines, but being a more compact skid style of machine is definitely going to be a big selling feature.”

The X4.120TM also offers a Deutz AG 2.9L, eight-valve, four-cylinder turbo aftercooled engine, along with a mechanical transmission entirely designed and manufactured by McCormick.

Four gears in two ranges provide a total of 16 speeds forward and eight in reverse, while the tractor can be equipped with an overdrive or creeper.

This adds versatility by enabling the maximum speed range to be extended from 30km/h down to just 300m per hour, depending on individual requirements.

Operator comfort is also ensured thanks to a sound insulated and air-conditioned

cabin, while the driving platform is completely suspended from the wagon and engine compartment to provide total insulation from both heat and vibrations.

Reaching out to Clark Equipment about the McCormick X4.120TM also exposed Gowing to another brand distributed by the company – Orsi mulchers.

Manufactured in Italy – as McCormick tractors are – it was an Orsi HF210 Hulk Forrest FTL forestry mulcher which Gowing chose to pair with his new tractor to tackle the fire trails.

Designed for tractors between 80hp and 160hp, it is perfectly suited to the 112hp McCormick X4.120TM.

It offers a 192cm working width that makes it ideal for tackling everything from overgrown vegetation to branches and shrubs up to 27cm.

A double frame in Hardox steel ensures the mulcher’s strength, while the counter knives are also made from Hardox steel.

The FTL in its model name refers to Orsi’s Flanges Tool Limiter technology, which the manufacturer says ensures exceptional speed and performance with less power demand thanks to steel flanges that limit the depth of tool action.

It also offers spherical roller bearings and a double row of front protection chains.

Gowing was also full of praise for the service from Clark Equipment throughout the process, with multiple staff members coming to his property to help.

When the contractor who will be doing most of the driving was unable to attend on the planned training and handover day, Gowing says the Clark team agreed to come back so the driver could learn the intricacies of the McCormick tractor from them directly.

While the tractor was primarily purchased for maintaining fire trails, its versatility means Gowing can already see it being useful with other attachments beyond the Orsi mulcher.

“We’ve got slashers and other bits and pieces that could be fairly easily connected up,” he says.

“Because it’s got tracks rather than big tyres, it sits nice and low and has a much more minimal impact on the paddocks.

“We’re looking at doing a lot more horticulture at our place, like Australian natives, so it could be quite useful in helping plant that and keeping the groves maintained, so there are some potential future plans for it.”

Clark Equipment’s full range, including McCormick and Orsi, can be viewed at www.clarkfarmequipment.com.au

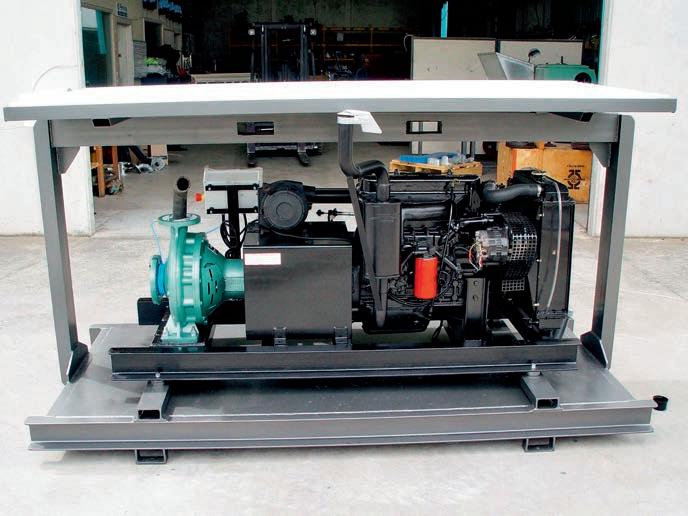

For farmers lacking a permanent water system, look no further than Veldonas’ water cart pump and engine sets

Having a reliable water source is a crucial aspect of every farm, but not all farmers have permanent or automated water systems.

Farmers lacking these types of systems may take up water carting – a practice which is more commonly seen in the civil construction industry for controlling the amount of dust generated on site.

Water carting on-farm can be significantly beneficial for a range of tasks, such as irrigating crops, delivering water to livestock which lack a natural water source, and for wash down purposes on dairy farms.

Melbourne-based pump supplier and water management equipment business, Veldonas, offers water carting pump sets in various sizes to help with this process.

“If you’ve had enough of rebuilding or replacing your old petrol-powered water transfer pump, we have the solution,” Veldonas director Gatis Gregors says.

This comes in the form of Veldonas’ Water Carters Special, which combines a Perkins diesel engine and a Rovatti pump to deliver more water and pressure.

Gregors says the choice of these two brands is all about providing the reliability required on-farm, ensuring minimal downtime.

“Perkins engines are highly reliable, they’ve been manufactured for many decades, they’re covered by a 24-month warranty, and parts are readily available,” he says.

“We use Rovatti a lot because they’re a trusted name and a high-quality Italian brand, with 12-months warranty on its pumps.”

Using this pump set, farmers can discharge the amount of water they want at different pressures. If set up correctly, it can also be used for pumping water into the cart and filling up the tank.

“This can be done by pulling up to a

water source and running the pump through different valve setups to fill up the tank,” Gregors says.

An electric start and stop are key features of the pump set, enabling easy cabin control. This can streamline the efficiency of the water carting process, as farmers don’t need to exit the cabin to turn the pump on and off.

Other features include a heavy-duty pump housing, large impeller for higher pressure, slow engine speeds to prolong its life, large oil capacity for reduced engine wear, and a close coupled design to reduce the overall length.

Not only does Veldonas offer this engine and pump set, but it can also supply ready-to-go water carts, including a truck with the pump set already installed.

Broader offering

Other agricultural solutions available at Veldonas include generators, repower

units, diesel engines for farm machinery, and customised pumps for frost and fire control, irrigation, effluent, and dust suppression.

All pumps can be complemented by Veldonas’ control equipment, offering customers greater optionality on their product.

For diesel equipment, Gregors says control equipment can include an oil and temperature watchdog, which protects the engine from lower pressure and high temperature, while other units may require timing, automatic start/stop and phone start/stop systems.

This ability enables customers to remotely operate their equipment and have greater control of its operation.

“Every job is different, so we can assist our customers in understanding their requirements,” Gregors says.

“We’ll ask questions about what flow rates and discharge arrangements they have, including pressures, and then we can come up with a solution.”

For more information, visit www.veldonas.com.au

The JCB 542-70S Loadall is the ultimate tool for a wide range of tasks with unmatched versatility. This isn’t just a telehandler; it’s an investment in your farm’s efficiency and output.

Why buy the 542-70S?

• Increased Productivity: Move more, lift higher, and stack smarter with 4.2-tonne lift capacity and 7-meter reach.

• Enhanced Safety: Superior visibility, stability, and control keeping your operators safe and your operations running smoothly.

• Fuel Efficiency: Advanced engine technology and hydraulics mean more work for less fuel.

• JCB Reliability: Backed by industry-leading support and parts availability, ensuring your machine is always ready for work.

D

Don’t compromise on performance, speak to your nearest JCB CEA dealership today!

For over a decade, Achmea Farm Insurance has been a trusted insurance partner for farmers across Australia.

It provides specialist, local, and direct farm insurance, dedicated to fulfilling its purpose of keeping farmers farming.

Among the thousands of agribusinesses

Achmea Farm Insurance insures is Spreyton Fresh, a fifth-generation family farm in Tasmania’s Mersey Valley.

With a rich history of innovation and resilience, Spreyton Fresh has chosen Achmea Farm Insurance to help protect its legacy as it continues to grow and diversify.

From local and personalised service to essential coverage like Business Interruption insurance, Achmea Farm Insurance has supported Spreyton Fresh to protect its operations and navigate the ups and downs of farming.

In this interview with Spreyton Fresh’s Michelle Distill, she highlights the importance of having a farm insurer that truly understands the unique challenges of agriculture.

Read on to discover more about this partnership, and how Spreyton Fresh is growing, innovating, and securing their legacy for generations to come.

We trace our roots back to the late 1800s when the first apple trees were planted in the valley, and we picked our first crop around 1904 or 1905.

My son Jorden has recently come into the business and is a fifth generation farmer.

The growth of our family farm has been an ongoing evolution, as we have adapted with the times and continued farming, while also expanding to grow cherries alongside apples.

This diversity in our products allows us to cater to different markets.

As any farmer would tell you, you can be at the mercy of what anyone is prepared to pay for your products. That’s just part and parcel of running a business, but that led to us diversifying.

In 1998, my brother decided to start making apple juice, leading to the juicing side of our business.

Then in 2012, we ventured into making alcoholic cider, facing challenges as we initially focused on products that we liked, rather than what had mass appeal.

This forced us to re-evaluate our approach and shift towards a more contemporary style of cider that resonated with the public.

In 2023, we underwent a major revamp at our cellar door, expanding our space and adding a commercial kitchen.

This has allowed us to host functions for up to 100 people and attract more tourists, making our cellar door a destination rather than just a stopover. The support from Tasmanian tourism groups has been instrumental in our growth.

We are obviously hoping that it will lead to the cellar door becoming a destination rather than just somewhere that you go.

With farming, you have your issues, but

then you bounce back, and you go again.

With three brothers directly involved in the business, and my son joining in as well, we truly operate as a family business.

As we navigate through the challenges of evolving and finding direction, we recognise the importance of building strong relationships in the industry.

It is a revolving process. It never, ever stops. I think if you stop, then you may as well just close your doors because you need to keep innovating and you need to keep trying. And, if you find an issue, you need to be working to fix it.

Since 2004, we have been growing all our cherries and apples using Regenerative Agriculture Practices and working towards being carbon neutral.

Regenerative Agriculture focuses on soil health, balancing soil chemistry and feeding the microbiological communities in the soil.

We minimise the use of synthetic chemicals and use organic inputs including humates, fulvic acid, kelp, fish, worm leachate, and natural compost.

We use targeted chemical applications when required. This ensures the ongoing viability of not just our orchards but helps

ensure food security and, also mitigate some of the increasing threats from climate change.

The aim is to leave the soil in better condition for future generations.

We have been very lucky that I ran into Rebecca Muir – Achmea Farm Insurance Business Development Manager for Tasmania and Victoria – at a forum that we went to.

Bec has been excellent to work with on the insurance side of things.

We have a very good working relationship with Bec and Achmea Farm Insurance more broadly, and I think that’s important.

The relationships that you build within any sort of business – whether it’s dealing with insurance or your label manufacturer or this or that – it’s all about relationships and it’s all about how you can hang everything together.

We were not directly looking for another insurer, but our previous insurer had told us that our insurance premiums would increase quite significantly. Encountering

Bec at a forum was fortuitous so that we could transition to Achmea Farm Insurance.

It makes sense to have our insurance with a farm insurer that has come from supporting farmers all the time. That helps, because Achmea Farm Insurance understand – they get the ebbs, peaks, and troughs and all the rest of it that come with any sort of agricultural business.

They just get it. It’s never a hard process to talk to them and say, ‘listen, we need some help with this or how can you help us with this’.

Having the support of a specialist agricultural insurer works very well for the farming sector, rather than just any bigger general insurer.

The fact that we were able to get similar coverage, but more competitively priced, just worked for us and it has been a good decision for us.

Primarily focusing on the Australian market, particularly the eastern seaboard and Tasmania, we have started exploring the export market with recent shipments of non-alcoholic ciders.

Our long-term goal is to gradually transition towards cider manufacturing, while also continuing with apple and cherry production.

With apple production ranging from 3,000-4,000 bins and around 100 tonnes of cherries annually, our operations are steadily growing. The apples are used not only for juicing but also sold to a company in Melbourne for direct supermarket sales.

An important cover we have with Achmea Farm Insurance is Business Interruption insurance.

We would not necessarily worry about it if we weren’t manufacturing, but because we are manufacturing the juice and we’re manufacturing the cider, if anything went wrong and we couldn’t manufacture for any length of time, we would need that cover.

So, for us, it is critical. You have just got to weigh it all up and decide which way you want to go with it.

Our cider brand, Spreyton Cider, along with a hard ginger beer, has its roots in a family recipe that dates to one of my great-grandfathers, adding a unique touch to our products.

He was a sailing captain and always used to make ginger beer for his crew to stop seasickness, and then he became a publican down in Hobart.

He owned two or three pubs in Hobart, his name as licensee is still on board at Shipwright Arms in Battery Point.

The family story was that there was always a keg of ginger beer behind the bar, so we have modified a very old recipe to incorporate ginger beer in our range.

It has been a journey that has really evolved over the last five generations.

As a family business, we believe in constantly moving forward, finding new opportunities, and innovating with the changing times.

It is a journey we embrace, and we are grateful for the support from Achmea Farm Insurance and others along the way.

Insurance issued by Achmea Schadeverzekeringen N.V. (Achmea) ABN 86 158 237 702 AFSL 433984. This information is general advice only.

For more information and/or to request a

Antonio Carraro tractors provide unique features tailored to horticulture growers, and its TGF models are no exception

Every tractor manufacturer aims to provide a point of difference, with Antonio Carraro offering many.

As an experienced Italian manufacturer, the company knows horticulture growers have specific requirements which are different to many other farmers.

Two of its models – the TGF 8900R and TGF 9900 – provide an insight into these differences by offering a super low profile that means the tractor’s overall height can be just 1.74m.

For horticulture uses such as table grapes, almonds and Kiwi fruit, where the tractor has to work under low-height canopies, crop netting and overhanging tree branches, this design can make all

the difference in ensuring smooth and damage-free operation.

A slim design offers an overall width of just 1.3m, depending on tyre configuration, and makes it ideal for working in narrow rows.

The TGF 9900 offers a 90hp (67kW) engine, which steps up to 110hp (82kW) for the TGF 8900R.

This kind of power shows that Antonio Carraro’s efforts to make these tractors compact has not come at the expense of performance or capability.

Both tractors also included fully enclosed Protector 100 cabins, which the manufacturer describes as being the lowest-sitting pressurised cabin on the market, along with a tapered profile that adapts perfectly to the gap between

even the most dense vegetation found in orchards.

Air conditioning and an active carbon filter makes the cabin comfortable for operators, while great 360-degree visibility ensures safety in any operation.

Despite being compact, Antonio Carraro says they still offer an operating space and comfort equal to traditional tractors.

They each include the patented Actio chassis, which helps to improve stability and traction.

It has been tested at up to 38 degrees of angle at Antonio Carraro’s Italian factory and has the axles going through the chassis, helping to bring a lower centre of gravity, along with having an oscillation point on every tractor.

Its low profile avoids damaging overhanging branches

A feature of the Actio chassis is having 60 per cent of the weight on the front axle and 40 per cent on the rear, which helps to ensure the weight is then distributed 50/50 when a rear implement is attached.

Antonio Carraro Australia sales manager Marco Corra describes the TGF models as being a “panther” among the rows.

“It is born for vineyards and orchards and distinguished by its extremely compact dimensions,” he says.

“There is a very tight turning radius, allowed by smaller front wheels, which results in exceptional manoeuvring precision.

“It is a specialist tractor perfect for narrow rows, even sloping orchards, as well as for lowered crops, a marquee and greenhouses.”

Multiple dimension options are available for the rear wheels, according to both operational needs and the ground.

The TGF 8900R also offers three doubleeffect hydraulic valves and a 50L per minute constant hydraulic flow with two returns, along with up to five double effects and an oversized pump with oil cooler.

An e-Drive transmission helps to make direction changes easy, particularly

when implements are attached, and other features include an Eco mode to improve the gearbox’s functionality.

Electronic linkage is also available as an

option, and there is also a double frame configurations with two types of reducer for either 20-inch (51cm) or 24-inch (61cm) rear wheels.

DLL has powered the growth of Australian agribusiness GO.FARM, with fast machinery financing helping to prepare a Victorian property for sowing

Founded in 2013, Australian agribusiness

GO.FARM helps farms reach their full productive potential.

Its purpose is to transform Australian agriculture, generate a positive legacy on the communities in which we live and work, and generate wealth for its investors.

GO.FARM operates a variety of farms in Tasmania, Victoria and New South Wales, which involve permanent horticulture, viticulture, processing tomatoes and broadacre cropping.

Through a focus on identifying and transforming underutilised and undercapitalised agricultural assets like land use, asset configuration and people investment, GO.FARM seeks to invest in ways which help uncover that trapped potential. The goal is to put farms to their best use, with one example of this being shown at Sandmount Farms, in Victoria’s Goulburn Murray Irrigation District.

GO.FARM transformed Sandmount Farms by reconfiguring the portfolio into a large-scale horticultural and broadacre cropping enterprise.

It focused on soil rehabilitation for improved farm productivity and efficiency, as well as significant upgrades to irrigation infrastructure, machinery and accommodation, establishing a scalable system for the production of almonds, mandarins, field tomatoes and cropping.

Most recently, GO.FARM acquired a property in the rural region of Beaufort, Victoria, to prepare and commence the land for sowing.

of preparation time, the business was under immense pressure to identify and source machinery to enable the land for production.

As an existing Rabobank customer and needing a flexible finance partner, GO.FARM turned to Rabobank’s head of major Agri clients team in Melbourne, Jock Thomas.

“A great thing at Rabobank is connecting clients to other businesses to help them

“So, one thing that we’ve done recently with GO.FARM is connecting with DLL.”

DLL is a subsidiary of Rabobank, with both businesses housing a real passion for Australian agriculture.

Combining DLL’s expertise on equipment, finance and leasing aspects with Rabobank’s focus to term debt and working capital, DLL aims to effectively drive outcomes for customers like GO.FARM and delivers desirable results.

For Thomas, it only made sense to connect with DLL equipment finance manager Alister Cameron, in the southern Victoria and Tasmania region to work together on the deal.

“With DLL, the application process to get a new entity set up was really quick and simple, and the team was really responsive in helping us to get that equipment on the farm when we needed it,” GO.FARM chief investment officer Matt Adams says.

“We had a short notice on a Thursday afternoon for a piece of machinery, we were able to settle it on Friday afternoon and have it in the field sowing the crop at 8am Saturday morning.

“I think that speaks volumes to DLL’s commitment to our business. DLL helped

being a really critical growth partner to enable that journey.”

He adds DLL’s comprehensive industry knowledge, alongside its wide variety of financing solutions, seamlessly supported the needs of GO.FARM in providing high quality and flexible services.

DLL’s Alistair Cameron is looking forward to continuing the excellent working relationship with GO.FARM.

“With DLL’s expertise in equipment financing and GO.FARM’s approach to agribusiness, the collaboration is set to drive further advancements in agricultural productivity and sustainability,” Cameron says.

“We’re both committed to leveraging each other’s strengths to support the growth and success of Australian farms, ensuring that we remain at the forefront of agricultural innovation. As we continue to work together, we aim to explore new opportunities, expand our partnership and deliver even greater value to the farming communities we serve.”

For more information on DLL’s financial solutions, scan the

Brought together under a theme of ‘be curious, drive change’, the latest group of Nuffield scholars has been revealed

Five of this year’s Nuffield scholars will study ways to safeguard agriculture against climate extremes and help farmers and communities adapt to increasingly variable conditions.

Each of the 19 scholar will undertake 15 weeks of international travel, exploring cutting-edge practices and research on topics from traceability tools and virtual farm replicas to achieving work-life balance and community resilience. It will culminate in their findings being shared with peers and industry stakeholders, helping to shape the future of farming in Australia.

“Our 2026 scholars embody the innovation and resilience that define Australian agriculture,” Nuffield Australia executive director and 2013 scholar Guy Hebblewhite says.

“A scholarship is about building on generations of knowledge while boldly exploring new ideas to shape a more sustainable and profitable future.

“Their drive to learn from global leaders and apply insights locally will spark fresh thinking and strengthen agricultural communities nationwide.”

Each of the scholars are supported by a particular organisation, with the five climate-focused scholars backed by the government’s Future Drought Fund.

The 2026 Nuffield scholarship recipient list, which covers all areas of Australia, is:

New South Wales

• Simon Blyth from Delungra. Supported by Cotton Australia, Cotton Research and Development Corporation and AgriFutures Australia, Simon will explore how the Internet of Things, AI, automation and robotics can unlock the next frontier of farming performance.

• L aura Davies from Sydney. Supported by 1979 scholar Michael Bennett, Laura will study how diversifying Australia’s export destinations can strengthen and future-proof primary industries.

• Jessica Fedorow from Lewis Ponds, near Orange. Supported by Nuveen Natural Capital, Jessica will study ROI

and outcomes of investment in farm infrastructure.

• K risten Hegarty from Cassilis. Supported by the Future Drought Fund, Kristen will investigate ways to add value to traditional livestock enterprises with outcomes focused on improved business and climate resilience.

• S ally Turner from Trundle. Supported by Meat & Livestock Australia, Sally will study how farmers around the world are reframing administration as a strategic activity rather than a burden.

Northern Territory

• I sobel Heffernan from Daly Waters. Supported by the Future Drought Fund, Isobel will study new ways to empower communities to drive climate resilience in grazing landscapes.

Queensland

• Jackson Boardman from Ravensbourne. Supported by Hort Innovation’s Avocado Fund, Jackson will explore how to integrate drones into horticultural tree crop systems.

• Jessica Bidgood from Central Queensland. Supported by the Future Drought Fund, Jessica will investigate how integrated approaches can help improve the production, profitability and ecological health of grazing systems in Australia.

• Nathan Cleasby from Townsville. Supported by the Fisheries Research and Development Corporation, Nathan will study how Australian farmers can innovate and supply a greater percentage of the global freshwater crayfish market.

• M ichelle Lyons from south of Charters Towers. Supported by Rabobank and the Northern Pastoral Scholarship, Michelle will study how edutourism can foster public trust and understanding of red meat production.

• Abby Templeton from Kybong. Supported by AgriFutures Australia, Abby will explore how to bridge the gap between research and

commercialisation of a tissue culture program to tackle the rise of off-type plants in the ginger industry.

• Kate Watts from Toowoomba. Supported by the Future Drought Fund, Kate will explore how traceability tools, such as ultra-high frequency ear tags and automated data systems, can improve real-time decision-making.

• S am Clothier from Lucindale. Supported by the Public Sector Pension Investment Board’s Nature Resources group, Sam will study free range poultry systems, hen health, productivity and longevity.

• Jock McNeil from Loxton. Supported by Grains Research & Development Corporation, Jock will study strip-till systems, precision application and automation and how these technologies can help overcome multi-layered soil constraints for croppers.

• Penny Hooper from Longford. Supported by Tasmanian Institute of Agriculture and JM Roberts Charitable Trust, Penny will study how to make livestock and dairy farming compatible with a sustainable work-life balance.

Victoria