WHAT YOU SHOULD KNOW

CONCEPT DESIGN

To guarantee efficiency, safety and long-term sustainability, it is essential to consider maintenance from the very first stages of design.

WINDOWS

CLEANING WINDOWS REPLACEMENT

TECHNICAL DESIGN COORDINATION CONSTRUCTION

Architects and designers need to carefully assess the technical and economic feasibility of façade access systems and integrate them into the overall project.

For safe and effective suspended operations, the access system should be designed in collaboration with rope access specialists and structural engineers.

Permanent access systems can already be used during construction, allowing rope access operators to work without temporary solutions.

WHAT ARE THE ADVANTAGES OF ROPE ACCESS?

Rope access is an advanced method for façade access and maintenance: fast, safe and suitable for any building, with no impact on its architectural appearance.

CUSTOM SOLUTIONS

Rope access is easy to design and integrates seamlessly into the building without the need for invasive works. It is also suitable for complex forms such as slanted walls and cantilevered structures.

AESTHETIC INTEGRATION

The system does not alter the visual perception of the building. Anchor points are discreet, barely visible and, in some cases, removable – ideal for historic buildings, continuous façades or settings characterised by high architectural value.

MAXIMUM FLEXIBILITY, MINIMUM IMPACT

Rope access enables rapid interventions – whether localised or large-scale – even in confined or hard-to-reach spaces. It does not require the occupation of public space or alterations to existing structures.

ECONOMIC ADVANTAGES

Rope access reduces costs compared with scaffolding and BMUs by eliminating the need for rentals, complex handling and the installation of heavy machinery. It requires less time and manpower, minimising indirect costs for the client such as downtime or restricted access.

SUSTAINABLE ADVANTAGE

As a lightweight, non-invasive method, rope access has a low environmental impact at every stage. Reduced logistics means less transport, lower emissions and a minimal site footprint, with clear benefits for safety and work organisation.

ROPE ACCESS: WHY IT OUTPERFORMS TRADITIONAL SYSTEMS

GENERAL FAÇADE REFURBISHMENT

The use of scaffoldings implicates renting costs and a huge visible impact.

FAÇADE PLASTER REPAIR

Temporary BMUs are not always compatible with site conditions or with the building’s morphology.

FAÇADE MAINTENANCE AND PAINTING

Temporary MEWP units are not consistently reliable or efficient, and in some cases they are used incorrectly.

FAÇADE MAINTENANCE

BMUs have a significant impact on architectural design. Concealing them within the building reduces usable space and impacts its commercial value.

PROJECT PHASES

SAFE ACCESS, AS EARLY AS THE DESIGN STAGE

The choice of access system must be considered from the outset to avoid invasive or inefficient solutions once the building is complete. Architects, engineers and specialists work together to develop a safe, compliant solution suited to the project’s requirements. Elements are integrated without aesthetic or structural compromise, delivering tangible time and cost benefits even during construction.

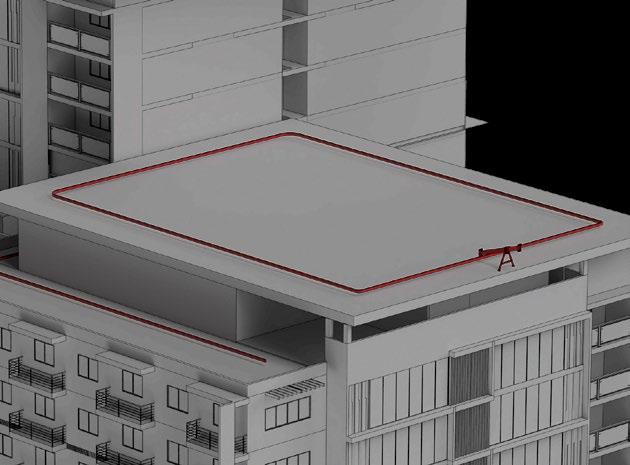

RESIDENTIAL BUILDING

For residential buildings with flat roofs and vertical façades, rope access offers a practical and efficient alternative to scaffolding, platforms and cranes.

BUILDING

RESIDENTIAL

COMMERCIAL

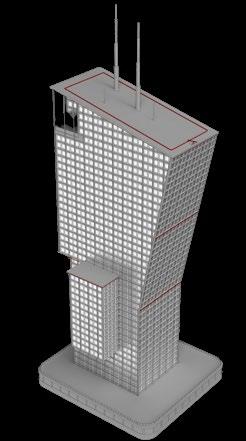

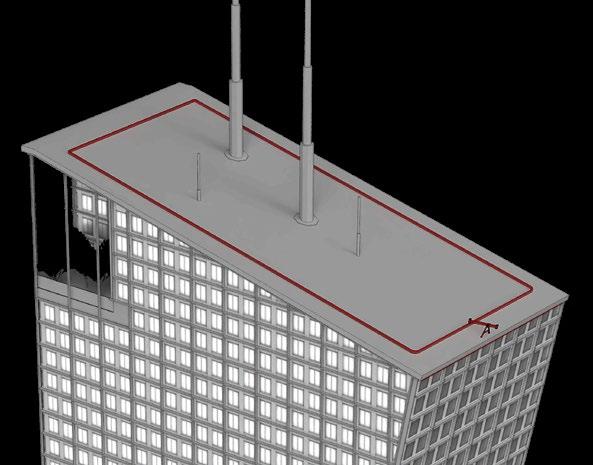

COMMERCIAL BUILDING

For commercial buildings with complex forms or hard-to-reach surfaces, rope access enables comprehensive maintenance without the need for bulky systems.

EXAMPLE IN RESIDENTIAL BUILDING

Technical Salesmen & Technical Consultant

1

CONCEPT DESIGN Architect & Designer

2 COORDINATION Architect

Choice of façade access method

Final system described

3 TECHNICAL DESIGN Structural engineer

Safety Specialist

4 CONSTRUCTION General contractor

5 USE Property owner

Tender set out

Rothoblaas Technical Salesmen & Technical Consultant

Safety Specialist

EXAMPLE IN COMMERCIAL BUILDING

©Høyden

©Høyden

©Høyden

©Høyden

Rothoblaas

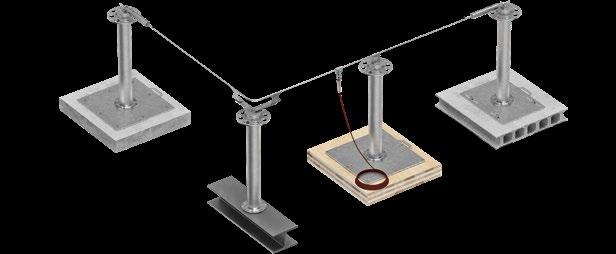

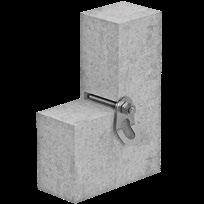

RIGID ANCHOR POINT FOR ROPE ACCESS WORK

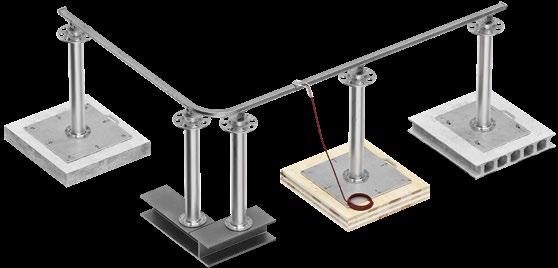

LIFELINE ON RIGID SUPPORT FOR ROPE ACCESS WORK

posizionamento

HORIZONTAL OVERHEAD RAIL SYSTEM

posizionamento

H-RAIL ON WALL

posizionamento

WING S355J2 - zinc plated Fe/Zn 12μ + powder coated (RAL7032-grey)

WINGY S355J2 - zinc plated Fe/Zn 12μ + powder coated (RAL1016-yellow)

AOSWS

PPE - PERSONAL PROTECTIVE EQUIPMENT

At “Laboratorio Gravità”, our in-house testing facility, we rigorously test vertical and horizontal fall protection systems, including fastenings. Our CEcertified test bench speeds up product development and ensures that every fall protection system undergoes strict testing before reaching the market.

rothoblaas.com/safe

TECHNICAL ASSISTANCE

Get maximum efficiency and performance from Rothoblaas solutions: a team of highly qualified technical consultants is always at the disposal of designers, technicians and installers.

• Consulting and checks for personal protective equipment

• Assistance for positioning and assembly of lifelines

• Technical documentation

• Accompanying certification

• Reference to standards

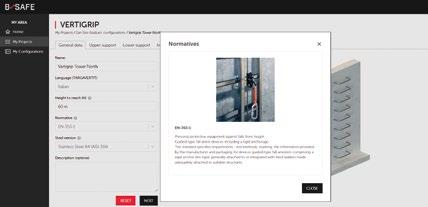

B-SAFE CONFIGURATOR

The multifunctional Rothoblaas portal allows:

• Configuration and calculation of fall protection systems

• Calculation of anchor loads and cable deflection

• Practical management of technical documentation and bill of materials

Subscribe to our Youtube channel and stay updated on Rothoblaas products and news.

DON'T FORGET TO ACTIVATE THE NOTIFICATIONS!

ONLINE RESOURCES

• Building Information Modelling (BIM) on ProLib

• CAD files and specification items available on our website

Rotho Blaas Srl info@rothoblaas.com | www.rothoblaas.com