As Australia’s largest supplier and extruder of aluminium, Capral is committed to supporting Australian manufacturing with high-quality, locally produced aluminium extrusions. Our stateof-the-art facilities provide precision-engineered solutions for industries nationwide, from construction, to transport, and marine.

Choosing Capral is an investment in reliable supply, shorter lead times, and a stronger Australian manufacturing sector.

When you need Australian-made aluminium, Capral can do.

Chairman: John Murphy

CEO: Christine Clancy

Managing Editor: Mike Wheeler

Editor: Jack Lloyd jack.lloyd@primecreative.com.au

Design: Alejandro Molano

Head of Design: Blake Storey

Sales/Advertising: Emily Gorgievska Ph: 0432 083 392 emily.gorgievska@primecreative.com.au

Subscriptions

Published 11 times a year

Subscriptions $140.00 per annum (inc GST)

Overseas prices apply Ph: (03) 9690 8766

Copyright Manufacturers’ Monthly is owned by Prime Creative Media and published by John Murphy.

All material in Manufacturers’ Monthly is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Manufacturers’ Monthly are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2024

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Drive

Docklands VIC 3008

P: +61 3 9690 8766 info@primecreative.com.au www.primecreative.com.au

Sydney Office Suite 11.01, 201 Miller St, North Sydney, NSW 2060

Printed by: The Precision Group

83-89 Freight Drive. Somerton Vic 3062 Ph: (03) 9794 8337

Welcome to the October edition of Manufacturers’ Monthly.

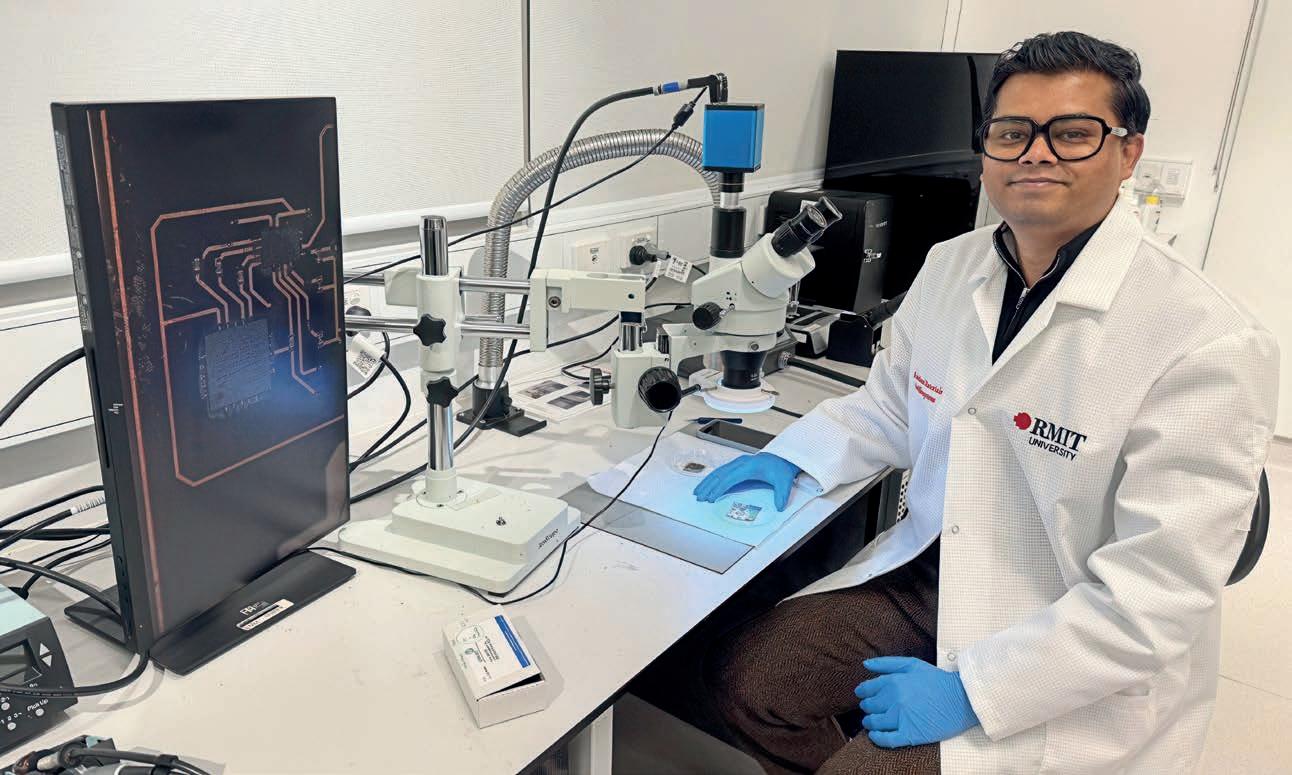

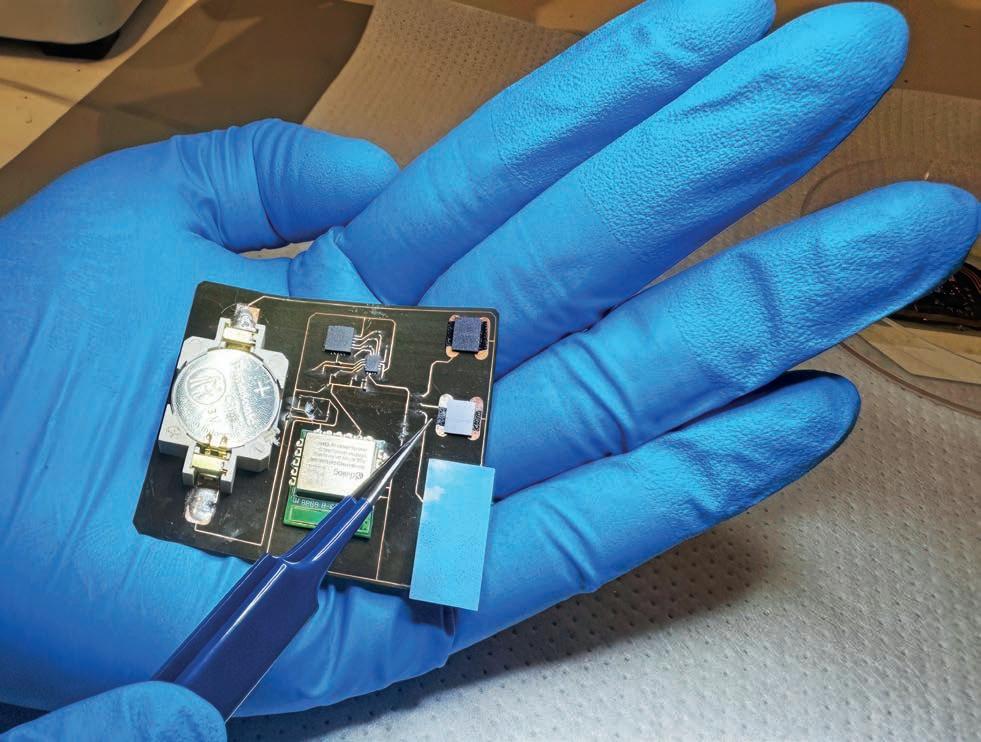

This month’s Manufacturer Focus features Andy Coxall of BAE Systems, who outlines the company’s Australian manufacturing footprint, the Hunter Frigate program, and its collaboration with partners such as Lockheed Martin. In our Engineering Focus, RMIT University researchers reveal a smart wound dressing that uses nanosensors and reusable materials to track healing in real time.

Finally, in this issue’s Decision Maker Column, Robert Clifford, chairman of Incat Tasmania, discusses how the company is setting a new global standard for sustainable maritime transport with the build of a large-scale electric ship.

With the release of this issue of Manufacturers’ Monthly, we recognise the shipbuilding and maritime manufacturing sector – an industry that has navigated a remarkable year of progress and innovation. In 2025, the sector has been marked by defence and commercial vessel developments that reinforce its often overlooked, yet critical role, in Australia’s manufacturing landscape.

Economic figures highlight the scale of the sector’s continued contribution. According to a 2023 report commissioned by the Australian Institute of Marine Science, marine industries generated A$105 billion in value added and supported 462,000 full-time jobs in 2020–21. This underscores the importance of maritime manufacturing not just for national defence, but also for prosperity, jobs, and innovation across the broader economy.

Within the Defence shipbuilding industry, momentum is accelerating thanks to the federal government’s commitment of up to A$159 billion over the three decades under the 2024 Naval Shipbuilding and Sustainment Plan. The initiative includes the delivery of surface combatants, submarines, and landing craft, representing one of the largest intergenerational pipelines of construction and sustainment work in the country’s history. Recently, the Federal Government has committed $12 billion – a part of an expected $25 billion investment over the next decade –to develop the Henderson Defence Precinct in

Western Australia, a move it says will underpin continuous naval shipbuilding and support Australia’s AUKUS obligations.

This long-term vision is perhaps most evident in this issue’s feature on BAE Systems Australia. Andrew Coxall, Director of Acquisition and Build at BAE Systems Maritime Australia, sheds light on the company’s Hunter Class Frigate program at Osborne shipyard in Adelaide. These advanced anti-submarine warfare vessels combine traditional shipbuilding craft with Industry 4.0 and 5.0 technologies, developed in partnership with Lockheed Martin and Saab. More than just building ships, the program is reinvigorating sovereign capability, embedding advanced digital systems, and setting new benchmarks for precision manufacturing in defence.

Equally significant is the workforce being built around this program. BAE Systems has invested heavily in apprenticeships, STEM outreach, and structured career pathways that will ensure generational capability in defence manufacturing. As Coxall explains, the Hunter program is designed not only to bolster national security but to provide stable, long-term careers for thousands of Australians, securing a skilled workforce that can sustain the industry for decades to come.

Defence shipbuilding’s strategic importance will also be on display at Indo Pacific 2025, the region’s premier maritime and naval defence exposition, running from 4-6 November at ICC Sydney. The event

will convene more than 800 exhibitors, 90 symposia and workshops, and key delegations from across defence, industry, government, academia, and technology. Anchored by the Royal Australian Navy’s Sea Power Conference, the program will showcase innovation in shipbuilding, uncrewed systems, maritime strategies, and defence technologies –providing a global stage for Australia’s capabilities and a forum to shape the future of the Indo-Pacific. Commercial maritime manufacturing is also advancing at pace. The Australian Maritime Safety Authority certified 1,445 new vessels in FY 2024 alone, spanning offshore energy, aquaculture, tourism, and transport. This reflects rising demand and innovation in vessel design, materials, and sustainable propulsion technologies.

Tasmania’s Incat has set a global benchmark in this space with Hull 096, the world’s largest electric ship. Built in Hobart with renewable energy and lightweight aluminium, the vessel exemplifies how advanced manufacturing, clean energy, and highly skilled local labour can deliver world-first solutions. With international demand rapidly growing, Incat is scaling production, creating new jobs, and positioning Australia as a leader in the fast-growing global market for sustainable maritime transport. As this issue makes clear, shipbuilding and maritime manufacturing is not only one of Australia’s oldest industries, but one that continues to propel the nation forward into a new era of innovation, sustainability, and sovereign capability.

MaXXlink is an intelligent solution that unites CAD and ERP systems, closing the critical integration gap that slows manufacturing output and creates risk.

Unlike generic connectors, MaXXlink is purpose-built for manufacturing and engineered to integrate disparate or siloed environments—such as SolidWorks, Inventor, Epicor, and MYOB Advanced—without disrupting established workflows. It transforms engineering BOMs into fully validated manufacturing BOMs with precision, speed, and complete traceability.

Visual BOM Interface — Restructure assemblies with drag-and-drop speed

CAD to E-BOM Conversion — Native compatibility with SolidWorks and Inventor

E-BOM to M-BOM Mapping — Get from design to production-ready structures in minutes

Pull non-modelled parts from your ERP — Drag and drop these parts with full traceability

Local ERP Integration — Works with Epicor, MYOB Advanced, and custom systems

Full Change Control — Built-in version tracking, approval workflows, and audit trails

Manufacturers’ Monthly looks the moments that have shaped Australia’s shipbuilding and maritime manufacturing sector in 2025, from defence investments to commercial vessel developments.

The Federal Government is investing $480 million in the naval shipbuilding and submarine construction workforce with the build of the Skills and Training Academy at Osborne in South Australia (SA).

This originates from the AUKUS Pathway in March 2023 and will involve the Federal and SA Governments establishing a dedicated academy to deliver the high-tech education and training needed for continuous naval shipbuilding and AUKUS in SA.

“South Australia’s industry will deliver billions of dollars in defence capabilities and thousands

of well-paid, high skilled jobs – and the Skills and Training Academy Campus at Osborne is at the centre of this work,” said deputy prime minister, Richard Marles.

“This isn’t just an investment in bricks and mortar – it is also an investment in generations of Australian workers who will be building our submarines, making their contribution to defending our nation and building a career for themselves as part of a future made in Australia.”

Ground works have now commenced at the site for the Skills and Training Academy Campus, which will be designed and delivered by Australian Naval

Infrastructure (ANI). Kellogg, Brown and Root, and Architectus have been engaged as design partners.

The design and build will also be supported by Australia’s Sovereign Submarine Build Partners, BAE Systems and ASC Pty Ltd.

The Skills and Training Academy Campus are a pillar of the Federal Government’s uplift of Australian infrastructure and industry through AUKUS, which will see $30 billion worth of investment over the coming decade.

At its peak, up to 4,000 Australian workers will be employed to design and build the infrastructure for the submarine construction yard at Osborne. A further 4,000 5,500 direct jobs will be created to build Australia’s conventionally armed, nuclear powered submarines when the program reaches its peak.

The design of the Skills and Training Academy Campus will simulate the submarine construction yard, providing hands-on skills and classroombased learning.

The facility will include trade workshops, state-of-the-art classrooms and a large central submarine mock-up area.

The courses and skills will also support the workforce required to deliver the Hunter class frigate, which will sustain at least 2,000 jobs and create at least 500 new jobs over the next decade.

Yamaha Motor Australia has signed a purchase agreement to acquire all shares of Telwater, an Australian aluminium boat manufacturer.

This acquisition is premised on obtaining the clearances, permits, etc., required by competition laws and other regulations.

Telwater, one of Australia’s oldest boat manufacturers, is a producer and seller in the Southern Hemisphere, known for its aluminium boat brands Quintrex, Stacer and Savage, which cater to a range of customer needs.

With decades of experience and advanced manufacturing expertise, the company has built a reputation for producing high-quality, durable boats.

The acquisition of Telwater is intended to strengthen the foundations of Yamaha Motor’s marine business, with the company not only aiming to expand its sales network in the country but also reinforce the foundations of its outboard motor business.

Yamaha Motor positions Marine Products as core to its business, and in its new Medium-Term Management Plan announced this February.

Going forward, Yamaha Motor is set to continue to accelerate its growth by making strategic investments, offering attractive products and services, and expanding global sales channels.

Austal Limited has secured $488 million in new debt facilities to support its $1.2 billion capital expansion in the U.S, completing the final funding piece for its shipbuilding and submarine projects.

The funding comes from a group of tierone banks, including both Australian and international institutions, as well as Export Finance Australia (EFA). The new arrangement replaces Austal’s existing syndicated facilities and provides improved pricing, longer tenors of fi ve to ten years, and greater financial flexibility.

Austal is currently delivering two projects in the US, the Final Assembly 2 (FA2) and the Module Manufacturing Facility 3 (MMF3) for submarines. The new funding complements an earlier $220 million capital raise in April 2025 and US$450 million in funding from General Dynamics Electric Boat. Chief executive Paddy Gregg said the refinancing reflects investor confidence in Austal’s future.

“The successful refinancing of the company’s debt facilities positions Austal for the tremendous growth opportunities ahead,” Gregg said. “Existing and new lenders participated, and better terms and longer tenor were achieved.

“With this capital expansion and working

capital funding in place – funded through a combination of debt, equity and cashflow – we can focus on efficient construction of both FA2 and MMF3.”

The deal also includes $634 million in contingent instruments from lenders and other

US-based financial institutions to support Austal’s existing $136 million in Go Zone Bonds through letters of credit and guarantees.

Austal will now terminate its previous $280 million syndicated facility agreement, which included a $65 million undrawn loan sublimit.

The Australian Government is set to invest $262 million to boost the local defence industry and develop the AUKUS nuclear-powered submarines supply chain.

This move is set to support jobs that are at the forefront of the build and sustainment of Australia’s next generation of conventionally armed, nuclearpowered submarines and grow resilient supply chains between Australia, the United Kingdom and the United States.

“We are continuing to build and invest in an Australian submarine industrial base capable of supporting our future nuclear-powered submarine fleet and underpinning a strong local economy over the coming decades,” said deputy prime minister, the Hon Richard Marles MP.

The Government is set to fund a range of initiatives to uplift our local defence industry, supporting around 125 businesses across Australia in the next two years.

This includes new initiatives and boosts support for existing programs. The first tranche of funding will support the industry through three targeted programs.

• Defence Industry Development Grants Program: more investment for eligible Australian businesses

in the AUKUS submarine supply chain, providing funding for security, skills, international accreditations and defence manufacturing equipment for domestic and export markets.

• Global Supply Chain Program: expanded to help UK and US submarine suppliers create commercial opportunities for Australian firms and boost participation in trilateral supply chains.

• Defence Industry Vendor Qualification Program: accelerating qualification of Australian products – such as mechanical assemblies, castings, forgings and electro-mechanical components – into US submarine supply chains, with AUKUS partners streamlining processes and reducing regulatory barriers.

The Federal Government has invested more than $400 million into a contract with Navantia Australia to maintain vessels for the Navy. This seven-year contract is set to support small to medium enterprises that play a vital role in Australia’s defence industry and national security. It is also set to secure about 200 local jobs for Australians primarily within Sydney, Melbourne and Perth.

“The Australian defence industry has grown under the Federal Government and now employs more than 100,000 people,” said Minister for Defence Industry and Capability Delivery Pat Conroy. “This contract is yet another example of our commitment to supporting them and the businesses that employ them.”

Selected as the first multi-class Design Support Contractor, Navantia Australia will engage with Australian businesses to ensure work is spread across the domestic supply chain. Their responsibilities will include the provision of design knowledge and through-life engineering on the Navy’s Canberra Class helicopter landing docks

and landing crafts, the Supply-class ships, and the Hobart-class guided missile destroyers.

As the first of several Design Support Contracts, this agreement is part of the $159 billion record investment by the government to sustain and support maritime capabilities over the next decade.

“Through this contract, we have secured 200 jobs

The Government is set to fund a range of initiatives to help support around 125 businesses across Australia.

This investment comes as the AUKUS Naval Nuclear Propulsion Agreement, signed last in 2024, enters into force.

“The Australian Government continues to work in a targeted way with our AUKUS partners and Australian industry to get Australian products into UK and US supply chains,” said Minister for Defence Industry and Capability Delivery, the Hon Pat Conroy MP.

The Agreement is set to enable the transfer of Virginia-class submarines from the US to Australia from the 2030s, as well as the transfer of information and equipment from the UK for use in Australia’s SSNAUKUS submarines.

and are supporting our sovereign defence industry, which is delivering critical engineering work for our Navy and helping to keep Australia safe,” Conroy said. “The Federal Government is committed to ensuring more work on our naval vessels is done locally, supporting more work for Australian small and medium businesses and jobs for Australians.”

Civmec and Germany’s Naval Vessels Lürssen have signed a non-binding Heads of Agreement for Civmec to acquire Luerssen Australia.

Luerssen Australia’s sole business is the build of six Arafura Class Offshore Patrol vessels for the Royal Australian Navy under the existing SEA1180 contract with the Australian Department of Defence.

“The acquisition of Luerssen Australia is a natural step for Civmec as a sovereign Australian

shipbuilder with world class shipbuilding facilities and an experienced shipbuilding workforce,” said Civmec’s executive chairman, Jim Fitzgerald.

“Having worked on the project since 2018 we’re confident in our ability to execute the remaining work scope and ensure a smooth transition for all stakeholders.”

Upon completion of the potential transaction, NVL will transfer all its shareholding in Luerssen

Australia to Civmec, including all assets, employees, and licences.

This ensures the uninterrupted design and build of the Arafura Class vessels at the Osborne South shipyard in South Australia and the Civmec-owned facility in Henderson, Western Australia.

The proposed change of ownership and control of Luerssen Australia is subject to the Commonwealth granting its consent.

Incat’s story is one of clean energy, advanced manufacturing, and skilled local labour coming together to deliver world-first solutions.

Tasmania’s Incat is proving that large-scale electric ships aren’t just possible – they’re already being built, setting a new global standard for sustainable maritime transport.

On 2 May 2025, a ship unlike any other was launched into Hobart’s River Derwent. At 130 metres long and powered by over 250 tonnes of batteries, Incat Hull 096 is the largest electric ship the world has ever seen – and the largest electric vehicle of any kind built. Its launch marked a defining moment not just for Incat and sustainable shipbuilding, but for Australia’s manufacturing industry.

While Hull 096 is still undergoing the final stages of completion, its scale and ambition have already made waves internationally. The vessel is a glimpse into what’s possible for the future of maritime transport – a signal that large-scale, low-emission ships are no longer just a vision.

From the New York Post to major news outlets across India and Europe, the vessel has captured global attention and sparked new conversations about what a sustainable shipping future looks like.

And it’s all happening in Tasmania.

The maritime sector is under mounting pressure to decarbonise. With tightening regulations and growing public demand for climate action, ferry operators across the world are urgently seeking scalable, low-emission alternatives to fossil fuels. Lightweight, battery-electric and hybrid electric

vessels are increasingly seen as the way forward – but until recently, many questioned whether such solutions could be delivered at scale.

Hull 096 has shifted that narrative. By showcasing a vessel of this size designed for fully electric operation, it shows that the next generation of ferry transport is not only viable –it’s already being built.

Incat’s next generation of vessels are being constructed at our Hobart shipyard, powered by Tasmania’s 100 per cent renewable electricity grid. That makes Incat one of the only shipyards in the world capable of building large electric ships in a net-zero energy location.

Our ships are crafted from lightweight, marine-

grade aluminium – a material that reduces vessel weight, lowers energy use, and is recyclable at end-of-life. Electric ferries like Hull 096 offer long-term savings on energy and maintenance costs compared to diesel vessels. And ferries themselves are already among the most efficient forms of passenger transport, emitting far less CO₂ per kilometre than cars, planes, or conventional steel ships.

When you combine all these factors – clean construction, low operational emissions, and recyclability – the result is a vessel with a lower lifecycle carbon footprint. In a decarbonising world, that matters more than ever.

Incat’s story is also a story of Australian manufacturing. In an era where high costs, offshore competition, and declining output have put pressure on the sector, our success offers an important counter-narrative – one where clean energy, advanced manufacturing, and skilled local labour come together to deliver world-first solutions to global challenges.

The ripple effect from Hull 096 is already being felt. Incat is now in discussions with international operators preparing to decarbonise their fleets. We’re scaling up production capacity, planning to expand our existing shipyard and develop a second facility to meet demand. Hundreds –potentially thousands – of new roles are expected as a result.

We’re also investing heavily in people. Our apprenticeship program is training the next

generation of shipbuilders, creating meaningful career pathways and building a resilient, futureready manufacturing workforce.

Our transition from diesel to electric and hybridelectric shipbuilding is only the beginning. Incat’s team is exploring the next generation of energy storage systems, hull designs, and lightweight materials to improve performance and reduce emissions further.

We’re building strategic supply chain partnerships, strengthening export capability, and showcasing our progress through an ambitious

global marketing strategy. The goal is simple: to ensure the world knows that a quiet corner of Tasmania is home to the future of shipbuilding. Countries that invest in low-emission vessel production today will be the suppliers of choice for a decarbonising world tomorrow. The global ferry market is massive and growing, driven by urbanisation, regional mobility needs, and the surge in sustainable transport demand.

Australia has everything it needs to lead this shift – from clean energy and advanced manufacturing capabilities to a highly skilled

technical workforce. What we need now is bold investment, forward-thinking policy, and a national strategy that positions industries like ours to lead on the global stage.

Incat’s journey shows what’s possible when vision meets execution. But we’re not alone in this transition. Across Australia, manufacturers are rethinking what they build, how they build it, and who they build it for. If we seize this moment – through innovation, collaboration, and an unwavering commitment to sustainability – we can position Australian manufacturing not just as globally competitive, but globally essential.

The ships of tomorrow are clean, innovative, and already under construction. Let’s make sure the world keeps coming to Australia to find them.

As a leading defence consulting firm, Systematiq has the experience & expertise to navigate the complexities across the defence project lifecycle from procurement, bid and tender support, project management and delivery.

Our experience, attention to detail and knowledge of industry-leading practices ensure our clients achieve their strategic goals.

Talk to us about how we can support your entry into the defence industry and moving your projects forward.

BAE Systems Australia’s Andy Coxall explores the company’s manufacturing footprint, highlighting the Hunter Class Frigate Program and its collaboration with partners such as Lockheed Martin Australia. Jack Lloyd writes.

BAE Systems began life as British Aerospace, a gradual amalgamation of around 80 per cent of the historic British defence companies. During this time, it produced much of the equipment used over the past 100 years including the Supermarine Spitfire and Hawker Hurricane aircraft that were prominent in World War II, Navy ships at the Clyde, and Vickers tanks. In 1999, British Aerospace merged with Marconi Defence Systems to become BAE Systems as it exists today. The rest is history.

The company first came to Australia in the 1950s to develop the nation’s defence capability in missiles at the Woomera Range, making it one of the country’s longest-standing defence companies. Initially focused on aerospace and some land systems, its presence has since expanded, particularly in maritime following a major acquisition.

“The maritime element for BAE Systems in Australia really took off when we acquired Tenix Defence in the late 2000s. Tenix had been heavily involved in maritime sustainment and building the original Anzac class frigates,” said acquisition and build director, BAE Systems Australia – Maritime, Andrew Coxall. “That acquisition forms the foundation of our maritime business here today.”

With an established presence in Australia, BAE Systems Australia now runs some of the nation’s largest defence manufacturing projects, employing nearly 7000 people across 40 sites. This includes maritime support in Sydney, sustaining air warfare destroyers, and upgrades to Anzac frigates in Henderson, WA. In Victoria, the Melbourne office handles engineering design work for Anzac class sustainment and the Hunter class frigate build, while the Cairns capability hub

allows remote program support – a flexibility Coxall said is central to how BAE operates. Outside of the Osborne Naval Shipyard, the next largest site is at Edinburgh Parks in Adelaide. Over 1000 employees work across multiple domains, supporting the Jindalee Operational Radar Network (JORN) and delivering High Frequency Export technology. It is a critical hub for defence advanced manufacturing, research, development and sustainment, delivering guided weapons, electronic warfare capabilities, and vertical tail components for the global F-35 program. Williamtown, NSW, hosts several hundred staff providing maintenance, repair, overhaul and upgrade (MRO&U) services for the Royal Australian Air Force’s Hawk Lead-In Fighter and fifth-generation F-35A Lightning II aircraft.

Complementing its land, air, and maritime presence in Australia, the company’s Hunter Class Frigate Program is its largest maritime project. Employing more than 2,500 people –around 2,200 in Australia and the rest in the UK – the program is based at the Osborne Naval Shipyard in Adelaide. The shipyard is home to 1,900 staff, including 700 tradespeople, who work towards the construction of the frigates for the Royal Australian Navy (RAN). Work on the project is also spread elsewhere nationally, with teams at Tonsley Innovation District (Adelaide), Melbourne, Henderson shipyard (Perth), Canberra and Sydney offices, and the Cairns Capability Hub, while warehousing and logistics are centred in greater Adelaide.

The Hunter Class Frigate Program is one that is not only important to BAE Systems Australia, but to the country. The Hunter program came out of the SEA 5000 project, which required dedicated anti-submarine warfare vessels with multiple combat capabilities. At its heart, the Hunter class is a purpose-built anti-submarine warfare ship, optimised to counter modern threats using layered defence through a worldclass combat system. He said this is necessary because defence experts anticipate that by the early 2030’s approximately half of the global submarine fleet will be operating in the IndoPacific region.

“The Anzac class frigates have an antisubmarine warfare capability, but they were not purpose-built for that threat,” said Coxall. “We’re an island nation with only about ten days’ worth of fuel reserves, vital undersea cables that carry our data, and sea lanes that must be protected. There is a massive security threat evolving from less than friendly nations with submarine capability. This has also been reinforced by the AUKUS decision.”

Coxall emphasised that the ship is designed so that every rivet, system and component is built and tested around hunting submarines in a way the RAN hasn’t had before. However, he noted that while the ship can take out submarines, its intent is to ensure threats don’t get close enough to require that.

“You can think of it like a quarterback on an American football field. It sits quietly in the background to listen, monitor, and then coordinate a joint tactical response with other Australian Defence Force (ADF) assets and coalition forces when it detects a threat,” he said.

The Hunter class frigate is a tier-one warship, larger and more capable than tier-two vessels like the Anzacs or future Mogami-class ships. While the Anzacs will be replaced by the Mogami-

class, the Hunter adds new capabilities to the RAN rather than serving as a direct replacement. Alongside aforementioned features, the multicapable ship carries a 32 cell Mk 41 vertical launching system (VLS) that can launch missiles against both sea and air targets depending on their loadout, a built-in helicopter capability, and a multi-mission bay that can take at least 10 shipping containers of equipment.

“That flexibility means it can host special

forces, drones, additional personnel, or be used for humanitarian operations and disaster relief,” said Coxall.

The Hunter class frigate also features the advanced CEAFAR2 phased array radar. This is integrated with the Aegis combat management system by Lockheed Martin Australia and managed through the Saab Australia developed Australian Tactical Interface, which gives the Hunter class exceptional anti-air capability.

Building towards a major capability

To date, the government has committed to the build of six Hunter class frigates, with BAE Systems Australia currently contracted for three, scheduled for delivery in July 2032, January 2035, and November 2036. While the drumbeat of delivery quickens as the program progresses, Coxall said it’s important to understand this contract is not just about building ships but about re-establishing a continuous naval shipbuilding capability in Australia and commissioning a new shipyard at Osborne.

Learning from the “valleys of death” that have hampered past shipbuilding programs, Coxall explained that the delivery timetable is designed to maintain a steady workforce. Scheduling, he noted, is as much about managing personnel as it is about the physical construction, since shipbuilding accounts for only around 60 per cent of BAE Systems Australia’s contracted work. The remaining 40 per cent involves sustaining and testing the national capability.

Yet, steady progress is being made on the Hunter class frigates, which Coxall described as being built like Lego. The ships are constructed modularly, with 78 fabricated units combined into 22 blocks before assembly. Fabrication and block assembly take place in separate

facilities, with a new unit started roughly every two weeks. Fourteen months after the Batch 1 contract signing, half of the ship 1 units and 14 of 22 blocks are in production and Block 11 has completed blast and paint. So far, the project is on track for a key milestone in 2028, when the first ship will roll out of the construction hall onto the hard stand.

“We need to move it out because the mast and radar are so large they can’t be installed under cover,” he said. “Once on the hard stand, we’ll begin installing the more complex systems and equipment, marking a major stage in the build process.”

The production team for the program draws on the best of shipbuilding traditions. Much like the old car industry, the program employs a range of trades and white-collar support, from cleaners to naval architects, truck drivers, electricians, welders, boilermakers, and cabinet makers. Each contributes different skills and techniques, and shipbuilding integrates them all.

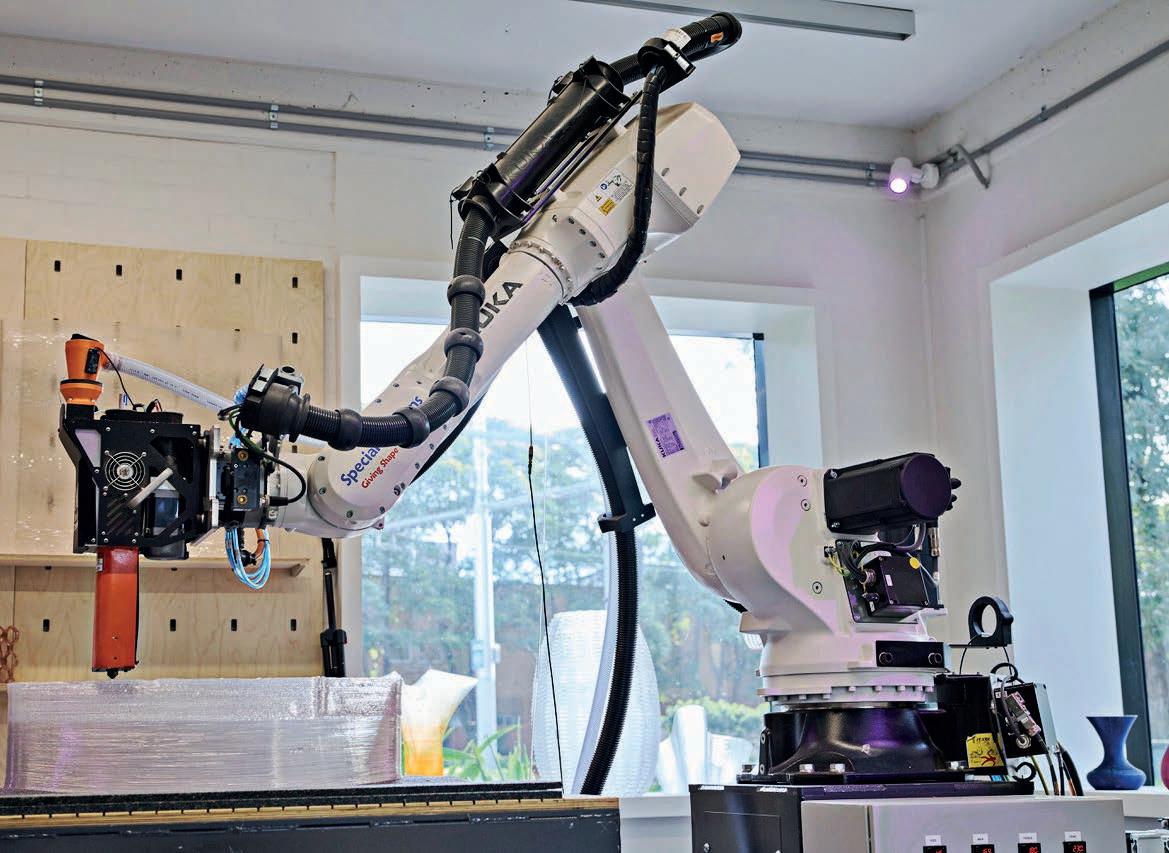

Building on a strong workforce base, the Osborne shipyard features a state-of-the-art manufacturing facility that blends traditional

shipbuilding processes with advanced technologies set to define Industry 4.0 and 5.0. Coxall highlighted the facility’s pulse line as a prime example, where units move down the line like a car on an assembly line, passing through robot welders, cobot welders, and the latest machinery. At peak production, a unit completes the pulse every 10 to 15 days after fabrication. Beyond the pulse line, BAE Systems Australia employs edge bevelling machines, plasma cutters, and oxy cutters within one building, while a Nieland press in another cold-forms steel under 600 tonnes of pressure

“You see this incredible spectrum – from laser measuring, 3D modelling, digital projections and fully digitised shipyard processes, right through to traditional artisan techniques that would be instantly recognisable to shipbuilders a century ago,” said Coxall. “The Nieland press is only fi ve years old, but the technology is essentially the same as shipbuilders were using 120 years ago. “

Part of this manufacturing process is testing and quality control measures, which are in place to ensure that every stage of production meets the standards required for defence. This includes every component being flood-tested, fire-tested, and shock- and sound-tested.

The company also operates to Lloyd’s

accreditation, meaning Lloyd’s shipbuilders out of the UK certify everything it does to class – from welding techniques and manufacturing processes to the acceptance of compartments, as well as whole-ship acceptance and seaworthiness.

“Quality is critical to us. This is both a warship and a home, which means product quality and seaworthiness are at the forefront of everything we do. Ultimately, our sons and daughters may

up to 55 dedicated combat systems resources engineers covering areas such as safety, cyber security, design, testing and activation,” said Lockheed Martin Australia’s Integrated Warfare Systems and Sensors Line of business lead, Gavin Douglas. “CSI is what we do, from the Attack Class to the Hobart class upgrades and now on the Hunter program.”

According to Business Development Integrated

Perhaps the bigger picture of the Hunter Class Frigate Program is not just the ships themselves, but the skilled workforce being built around them. Coxall said that because of the program’s importance in protecting Australia from unique threats, most employees come to work not just for a wage, but because they genuinely believe in what they’re doing. As a former ADF member, he shares that sense of purpose.

As a part of this emphasis on workforce, BAE Systems Australia has committed to creating early career positions over the life of the program, with apprentices and graduates forming the backbone of this long-term skills strategy. Already, 105 apprentices are on the tools – 47 of them started in 2025 – learning trades such as fabrication, pipefitting, mechanical and electrical work. Among them are 11 school-based apprentices, reflecting a push to engage young talent early.

“The direct benefit is clear: we’re providing what we believe is the world’s best anti-submarine warfare ship to the Australian Navy,” said Coxall. “But there’s also a secondary benefit, which is

rebuilding capability in Adelaide. This region lost a lot when the car industry ended. Now we’re providing thousands of highly skilled, highly committed manufacturing jobs that could last 15 to 20 years.

“These are the kind of jobs that allow people to say their kids could one day work at Osborne too.”

BAE Systems Australia has been deliberate about strengthening the pipeline before people even enter the workforce. Its outreach stretches from STEM programs in primary schools to high school work experience placements in the shipyard as well as partnerships with technical colleges. The company also offers degree apprenticeships, summer placements, Career Tracker internships for First Nations students, and traineeships through the Defence Industry Pathways Program (DIPP) initiative. Last year, that long-term vision came into focus at an apprentice milestone event.

“Parents came to the shipyard, and I told the 16 and 17-year-olds sitting there that it’s not beyond possibility they’ll be back in 20 years, this time as parents themselves, watching their own children join the program,” said Coxall. “There aren’t many

operations in Australia that can offer that kind of security and career progression. It’s a real opportunity to make a difference.”

Workforce development is also being tackled through diversity and reskilling. Scholarships are being offered in engineering, alongside targeted initiatives to bring more women into defence trades. Those returning to the workforce are supported through the STEM Returners program, while existing employees can reskill via adult apprenticeships or move into paraprofessional roles with a Diploma of Digital Technologies delivered in partnership with Flinders University.

The effort also links into broader national priorities. BAE Systems Australia is supporting the transition of the Offshore Patrol Vessel workforce and working with the South Australia Commonwealth Defence Industry Skills and Workforce Taskforce to align local skills with future defence needs. To strengthen its own recruitment and retention efforts, it has established capability hubs in Melbourne and Cairns, along with a dedicated recruitment and onboarding centre at Osborne.

By investing in skills, diversity and long-term career pathways, BAE Systems Australia is helping to lay the foundations of a defence industry workforce capable of meeting the challenges of tomorrow. Lockheed Martin Australia aligns with this sentiment, believing there’s no substitute for walking the shipyard floor, talking to people, and then three or four years later seeing a ship in the water that’s ready for service. Douglas believes that BAE Systems Australia has done a lot to bring people together under the company’s ethos of training, culture and career pathways.

“This is one of the rare industries in Australia where you can offer guaranteed, decades-long careers – through new shipbuilding, sustainment and upgrades – and that’s what keeps people engaged and motivated,” he said.

Lockheed Martin Australia’s role in the Hunter Class Frigate Program extends beyond delivery to the long-term sustainment of the fleet. Building on its experience with the Hobart class, the company has invested in developing local expertise, combining international training, recruitment of professionals and structured knowledge transfer

with Navy personnel to strengthen Australia’s sovereign capability. It has also partnered with universities to fast-track specialist skills in combat systems engineering, ensuring the next generation of talent can contribute sooner to critical defence programs.

“Starting in 2022 we partnered with Defence Trailblazer, the University of Adelaide and UNSW to develop Australia’s first university level creditready micro-credential course in combat systems engineering,” said Douglas. “Instead of waiting fi ve years on the job to build that expertise, the six-module course provides a recognised upskilling pathway, and we’re already running our second iteration with university students, defence partners and industry participants.”

The Hunter Class Frigate Program represents more than a shipbuilding contract – it is a longterm investment in skills and sovereign capability. By bringing together partners like Lockheed Martin Australia and Saab Australia while fostering a new generation of talent, BAE Systems Australia is doing its part to secure both the nation’s defence and industrial futures.

RSM Australia is helping small and medium manufacturers navigate the barriers, requirements and opportunities of the defence supply chain.

Australia’s defence manufacturing landscape is fluid, with opportunities and challenges for businesses of all sizes. For RSM Australia, an Australian professional services firm, supporting small and medium manufacturers to navigate the complex demands of the defence supply chain has become a core focus.

From its Rockingham office, RSM is positioned in the heart of Western Australia’s defence and heavy industry hub. Located close to HMAS Stirling, the Henderson Precinct, and Kwinana’s heavy industrial zone – as well as the state’s future main port – the firm has built a dedicated defence advisory team that helps local businesses seize new opportunities.

Tom Hüberli, partner in RSM’s Rockingham Business Advisory division, has been instrumental in developing this focus. When he transitioned into the role in 2021, he looked at the economy surrounding Rockingham and recognised defence as a key driver. Garden Island, home to HMAS Stirling, looms large on the horizon, while nearby Henderson is the state’s premier defence industry location. Around the same time, the announcement of the AUKUS trilateral partnership reinforced his view of the sector’s long-term significance.

Since then, RSM Australia has expanded from a small starting point to a 30-strong national

defence advisory team. The firm’s service model spans four categories: risk and assurance, R&D tax and grants, corporate finance, and business advisory.

Risk and assurance cover areas like cyber security, financial audit, ESG compliance, contract management and fraud forensics. R&D tax and grants are crucial for innovative businesses developing and testing new solutions, while corporate finance supports mergers, acquisitions, valuations and transaction advisory. Finally, the business advisory stream – which Hüberli leads –offers structuring, tax management, reporting, and factory floor financial decision-making support.

“Our role with local manufacturing businesses is to help them know and understand their numbers for real-time influence on decision-making,” Hüberli said. “We also look after their compliance needs so they can focus on their business more. The key is that we act as connectors and identify where clients need help from other services or support.”

One of the first questions Hüberli faced when developing this branch of RSM Australia was whether defence warranted treatment as a distinct subsector of manufacturing. He concluded that it did, citing three defining challenges: barriers to entry, ongoing

regulation, and the pace required to meet demand. Despite government efforts, entry into the defence supply chain remains highly competitive. Businesses must first identify a gap or demand, then demonstrate capability. Certifications and documentation such as a Defence Industry Security Programme (DISP) accreditation and a quad chart summarising competitive advantages and qualifications also help the process.

“Government bodies are not shy in telling you if you don’t meet the criteria – you can be chopped out very quickly if you can’t offer anything,” said Hüberli. “It also helps immensely to have strong industry connections. It’s not so much about who you know, but knowing the right government departments and networking groups can really help.”

Once in, manufacturers must keep pace with evolving regulations, certifications, and compliance requirements. Defence’s heightened public profile makes it critical for companies to operate with transparency and professionalism, while poor governance or financial instability can quickly damage opportunities.

The third challenge is speed. Following the 2023 Defence Strategic Review, the government acknowledged capability gaps amid strained international relations and rapid technological change. That has created pressure for prime contractors to work more closely with smaller, agile businesses to deliver results.

“We’ve had examples of businesses being asked to ramp up production significantly to the point where it’s life-changing,” Hüberli said.

RSM can support those providers struggling with

these requirements by offering guidance across critical areas such as connections, certification, funding options, business structure and risk management, and ensuring their operations and systems are secure and sustainable. According to Hüberli, the firm emphasises that building capability quickly requires more than short-term fixes or one-off grants – it depends on both business and government embracing innovation with genuine investment and long-term strategy.

Managing risk and requirements through financial literacy

Hüberli said financial literacy is an essential foundation for SMEs seeking entry into the defence supply chain. He argued that robust monitoring and visibility of financial indicators such as margins, cash flow, and return on investment form the backbone of sustainable operations. Without high-quality, timely factory-floor data, he said decision-making is compromised.

“In defence manufacturing, where precision, compliance and cost efficiency are paramount, financial soundness must be achieved alongside complimentary services like R&D or ESG,” he said. “Manufacturers need clear visibility into profit margins, productivity trends, interest cover ratios, inventory movements, and utilisation versus capacity.”

RSM Australia also helps manufacturers meet strict compliance and reporting obligations by guiding them through defence readiness assessments and supporting them in addressing

capability gaps. The firm has supported clients with R&D tax incentive applications and defence industry development grants, the latter potentially being worth up to $1 million, while also restructuring businesses and mitigating capital gains or stamp duty impacts.

Risk management – particularly cyber security – is another growing priority. DISP certification is widely recognised as base-level security for defence supply chain participants, though processing backlogs mean many SMEs face frustrating delays.

“It’s not a simple process to navigate yourself, and it’s often better to get help to do it right. Beyond DISP, we assist clients with higher-level certifications in cyber and process security, which demonstrate readiness for larger contracts too,” Hüberli said.

Because many defence projects span years, RSM also focuses on helping businesses prepare for long-term sustainability through consistently processed data and sound reporting platforms. This includes guiding cash flow management, planning for plant replacement or refurbishment, managing provision accounts, and building investor readiness. According to Hüberli, this can be as simple as not buying an item of plant from cash surplus but instead seeking finance, or as complex as keeping an eye on threeway budgets to prepare for increased scale or seeking an investor.

“There’s a saying that suggests we should live for today, and that’s fine, but in business we also have to plan for tomorrow,” Hüberli said.

Local presence, national reach

Rockingham’s position as a hub for defencerelated activity gives RSM a unique vantage point. With a national network of 32 offices – including 19 in WA – the firm can blend local business advisory expertise with access to specialised services such as cyber security, R&D, grants, and corporate finance.

“The geographic spread of our offices allows a smaller metro-based office like Rockingham to pull in specialist services and become more than just advisors – we’re conduits to other services and networks,” Hüberli explained. “We’re building a one-stop shop for defence across funding, tax, compliance, assurance and risk.”

The collaborative nature of the sector is also a strength. Defence networking events bring together SMEs, government, primes, advisors and industry bodies in a way that fosters genuine partnerships. Hüberli believes RSM is ahead of the curve in providing coordinated national services tailored to defence.

“Defence is probably one of the most collaborative environments out there. Industry meets government meets advisory, and together they’ve got a great opportunity to build something special – something that supports national security and the sovereignty of Australia,” he said.

As RSM continues to expand its role in this space, Hüberli remains optimistic. The work may be complex, but its impact is profound – shaping industries, strengthening communities, and ultimately helping secure the nation.

Marine Air Flow delivers advanced marine ventilation worldwide, with Capral aluminium at the core of its sustainable and custom-engineered solutions.

In marine engineering, engines, hulls, and navigation technologies usually take centre stage. Yet one company has carved out an unlikely niche and turned it into a global success. That company is Marine Air Flow, a designer and manufacturer of advanced ventilation systems for vessels of every scale.

Marine Air Flow was founded in 2005 by Brad Marsden, who drew on decades of boatbuilding experience and training in Western Australia. He recognised ventilation as a persistent weak point in otherwise sophisticated vessels, particularly in tropical climates. The company’s beginnings coincided with a wave of innovation in the industry that would ultimately shape its philosophy.

“It was a time of change from where the average boat was sort of 30 or 40 feet long, very old school, very slow, and all of a sudden these new modern, high-speed aluminium cray boats were born,” Marsden recalled. “Over the space of a year experimenting and sampling, basically Marine Air Flow was born.”

What might seem like a narrow specialty has since become a crucial differentiator for shipbuilders, defence projects, and commercial operators worldwide. Poor ventilation – allowing salt mist and spray to drive inefficiency, high maintenance, and early failures – is now seen across the maritime industry as a challenge that must be eliminated.

“Engines create a lot of heat, so if there’s no proper

ventilation, they can overheat, damage equipment, increase fuel consumption, and even risk safety,” said Yael Abitbol, general manager of Marine Air Flow.

Marsden’s first innovation was deceptively simple: a cool room converted into a wind tunnel to protect engines while extending their lifespan. It brought fresh air in while keeping salt mist out. That 2005 invention marked the start of a product line that has grown into complete ventilation systems – intake grills, ducts, fans, dampers, and controls – designed as integrated packages.

Unlike the traditional piecemeal approach, Marine Air Flow offers a one-stop shop, backed by a threeyear global warranty and what Marsden calls “a 110 per cent money back guarantee on performance.”

More than 4,000 projects later, no client has ever claimed it.

From its Gold Coast base, Marine Air Flow ships systems worldwide every Thursday, often by air freight. Projects span six-metre craft to 260-metre giants, across recreational, commercial, and defence sectors. Exports now account for about half of all projects, up from just 10 per cent in 2017.

“The problem is exactly the same. It’s just on a different scale,” Marsden said.

“Growing internationally has balanced the business and made us far more resilient,” Abitbol added.

One innovation from Marine Air Flow is a 600mm, 24-volt DC fan moving 3,500 litres of air per second, supporting 2,400hp engines. Weighing just 17.5kg versus 60kg for AC versions, it saves operators weight and cost – equating to four extra passengers per trip on a ferry. Such offerings have made Marine Air Flow a go-to supplier for Australian names. Abitbol recalled a turning point with Riviera yachts.

“We said ‘We’ll give you a system free of charge – if it works, you can use us for future models.’ It did, and since then every new Riviera model has integrated our systems,” she said. “Today, we build and ship systems for Riviera vessels almost every week.”

The company’s attention to detail has also built strong international demand and recognition at home. In 2024, the company won both the Queensland Export Award (Small Business) and the National Export Award.

“It’s a recognition that shows why we’re considered number one in marine ventilation,” Abitbol said.

Behind the success sits a diverse team. Staff hail from Burma, Chile, Brazil, France, Spain and more. Many are trained in-house to build skills from scratch rather than unpick old habits. Abitbol said this culture underpins staff retention and quality.

“Many of our people have been here for 10 or 15 years. We have a very flat structure – apprentices take part in leadership meetings, and everyone’s ideas are heard,” she said.

A critical factor in Marine Air Flow’s success has been its reliance on aluminium – and its long partnership with Capral Aluminium, a company specialising aluminium extrusion and distribution. Since 2005, Capral has supplied proprietary extrusions for its bespoke systems.

Abitbol said aluminium’s lightweight, durable and resistant to corrosion nature have made the

material critical and perfectly suited for the marine environment. Agreeing with the sentiment, Marsden placed an importance on the material by comparing to alternatives like plastic of which the company is replacing every four or fi ve years.

“Our clients are usually very proactive in reaching out and saying, ‘oh my God, we didn’t realise how much more superior the aluminium product was compared to the plastic product,” said Marsden.

Marine Air Flow takes aluminium a step further. Components are CNC cut, jig-assembled, and welded to avoid dissimilar metal issues. Units are aciddipped, chromated, and powder coated for marinegrade durability. Where bolts are used, isolation bushes prevent metal contact.

“By eliminating that dissimilar metal, it saves all that reaction and corrosion. The aluminium becomes very superior when it’s treated and designed correctly,” Marsden said.

Marine Air Flow now uses around 18 proprietary extrusions, three of which were developed in collaboration with Capral. According to Abitbol, the company has relied on the product since its inception because of its quality, Capral’s “second to none” service, and the flexibility to create custom sections tailored to its needs. Marsden echoed this sentiment.

“They’ve been a really good go-to source and are proactive in assisting us in designing and developing new sections,” Marsden said. “Yes, we could go offshore, but we believe strongly in supporting Australian industry – and fortunately the Australian industry has been pretty proactive in supporting us.”

Marsden credited the personal support of longtime Capral staff including John Smith and account manager David Betham.

“Whether we make a phone call, send a text, or an email, most of the time we’ve got a response within two hours – often within ten minutes. To be looked after at that level, on the scale of what Capral is, I think it’s pretty impressive,” he said.

Recently, the company switched to Capral’s LocAl Green lower-carbon aluminium, something that aligns with its large emphasis on sustainability.

“Clients are demanding greener solutions, and by choosing LocAl we’re reducing our footprint while reinforcing our position as industry leaders,” Abitbol said.

As Marine Air Flow enters its third decade, its ambitions remain global. The company is targeting a project mix of 30 per cent commercial, 30 per cent recreational, and 40 per cent defence, recognising defence as especially resilient and full of opportunity.

Expansion will be careful, as the business depends on deep technical engagement and a skilled team –qualities not easily scaled. But growth is coming.

“We’re expecting around 20 per cent growth in staff and space over the next few years and may even need a larger factory – though we hope to stay in Miami. The marine sector is booming and we intend to grow with it,” Abitbol said.

For an industry that rarely stops to think about airflow, Marine Air Flow has shown how critical it is. With Capral aluminium at its core, and a global client base depending on its systems, the Gold Coast manufacturer has proven that even in the most specialised niches, Australian engineering can lead the world.

With AVT’s expertise and Oracle NetSuite, Fulton Industries Australia transformed fragmented systems into a unified platform that drives efficiency, automation, and scalable growth.

Every manufacturer reaches a critical point where their ambition exceeds the capabilities of their systems. For many, the very processes that once defined their success become the biggest obstacle to growth.

This was the situation at Fulton Industries Australia, a family-owned business founded in 1981 in West Gosford, NSW. The company had built a reputation as a manufacturer and distributor of underground and overhead electrical equipment, but its journey offers a powerful lesson on how a commitment to granular detail can lead to a fundamental digital change.

When the AVT team first met with Fulton Industries Australia, it was clear they were a business with enormous potential that was being held back by its own IT systems and processes.

The company’s ambitions were hitting a wall built from three disconnected systems: Sybiz for finance, MYOB for accounting, and a reliance on fragmented spreadsheets for everything else. This operational inefficiency was preventing them from scaling, causing errors and frustrating delays.

“Our sales staff could never be certain if stock was available, and costing sheets had to be manually pieced together. There were times when products were being quoted on for sales orders that had already been sold the day before. The fragmentation and lack of visibility were holding us back from growing,” said CEO and co-owner Mark Donnelly.

The priority was to establish a single source of truth. The previous setup meant a single product record

could exist in multiple places, creating a constant risk of inconsistency and error. This was the root cause of issues, such as quoting on products that had already been sold.

The partnership with Fulton Industries began with a clean, strategic migration of its business data into Oracle NetSuite, delivered by its implementation partner, AVT. The project did not simply involve moving information; its architecture was redesigned to ensure that every piece of data, from customer details to individual inventory items, was accurate and connected within a unified platform. This foundational work enabled every other success, where the big-picture benefits, such as tripled revenue and national expansion, are a direct consequence of the small, strategic automations and data integrity built into the NetSuite platform.

The big-picture benefits, like tripled revenue and national expansion, are a direct consequence of the small, strategic automations and data integrity built into their NetSuite platform.

The power of precision automation

With the company’s data consolidated, automations were built that would have a large impact on efficiency. NetSuite was configured to integrate live inventory data directly into the sales quoting process, empowering sales staff with real-time accuracy and cutting down quote generation from hours to minutes. This kind of detail-oriented automation drove transformative results. Director of operations and co-owner, Todd Fulton, experienced this change firsthand.

“The move from manual systems into NetSuite was daunting, but the change has been enormous. Customer enquiries that once took days now take minutes,” he said.

One of the most powerful automations implemented was the leveraging of NetSuite’s matrix item functionality. This was key to managing its massive and growing product catalogue of over 500,000 SKUs with customised variations. By automating the linking of product drawings and documents to quotes, the manual search for files was eliminated, resulting in time savings and reduced errors.

Fulton Industries Australia’s business model is unique and complex, so the strategy had to be equally sophisticated. As David Podger, commercial & marketing manager, who leads its online strategy, explained.

“Our business is not out of the box. Every

customer requires variations,” he said

With NetSuite SuiteCommerce Advanced, a tool for customer empowerment was built. The platform was tailored to allow clients to configure complex industrial products themselves, ensuring accurate pricing and data capture from the first click. This self-service automation has become a hallmark of its modern operation and is positioning it for expansion across Australia and into New Zealand.

The implementation of NetSuite’s Warehouse Management System (WMS) has revolutionised key processes such as picking, dispatching, labelling, and replenishment. By leveraging the capabilities of NetSuite’s SuiteCloud module, AVT developed numerous customised workflow automations designed for Fulton Industries Australia, effectively eliminating manual tasks. This shift not only enhanced automation and streamlined processes but also achieved operational efficiencies across departments, positioning Fulton Industries Australia for scalable growth and success.

Since the implementation in 2019, the company has doubled its staff, tripled its revenue, and is well placed to handle a projected catalogue of more than one million SKUs. The visibility integrated into its system allows its management team to make decisions more quickly and with greater confidence.

The story of Fulton Industries Australia is a testament to what is possible when a company commits to a digital change, from the ground up. As Donnelly told us in a final reflection on their journey, “NetSuite gives us clarity, efficiency and scalability, and with AVT by our side, we are confident about the next stage of our journey.”

The Industrial PC that adapts to your needs

A modular, Linux-based industrial PC built on Raspberry Pi technology - perfect for automation, IIoT, and motion control. Use it as a soft PLC, IIoT gateway, or industrial controller.

Your Benefits at a glance:

IndustrialPI as an automation controller and IIoT gateway for machinery with synchronous axis movements.

Expandable I/O modulesthe optimum solution for many industrial application areas

Enables flexible use as an automation controller or IIoT gateway, tailored to your application

Rugged housing and 24 V connection

Can be integrated into all common system architectures

Simple programming possible

Soft PLC, IIoT gateway, Industrial ControllerYou Decide.

Loctite’s upgraded Threadlocker formulations preserve performance while introducing smarter packaging and chemistry for the next generation of manufacturing.

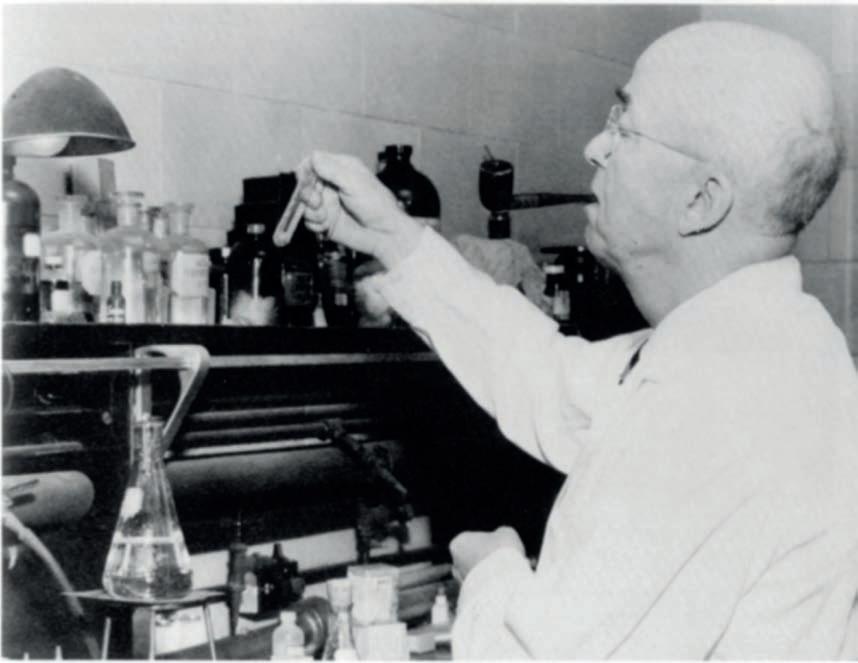

Loctite is a brand that specialises in industrial bonding and sealing. From its invention in the 1950s to its global presence today, Loctite has become synonymous with reliability across manufacturing industries like automotive, aerospace, defence, electronics and heavy machinery.

Recently, the brand has begun rolling out a new generation of its flagship products Threadlockers. This new generation builds on decades of proven performance, reformulated to meet the evolving demands of modern industry.

The team at Henkel Adhesive Technologies ANZ shared that the upgrade represents more than just a technical tweak. It’s part of a broader goal to continuously innovate and shape a purposeful future for the next generations.

An adhesive solution to mechanical problems

While Henkel itself has a history of almost 150 years, Loctite’s story began in the mid-20th century. The brand was born in the laboratory of Professor Vernon Krieble in the 1950s, when he developed thread locking technology using a liquid adhesive applied to threaded fasteners to prevent loosening, leakage, and corrosion by locking them in place.

Within ten years of that invention, it became the state-of-the-art solution for bonding, sealing and locking metal parts. Today, they are used in robotics, electronics, the military, aviation – even in something as simple as a bike. If it has a nut and bolt, Loctite has a solution.

From the beginning, Loctite offered a chemical solution to mechanical reliability problems. This gave an alternative to engineers who could now trust a liquid to lock parts in place instead of relying solely on washers, lock nuts, or other mechanical fastening methods.

“Chemical threadlocking is a non-mechanical solution for mechanical problems,” said John Karasavidis, application engineer at Henkel. “It sets within minutes in the absence of air, filling the gap in threaded fasteners to mitigate and prevent corrosion in the threads.”

Threadlockers may not always be visible, but they have become critical in the fight against vibration, rust, and wear that can undermine even the best machinery. By filling the gaps in threaded fasteners, they prevent micro-movements that would otherwise lead to loosening or failure. Compared with traditional fastening methods, Loctite’s approach delivers greater stability and cost efficiency.

With washers or lock nuts, equipment is still prone to movement over time when exposed to environmental conditions. A threadlocker provides a long-term solution that minimises those issues.

Despite the complexity of their chemistry, Loctite Threadlockers have always been designed with practicality in mind. The products are offered in a range of strengths, identified by colour for easy reference. This coding system simplifies use for technicians and engineers across sectors.

The recent upgrade in the product’s formulations is part of a global initiative designed to future-proof the product line. The update focuses on three key areas: formulation, packaging, and consistent performance. This upgrade particularly affects the medium and high strength products – specifically Loctite 243 and Loctite 263.

“The first change is in the formulation itself,” Kimberly Kountur, product manager at Henkel explained. “The new version no longer contains CHP and APH, which is cumene hydroperoxide and 1-acetyl-2-phenylhydrazine. This enables easier handling and aligns with regulatory readiness as industries move towards a more sustainable future.”

The second change lies in the packaging. Loctite bottles will now contain 50 per cent Post-Consumer Resin (PCR), reducing reliance on virgin plastic and supporting the circular economy.

“The packaging is an important part of the story,” said Kountur. “It’s about using recycled materials responsibly while still making sure the product remains as easy to use as ever.”

None of these changes compromise the performance characteristics of the product.

Users can still rely on the same viscosity, torque, and strength, making the transition to the new formulations seamless.

Kitty Zhao, head of marketing at Henkel, said that feedback has been encouraging. While local customers are just now being provided with these upgraded Threadlockers, the products have been well received internationally.

“Globally, we’ve had positive feedback,” Zhao said. “What really resonates is that the changes align with our customers’ internal sustainability goals. We’re moving in the same direction as them. We’re not asking them to change how they work with our products.”

For industries increasingly shaped by regulation and environmental accountability, that alignment

is critical. Loctite is positioning itself not only as a provider of adhesives but as a partner for manufacturers navigating the pressures of sustainability, regulations, and efficiency.

Preparing for the next generation

Looking ahead, Henkel is clear that innovation will continue to drive Loctite forward. The company’s 149 year history speaks to its ability to adapt and improve without losing sight of reliability – a balance it intends to maintain in the years to come. Future developments are likely to respond to the needs of advanced manufacturing, where

digital integration and sustainability will play an increasingly important role.

“What people can expect in the coming years is preparation for the next generation of manufacturing,” Matt Greaves, general manager at Henkel said. “That could mean integrating smart technologies, embracing digitalisation, and always keeping customer needs at the centre – all while ensuring that sustainability is embedded into every step of the process.”

The evolution of Loctite Threadlockers reflects both Henkel’s heritage and its forward-looking ethos. By upgrading formulations, incorporating

recycled packaging, and ensuring consistency of performance, the new formulations are designed to meet the realities of today’s industrial landscape without losing sight of quality control.

“At the end of the day, it’s about keeping that trust with customers,” said Greaves. “They know Loctite works, and now they can have the same confidence while also meeting new standards for sustainability and regulation.”

From a small laboratory breakthrough in the 1950s to the latest global upgrade in 2025, Loctite’s journey is a reminder that legacy and reinvention need not be opposites.

Systematiq specialises in defence project management by guiding organisations through every phase of complex programs.

When it comes to navigating defence projects, businesses often find themselves grappling with compliance requirements and demanding timelines. With Australia’s defence sector being both highly regulated and uniquely structured, the stakes are high. This means for manufacturers eager to work with Defence, winning a contract and delivering on it can feel daunting without the right expertise.

This is exactly where Systematiq fits in.

Founded more than 13 years ago, the veteranowned consultancy has grown from a small partnership into a trusted player in the Australian defence industry.

“Systematiq supports clients across each of the Defence domains – land, air, maritime and Aerospace,” said head of capability at Systematiq, Ben Burrows. “We are unique in that we provide skills and experience across the Defence project lifecycle, which is relevant to all Domains and includes project management, engineering, logistics and training capabilities.”

With a team of around 30 skilled consultants, Systematiq has supported over 500 projects to over 200 clients. Its services stretch across the defence lifecycle, from initial tenders through acquisition and into sustainment.

Tender and project procurement support

Breaking into the defence supply chain is no simple feat. The process of preparing and submitting a tender is resource-intensive, competitive, and riddled with compliance hurdles.

For smaller companies especially, the barriers can feel insurmountable.

“Defence is a single-buyer market with a highly regulated procurement process,” said Burrows. “Getting into contract with Defence is timeconsuming, with delays often outside a company’s control. That creates challenges for cash flow, strategic planning, and resource management.”

While many businesses are excellent at what they manufacture or develop, head of delivery at Systematiq, Sarah Norton admitted that sometimes they’re not set up to respond to tenders at the level Defence expects. This is where consultancy can be the difference between success and failure. Systematiq has filled this niche to guide clients through the tendering process, from early capture planning to final bid submission.

“We provide bid management methodology and expertise – helping them answer complianceheavy questions, , provide solution architects, tender writers, Defence subject matter experts, graphics and prepare executive summaries. Our expertise ranges from Systems Engineering, Commercial, ILS, Project Management, Scheduling, AIC and Pricing. Our role is to make the process second nature,” said Norton.

According to Norton, Systematiq embeds its consultants within client teams, instead of operating in silos. This collaborative approach ensures the bid draws on both the client’s technical expertise and Systematiq’s understanding of Defence expectations.

“When we work as one team, the product is always better. We can either run the entire bid, provide targeted expertise, or supplement a client’s team when resources are stretched,” said Norton. “But the earlier we’re engaged, the more effective we can be in supporting our client in shaping relationships, building a value proposition, and positioning them for success.”

Winning the tender is just the start. Burrows said once a project is in contract and acquired, businesses face “hundreds of risks” when introducing new capabilities into service with Defence. This stage is marked by risks such as scope creep and stakeholder complexity which means strong project management is essential.

“One of the biggest is scope creep. The

Commonwealth might define a broad capability at contract signing, but as details emerge and operational requirements evolve, the level of detail demanded changes,” said Burrows. “Additionally, strong project management is essential to control scope and ensure companies are paid fairly for what they deliver.”

Beyond scope, Burrows said that Systematiq can help businesses across other technical certification hurdles that require expertise that many manufacturers simply don’t have in-house. These include certification, environmental compliance, engineering documentation, lifecycle costing, and integrated logistics support.

He said that stakeholder management is another critical challenge. Defence projects rarely exist in isolation; they intersect with multiple agencies, services, and contractors.

“You need strong communicators and leaders who can align diverse stakeholders, run workshops, and keep projects on track,” said Burrows. “That kind of relationship-building and trust can’t be replaced by AI. It comes down to people with the right skills and experience.”

Even after a capability has been introduced into service, the demands on contractors don’t end. Sustainment brings its own complexities, particularly when it comes to contract management and aligning with Defence’s funding cycles. Burrows said this dynamic is one that

can puzzle companies unfamiliar with Defence’s internal drivers.

“In sustainment, the Commonwealth’s priorities are very different. They’re trying to spend their allocated budget to deliver capability, while businesses are trying to make money,” said Burrows

While all the disciplines of acquisition – project controls, communication skills, documentation – remain essential, Burrows said Systematiq continues to help clients adapt by providing ongoing project management support through contract oversight.

“In sustainment, understanding Defence’s funding processes and planning cycles becomes critical. Our role is to help clients align with those realities while continuing to meet compliance and performance obligations,” he said.

One of the clearest demonstrations of Systematiq’s value comes from its work with Thomas Global Systems, an Australian company specialising in advanced electronics and simulation. This work began right from the project’s outset, helping the company position and shape their response to a tender.

“They won the contract, and we’ve continued to support them through acquisition and now moving

towards sustainment,” said Burrows.

The project involved delivering simulator support for the M1A2 Abrams tank under LAND 907 Phase 2. While Thomas Global brought expertise in simulation technology, they needed support to meet Defence’s rigorous requirements around sustainment.

“Thomas Global is excellent at building simulators. But they weren’t necessarily experts or resourced to develop logistics and training frameworks for Defence,” said Burrows. “Our consultants provided that expertise – ensuring the simulators will be properly integrated into Defence’s inventory, with the right training, maintenance, spares, and troubleshooting support.”

The partnership highlights how consultancy can help innovative Australian companies thrive in Defence, ensuring technical strengths are backed by the capabilities that Defence demands.

As the defence landscape evolves, so too must the strategies of companies seeking to work within it. Systematiq’s team sees several key trends shaping the future, as Defence attempts to move faster and requirements become stricter.

“While there’s a clear push to accelerate, Australian Industry Capability requirements

are becoming more stringent, and through-life value and sustainment is now a stronger focus,” said Norton.

According to Burrows, Cybersecurity is also becoming a non-negotiable requirement, with Defence expecting industry partners to safeguard systems and processes against external threats. He also noted another shift that lies in the types of capabilities Defence is prioritising.