Extraction of 0.5-1 kg of concentrate per 1 megalitre of PFAS contaminated water, soil & biosolids

High-speed treatment – 20,000 L/hr

No activated carbon or extra

Mobile or fixed plants available

Research-based & active on EPA-approved site

Book a free consultation: Lance McKay Business Development Manager lance.mckay@egl.com.au

EcoBatt’s world- rst shredding plant tackles the hidden hazard of batteries embedded in devices.

Liebherr introduces two new revolutionary machines.

New technologies unlock hidden value in

Two sustainability-driven heavyweights join forces.

Transforming

table solutions.

New narrative emerges for plastic pipe systems.

Solution

Removing cost barriers that plague PFAS

Workplace training that’s always on, always relevant.

“EVERY TIME A BATTERY GOES INTO GENERAL WASTE, IT IS A MISSED OPPORTUNITY AND A RISK CREATED.”

ou owe, Chief Executive Officer, EcoCycle Group

Tailored, adaptive, and scalable organics solutions.

What’s behind a new equipment purchase.

Debunking common composting myths.

Melbourne-made tech cleaning up waste problem.

Tailored reporting for tricky to recycle items.

Data platform reveals hidden e ciencies.

New delivery adds to material handling eet.

Under.

Introducing two new revolutionary machines. 48 POWER OF COMPACTION

e key to maximising capacity and pro tability. 50 THE TYRE TAKEDOWN

How preparation enables high-quality output.

TAKING CENTRE STAGE

Countdown to Waste Expo Australia.

Why awards are a good news story.

Next level award nominations open.

The all-new Isuzu truck range. Reliability

The all-new range of Isuzu trucks has arrived. With a sleek new cab design, more advanced safety features and a smoother, more comfortable drive, the new range will change the way we rely on our trucks. Forever.

To find out more, visit your nearest Isuzu Trucks Dealer or visit isuzu.com.au

letter for a milestone 100th edition of Waste Management Review magazine.

It was in August-September 2015 that the magazine was launched, with a simple yet ambitious goal: to provide a resource that showcases the best of the domestic and international waste and resource recovery industries. A decade on, that mission remains as vital as ever.

Waste Management Review has championed the early innovators and highlighted the importance of the industry in Australia’s journey towards a more sustainable future. Back in 2015, resource recovery was in its nascent stages. e conversations of the time centred on the need to improve sorting and collection, while land ll remained the default for a signi cant portion of waste.

Today, resource recovery is no longer a fringe concept; it is a core pillar of the economy. e industry is a powerhouse of innovation and technology providing solutions for everything from hard-to-recycle plastics to organics and a nationwide push for a true circular economy.

e challenges remain, but the solutions are more sophisticated than ever, and so it seems tting that our cover story for this 100th edition highlights a company bringing world- rst technology to Australia to address one of the industry’s most insidious challenges – batteries embedded in devices.

We also look at proven solutions for PFAS in wastewater, and examine advances in the circular economy – from smarter equipment, and powerhouse partnerships to long-life products.

As we re ect on 100 editions, we are not just celebrating a publication; we are celebrating the progress of an industry that is shaping a cleaner, more prosperous, and sustainable Australia.

Happy reading.

CEO

Christine Clancy

christine.clancy@primecreative.com.au

PUBLISHER

Sarah Baker sarah.baker@primecreative.com.au

MANAGING EDITOR

Lisa Korycki lisa.korycki@primecreative.com.au

JOURNALIST

Jennifer Pittorino jennifer.pittorino@primecreative.com.au

HEAD OF DESIGN

Blake Storey blake.storey@primecreative.com.au

DESIGN

Laura Drinkwater

BRAND MANAGER

Chelsea Daniel chelsea.daniel@primecreative.com.au p: +61 425 699 878

CLIENT SUCCESS MANAGER

Justine Nardone justine.nardone@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive Docklands VIC 3008 Australia P: +61 3 9690 8766

info@primecreative.com.au www.wastemanagementreview.com.au

SUBSCRIPTIONS

+61 3 9690 8766

subscriptions@primecreative.com.au

Waste Management Review is available by subscription from the publisher. e rights of refusal are reserved by the publisher

ARTICLES

All articles submitted for publication become the property of the publisher. e Editor reserves the right to adjust any article to conform with the magazine format.

COVER

Cover image: EcoCycle Group

COPYRIGHT

Waste Management Review is owned by Prime Creative Media and published by John Murphy.

All material in Waste Management Review is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. e Editor welcomes contributions but reserves the right to accept or reject any material. While every e ort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. e opinions expressed in Waste Management Review are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Transforming waste into high-quality aggregates and recovered metals. By recovering these materials from IBA, we're reducing landfill reliance and enabling sustainable solutions for civil construction.

erating across the globe, we lead in develo ing end-mar ets and wor ing with regulators to enable res onsible reuse, reserve resources, and drive the circular economy forward.

Blue Phoenix Australia

Mr Ian Lynass, Managing Director

ian.lynass@bluephoenix-group.com

0418 290 080 | www.bluephoenix-group.com

n a world first, Eco att s new ictorian shredding plant is tac ling the hidden ha ard of batteries embedded in devices, creating a safer waste stream.

EcoBatt, a subsidiary of the EcoCycle Group, has o cially opened the world’s rst Battery-in-Device Shredding (BIDS) Plant in Campbell eld, Victoria, marking a signi cant step forward in how Australia manages embedded battery waste.

On 3 September, Victorian Environment Minister Steve Dimopoulos joined EcoCycle Group Chief Executive O cer Doug Rowe to o cially open the plant, which has been supported by the Circular Economy Infrastructure Fund – Hazardous Waste.

e fund is delivered by Sustainability Victoria under the Victorian Government’s circular economy plan, Recycling Victoria: a new economy. Addressing the crowd, the minister said the new plant represents a clear example of how government and

industry can work together to deliver solutions with lasting impact.

“ is project shows how investment in recycling infrastructure can deliver real results for our circular economy and keep batteries charging our economy throughout their life cycle,” he said.

Doug said the project shows how smart investment in recycling infrastructure delivers genuine outcomes for the circular economy.

“Our innovation is enabling Victoria to lead the way in managing hazardous waste safely and sustainably.”

Australia’s appetite for battery-powered products is increasing. Phones, toys, vapes, power tools, light-up sneakers, robot vacuums, and countless other items contain batteries that are often discarded with the battery still embedded in the device.

When these devices end up in household waste or kerbside recycling, they pose serious risks. Fires linked to lithium-ion batteries have grown signi cantly, with incidents recorded in collection trucks, transfer stations, metal recycling yards, and material recovery facilities across the country.

Alongside re risks, batteries and embedded batteries that reach land ll can leak toxic materials into the environment.

Doug says the BIDS Plant was designed to address these challenges directly.

“Loose batteries have established pathways for safe recycling, but embedded batteries have remained a gap. is plant lls that gap. It takes the risk out of the waste system and ensures valuable materials are recovered responsibly,” he says.

e facility combines controlled discharge systems with automated

shredding and separation. Devices are neutralised to eliminate re hazards, then mechanically processed into plastics, metals, and black mass containing critical minerals such as lithium, graphite, cobalt, nickel, manganese and zinc.

By treating both the batteries and the surrounding materials, the plant supports circular economy outcomes while improving safety for the waste sector and the wider community.

Doug says the BIDS Plant demonstrates that Australia has the capability to deliver world-leading recycling solutions.

“ is facility shows that we can build the infrastructure needed to deal with modern waste streams onshore, at scale, and to the highest standards of safety,” he says. “It’s happening now.”

e BIDS Plant adds a new layer to EcoBatt’s national collection and processing network, which already includes more than 7500 battery drop-o points, United Nations and Dangerous Goods-rated bins, drums and kiosks, and a eet of dangerous goodslicensed vehicles.

By integrating the new plant into this network, EcoBatt can now manage the full spectrum of batteries – from standalone cells to those embedded in complex devices.

Doug says the plant reduces the risk of re incidents caused by incorrectly discarded batteries for local councils and waste operators. For the community, it o ers assurance that there is a safe pathway for everyday products that were previously di cult to recycle. For industry, it provides certainty that processing can occur onshore, without reliance on export markets.

“ is is a win across the board,” he says. “It improves safety, protects the environment, and helps Australia keep hold of the resources that will be vital to future industries.

“We must stop e-waste, embedded batteries and loose batteries being exported with permits. Tens of millions of dollars have been invested to process this problem waste onshore, and one would expect the government would want to support that.”

While the infrastructure now exists, Doug says its success relies on people knowing how and where to correctly dispose of batteries and embedded battery products.

“ e community is willing to do the right thing, but awareness remains low. We need clear, consistent education so that people understand where to take their devices and why it matters,” he says.

to pay for great recycling solutions –rather than the cost of rebuilding waste and recycling facilities destroyed by preventable battery res from loose and embedded lithium batteries.”

EcoBatt has invested heavily in collection systems, including smart bins, re-rated drums and monitored kiosks. However, Doug says government support is essential to drive national education campaigns that reach households, schools and businesses.

general waste, it is a missed opportunity and a risk created. e more people know, the safer and more sustainable the system becomes,” he says.

e opening served as a platform for Doug to renew calls for a strong national stewardship framework to underpin the system and ensure it becomes commercially viable.

“We now have the collection points, the safe transport systems, and the

world- rst facility,” he says. “What we need is a strong, government-supported extended producer responsibility scheme that ensures the industry contribute fairly with the correct Equivalent Battery Unit rates.”

e BIDS Plant will process up to 5000 tonnes of devices annually, providing a scalable model that can be expanded nationally. Plants in other states and New Zealand are planned for 2026.

For EcoBatt, the new plant represents more than a milestone. It’s part of a broader strategy to create a complete, closed-loop battery recycling system across Australasia.

“ is is a major step forward for onshore processing in Australia,” Doug says. “It demonstrates what is possible when industry invests and when government provides support. With the right policy settings, government backing, and community participation, Australia can lead the way in closing the loop on one of the fastest-growing waste streams of our generation.”

For more information, visit www.ecobatt.com.au

Softplay Playground Mulch

we can repurpose your waste.

New technologies are helping businesses unlock hidden value in rejected products that were once destined for landfill.

new breed of waste management is emerging, where a production line’s rejects are no longer seen as a liability. Companies are transforming reject products from waste into valuable resources, thanks to advanced depackaging technology and a new mindset.

Historically, a food item with a faulty label or a pharmaceutical product with

a slight defect was simply designated for land ll. But as the cost of waste disposal continues to rise and corporate zero-waste-to-land ll targets loom, an increasing number of businesses are looking for a better way.

is shift is giving rise to a new type of waste processing, focused on separating recyclable packaging from its contents.

As Waste Initiatives Managing Director Dwayne Smith explains, a company that bottles water is now realising that there are solutions that can divert “100 per cent of the weight of that reject product to another use, resulting in substantial savings in waste costs”.

is change is driven by major players in the food and beverage and pharmaceutical industries, responding to shareholder pressure and new corporate environmental and social governance goals.

Sales Manager Shannon Sangster says clients are coming to Waste Initiatives for these solutions because they are required by law to destroy certain products and want to do so in the most sustainable way possible.

“ e focus is no longer just on destruction but on maximising material recovery while minimising waste management costs,” he says.

Waste Initiatives’ success stems from its highly consultative approach, recognising that no two solutions are the same.

“No one size ts all,” Dwayne says, “equipment for processing a glass container is very di erent to the equipment for processing material like aluminium cans or yoghurt containers.

“Our primary objective is to establish how to e ectively manage the separation of organics and packaging and the

intended solution of each of these byproduct once separated.”

Dwayne says the consultation phase can take some time to tailor the solution to the customer’s requirements. is bespoke approach often involves taking a customer’s product and trialling it in a pilot system to ensure a perfect t before a full-scale implementation.

“ is provides full assurance and con dence that the nal solution will deliver exactly what is needed, without any surprises,” Dwayne says.

Waste Initiatives o ers a wide range of product destruction and depackaging systems designed for speci c materials, including the Mavitec range, which delivers purity outputs of up to 99.7 per cent.

“ is technology provides a clean plastic source and a clean food source free of microplastics or any other contaminants,” Shannon says.

It’s suitable for supermarket, kerbside and restaurant waste, as well as factory rejects and other food co-products.

Waste Initiatives provides systems capable of handling everything from aluminium cans and plastic bottles to glass jars; separating the recyclable package from the contents inside.

e team melds best-in-class technology with in-house engineering expertise to overcome an impressive range of challenges.

“ ere’s quite a breadth of experience within the Waste Initiatives team

that the customer bene ts from,” Dwayne says.

He recalls a milk facility in Queensland where the team developed a system to separate milk from highly recyclable high-density polyethylene plastic.

“ e depackaging solution prevented the whole lot from going to land ll. Instead, the plastic could be recycled and the milk used as stock feed,” he says.

“What was once a costly mixedwaste stream is now a source of valuable material, but more importantly, an important diversion of waste into recycling.”

Another unique challenge was the depackaging of frozen ice cream, which required custom modi cations to prevent the equipment from freezing while processing the ice cream in its solid state.

Shannon says the engineering team will often integrate equipment from di erent suppliers, such as a separating machine and a baler, to create a single system that delivers a complete solution. He says Waste Initiatives’ in-house

engineering and equipment portfolio allows it to bring together shredding, separation and baling solutions into a single system.

e technology is built to last, with the team often upgrading from standard steel to stainless-steel options for applications involving corrosive products such as those found in the pharmaceutical industry.

Local support and nationwide aftersales service are also a core part of the company’s value proposition.

“It’s crucial that the equipment continues to do what it’s meant to,” Shannon says. “ at requires on-site support and spare parts available locally, so that if something does happen to the equipment, a solution is back up and running with little to no delays.

“It’s not just our range and tailoring the solution, Waste Initiatives has been going for 40 years with a depth of knowledge and experience throughout the team. We know what works and what doesn’t.”

For more information, visit: www.wasteinitiatives.com.au

At EcoBatt, we are driving real change through our nationwide Battery Collection Service, which is designed to significantly reduce the number of batteries ending up in landfill. With approximately 7,000 collection units located across Australia in partnership with major retailers, we are making battery recycling more convenient and accessible than ever before.

Improper battery disposal can have serious consequences. From fires in waste trucks and landfill sites to toxic chemicals leaking into soil and waterways, the risks to our environment, wildlife and community health are far-reaching.

Recycling batteries correctly is a simple yet powerful way to protect what matters. By working together, we can create a cleaner, safer future and preserve valuable resources for generations to come.

What’s recyclable through EcoBatt’s Smart Bins?

Button cell batteries

Mobile phones

Easily removable batteries

Rechargeable batteries under 5kg

Regular AA & other household batteries

For organisations grappling with substantial battery waste, EcoBatt offers tailored solutions. From battery recycling bins ranging from 2L to 120L to our larger-scale Mixed Battery Safety Bins available in 600L and 800L capacities, we’ve got you covered.

Reach out to us at 1300 32 62 92 to connect with one of our battery recycling specialists who will craft a bespoke solution to suit your needs. Because protecting what matters starts with all of us working towards a cleaner, greener tomorrow, join with EcoBatt today.

What happens when two sustainability-driven organisations come together with a shared vision? For Opal and Repurpose It, the answer is clear: waste becomes opportunity.

As one of Australia and New Zealand’s largest recycling, paper and packaging businesses, Opal is committed to sustainable circular economy business practices.

In a new move, Opal and resource recovery specialist Repurpose It have aligned with one common goal – recovering resources, such as timber residues from the papermaking process, and giving them a new life.

ushan Jayawardena, General Manager of Strategic Sourcing for Opal, says the partnership with Repurpose It focuses on recovering timber residues, made up of wood bark and sawdust, which are a by-product from the paper making process at the Maryvale Paper Mill.

“Repurpose It recovers the timber resources and gives them a new life as decorative landscape bark, soil conditioners, compost mixes and mulches,” says ushan.

rough the partnership, bark can be processed into a range of landscaping mulches and soil conditioner blends, as well as base material for engineered soils. Sawdust and nes are blended into compost mixes and used as bulking agents to support organics processing, while mixed residues are screened and re ned so they can be incorporated into Repurpose It’s engineered soil and compost products, ensuring maximum recovery.

Opal and Repurpose It have partnered to deliver sustainability goals. Images: Repurpose It

Opal’s commitment to a circular economy is displayed through its operations as a manufacturer of cardboard packaging and paper solutions.

One aspect of Opal’s business is creating a fully integrated cardboard packaging value chain, collecting used cardboard from retailers and businesses, and remanufacturing it into new paper and cardboard packaging.

“Opal is focused on providing customers with products and solutions that replace hard-to-recycle materials and single-use plastic packaging,” says David.

“By nding alternative uses for our waste streams, we are advancing our waste minimisation initiatives.”

He says the partnership with Repurpose It supports Opal’s broader operations, which span more than 70 sites across Australia and New Zealand.

our broader commitment to the circular economy and land ll avoidance,” says David.

ushan says Opal is actively exploring alternative uses for waste streams across its entire paper and cardboard packaging businesses, to better align with sustainability objectives.

Safety First

Designed top safety standards

David Jettner, General Manager of Environment and Sustainability for Opal, says the paper division manufactures paper from used cardboard and locally-grown plantation wood across paper mills in Victoria and New South Wales. is is processed into a range of packaging papers and boards for Australia, New Zealand and overseas.

Machines run clean and efficient

Repurpose It works to eliminate waste and pollution through closed-loop resource recovery. It creates repurposed materials from a range of waste streams, including food organics, garden organics, hard green waste, mixed rubble, concrete, and brick.

Sustainable

Built to support a greener future

It delivers all the need for demanding without compromising

Aligning with a like-minded organisation, such as Repurpose It, to reuse traditional waste streams has always been on the cards. But ushan says more than operational and environmental value, Repurpose It brings creativity and initiative to the table.

Volvo leads in sustainable construction

“By partnering with Repurpose It, Opal can ensure its timber residue waste is put to productive use, which supports

Cutting-edge features enhance control

“ ey are proactively presenting innovative ideas for improving our current processes, demonstrating an understanding of our operational needs,” he says. “ eir comprehensive industry knowledge and specialised insights distinguish them as true subject matter experts.

Delivers powerful, precise performance

“From our initial engagement, it became clear that Repurpose It is a partner we genuinely value collaborating with.”

Finding value in what would otherwise be considered waste is built into Repurpose It’s DNA, says Ashley Johnston, General Manager of Business Development.

“By repurposing all recovered residues, including bark, hardwood waste, sawdust, and nes, through our organics facility, we transform them into high-quality landscaping products,” he says. “ is approach keeps timber residues in productive use and supports our broader commitment to the circular economy by supplying sustainable products back into horticulture, landscaping, and infrastructure markets.”

For more information: www.repurposeit.com.au

Volvo's technology utilises battery power to achieve zero tailpipe emissions and remarkably low noise levels.

Electric Leadership

Volvo leads in sustainable construction

Zero Emissions

Safety First

Machines run clean and efficient

High Productivity

Delivers powerful, precise performance

Designed with top safety standards

Smart Technology

Smart Technology

features enhance

Cutting-edge features enhance control

Sustainable Focus

Built to support a greener future

Volvo's technology utilises battery power to achieve zero tailpipe emissions and remarkably low noise levels.

It delivers all the performance you need for demanding construction tasks without compromising on sustainability.

Vortair technology is transforming waste disposal challenges into profitable, sustainable solutions.

Australia is grappling with a waste crisis growing faster than existing solutions. Traditional waste-toenergy plants may reduce land ll volumes, but concerns remain about emissions, recycling displacement, and limited circular outcomes, says Vortair Chief Executive O cer Je Lang.

As the sector faces pressure to move beyond these traditional methods, Je says Vortair’s autogenous grinding technology could provide the missing link to true circularity, combining scalability, environmental integrity, and commercial viability.

He says Vortair has created fully integrated circular processes that transform waste streams into valuable resources by combining its milling technology with other waste processing technologies such as biochar pyrolysis, bioconversion using black soldier y larvae, and anaerobic digestion.

Vortair is partnering with several companies and has completed successful trials using biochar pyrolysis and Vortair milling to create biogas and carbon black from municipal solid waste (MSW).

“We’re not just reducing waste, we’re unlocking value streams that make circularity nancially viable,” Je says. e process is designed for a seamless, circular work ow:

• MSW feedstock milling: Vortair’s milling technology pulverises waste into micronised feedstock, reducing volume by up to 90 per cent.

• Biochar pyrolysis: e milled waste is heated in oxygen-limited conditions to produce biochar, syngas, and bio-oils.

• Biochar to carbon black: Biochar akes are micronised with Vortair’s milling technology to create high-value industrial carbon black powder.

• Biogas loop: Pyrolysis gases power the facility, achieving energy selfsu ciency, completing the loop.

Je says this approach highlights true circularity that avoids land ll, cuts emissions, and provides revenue from waste streams and industries with secondary raw materials at scale. “ e environmental upside is clear: near-zero methane leakage, carbon sequestration through longlived biochar, and circular resource recovery that reduces reliance on virgin materials,” he says.

e re not just reducing waste, we re unloc ing value streams that ma e circularity financially viable.

e an , ortair, Chief Executive Officer

On the commercial side, Vortair shifts waste management from a compliance cost to a revenue-generating model.

“ e technology for processing MSW, combined with other waste processing technologies, monetises carbon black sales across multiple industries and o sets power needs and costs through on-site biogas use,” Je says.

“ e missing driver in circularity has always been pro tability. Vortair delivers both ecological integrity and nancial returns.”

Vortair’s modular design means the technology can be deployed in both small, regional councils and large-scale industrial facilities. is scalability is critical not only for Australia’s circular economy targets but also for global regions where land ll remains dominant.

Je says as governments and businesses pursue carbon neutrality and waste reduction, Vortair is positioning

itself as a leading global resolution on waste circularity that transforms waste into wealth, aligns with policy goals, and addresses humanity’s growing ecological burden.

“By using its autogenous grinding technology, which reduces waste volume by up to 90 per cent, Vortair creates a uniform feedstock for downstream value recovery. Seafood waste becomes premium sh meal, MSW is converted into carbon black and fuels, and glass transforms into sand replacement for concrete.

“Every metric tonne of glass waste sent to land ll costs Victoria up to $640 – a waste of money and materials.”

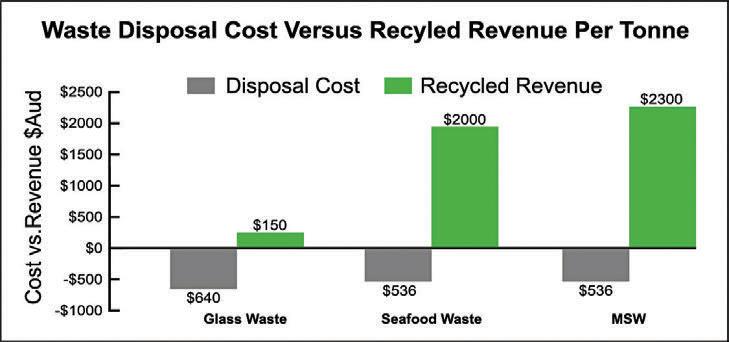

Je sites three case studies:

Glass waste: Disposing of one metric tonne of glass in Victoria costs on average AU$640, comprising land ll gate fees of $390 per tonne, the Victorian Environment Protection Authority (EPA) waste levy of

$169.79 tonne (metro 2025 rate), and transport averaging $80 tonne depending on distance and load.

Vortair milling and processing technology transforms this glass into resourced glass powder, a sand replacement for concrete, that can be sold for up to $150 per tonne. is approach o ers a viable circular solution when considering disposal cost, energy savings, volume reduction and environmental and sustainability policies.

Seafood processing waste: Disposing of one metric tonne of wet seafood waste in metropolitan Melbourne costs on average $536 – comprising land ll gate fees of $286.50 tonne, waste levy of $169.79 tonne and transport and handling averaging $80 tonne, depending on distance and containment requirements. By using Vortair’s milling technology, this waste can be converted into sh meal, yielding more than $2000 per tonne. Beyond nancial bene ts, this process reduces moisture and volume, lowers disposal fees, and creates a market-ready commodity that supports sustainability goals.

Municipal solid waste: Disposing of one metric tonne of MSW in metropolitan Melbourne costs on average $536 – comprising land ll gate fees of $286.50 tonne, waste levy of $169.79 tonne (metro 2025 rate), and transport and handling averaging $80 tonne, depending on distance and containment requirements. Processing this waste via Vortair milling into carbon black derived from MSW can be sold for a price per tonne of $2300 ($2.30 per kilogram).

e process also achieves a volume reduction of about 90 per cent and contributes to signi cant greenhouse gas savings, enhancing both environmental and nancial outcomes.

For more information, visit: www.vortair.com.au

A new narrative is emerging for plastic pipe systems. They are not single-use plastics, but robust, long-life products with a commitment to circularity.

When we think of plastics we generally think of waste, often picturing single use such as bottles and disposable packaging. But the Plastics Industry Pipe Association of Australia Limited (PIPA) is working to change the narrative, highlighting the positive use of plastics – how plastic pipes are designed for longevity and have a vital role to play in the circular economy. ese are engineered products, built to last for at least 100 years. Not only are they designed to be durable, their manufacturing process is clean and e cient, with low embodied energy and the ability to be manufactured with re-used scrap material, ensuring that waste is designed out from the very beginning.

e core of their environmental bene t lies in their long life span and durability in use, according to Cindy Bray, PIPA Executive General Manager.

“We want people to understand that plastic pipes are an engineered solution that, when designed and made to the relevant Australian standards, are durable and long-lasting and can be used for the good of the environment,” Cindy says.

Unlike other materials that may corrode or degrade over time, plastic pipes are resistant to chemical attack and maintain their integrity in harsh soil and wastewater environments.

is ensures they can deliver vital services reliably for decades with minimal maintenance.

e commitment to circularity extends beyond their long life. PIPA has established a recycling program to ensure that even after a century of use, plastic pipes can be recovered and recycled into new products.

Cindy says while the low volume of pipes in waste streams means the vast majority are still in their rst life cycle, the industry is proactively working with stakeholders and recyclers to divert resources from land ll.

“Our commitment to the Australian community is simple – we aim to recycle the maximum amount of usable plastic pipe and other suitable materials into new plastic pipes,” she says.

“PIPA, working with a variety of partners, has established a Plastic Pipes Recycling Program, linking PIPA members and established plastic recyclers with information and locations for end users to deliver their no longer needed pipes.”

Not all plastic is the same, and Cindy emphasises that you can’t use just any recycled content in plastic pipes – it must be the same requirements as virgin material to ensure product performance.

PIPA’s POP208 guideline provides a clear framework for how recycled polyethylene (PE), polypropylene (PP), and rigid PVC (polyvinyl chloride) can be safely and e ectively incorporated into non-pressure pipe applications. e association has also released a discussion paper e Use of

Recycled Content in Plastic Pipes, highlighting the plastic pipe industry’s commitment to sustainability, safety, and performance.

PIPA is also a strong advocate for reuse and repair.

“Many plastic pipe systems in buried infrastructure can be reused as a host for new pipes, a process that signi cantly reduces environmental impact by eliminating the need for new trenches,” Cindy says. “ is approach, alongside readily available repair options, further extends the life span of critical infrastructure. rough these initiatives, the plastics pipe industry is not only engineering a product for longevity but also building a system for a true, long-term circular economy.”

For more information, visit: www.pipa.com.au

New regulations are coming for Australia’s PFAS challenge. The Environmental Group is ready with a solution to help industry act now and prepare for the future.

Early action beats delayed reaction,” says Jason Dixon.

As the Chief Executive O cer for e Environmental Group, Jason says getting ahead of the curve is the only sustainable path forward for industry, with new regulations on the horizon that will make the disposal of “forever chemicals” a major concern.

In March 2025, the Federal Government released the third version of the PFAS National Environmental Management Plan (NEMP), which provides a framework for the environmental management of per- and poly uoroalkyl substances (PFAS)contaminated materials and sites.

NEMP 3.0 speci cally introduces new rules for PFAS in recovered wastes, PFAS in biosolids (setting new maximum values for PFAS that can be in treated sewage sludge that are spread on land) and mandates the monitoring of PFAS levels in wastewater and various waste streams, such as leachate from land lls.

In response, the Environment Protection Authority (EPA) is working on adding new monitoring requirements for PFAS to the licenses of sewage treatment plants and land lls. ese new requirements are being developed in collaboration with key industry players and are expected to come into e ect soon.

Jason says that while changes are inevitable, the right thing to do is to act now.

“ e invisible nature of PFAS and its persistence in the environment mean the problem will not go away on its own. It’s just a never-ending cycle unless we actually remove it,” he says.

“Environmentally, it’s not the right thing to do to wait for legislation. Early adopters will not only avoid penalties but position themselves as leaders in sustainable, compliant waste management.”

e Environmental Group’s solution, which has developed over many years from a research project in conjunction with Victoria University

to a fully operational industrial-scale plants today, uses a process called foam fractionation. is technology extracts PFAS from wastewater, soil and biosolids without creating additional waste streams, leaving behind only the concentrated PFAS component for safe destruction.

Jason says it’s an advantage over other systems that use lter mediums or activated carbon, which become a contaminated waste stream that then needs to be paid for and disposed of.

“ e Environmental Group’s process means that a site can avoid creating a by-product that needs to be discarded,” he says. “Ultimately, e Environmental Group’s solution contributes to a circular economy by producing a reusable product. e processed material can be used for manufacturing, processing, compost or even for purposes like dust suppression at land lls.”

e team at e Environmental Group works with clients to ensure a solution is built speci cally for them and their needs. Samples are taken from each site and tested for contamination levels. e size of the treatment plant is scaled in proportion to the amount of wastewater discharge per day.

“If they can discharge 200,000 litres a day, then you scale the plant to meet that need,” Jason says. “We want to make sure that any of our products and services are customerspeci c. at’s where our experienced team come into play.

“Businesses are encouraged that PFAS are removed before further processing as they can risk non-compliance, environmental harm and reputational damage.

“ e Environmental Group has a proven, local solution that meets current and upcoming PFAS compliance standards, while future-proo ng operations for even stricter environmental oversight.”

For more information, visit: www.environmental.com.au

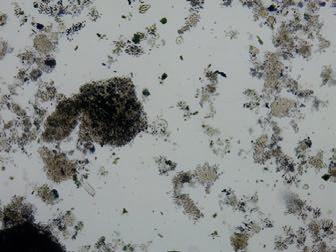

ew technology o ers a critical solution to a universal problem, tac ling P and co contaminant removal with a focus on a ordability and efficiency.

In the world of environmental contaminants, few present a greater challenge than per- and poly uoroalkyl substances (PFAS). Often called “forever chemicals,” they’ve found their way into water systems across the globe, leading to a new class of problems for waste and water treatment facilities.

e cost and complexity of their removal have been a barrier, but Montrose Environmental Group, through its subsidiary ECT2 (a technology company focused on environmental solutions), believes it has a new way forward.

Its latest innovation, nanoSORB, is designed to be an a ordable, largescale solution for removing PFAS from complex waste streams.

Paul Rodriguez, Director of PFAS Residuals Management for ECT2, has spent his career in the water treatment industry and understands the need for e ective yet economical solutions.

nanoSORB is the result of years of research and is a direct response to cost barriers that plague PFAS treatment.

“We’re turning the oc (the visible aggregate of small, suspended particles that have clumped together) – the soup in the water treatment process – into our PFAS removal device,” Paul says.

e process involves embedding a nely divided, organically sourced adsorbent material directly into a biological or chemical oc. e approach is a departure from traditional methods,

eliminating the need for expensive pretreatment steps.

Paul says nanoSORB’s primary bene t is its ability to lower both the capital and operating costs of PFAS removal, making it accessible to a much wider range of facilities.

“While other technologies can achieve high purity, they come at a much higher price point,” he says. “nanoSORB, however, is designed to deliver a similar result at a much lower cost.

“In a recent pilot trial, the technology demonstrated an average reduction of between 90 to 95 per cent of PFAS in a waste stream. is level of removal is a game-changer, as it allows facilities to meet regulatory requirements without breaking the bank.”

Its compact design also means that facilities with space constraints, such as municipal treatment plants or land ll leachate systems, can implement the technology without major infrastructure overhauls.

nanoSORB is designed to be integrated into existing waste streams and works particularly well in activated sludge processes, such as those that treat land ll leachate. Once the PFAS is adsorbed into the oc, it can be disposed of along with the plant’s residuals, which can then be thermally destroyed or land lled with the contaminant contained and immobilised.

Paul says this process is key to breaking the cycle of PFAS in the

environment, ensuring the contaminant is not simply pushed from one waste stream to another.

ECT2 is seeking pilot candidates to test nanoSORB in Australia. e ideal candidate would be an activated sludge process currently treating land ll leachate that needs to remove PFAS from its treated e uent, or biological treatment systems that are already land lling or incinerating their sludge.

For ECT2, the development of nanoSORB is part of a larger mission.

“ e end goal is to break the cycle of PFAS in the environment in a way that’s sustainable from a cost perspective,” Paul says. “We don’t want to just continue to put PFAS into land lls and have it come back at us.”

For more information, visit: www.montrose-env.com

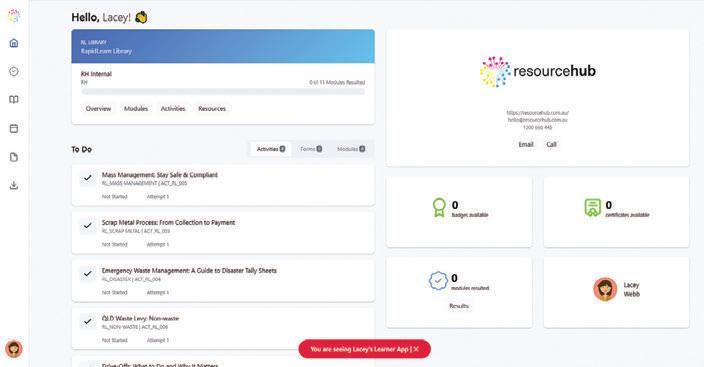

New digital training is helping the waste industry upskill its people, with courses designed for immediate and practical learning.

When an industry is rapidly evolving, a workforce’s skill set can’t a ord to stand still. For Resource Hub, this challenge became an opportunity to deliver training that is always on, and always relevant.

e waste management consultancy already has an impressive resume delivering training sessions for waste management facilities across Australia. Founder and Director Lacey Webb has long espoused that investing in people is essential for the future of the sector.

e company’s new digital training portal is an extension of these e orts. It was inspired by Mackay Regional Council, who approached Resource Hub to build content for their own digital platform to supplement the inperson, annual training provided for its on-site contractor.

Lacey says the council had realised that some skills needed to be reinforced more frequently than once a year

to address “real-world challenges,” particularly for its nine gatehouses and the teams running its transfer stations and land lls.

e cost and logistical challenges of in-person training, especially for remote sites with only one or two sta , could be a hurdle. e council needed something more e cient but wasn’t quite sure of the best path forward.

While there were limitations on the council’s own platform, and it needed time to plan, Resource Hub was inspired! It developed a new learning management system, the RH Learning Portal, designed to make bestpractice standards accessible to waste professionals across the country.

Lacey says the new digital platform is more than just a convenient alternative to traditional training; it’s a vital tool for a modern industry.

e portal o ers two distinct types of content, starting with CoreLearn, which

consists of comprehensive courses that are four to six hours in length.

Courses, like the Queensland Waste Levy and Gatehouse Best Practice packages, are broken down into modules that include digital avatars, short video lessons, and quizzes to ensure understanding. Upon completion, users receive a certi cate and badges for mastering speci c topics.

e second program, RapidLearn, o ers micro-credentials that can be completed in ve to 10 minutes, with a library of more than 40 topics available to the market. ese short, interactive courses are designed for quick, on-thego learning and include quick reference guides or “cheat sheet” handouts for a tangible takeaway.

e portal’s accessibility is a key feature.

“It provides an avenue that doesn’t have the extra cost burden of travel and gives users real-time access to what they need when they need it,” Lacey says.

e system also allows councils and other organisations to onboard new sta immediately without waiting for a scheduled in-person session. And the easy-to-use dashboards allow managers to allocate di erent learning requirements to their team and manage their progression.

e RH Learning Portal will also shortly o er a white-labelling option, allowing customers to customise the portal with their own branding, sitespeci c details, and unique routines.

Lacey says Resource Hub was intent on creating a relatable and engaging user experience, but one that didn’t require

re- lming every time a regulatory shift or industry change occurs.

“ e content is presented by digital avatars with Australian voices from diverse regions, genders, and ages, helping to ensure the training feels relevant and not like it’s coming from a big overseas company,” she says.

“You’re hearing from someone who doesn’t sound like they’re a computer; they sound like someone you’ve met before.

“It’s possible you might even have a few familiar faces from across industry in the mix!”

is focus on credibility extends to its partnerships with national peak bodies, where the company is helping to create training videos featuring managers and even truck drivers from within the industry.

While acknowledging the continued importance of annual in-person training for fostering team connection and cross-skilling, Lacey believes the digital platform is a critical tool for a fastchanging industry.

“In-person, once a year, annual refreshers are critical – they’re 50 per cent about the training and education, the other 50 per cent is about bringing your team together where they have an opportunity to cross skill and learn from each other,” she says.

“But digital learning means you don’t have to wait for that anymore.”

Resource Hub will soon be building out a digital alternative to its existing in-person course content for new councillors to help them understand the waste sector’s nancial, legislative, and commercial considerations, as well as the key players in the industry.

“Councillors get great investment in what the requirements are of being a councillor and what’s required of a council more broadly, but there’s very little education about the waste sector to help a councillor understand and make the right decisions for their region,” Lacey says.

“We’re going to focus on what happens in their region. What do they need to be considerate of, and who are the players they need to think about when making decisions as a councillor, from a waste and resource recovery perspective.”

For Lacey, this is all part of a larger mission to ensure that everyone in the industry is “learning something new as often as possible,” helping the waste sector to invest in its people and its future.

“So often we need to be focused on the big, immediate challenge; batteries or battery res are a critical challenge

right now, PFAS is a topic that everyone’s talking about, FOGO (food organics and garden organics) mandates are rolling out across states,” Lacey says.

“And while those are critical, often the thing that gets left by the wayside is that investment in team. You can get incredible wins with some great outcomes very quickly, whether it’s in person training or heading onto a digital platform, by investing in your people.”

For more information, visit: www.resourcehub.com.au

CEMAC technologies’ integrated systems are designed to future-proof processing assets as the organics economy evolves, enabling operators to consistently produce uality, mar et ready outputs.

Australia’s rapidly growing organics processing sector is navigating a challenging and dynamic environment.

With food organics and garden organics (FOGO) mandates driving change, councils and industry operators are under pressure to adopt smarter, more resilient systems. However, persistent issues such as contamination and inconsistent feedstock quality continue to impact product standards and facility e ciency.

In response, CEMAC technologies is leading the way with integrated, future-ready solutions that support the entire process, from material handling to the production of high-quality compost or digestate.

Eric Paulsen, Managing Director for CEMAC technologies, says being an active member and sponsor of the Australian Organics Recycling Association (AORA), ensures CEMAC’s solutions are not only technically advanced, but also aligned with the realworld needs of Australian processors.

CEMAC technologies boasts two decades of engineering experience and proven technologies for the circular economy, specialising in resourcerecovery, plant engineering and equipment design.

Eric says CEMAC understands that operators need solutions that are not just o -the-shelf, but tailored, adaptive, and scalable.

“What makes CEMAC technologies unique is not just the highly automated technology solutions it supplies, but the way those machines are integrated into a processing plant to cater for individual customer needs,” he says.

By drawing on trusted global partners, CEMAC technologies designs plants where each stage supports the next to deliver consistent outputs that meet Australia’s rising standards for organics processing.

When raw FOGO material arrive from kerbside collections, it often presents signi cant variability. Some

loads can be dominated by bulky garden waste, others dense with food scraps and contamination.

CEMAC technologies addresses this challenge with Westeria’s advanced dosing solutions, including the Tumble Back Conveyor and Disc Spreader. ese systems ensure even, consistent distribution of material across a processing line, preventing overload on downstream equipment and optimising overall plant performance.

e DiscSpreader can be integrated with arti cial-intelligence (AI)-driven technology to maintain consistent material distribution across individual machines, enhancing e ciency of the decontamination process.

After initial screening, the rst stage of cleaning is carried out using Westeria’s AirBasic or stationary AirStar Windsifter. ese machines use strong blasts of air to separate light waste such as plastic and paper from heavier organic materials. Settings can easily be adjusted by hand or automated.

“By removing these troublesome items early, the Windsifter not only reduces downstream contamination but also improves the performance and e ciency of subsequent machinery,” Eric says.

As material progresses through the system, initial contaminants are quickly addressed including ferrous and non-ferrous metals. ese not only

compromise product quality but also pose a risk to downstream equipment.

CEMAC technologies integrates overbelt magnets and eddy current separators manufactured by Wagner Magnete to extract metal contaminants such as nails, cans, and stray aluminium fragments.

In loads with higher contamination levels, complex materials such as plastics, glass, and multilayer packaging may bypass early separation stages. is is where advanced deep learning sorting technology by TOMRA proves invaluable.

By combining AI-powered pattern recognition with cutting-edge NIR (Near-Infrared), X-ray, and visual camera systems, TOMRA’s units can accurately identify and remove a wide range of contaminants, far beyond what manual sorting can achieve. is advanced step enhances the purity of the organic stream, enabling facilities to consistently meet the strict contamination

thresholds set by councils and regulatory bodies.

With contaminants removed, the organic fraction is ready for conditioning. At this stage, a BioGrinder by BHS Sonthofen, engineered speci cally for biological waste, takes over.

Unlike traditional shredders, the BioGrinder ruptures cell structures and homogenises the material, optimising it for rapid microbial activity. is signi cantly shortens composting times or boosts biogas yields in anaerobic digestion processes, delivering measurable e ciency gains for operators.

e nal stage focuses on product re nement.

Spaleck’s 3D Combi screening technology is purpose-built to handle wet, sticky materials that often challenge conventional screening systems.

By precisely separating nes from overs, it ensures a consistent particle

size and captures any remaining contaminants before the material exits the facility.

Eric says the result is a clean, highquality compost or digestate that meets market and regulatory expectations.

From feed to nished product, each component in the process plays its role. By o ering a single contract and point of responsibility, CEMAC technologies reduces risks and simpli es project delivery.

Eric says that as the nation gears up to meet its FOGO targets, facilities that can handle contamination, scale swiftly, and deliver high-quality outputs will drive industry success.

John McKew, AORA National Executive O cer, says CEMAC’s systems will make a di erence in the industry. “It is exciting to see this start to become commercially available sooner than anticipated.”

For more information, visit: www.aora.org.au

Why Valoriza has put its faith in the Komptech Multistar L3.

Processing high-moisture organic waste is one of the most demanding challenges in modern resource recovery, particularly for facilities operating at scale.

Valoriza, a business at the forefront of sustainable waste processing solutions in Victoria, designed its operations around maximising resource recovery and producing AS4454 certi ed high-quality compost.

To improve composted food organics and garden organics (FOGO) screening performance and manage wetter and varied input materials, Valoriza identi ed the need for a more advanced processing solution that could consistently perform better where traditional methods such as trommels, and ip- ow screens were falling short.

To further enhance the capability of its Dandenong South facility, Valoriza recently upgraded its equipment to include the Komptech Multistar L3.

Situated in one of Victoria’s key industrial zones, Valoriza processes more than 100,000 tonnes of kerbsidecollected organic waste each year from households and businesses in Melbourne’s south-east.

e Komptech Multistar L3’s role is to cleanly divide the composted FOGO into ne, medium, and oversized fractions. With its ability to maintain throughput even in wet, sticky conditions, the star screen delivers greater e ciency, reliability, and exibility. Michael Allaway,

Valoriza’s Country Head – Australia, says the business rmly believes no other machine matches the throughput and separation e ciency of the Komptech L3, especially under highmoisture conditions.

“Combined with an electric Crambo shredder, also on site, and the strong support from Lincom Group, Valoriza’s decision to reinvest in Komptech was easy,” says Michael.

“ e new Komptech Multistar L3 forms part of our reinvestment in the Dandenong facility as we optimise our operations to deliver a FOGO processing showcase to the market over the next two years.”

is high-e ciency star screen features a fully electric drive system rated between 60 and 80 kilowatts, providing quiet, low-emission operation.

With a capacity of up to 250 cubic metres per hour, the machine can

adjust particle size at the press of a button, o ering outstanding exibility and control.

Built on a semi-trailer chassis, the machine is highly mobile and easy to integrate into existing composting lines.

As with all equipment supplied by Lincom, the new unit is backed by comprehensive after-sales support.

Lincom Group maintains a national inventory of genuine spare parts and provides ongoing maintenance, repair, and operator training to ensure peak machine performance.

rough Komptech Connect! monitoring and a responsive service footprint, Lincom Group supports customers like Valoriza to achieve their performance and environmental targets.

For more information, visit:

Debunking common composting myths.

Composting is often shrouded in misconceptions. Some envision foul-smelling piles that require costly high-tech systems, while others question whether composting can truly scale to meet modern waste challenges.

With Australia’s ambitious organics diversion targets in place, including a national goal to halve organic waste diverted from land lls by 2030, separating fact from ction is more important than ever.

Scott Woods, Founder and Chief Executive O cer of Sustainable Generation, says the reality, backed by data and decades of experience, is that today’s advanced composting technologies are busting old myths and delivering sustainable solutions. He addresses some of the most common

misconceptions about composting, with insights from industry experts.

Fiction: Only elaborate in-vessel digesters or concrete tunnel systems can manage odours and emissions.

Fact: Modern aerated static pile (ASP) composting with engineered covers achieves in-vessel performance without the complexity or cost.

Concrete tunnels and anaerobic digestion often fall short due to their complexity, high capital costs, and operational challenges. In contrast, covered ASP systems use computerised aeration and breathable membrane covers to create an ideal microclimate.

ese systems are simpler to install and operate than digesters yet can match or exceed their performance.

e SG Mobile System was designed as a robust solution that can be rapidly deployed to meet urgent organics recycling needs, something large, xed facilities often struggle to do.

E ective composting doesn’t require a massive concrete in-vessel structure. Smarter, streamlined, covered ASP systems can deliver the same outcomes at a fraction of the investment.

AND POLLUTES THE AIR

Fiction: Decomposing waste inevitably smells and emits harmful gases, making composting incompatible with communities.

Fact: Properly managed, covered composting virtually eliminates odour and emissions.

In a recent California project, SG Advanced Composting Technology with GORE Cover demonstrated 97.5 per cent odour reduction, 98 per cent volatile organic compound (VOC) emissions control, clear separation of stormwater from leachate during adverse weather events, and production of a stable and mature nal compost.

e results of independent tests from a nine-month program debunk the odour myth emphatically: composting, when done with the right technology, does not have to smell or pollute.

In fact, facilities using SG’s covered ASP systems consistently achieve more than 95 per cent odour and VOC reductions, meeting California’s toughest air district standards. Rather

than being a nuisance, composting can be a clean operation that turns organic waste into valuable resources.

Fiction: Composting is ne for small operations, but large cities or regions need incineration or land ll to handle volumes and meet regulations.

Fact: Large-scale facilities around the world prove that composting can scale and comply with the strictest standards.

New York City’s Department of Sanitation, for example, expanded its Staten Island compost facility using the SG Bunker System with GORE Covers to process tens of thousands of tonnes of food waste annually.

is covered ASP system provides an enclosed, aerated environment without

the need for a building, achieving “in-vessel” control in an open-air setting. e result is a high-throughput operation that meets rigorous odour and pollution controls, aligning with local and state requirements.

Likewise, in California and other jurisdictions with aggressive organics laws such as SB 1383, which mandates 75 per cent diversion, covered composting systems have risen to the challenge. ey consistently meet or exceed compliance targets, from pathogen kill requirements to air emissions limits, even at industrial scales.

With modular designs and smart controls, facilities can start small and expand capacity as needed, all while staying within environmental thresholds.

Composting is no longer a cottage industry; it’s an industrial-scale solution

helping cities and states hit their waste reduction and climate goals.

Composting technology has evolved, shattering the myths that once held it back. Far from being smelly, slow, or inferior, modern composting, exempli ed by SG Advanced Composting Technology and GORE Cover, is e cient, clean, and scalable. It transforms organic refuse into valuable resources safely and reliably, whether at a rural farm or the heart of a major city.

When done with today’s advanced methods, composting is more fact than ction. It stands as a proven cornerstone of sustainable waste management.

For more information, visit: www.sustainable-generation.com

ew Melbourne made technology is using artificial intelligence to clean up Australia’s waste problem.

CleanBins is an arti cial intelligence (AI)-powered waste monitoring solution developed by Melbourne company Alliance Software.

Installed in waste collection vehicles, CleanBins uses computer vision to identify and track waste contamination at the household level – providing councils with population-wide, highquality data to better manage their waste streams.

For decades, Alliance Software was best known as a professional software consultancy. But a strategic pivot toward product development opened the door to new opportunities – including the waste industry.

e idea for CleanBins emerged from a deceptively simple question: Can AI and computer vision be used to analyse the contents of a garbage truck in real time?

Alliance’s research con rmed it could – and revealed a signi cant market gap in the process.

As Alex Green, Chief Executive O cer of Alliance Software, explains, “Our rst exposure to the challenges came when we engaged in some consulting projects with local councils. We found out just how poor their access to data was.

“Essentially, they were limited to highly manual data gathering exercises – bin tagging, manual waste audits and driver-driven analysis. e data they had was high cost to gather and really didn’t give them value at a population level.

“Without data, it’s nearly impossible to implement targeted, e ective waste management strategies.”

of custom hardware and arti cial intelligence designed to give councils unprecedented visibility into their waste streams.

Hardware installed in truck cabs includes cameras and a small server. As bins are tipped into the hopper, images of their contents are captured automatically and a purpose-built AI model analyses the images, classifying materials and agging contaminants. e result is a continuous, high-resolution dataset on waste contamination – covering every bin, every collection.

Alex says that unlike traditional waste audits, which might occur once every few years, CleanBins provides an ongoing stream of data from every collection cycle.

“To be able to make a change in the waste industry, councils need data,” he says.

“Instead of a single, infrequent snapshot, CleanBins o ers a detailed picture of contamination every fortnight – or however often bins are collected.”

insights. Councils can easily identify contamination hotspots by suburb or route, repeat o enders (sometimes called “gross contaminators”), and trends over time to assess the impact of education or enforcement e orts.

Alex says the power of CleanBins lies in what councils can do with the data it provides.

“Feedback from the waste educators we’ve worked with says that 90 per cent of contamination comes from 10 per cent of households,” says Alex.

“CleanBins helps councils pinpoint those individuals so they can take appropriate action – whether it’s targeted education, follow-up inspections, or even removing a bin.

“ e key is to take the tens of thousands of collections across a council each fortnight and distill that down to the dozens that a council really care about – the ones where intervention at a speci c level is going to have the greatest impact.”

is is where AI shines – reducing what would take hundreds of hours of

human e ort down to a couple of hours looking at high quality data.

So far, CleanBins has been deployed by six councils across Australia, with early results showing strong promise.

Alex says councils are using the data to comply with upcoming regulations, improve recycling rates, and reduce contamination in kerbside collections – particularly for food organics and garden organics (FOGO).

He emphasises that the technology behind CleanBins isn’t speculative or bleeding edge. “We’re working with road-tested AI – technologies that have been around for more than a decade. We want to deliver reliable, realworld results.”

While compliance with new regulations is a short-term driver, Alliance Software

“Without data, it’s nearly impossible to implement targeted, e ective waste management strategies.”

Alex Green, Chief Executive Officer, Alliance Software

sees CleanBins as a long-term tool for systemic change.

“ is isn’t a short-term x,” says Alex. “CleanBins allows councils to continuously monitor and improve their waste streams. e ultimate goal is a near-zero contamination rate, higher recycling rates, and meaningful land ll diversion.”

With rising public awareness and government focus on sustainability,

Alex believes Australia is at a turning point.

“ is is a very good moment for this to come up,” he says. “Australia has the capacity and the expertise. What we need now is ambition and leadership to make our waste streams truly circular.”

For more information, visit: www.cleanbins.com.au

ecycle mart s office and commercial recycling pac s are a one stop shop for all tric y to recycle items, now e uipped with tailored reporting services.

As Australia pushes towards creating a circular economy, businesses frequently face growing pressure to meet sustainability targets and demonstrate corporate responsibility.

Accurate waste reporting is no longer a nice-to-have, it’s essential. It empowers businesses to improve resource management, track land ll diversion, support economic development, and prove their environmental impact with real data.

RecycleSmart’s newly enhanced o ce and commercial recycling packs make this easier than ever, combining simple collections for hard-to-recycle items with instant, transparent waste reporting –right down to how many kilograms of co ee capsules or soft plastics are picked up in one cycle.

Whether the business is a major institution or a small local business, achieving sustainability targets is now more accessible, measurable, and impactful.

RecycleSmart introduced its o ce recycling packs a year ago in hopes to reduce the number of tricky-to-recycle items landing in land ll. Now, it is expanding with the commercial pack for bigger volumes, as well as an extended list of items collected and providing instant waste reporting available on each collection made.

Mikey Duke, Head of B2B Sales for RecycleSmart, says the recently added reporting feature has been a game changer.

“Many businesses and industries are mandated to report on their waste and recycling habits. With this service, businesses can access a fully comprehensive report of data on their pickups,” says Mikey.

“When we introduced the two packs, we intended to make recycling as easy and accessible as possible for a workplace, whatever that workplace is.

“Depending on the size of the company and amount of waste required to be collected, the customer can now

choose from a weekly, fortnightly or monthly pickup, as opposed to the original fortnightly option. ey can also choose their preferred payment solution for full exibility.”

He says, RecycleSmart is all about exibility, o ering bespoke bin solutions tailored to each customer’s unique needs.

Westpac bank has speci c land ll diversion targets as part of its broader sustainability commitments.

By implementing smarter waste management strategies and leveraging transparent reporting tools through RecycleSmart, the organisation is able to track progress and stay accountable to its goals.

Meredith Epp, Executive Manager of Circular Economy and Nature for Westpac, says the bank worked closely with RecycleSmart to customise its recycling package to best suit the organisation’s sustainability goals.

“We knew from our waste assessments that soft plastics were a frequent item found in our land ll bins, the RecycleSmart Tricky Recyclables provided a solution to divert these from land ll.”

Westpac opted to focus on collecting soft plastics, pens, and blister packs, aligning with the waste streams most relevant to its workplace. Bins were installed in February 2025, and Westpac has continued to work closely with its RecycleSmart account manager to monitor the program.

Customers who sign up to the program receive one year’s worth of collections, a bin and access to RecycleSmart’s brand-new reporting features.

“We pride ourselves on being a one-stop-shop for all tricky to recycle items,” Mikey says.

“We happily accept soft plastics, e-waste, textiles, polystyrene, printers, co ee capsules and more. Anything that is reasonably clean

and dry we can accept, and we get it processed.”

Previously an assortment of these items would need to be kept separate for them to be sent to di erent recyclers. What makes this service so convenient is the need for only one RecycleSmart pink-branded bin, which is now made from up to 50 per cent recycled materials.

“We take on the hard part, which is the sorting, consolidating, and transferring of the items to the correct recycling facilities,” Mikey says.

“Even though we collect such a wide variety of waste, we have a resource recovery rate of 98 per cent across our facilities.”

W hile typical waste reporting is done at the end of a quarter or year, RecycleSmart does it as soon as the waste has been picked up from a location.

“It can be costly and time consuming to accumulate all the relevant information from various data sources to provide a thorough and accurate waste report,” says Mikey.

“What makes our service so unique is our online platform used by both the driver responsible for the pickup and the customer who is ordering the pickups.”

Each collection is logged in real time using the RecycleSmart app, giving drivers the tools to weigh and record every individual material collected. is data ows instantly into a live report that updates as the waste is sorted – no waiting, no guesswork. O ce and commercial pack customers can access this data anytime, select the date range they need, and lter by location when using the packs across multiple sites.

“RecycleSmart uses smaller vehicles equipped with source separation systems to preserve the integrity of materials,” says Mikey.

“Each 60-litre bin liner is carefully transported to either the vehicle or a dedicated facility, where sta manually sort through every bag by hand.” is meticulous process allows for accurate tracking of every waste stream, providing clear, day-by-day insights into what’s being diverted from land ll.

“Waste reporting is where the industry is headed,” says Mikey.

“We know consumers want to purchase from, work with and support more sustainable businesses, so these reports are a great way to share these impact statistics both internally and externally.”

For more information, visit: www.recyclesmart.com

Whether the job is running a waste site, quarry, or managing port logistics, Volvo’s newest data platform can reveal efficiencies operators didn t now were possible.

Across Australia, waste management, quarrying, bulk material handling and haulage companies are pressured to deliver more with less.

Work sites could be sitting on hidden cost savings valued at hundreds of thousands of dollars, says Volvo, all unlocked by its newest data platform – Volvo Site Solutions.

Exclusively delivered by CJD Equipment in Australia, Volvo Site Solutions turns standard daily data into actionable insights that improve e ciency, cut waste, and elevate safety.

Where other original equipment manufacturers o er generic telematics and eet tracking, Volvo Site Solutions goes one step further, connecting people, machines,

and site infrastructure into one integrated platform.

rough a suite of digital and physical services, operators can access real-time data and advanced technology for site management, production monitoring and consultancy services.

Comprising three major components, the Volvo Site Solutions system has been designed for ease of use and e ciency.

e connected map – a dynamic, digital twin of a job site – is a key feature and shows haul roads, restricted zones, and stockpiles in real time.

e combination of complete jobsite visibility and extensive visualisations of production data helps operators gain insights to optimise the performance of the site or even multiple sites at the same time.

Andy Oliveira, Sales Manager of Site Solutions for CJD Equipment says, “Giving managers a real-time positioning of vehicles, equipment, and people will help everyone on site make safer and more e ective choices on a daily basis.”

e connected loadout is a digital load ticketing system that eliminates paper trails and ensures every tonne is accounted for – nothing goes to waste and every item of stock is being used to its full potential.

e performance indicator is one of the most rewarding aspects of the system.

Live productivity, fuel e ciency, and operator performance dashboards are tailored to site goals and measured

against company key performance indicators (KPIs).

Tangible cost savings are to be expected when using the Volvo Site Solutions system.

Andy says one customer identi ed more than $400,000 in lost revenue annually from haul-back ine ciencies, something they’d never measured before.

For those looking to get started with Volvo Site Solutions, CJD Equipment recommends a free, no-obligation initial consultation.

Using real-world case examples, Volvo demonstrates how site solutions tackles production, utilisation, and safety. e meeting will also be used to explore operational priorities. is will be followed by a week-long on-site visit by a Volvo specialist to understand the layout, operations, and existing technology.

Volvo believes this is the best way to get an in depth and thorough understanding of the site to provide the best outcome from the system.

Specialists will consider everything on-site, from machine types and operator work ows to connectivity and integration opportunities.

Once the assessment is complete, Volvo specialists will design a customised system based on site size, number of machines, and desired KPIs. is site-speci c solution could include mapping haul roads, identifying restricted zones, planning for data capture, and determining what metrics matter most – load and haul, material processing, or sales tracking.

Hardware and software installation is the next stage of the system integration. Volvo specialists will install and con gure the required hardware, integrate it with existing systems, and set up dashboards and reporting tools.

Operator and supervisor training will be held simultaneously to the software installation.

Understanding that technology adoption is only as good as its users, Volvo specialists run detailed training sessions with operators, supervisors, and managers to ensure everyone can use the system.

Once everyone is comfortable, the solutions site will go live with continuous remote monitoring and onsite support.

Volvo says customers can expect to see tangible results, such as reduced carryback waste and improved fuel e ciency, within the rst three months.

Each month builds capability on several business operations.

Month one focuses on operations basics. Features implementation is month two and month three is advanced analytics.

Volvo will also conduct a full review of the system reporting on how the system has impacted operations, cost savings, safety improvements, and productivity gains.

Customers can also choose Volvo’s annual support package, which includes site visits, software updates, and continuous performance monitoring.

Volvo says this local expertise and support network means customers can get real people on-site, not just a software subscription.

For more information, visit: www.cjd.com.au

The recent delivery of a new McCloskey Environmental machine has set Tutt Bryant up to be a one-stop-shop for all recycled material handling machinery.

Tutt Bryant is reinforcing its commitment to delivering comprehensive solutions for the waste and recycling sector, with the addition of the McCloskey Environmental ET-620 tracked trommel to its growing environmental equipment portfolio.

Purpose-built for operations handling wood waste, compost, light construction and demolition (C&D) waste and municipal solid waste (MSW), the ET620 is a versatile machine designed to meet the evolving demands of modern waste facilities.

With McCloskey Environmental’s renowned environmental range now part of Tutt Bryant’s equipment o ering – from shredders, excavators, trommels, screens, stackers, crushers, and compactors – it provides the full spectrum of machinery required to establish and operate a waste facility.

“We can supply the entire gamut of equipment, and that’s what makes us unique,” says Paul Doran, National Business Manager of Crushing and Screening for Tutt Bryant Equipment.

e ET-620 is reliable and easy to operate. It has a large feed hopper capable of handling high volumes of material, and features a cleaning brush that prevents the drum apertures from clogging.

e aperture size is easily adjusted to achieve the desired material split, allowing ne materials to be discharged to the side, while larger materials exit through the front.

Paul says this functionality makes the ET-620 suitable for land lls,